Raw material bag applied to food processor and preparation method and application thereof

A food processing machine and raw material packaging technology, applied in the field of food processing, can solve the problems of weak slurry stability, protein denaturation, and poor solubility, and achieve the effect of retaining color and sensory characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

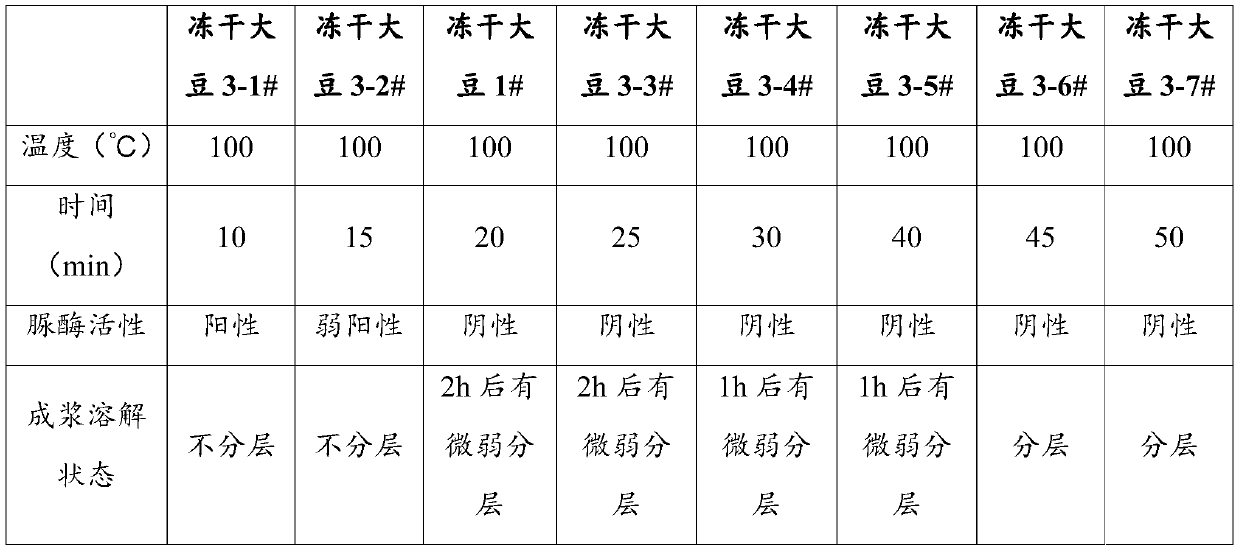

[0056] According to one embodiment of the present application, freeze-dried soybeans are prepared by a preparation method comprising the following steps:

[0057] 1) Washing, soaking and ripening soybean raw materials to obtain ripened soybeans;

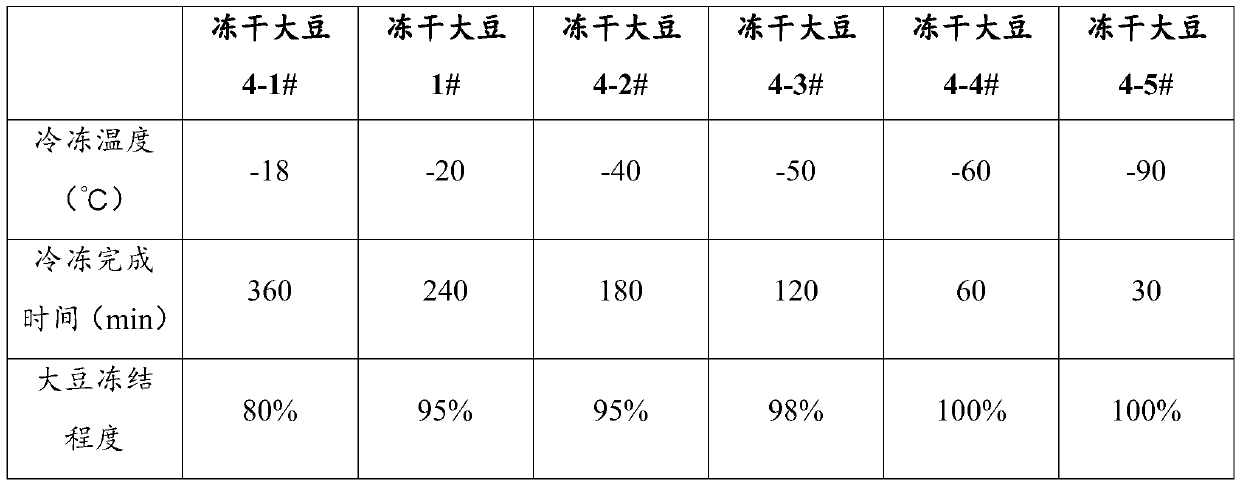

[0058] 2) Quickly freezing the mature soybeans to obtain frozen soybeans;

[0059] 3) Vacuum freeze-drying the frozen soybeans until the moisture content of the soybeans is less than 5wt%, that is, to obtain freeze-dried soybeans; wherein, the quick freezing in step 2) includes keeping the mature soybeans at a temperature of -20°C to -90°C 30-240min.

