A rapid pulping device for rare earth ore

A rare earth ore and pulping technology, used in clay preparation devices, clay mixing devices, mixing operation control devices, etc., can solve the problem of inability to pulp rare earth ore, and achieve the effects of high uniformity, high efficiency, and scratch prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

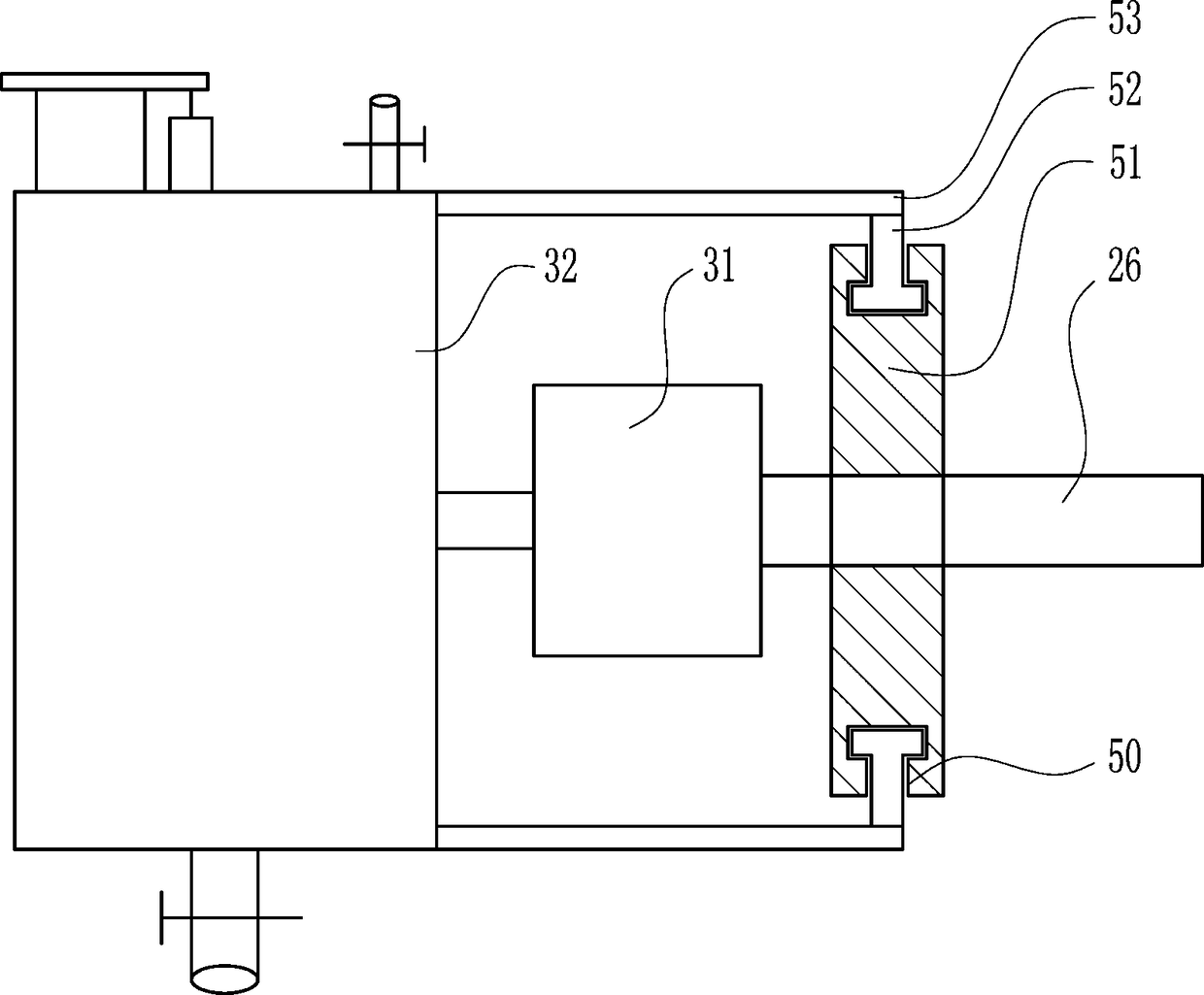

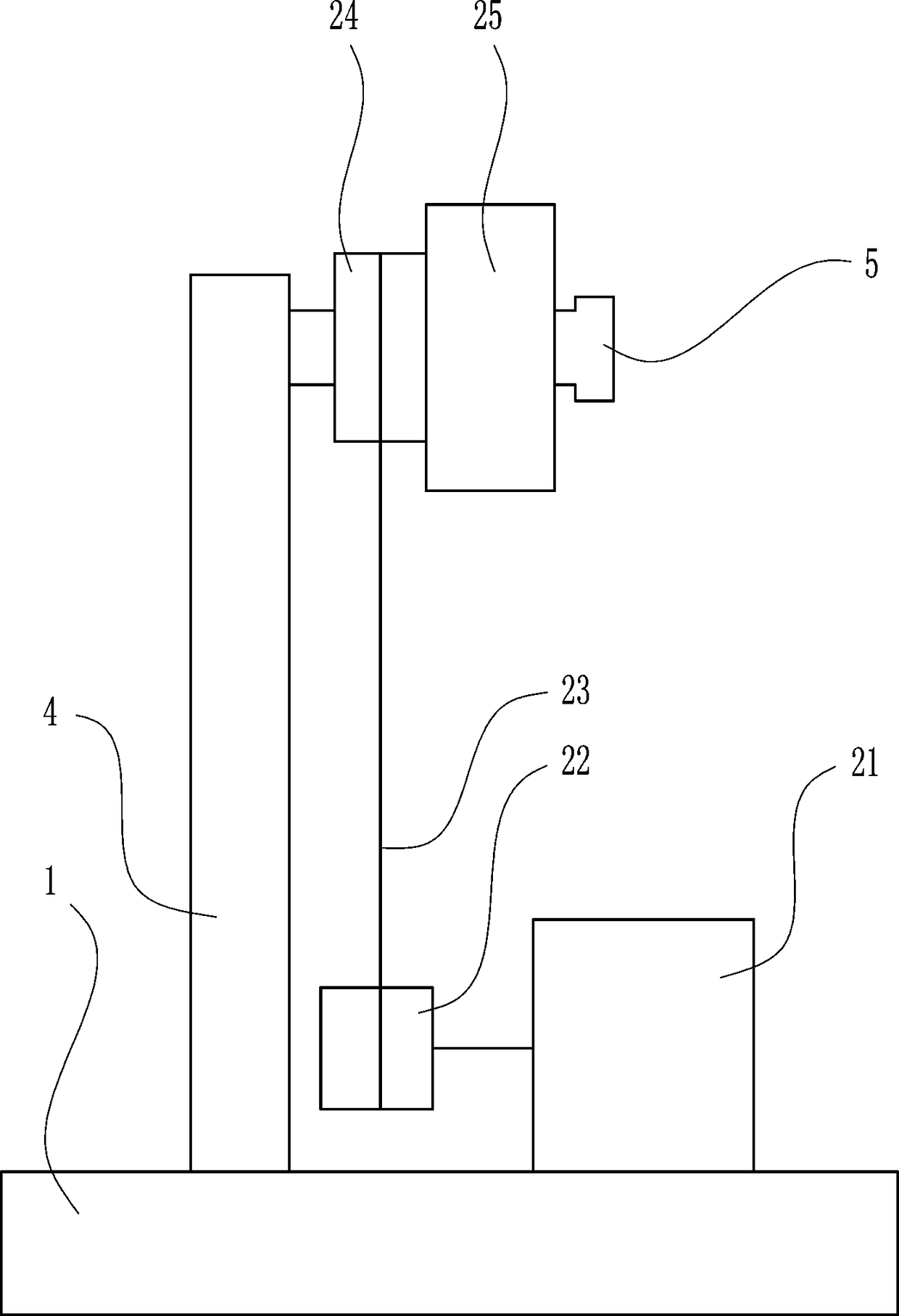

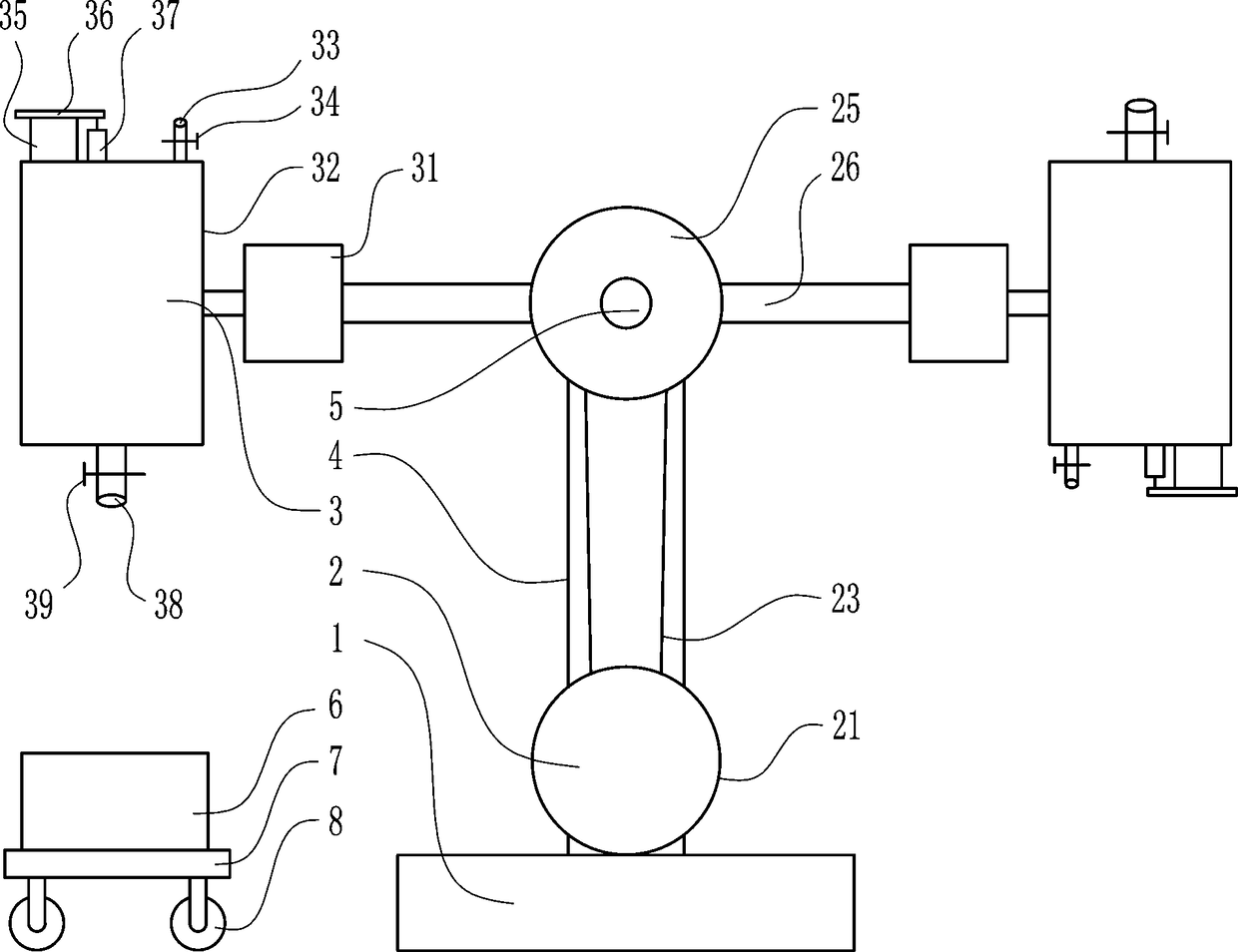

[0028] A rapid pulping device for rare earth ore, such as Figure 1-4 As shown, it includes a base 1, an up and down rotation device 2, a front and rear rotation device 3, a bracket 4, a connecting shaft 5, a receiving cylinder 6, a supporting plate 7 and a universal wheel 8; an up and down rotation device 2 is arranged above the base 1 And the front and rear rotation device 3, the front and rear rotation device 3 is connected with the up and down rotation device 2, the lower end of the bracket 4 is connected with the top of the base 1 by welding, the upper end of the front side wall of the bracket 4 is welded with a connecting shaft 5 extending