Efficient structural adhesive for temporary bonding and application thereof

A temporary bonding and adhesive technology, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems of low thermal stability of the adhesive layer, low bonding strength, and slow bonding speed , to achieve the effect of good solvent resistance, thorough degumming and fast bonding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

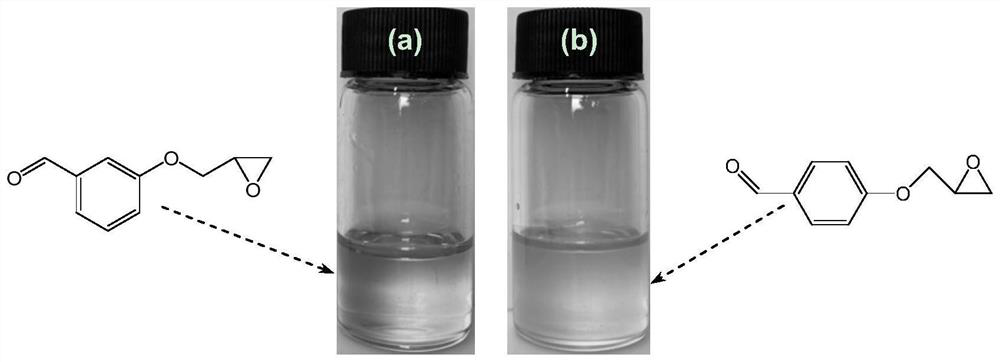

[0055]The A component includes only m-hydroxybenzaldehyde glycidyl ether, and the B component only includes tetraethylenepentamine. The tensile shear strength of the adhesive was tested according to the national standard GB / T 7124-2008 Determination of the tensile shear strength of adhesives (rigid material to rigid material). Quickly mix 10.0g m-hydroxybenzaldehyde glycidyl ether and 7.0g tetraethylene pentamine evenly, apply it to the bonding part of the stainless steel test piece, fit the steel piece tightly, remove the excess glue on the edge, and fix it with a reverse tail clip , 5 samples were tested in each group, and the average value was taken. After curing at room temperature for 10min, 1h, 2h, and 24h, the tensile shear strength reached 0.5, 8.0, 12.1, and 16.3MPa, respectively. The samples cured at room temperature for 24 hours were soaked in ethanol, methanol, acetone, methyl ethyl ketone, toluene, ethyl acetate, N-methylpyrrolidone, N,N-dimethylformamide, hydrog...

Embodiment 2

[0057] The adhesive composition and test method are the same as those in Example 1, and the curing conditions are different. After curing at 100℃ for 3min, 5min, 10min, and 1h, the tensile shear strength reached 1.5, 5.1, 11.8, and 22.1MPa, respectively. The samples cured at 100℃ for 1h were soaked in ethanol, methanol, acetone, methyl ethyl ketone, toluene, ethyl acetate, N-methylpyrrolidone, N,N-dimethylformamide, hydrogen peroxide and sodium hydroxide aqueous solution for 24h at room temperature. The adhesive is completely non-degradable and has no degumming phenomenon. The thermal decomposition temperature of 5wt% of the sample adhesive layer after curing at 100°C for 1h is 309°C. The samples cured at 100 °C for 1 h were soaked in 1 mol / L acetic acid aqueous solution at room temperature, and the adhesive was completely degraded in about 10 minutes to complete degumming.

Embodiment 3

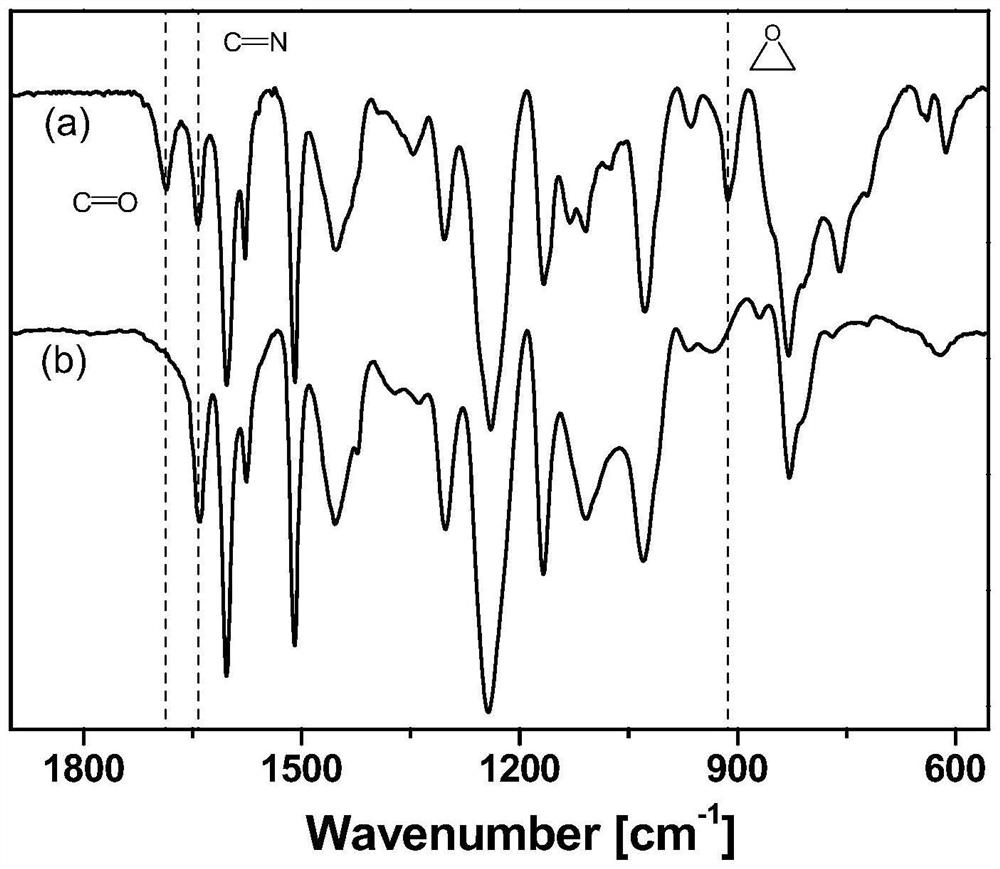

[0059] Adhesive component A includes only p-hydroxybenzaldehyde glycidyl ether See figure 2 ), other components and test methods are the same as in Example 1. After curing at room temperature for 30min, 1h, 2h, and 24h, the tensile shear strength reached 0.4, 7.9, 11.5, and 15.7MPa, respectively. The reaction process and reaction mechanism of the adhesive (the aldehyde group and epoxy group in the glycidyl ether structure of p-hydroxybenzaldehyde react with the amine group in the tetraethylene pentamine structure, respectively, to generate imine bonds and cross-linking structure) see infrared spectrum figure 2 . The samples cured at room temperature for 24h were soaked in ethanol, methanol, acetone, butanone, toluene, ethyl acetate, N-methylpyrrolidone, N,N-

[0060] In dimethylformamide, hydrogen peroxide and sodium hydroxide aqueous solution for 24h, the adhesive will not be degraded at all, and there will be no degumming phenomenon. The thermal decomposition temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com