Modified bentonite for seawater drilling and preparation method thereof, and drilling fluid

A bentonite and modified technology, applied in chemical instruments and methods, drilling compositions, inorganic chemistry, etc., can solve problems such as no emulsification performance, insufficient gelling effect, and unsatisfactory stability, and achieve pulping Fast, increase stability, promote gelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

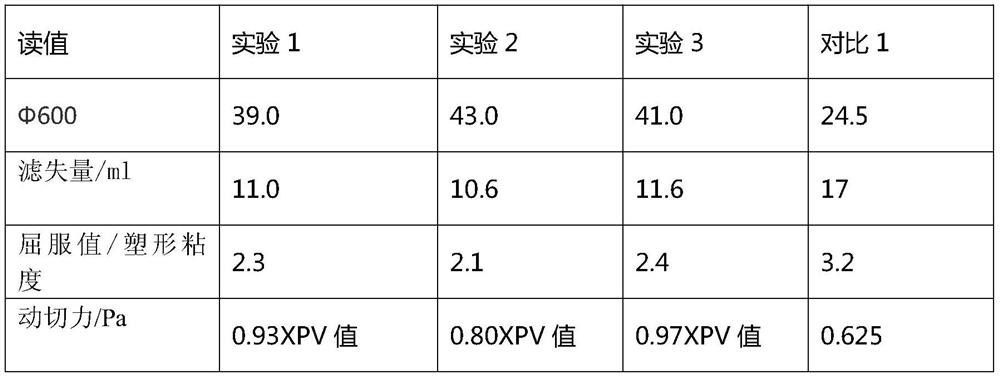

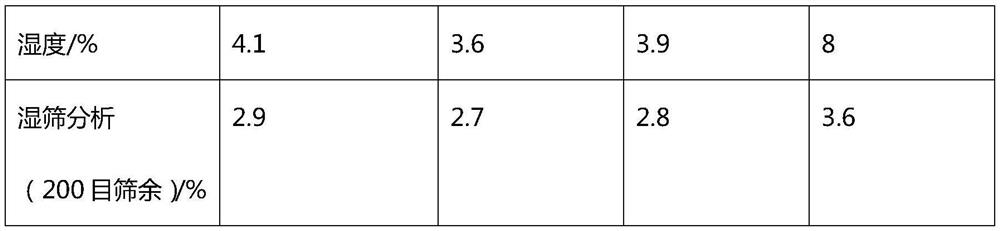

[0016] Embodiment 1: Preparation of modified bentonite for seawater drilling

[0017] The modified bentonite for seawater drilling includes the following components: bentonite, sepiolite, palygorskite, kaolinite, illite, chlorite, opal, calcite, siderite, talcum powder, gypsum, pyrite , Hornblende, quartz, nano-iron oxide particles, nano-silica particles, nano-graphite.

[0018] The parts by weight of each component of bentonite for above-mentioned modified seawater drilling can be as follows: bentonite 5%, sepiolite 1.5%, palygorskite 0.5%, kaolinite 0.3%, illite 0.2%, chlorite 0.15%, Opal 0.1%, Calcite 0.09%, Siderite 0.05%, Talc 0.03%, Gypsum 0.02%, Pyrite 0.02%, Hornblende 0.01%, Quartz 0.015%, Nano Iron Oxide Particles 0.2%, Nano Silica Particles 0.1%, nano-graphite 0.03%.

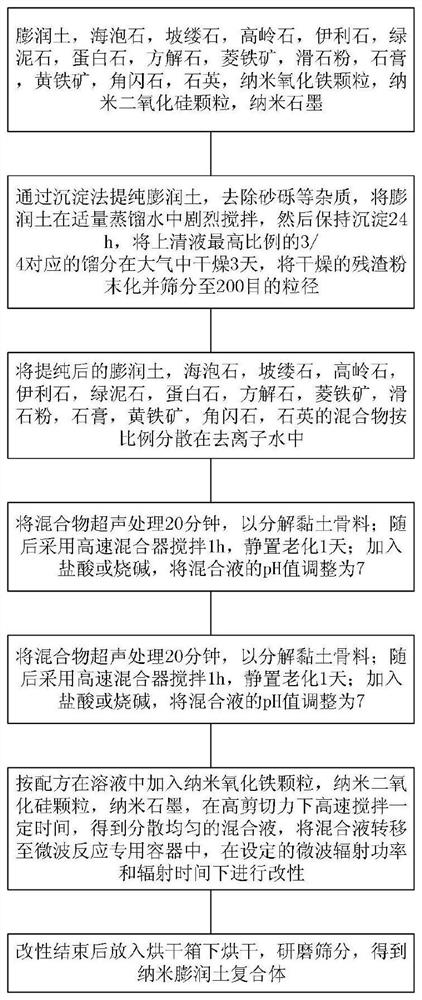

[0019]The preparation method of the above modified bentonite for seawater drilling includes the following steps: (1). Purify the bentonite by precipitation to remove impurities such as gravel, vigor...

Embodiment 2

[0020] Embodiment 2: Preparation of modified bentonite for seawater drilling

[0021] The modified bentonite for seawater drilling includes the following components: bentonite, sepiolite, palygorskite, kaolinite, illite, chlorite, opal, calcite, siderite, talcum powder, gypsum, pyrite , Hornblende, quartz, nano-iron oxide particles, nano-silica particles, nano-graphite.

[0022] The parts by weight of each component of bentonite for above-mentioned modified seawater drilling can be as follows: bentonite 8%, sepiolite 1.8%, palygorskite 0.8%, kaolinite 0.4%, illite 0.3%, chlorite 0.18%, Opal 0.15%, Calcite 0.1%, Siderite 0.06%, Talc 0.04%, Gypsum 0.03%, Pyrite 0.025%, Hornblende 0.02%, Quartz 0.02%, Nano Iron Oxide Particles 0.35%, Nano Silica Particles 0.2%, nano-graphite 0.035%.

[0023] The preparation method of the above modified bentonite for seawater drilling includes the following steps: (1). Purify the bentonite by precipitation to remove impurities such as gravel, vi...

Embodiment 3

[0024] Embodiment 3: Preparation of modified bentonite for seawater drilling

[0025] The modified bentonite for seawater drilling includes the following components: bentonite, sepiolite, palygorskite, kaolinite, illite, chlorite, opal, calcite, siderite, talcum powder, gypsum, pyrite , Hornblende, quartz, nano-iron oxide particles, nano-silica particles, nano-graphite.

[0026] The parts by weight of each component of the above-mentioned modified seawater drilling bentonite can be as follows: 10% of bentonite, 2% of sepiolite, 1% of palygorskite, 0.5% of kaolinite, 0.4% of illite, 0.2% of chlorite, Opal 0.2%, Calcite 0.12%, Siderite 0.08%, Talc 0.05%, Gypsum 0.04%, Pyrite 0.03%, Hornblende 0.03%, Quartz 0.03%, Nano Iron Oxide Particles 0.5%, Nano Silica Granules 0.3%, Nanographite 0.05%.

[0027] The preparation method of the above modified bentonite for seawater drilling includes the following steps: (1). Purify the bentonite by precipitation to remove impurities such as g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com