forward, The receiving cylinder 6 is arranged on the left side of the base 1, and the receiving cylinder 6 is placed on the supporting plate 7, and several universal wheels 8 are welded on the bottom of the supporting plate 7.

Embodiment 2

[0030] A rapid pulping device for rare earth ore, such as Figure 1-4 As shown, it includes a base 1, an up and down rotation device 2, a front and rear rotation device 3, a bracket 4, a connecting shaft 5, a receiving cylinder 6, a supporting plate 7 and a universal wheel 8; an up and down rotation device 2 is arranged above the base 1 And the front and rear rotation device 3, the front and rear rotation device 3 is connected with the up and down rotation device 2, the lower end of the bracket 4 is connected with the top of the base 1 by welding, the upper end of the front side wall of the bracket 4 is welded with a connecting shaft 5 extending forward, The receiving cylinder 6 is arranged on the left side of the base 1, and the receiving cylinder 6 is placed on the supporting plate 7, and several universal wheels 8 are welded on the bottom of the supporting plate 7.

[0031] The up and down rotation device 2 includes a motor I21, a lower pulley 22, an endless belt 23, an upp...

Embodiment 3

[0033] A rapid pulping device for rare earth ore, such as Figure 1-4 As shown, it includes a base 1, an up and down rotation device 2, a front and rear rotation device 3, a bracket 4, a connecting shaft 5, a receiving cylinder 6, a supporting plate 7 and a universal wheel 8; an up and down rotation device 2 is arranged above the base 1 And the front and rear rotation device 3, the front and rear rotation device 3 is connected with the up and down rotation device 2, the lower end of the bracket 4 is connected with the top of the base 1 by welding, the upper end of the front side wall of the bracket 4 is welded with a connecting shaft 5 extending forward, The receiving cylinder 6 is arranged on the left side of the base 1, and the receiving cylinder 6 is placed on the supporting plate 7, and several universal wheels 8 are welded on the bottom of the supporting plate 7.

[0034] The up and down rotation device 2 includes a motor I21, a lower pulley 22, an endless belt 23, an upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com