Sand-drainage construction system for diversion channel

A technology of diversion canal and structure, applied in the field of sand discharge system, can solve problems such as affecting the service life of hydraulic turbines and difficult to remove sand and gravel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

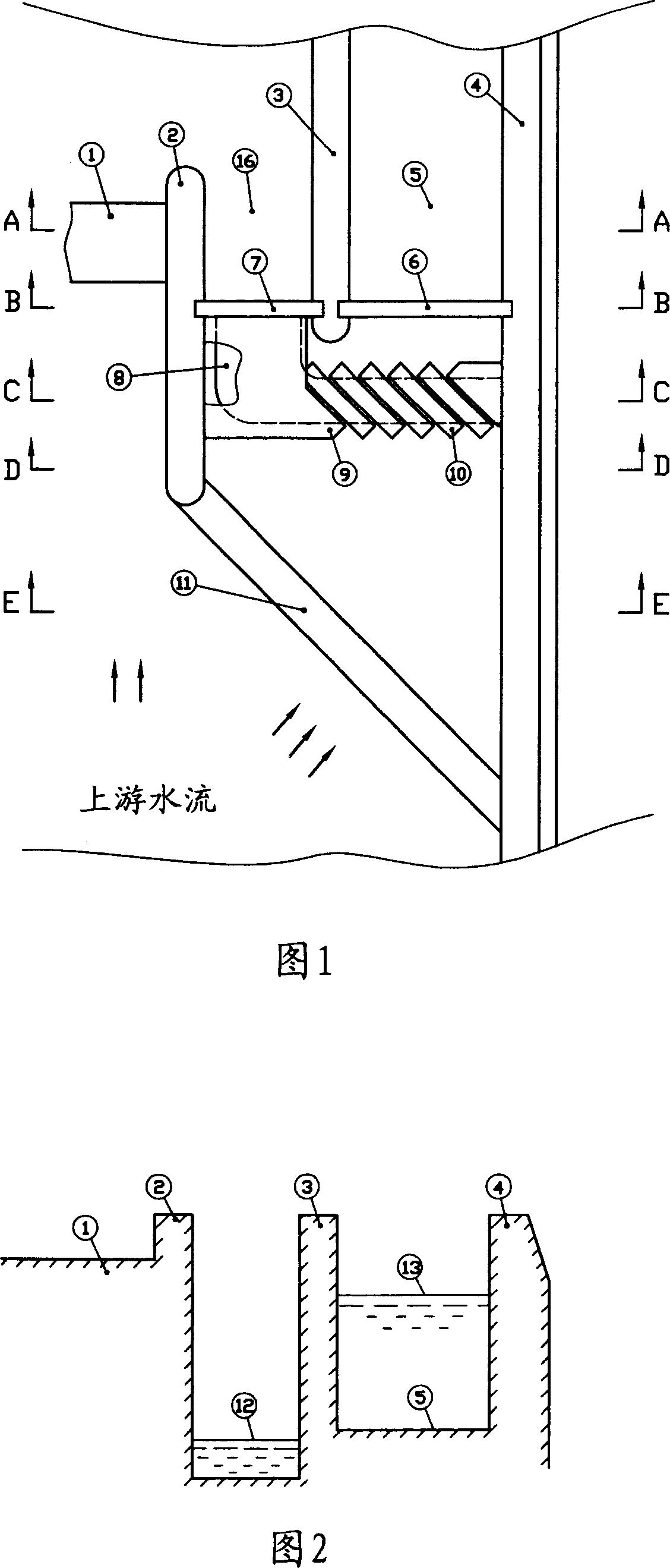

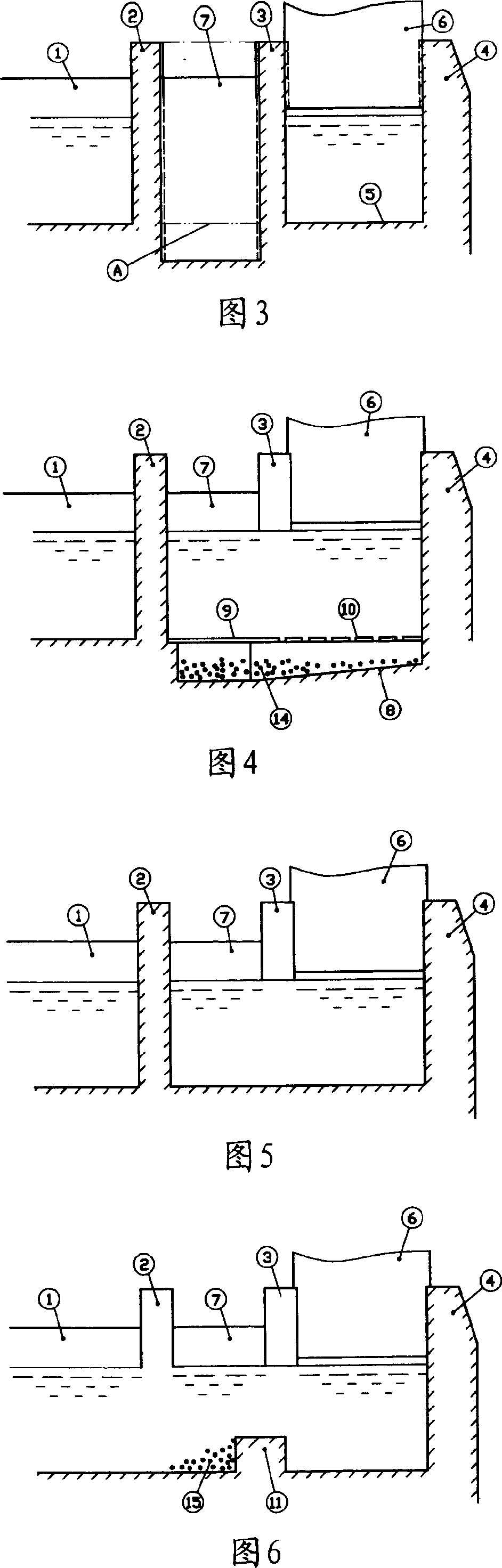

[0013] As shown in Figure 1, the system consists of the main channel dam 1, diversion dike 2, diversion dike 3, right dike 4, diversion channel 5, diversion sluice 6, sand washing channel 16, sand sluice gate 7, main channel The sand blocking weir 11, the grit chamber 8, the sand washing cover 9 and the sand introduction cover 10 are composed. The right side of the main channel dam 1 is connected with the dike 2, and the left side of the main channel dam 1 is connected with the left side embankment. The left side channel is omitted and not shown in the figure. Between the upstream end of the diversion embankment 2 and the right embankment 4, there is an inclined very long main channel sand retaining weir 11, and between the middle section of the diversion embankment 2 and the right embankment 4, a diversion embankment 3 is constructed in parallel. There is a sand washing gate 7 between the upstream end of the diversion dike 3 and the diversion dike 2 , and the sand washing cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com