A process for preparing catechin silk protein by liquid-solid fluidized state method

A technology of fibroin and fluidized state, applied in the field of silk protein, can solve the problems of protein destruction, low product utilization rate, increased discharge of waste liquid treatment, etc., achieve strong anti-histamine, enhance resistance, inhibit osmosis out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

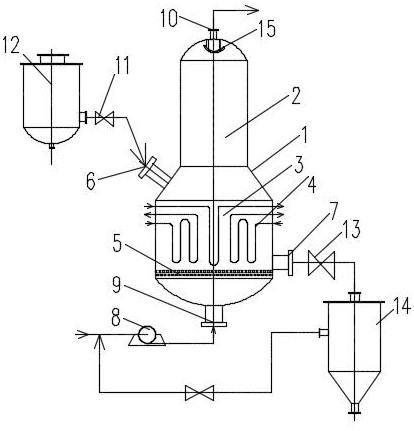

Image

Examples

Embodiment 1

[0048] A process for preparing catechin silk protein by a liquid-solid fluidized state method, comprising the steps of:

[0049] a. Remove impurities in tea raw materials, add gel granules after crushing and blowing dust, and obtain catechin granules after drying.

[0050] In this step, the tea raw material is preferably green tea leftovers or old tea leaves that cannot be directly made into tea, so as to save production costs. The gel is a food-grade gel made of animal skin, and the dosage of the gel is 5-10% of the tea raw material. The obtained catechu particles have a sphericity ≥ 0.8, a diameter of 0.2mm, and a specific surface area of 30m 2 / l.

[0051] b. Send catechu granules and silk protein solution into the fluidized reaction tower at a mass ratio of 1:9. The mass percentage concentration of the silk protein solution is generally 10-90%, and the fluidized reaction is carried out at a temperature of 30°C After 3 hours of reaction, a catechin silk protein solutio...

Embodiment 2

[0081] A process for preparing catechin silk protein by a liquid-solid fluidized state method, comprising the steps of:

[0082] a. Remove impurities in tea raw materials, add gel granules after crushing and blowing dust, and obtain catechin granules after drying.

[0083] In this step, the tea raw material is preferably green tea leftovers or old tea leaves that cannot be directly made into tea, so as to save production costs. The gel is a food-grade gel made of animal skin, and the dosage of the gel is 5-10% of the tea raw material. The obtained catechu particles have a sphericity ≥ 0.8, a diameter of 0.2mm, and a specific surface area of 30m 2 / l.

[0084] b. Send catechu granules and silk protein solution into the fluidized reaction tower at a mass ratio of 1: 11. The mass percentage concentration of the silk protein solution is generally 10-90%, and the fluidized reaction is carried out at a temperature of 40°C After 4 hours of reaction, a catechin silk protein solut...

Embodiment 3

[0098] A process for preparing catechin silk protein by a liquid-solid fluidized state method, comprising the steps of:

[0099] a. Remove impurities in tea raw materials, add gel granules after crushing and blowing dust, and obtain catechin granules after drying.

[0100] In this step, the tea raw material is preferably green tea leftovers or old tea leaves that cannot be directly made into tea, so as to save production costs. The gel is a food-grade gel made of animal skin, and the dosage of the gel is 5-10% of the tea raw material. The obtained catechu particles have a sphericity ≥ 0.8, a diameter of 0.2mm, and a specific surface area of 30m 2 / l.

[0101] b. Send catechu granules and silk protein solution into the fluidized reaction tower at a mass ratio of 1:10. The mass percentage concentration of the silk protein solution is generally 10-90%, and the fluidized reaction is carried out at a temperature of 35°C After 3.5 hours of reaction, a catechin silk protein solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com