Dry method processing process and device for corn

A dry processing and corn technology, applied in food science, application, grain processing and other directions, can solve the problems of low yield, many broken grains, difficult to separate, etc., to improve the comprehensive economic production efficiency and huge economic and social benefits. , the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

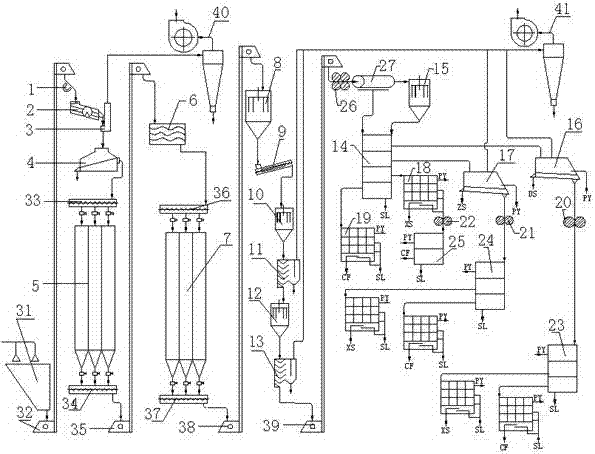

[0027] A kind of corn dry processing technology, the technological process is mainly: magnetic separation → screening → stone removal → raw corn storage → tempering → moistening corn → first stirring and peeling → watering → second stirring and peeling → first The first air selection → the third stirring and peeling → the second air selection → degerming and breaking of grits → embryo selection and grits extraction.

[0028] A device (such as figure 1 shown), the device includes a magnetic separator 1, a vibrating screen 2, a vertical suction duct 3, a destoner 4 (the destoner 4 is connected to the corn bin 5 through the first screw conveyor 33), the wool Corn bin 5 (the raw corn bin 5 is connected to the water vapor conditioner 6 via the second screw conveyor 34, the second hoist 35), the water vapor conditioner 6 (the water vapor conditioner 6 is connected to the wet corn bin 7 through the third screw conveyor 36 connection), moist corn bin 7 (moisten corn bin 7 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com