Ultrasonic multi-effect mixer for edible oil

A technology of ultrasonic wave and edible oil, applied in the field of degumming process, can solve the problem of incomplete separation of colloids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

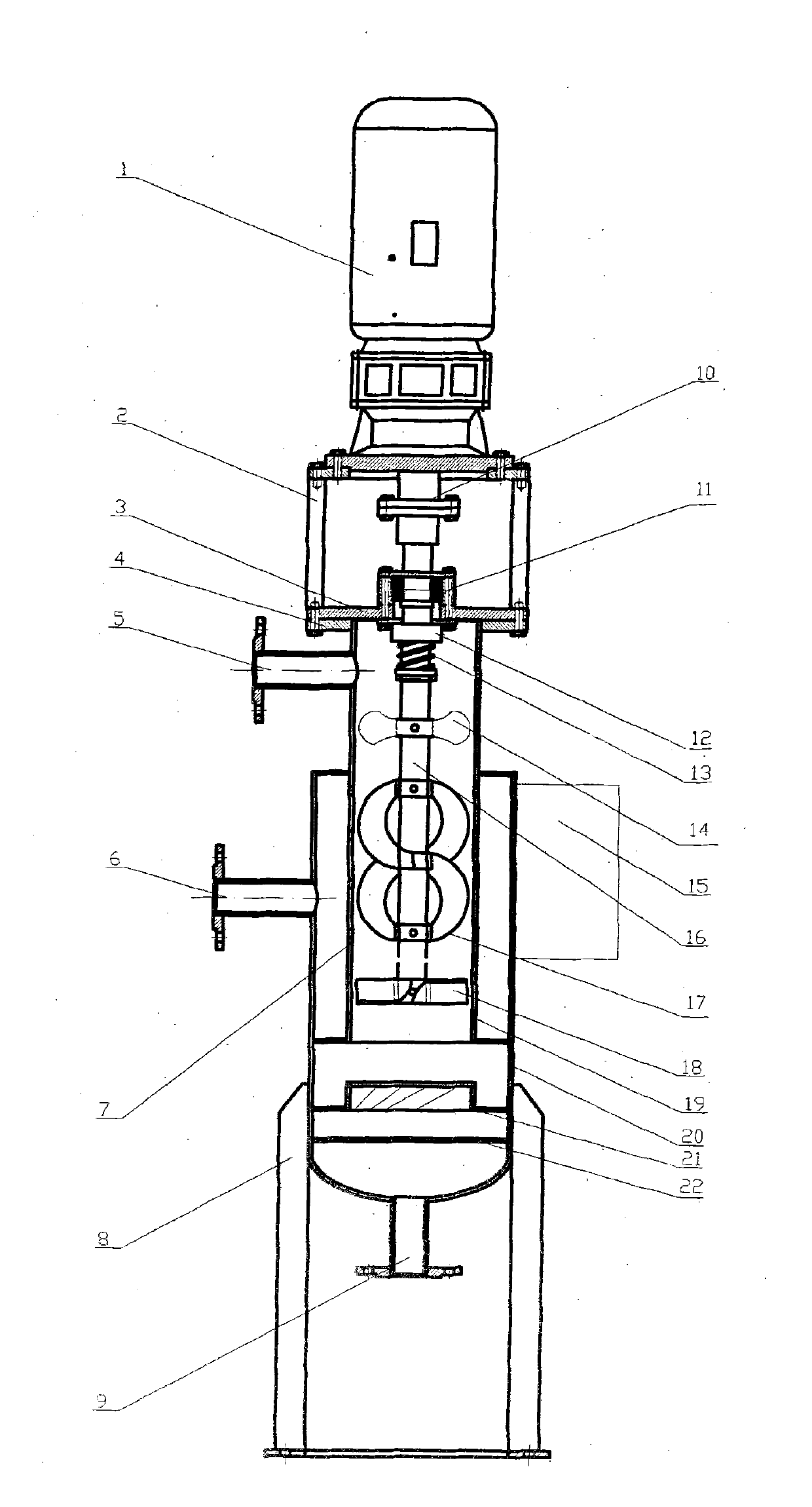

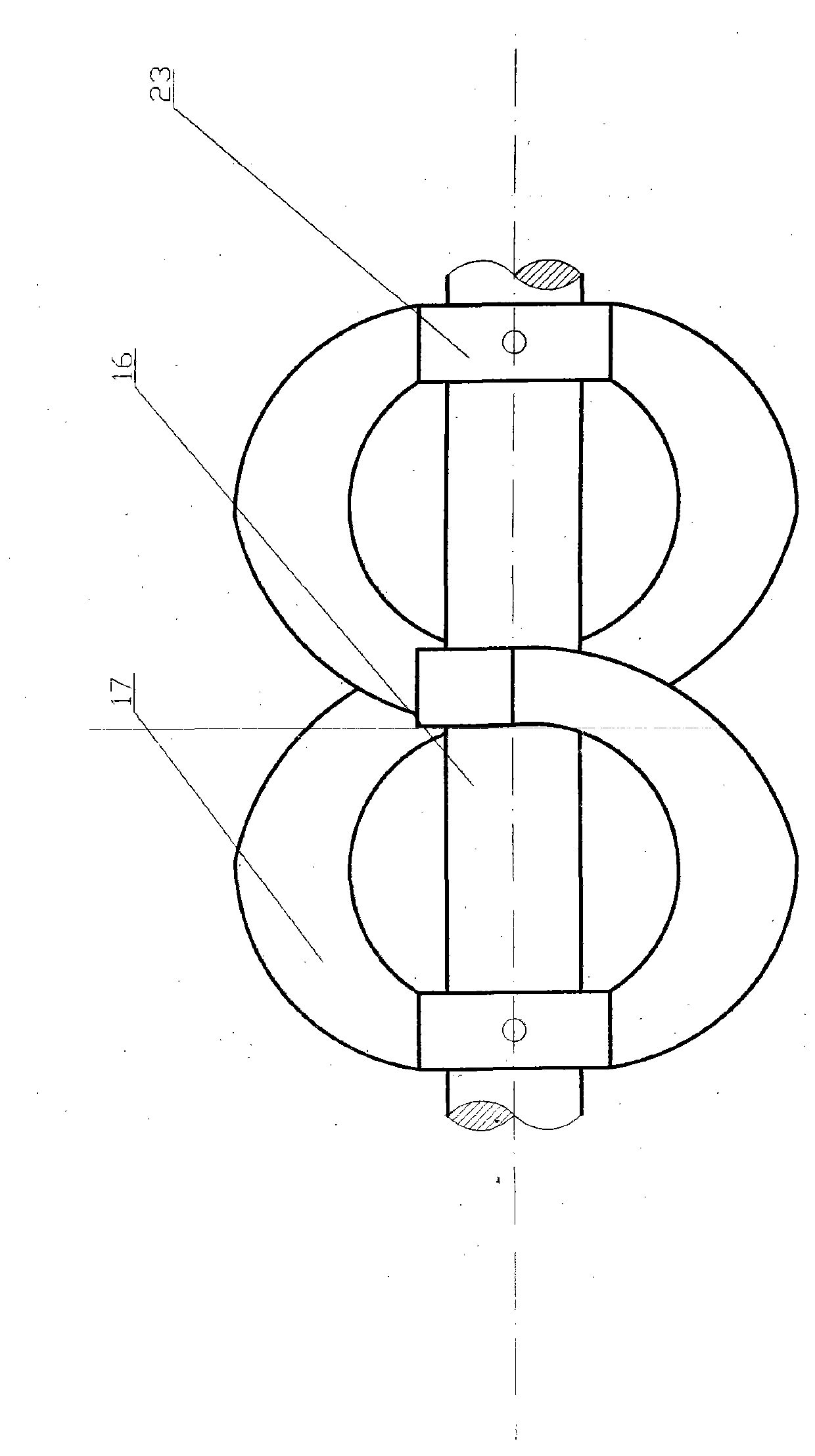

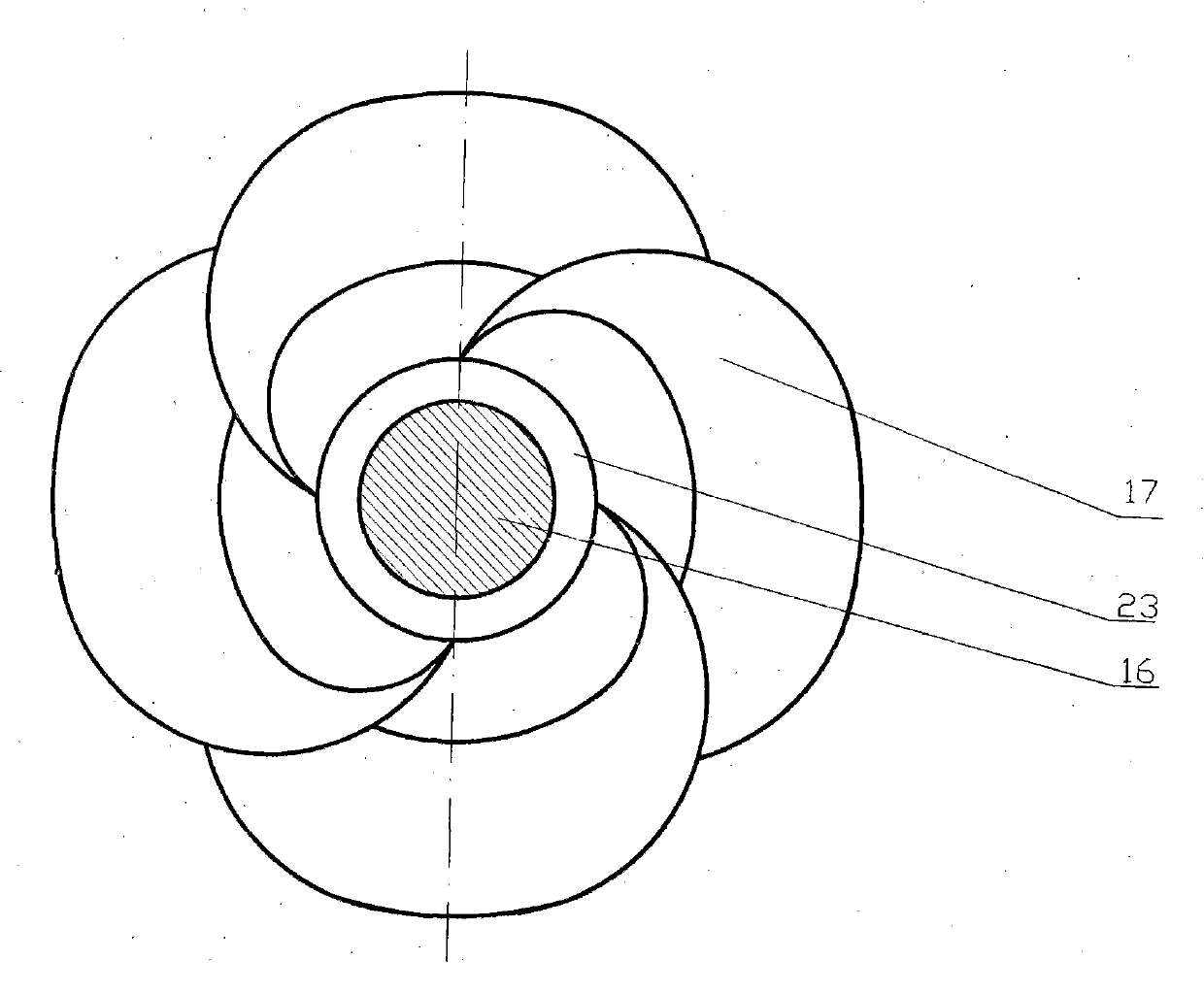

[0006] For the products involved in this project, the upper end of the inner cylinder 7 is provided with a connecting flange 4; the outer wall of the inner cylinder 7 is provided with an upper oil inlet pipe 5 and an ultrasonic generator 15, and the connecting flange 4 is connected to the bearing seat bottom plate 3 through bolts, and the bearing A bearing seat 11 is provided on the seat bottom plate 3; a bearing is housed in the bearing seat 11, and a mechanical seal seat 12 and a mechanical seal 13 are arranged below the bearing seat 11; Some connections are flange connections. The main shaft 16 is connected with the reducer shaft through a coupling 10, and the main shaft 16 is provided with a dispersing stirring blade 14, an 8-shaped stirring blade 17, and a straight stirring blade 18. The outer wall below the inner cylinder 7 is provided with an outer cylinder 20; the outer cylinder 20 and the inner cylinder 7 form a cavity, the cavity inner wall is provided with many oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com