Efficient pulping system for dry and wet broken paper

A technology of pulping, drying and wetting, applied in the field of papermaking, can solve the problem that dry and wet broke paper cannot be processed at the same time, and achieve the effect of saving equipment investment and speeding up pulping speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

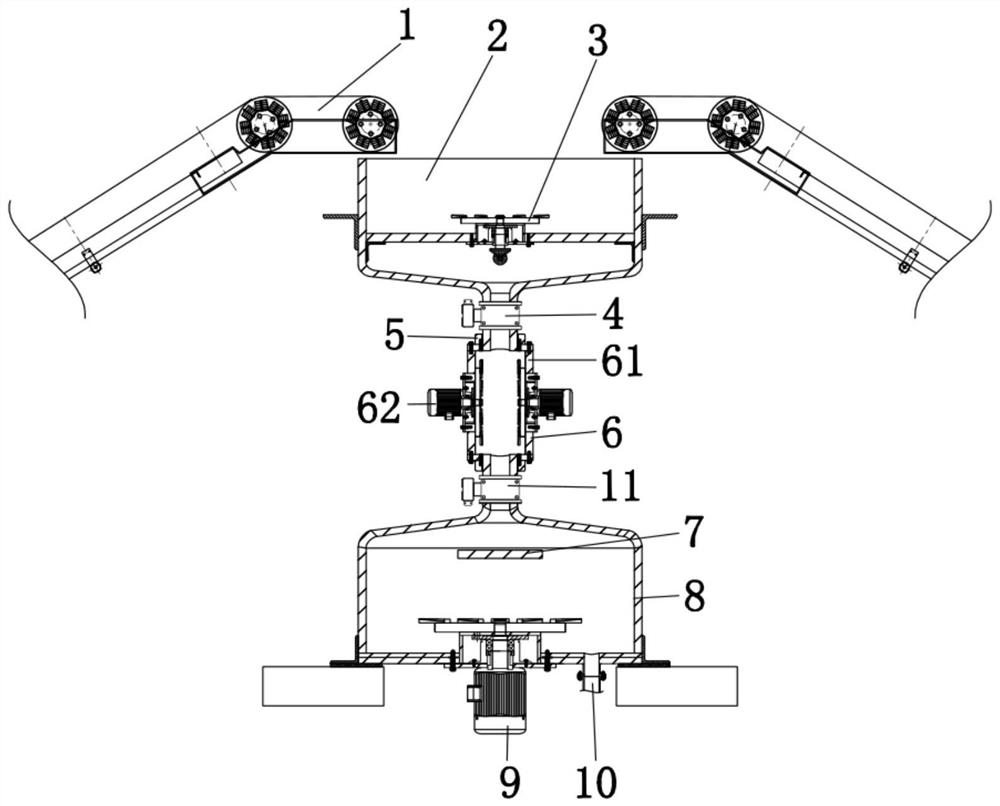

[0018] Depend on figure 1 It can be seen that a high-efficiency pulping system for dry and wet broken paper includes a pulping cylinder and a conveyor 1 for feeding, the pulping cylinder includes an upper pulping cylinder 2 and a lower pulping cylinder 8, and the upper pulping cylinder 2 and the lower pulping cylinder A pulping device A3 and a pulping device C9 are respectively arranged in the pulping cylinder 8, a discharge pipe 10 is provided at the bottom of the lower pulping cylinder 8, and the bottom of the upper pulping cylinder 2 passes through the central pulping cylinder 6 and the lower pulping cylinder 8. connected at the top;

[0019] The central pulping cylinder 6 includes a housing 61, and pulping devices B62 are installed on both sides of the housing 61;

[0020] In the specific implementation process, it is worth pointing out that after the dry broken paper is conveyed into the upper pulping cylinder 2 by the conveyor 1, it is initially pulped by the pulping de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com