Rapid soybean milk making method of soybean milk machine

A soymilk machine and pulping technology, which is applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of lengthening the pulping cycle, overflowing pulp, and affecting the quality of the soymilk machine, so as to improve the quality of pulping and make pulping quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The invention provides a rapid pulping method for a soybean milk machine. The soybean milk machine includes a small-space pulverizer, a pulp receiving cup, a water tank for storing pulping water, and a control system. The pulping method includes the following stages:

[0039] (1) At the stage of preparing thick slurry, the water and materials used for crushing are crushed and matured in a small space crusher to prepare a mature slurry / paste;

[0040] (2) In the slurry discharge stage, discharge the slurry / paste in the small space pulverizer into the slurry receiving cup;

[0041] It is characterized in that, before the pulping stage, the control system controls the water tank to inject water with a capacity of V1 into the pulp receiving cup, the current pulping volume of the soymilk machine is V, and the small The volume of the slurry / paste crushed by the space crusher is V2, V1=V-V2.

[0042] In the stage of preparing thick stock, the maturation of the slurry / paste has been co...

Embodiment 2

[0055] The difference between this embodiment and the above-mentioned embodiment 1 is that the preparation stage of thick slurry includes four steps:

[0056] Water into the downward space pulverizer. In this step, the water entering the small space pulverizer is cold water;

[0057] Preheating, heating the water and materials of the small space pulverizer to a preset temperature;

[0058] Crushing. In this step, the crushing device in the small space crusher works, so that the materials mixed in the small space crusher and water are mixed and crushed;

[0059] Maturation. In this step, the prepared thick slurry can be matured by the heat generated by the small space pulverizer during the pulverization process; or the thick slurry in the small space pulverizer can be matured by using a heating device.

[0060] Soymilk Maker Example 1:

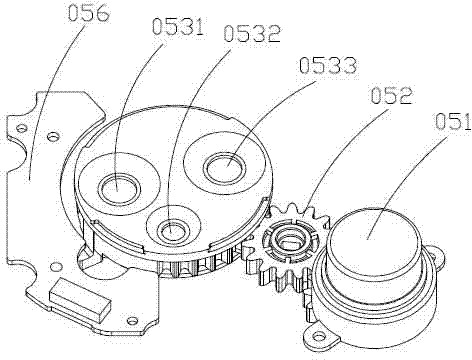

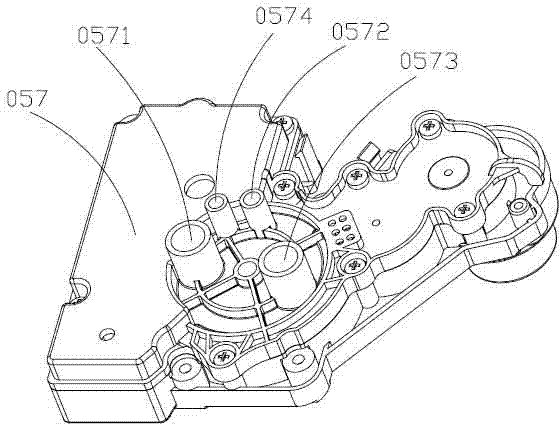

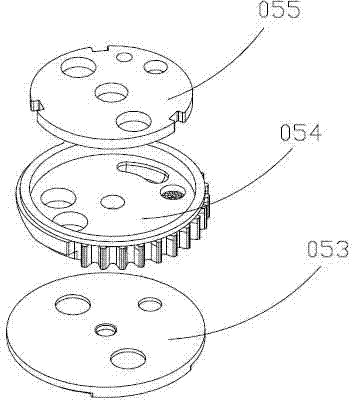

[0061] Such as figure 1 As shown, a soybean milk machine adopting a rapid pulping method is characterized by comprising a small space pulverizer 02, a sl...

Embodiment 3

[0077] Such as Image 6 As shown, the difference between this embodiment and the aforementioned embodiment 2 of the soybean milk maker is that the water tank is not provided with a heating device, but an instant heating device 18 is provided on the water flow channel.

[0078] Of course, in order to make pulp faster, a heating device can also be installed on the water tank and the water flow channel at the same time.

[0079] In the present invention, the heating device can be an electric heating tube device, an electromagnetic heating device, a thick film heating device, or a carbon fiber heating device.

[0080] In the present invention, the cold water that can be directly drinkable includes cold water that can be directly drinkable, such as cold boiled water, mineral water, and purified water, and the cold water refers to cold water that can be drinkable after heating.

[0081] In the preparation stage of thick stock, the maturation of the slurry / paste has been completed, and before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com