Adhesive able to realize rapid bonding and rapid separation and preparation method thereof

An adhesive and fast technology, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve problems such as serious energy consumption, high gas toxicity, environmental health pollution, etc., to improve curing speed and improve degumming performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

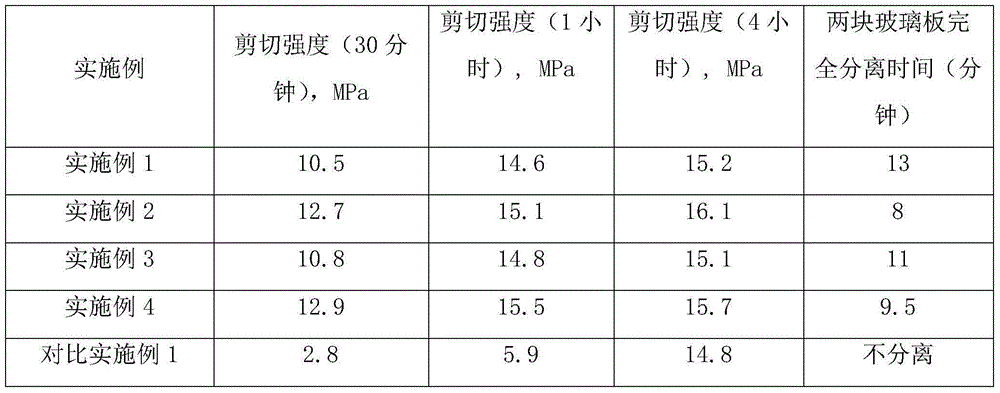

Examples

Embodiment 1

[0047] Accurately weigh the following raw materials: 55 parts of 711 epoxy resin, 12 parts of phenolic resin SP-6700, 12 parts of nonylphenol, 4 parts of thermal expansion agent 031F40, 6 parts of potassium borohydride, 13 parts of quicklime powder, gas phase Add 3 parts of silicon A300 into the double planetary power mixing mixer and mix, vacuumize to -0.09MPa, and mechanically stir under the condition that the rotation speed of the double planetary power mixing mixer is 800 revolutions per minute and the revolution speed is 10 revolutions per minute. 4 hours, discharge, promptly obtain the A component of adhesive of the present invention, pack and place stand-by;

[0048] Accurately weigh the following raw materials: 55 parts of modified polythiol curing agent JH-3380S, 8 parts of nonylphenol, 3 parts of sodium carbonate, 8 parts of calcium carbide powder, 25 parts of quicklime powder, and 3 parts of fumed silicon A300 Add in the double planetary power mixing mixer and mix, ...

Embodiment 2

[0050] Accurately weigh the following raw materials: 40 parts of PHQEP epoxy resin, 19 parts of phenolic resin SFP-118, 19 parts of benzyl alcohol, 1 part of thermal expansion agent 031DU40, 10 parts of calcium carbide powder, 5 parts of silica gel powder, fumed silicon A380 Add 0.5 parts into the double planetary power mixing mixer and mix, evacuate to -0.1MPa, and mechanically stir for 5 hours under the conditions that the double planetary power mixing mixer has a rotation speed of 1000 rpm and a revolution speed of 15 rpm. , discharging, that is, to obtain component A of the adhesive of the present invention, packaged and placed for use;

[0051] Accurately weigh the following raw materials: 40 parts of modified polythiol curing agent JH-3380S, 10 parts of benzyl alcohol, 0.5 parts of sodium hydroxide, 15 parts of potassium borohydride, 15 parts of quicklime powder, and 5 parts of fumed silicon A380 Parts were added to the double planetary power mixing mixer and mixed, vacu...

Embodiment 3

[0053] Accurately weigh the following raw materials: 65 parts of 731 epoxy resin, 6 parts of phenolic resin SFP-118, 7 parts of benzyl alcohol, 5 parts of thermal expansion agent 031DU40, 2 parts of sodium borohydride, 18 parts of quicklime powder, fumed silicon Add 4.5 parts of A300 into the dual-planetary power mixing mixer and mix, vacuumize to -0.08MPa, and mechanically stir 3.5 Hour, discharge, promptly obtain the A component of adhesive glue of the present invention, pack and place stand-by;

[0054] Accurately weigh the following raw materials: 65 parts of modified polythiol curing agent JH-3381, 6 parts of nonylphenol, 4.5 parts of sodium carbonate, 2 parts of sodium borohydride, 30 parts of silica gel powder, and 1 part of fumed silicon A300 Parts were added to the double planetary power mixing mixer and mixed, vacuumed to -0.09MPa, under the condition that the rotation speed of the double planetary power mixing mixer was 900 rpm and the revolution speed was 12 rpm, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com