Preparation method of degumming agent

A technology of degumming agent and preparation steps, applied in the field of preparation of degumming agent, can solve the problems of incomplete degumming, slow dissolution and degumming efficiency, etc., and achieve the effects of complete degumming, high degumming efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

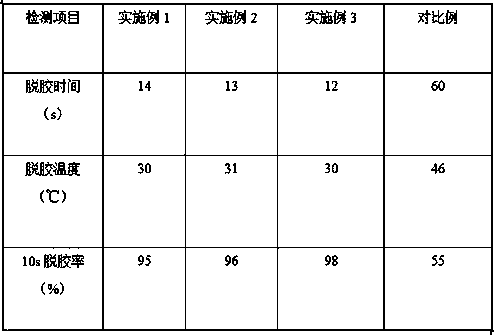

Examples

Embodiment 1

[0028] Wash the potatoes, peel them, cut them into pieces, add water and boil until rotten to obtain a suspension, pass the suspension through four layers of gauze to obtain a filtrate; the composition of the liquid medium is 20g / L of the filtrate, 20g / L of glucose, Agar 17g / L, the rest is deionized water, sterilized at 120°C for 20min; the components of the seed medium are glucose 20g / L, adenine 0.03g / L, calcium chloride 0.01g / L, thiamine Su 0.05g / L, ammonium sulfate 2.6g / L, MgSO 4 ·7H 2 O 0.5g / L, the rest is deionized water, sterilized at 120°C for 20 minutes; inoculate Bacillus subtilis on the liquid medium, culture by streaking, and pick out the bacteria with better growth after it is overgrown The body was inserted into the seed medium, and the temperature was 30°C, and the rotation speed was 200r / min, and the shaking culture was 2 days to obtain the mother liquor; the mother liquor was inoculated into the seed medium with an inoculation amount of 7%, and the temperature...

Embodiment 2

[0030] Wash the potatoes, peel them, cut them into pieces, add water and boil until rotten to obtain a suspension, pass the suspension through four layers of gauze to obtain a filtrate; the composition of the liquid medium is 20g / L of the filtrate, 20g / L of glucose, Agar 17g / L, the rest is deionized water, sterilized at 123°C for 25min; the components of the seed medium are glucose 20g / L, adenine 0.03g / L, calcium chloride 0.01g / L, thiamine Su 0.05g / L, ammonium sulfate 2.6g / L, MgSO 4 ·7H 2 O 0.5g / L, the rest is deionized water, sterilized at 123°C for 25min; inoculate Bacillus subtilis on the liquid medium, culture by streaking, and pick out the better-growing bacteria after they are overgrown. The body was inserted into the seed medium, and the temperature was 33°C, and the rotation speed was 250r / min, and the shaking culture was 2 days, and the mother liquor was obtained; the mother liquor was inoculated into the seed culture medium, the inoculation amount was 8%, and the te...

Embodiment 3

[0032] Wash the potatoes, peel them, cut them into pieces, add water and boil until rotten to obtain a suspension, pass the suspension through four layers of gauze to obtain a filtrate; the composition of the liquid medium is 20g / L of the filtrate, 20g / L of glucose, Agar 17g / L, the rest is deionized water, sterilized at 125°C for 30min; the components of the seed medium are glucose 20g / L, adenine 0.03g / L, calcium chloride 0.01g / L, thiamine Su 0.05g / L, ammonium sulfate 2.6g / L, MgSO 4 ·7H 2 O 0.5g / L, the rest is deionized water, sterilized at a temperature of 125°C for 30 minutes; inoculate Bacillus subtilis on the liquid medium, culture by streaking, and pick out the bacteria with better growth after it is overgrown. The body was inserted into the seed medium, and the temperature was 35°C, and the rotation speed was 300r / min, and the shaking culture was carried out for 2 days to obtain the mother liquor; the mother liquor was inoculated into the seed medium with an inoculum si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com