Modified epoxy resin of monocrystalline silicon rod cutting glue and preparation method thereof

A technology of epoxy resin and single crystal silicon rods, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of not meeting the production process of single crystal silicon wafer cutting, poor anti-crystallization performance, and many edge chipping, etc. problems, to achieve the effect of improving the overall leveling performance, good degumming performance, and reducing the chip drop rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

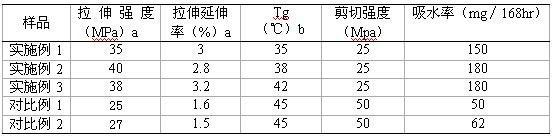

Examples

Embodiment 1

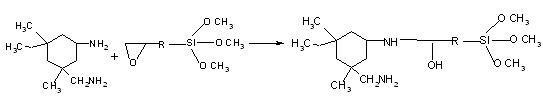

[0028] Preparation of modified amine: put alicyclic amine and epoxy silane into a spiral stirrer, stir rapidly for 20-30 minutes at a speed of 300-500 rpm, then put the mixture into a reaction kettle to heat, and the temperature is controlled at 100℃~150℃, stir rapidly for 2~3 hours;

[0029] The proportion of component A is as follows: 50% bisphenol A epoxy resin with an epoxy value of 0.51mol / 100g, 49% KR-628, 0.5% simethicone, and 0.5% borate coupling agent.

[0030] The proportion of component B is as follows: 68% Capcure 3800, 31% modified cycloaliphatic amine, 1% 2,4,6-tris(dimethylaminomethyl)phenol.

[0031] Accurately weigh various raw materials according to the above formula ratio, put them into the reaction kettle, control the temperature of the reaction kettle at about 60°C, stir in vacuum for 3 hours, put them into packaging bottles after cooling, and seal them for storage.

Embodiment 2

[0033] Preparation of modified amine: put alicyclic amine and epoxy silane into a spiral stirrer, stir rapidly for 20-30 minutes at a speed of 300-500 rpm, then put the mixture into a reaction kettle to heat, and the temperature is controlled at 100℃~150℃, stir rapidly for 2~3 hours;

[0034] The proportion of component A is as follows: 55% bisphenol A epoxy resin with an epoxy value of 0.54mol / 100g, 44% 1,4 butanediol diglycidyl ether, 0.5% polyoxyethylene glyceryl ether, 0.5% KH560.

[0035] The proportion of component B is as follows: 55% Capcure 3800, 44% modified cycloaliphatic amine, 1% resorcinol.

[0036] Accurately weigh various raw materials according to the above formula ratio, put them into the reaction kettle, heat up to 40°C~60°C, stir in vacuum for 3~4 hours and then cool; then put it into a packaging bottle and seal it for storage.

Embodiment 3

[0038] Preparation of modified amine: put alicyclic amine and epoxy silane into a spiral stirrer, stir rapidly for 20-30 minutes at a speed of 300-500 rpm, then put the mixture into a reaction kettle to heat, and the temperature is controlled at 100℃~150℃, stir rapidly for 2~3 hours;

[0039] The proportion of component A is as follows: 60% bisphenol A epoxy resin with an epoxy value of 0.56mol / 100g, 33% KR-102, 0.5% simethicone, and 2% KH560.

[0040] Preparation of component B, 60% Capcure 3800, 39% modified cycloaliphatic amine, 1% resorcinol. Put it into a reaction kettle, heat it to 40°C~60°C, stir it under vacuum for 3~4 hours, then cool it down; then put it into a packaging bottle and keep it sealed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com