Embodiment 1

[0060] Embodiment 1 freeze-dried soybean 1#

[0061] The preparation method of freeze-dried soybean 1# comprises the steps:

[0062] A. Selected soybeans, non-genetically modified, high-quality and high-protein, with a protein dry basis of more than 35%;

[0063] B. Soaking, the soaking time is 4 hours, the soaking temperature is below 60°C, the soybean volume expands to twice the original volume, and the soybean weight increases to 2.2 times the original weight;

[0064] C. Mature, steam or boil at 100°C for 20 minutes;

[0065] D. Quick freezing, freezing temperature -20°C, freezing time 240min;

[0066] E. Vacuum freeze-drying: vacuum degree 80pa, temperature 30°C, freeze-dry until the moisture content of soybeans is 5%, that is, freeze-dried soybeans 1# are obtained.

[0067] The prepared freeze-dried soybean 1#: the freeze-dried soybean has complete shape and good quality; the inactivation of freeze-dried soybean urease ensures safety, but the degree of internal protei...

Embodiment 2

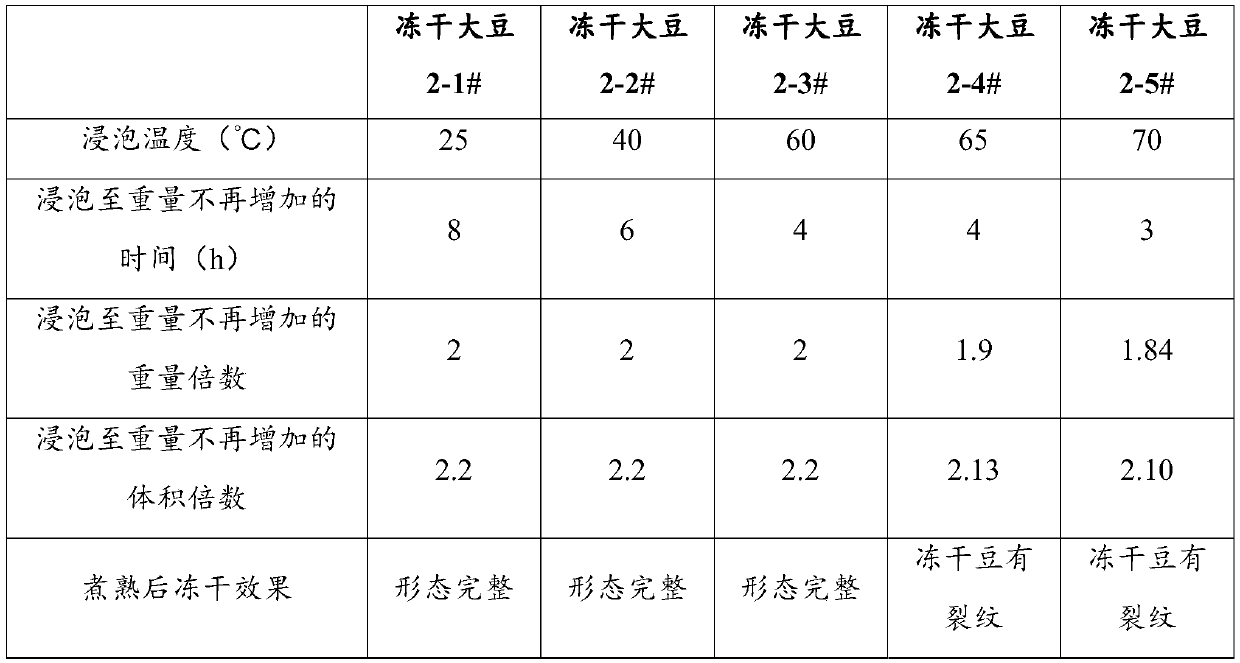

[0068] Embodiment 2 freeze-dried soybean 2-1#~2-5#

[0069] Prepare freeze-dried soybeans 2-1#~2-5# according to the preparation method of freeze-dried soybeans 1# in Example 1, and freeze-dried soybeans 2-1#~2-5# differ from freeze-dried soybeans 1# in that soybeans The soaking process is shown in Table 1.

[0070] Table 1 soybean soaking process

[0071]

[0072] The sufficiency of soaking affects the subsequent freeze-drying. Below 60°C, the weight of fully soaked soybeans increases to 2 times the weight of dry soybeans, and the volume expands to 2.2 times that of dry soybeans. Above 60°C, the starch in soybeans begins to gelatinize, hindering the penetration of water, until the soybeans absorb water unevenly, and the water absorption rate decreases, which in turn leads to inconsistent freezing rates inside soybeans during the freezing process, affecting the quality of the final freeze-dried soybeans.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com