Silicon wafer degumming agent, manufacturing method and use method thereof

A degumming agent and silica gel technology, applied in chemical instruments and methods, detergent compositions, soap detergent compositions, etc., can solve the problems of poor degumming effect, high degumming cost, strong corrosiveness, etc. No irritating odor, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

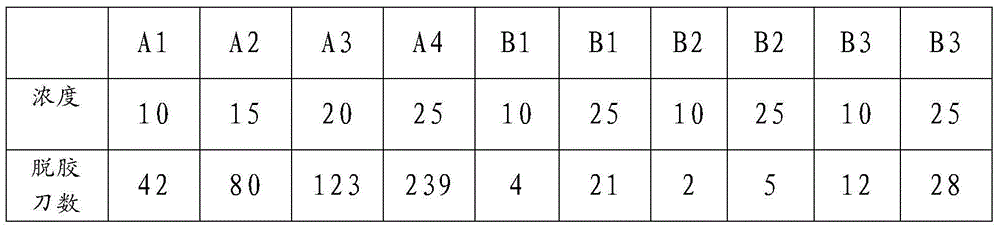

Examples

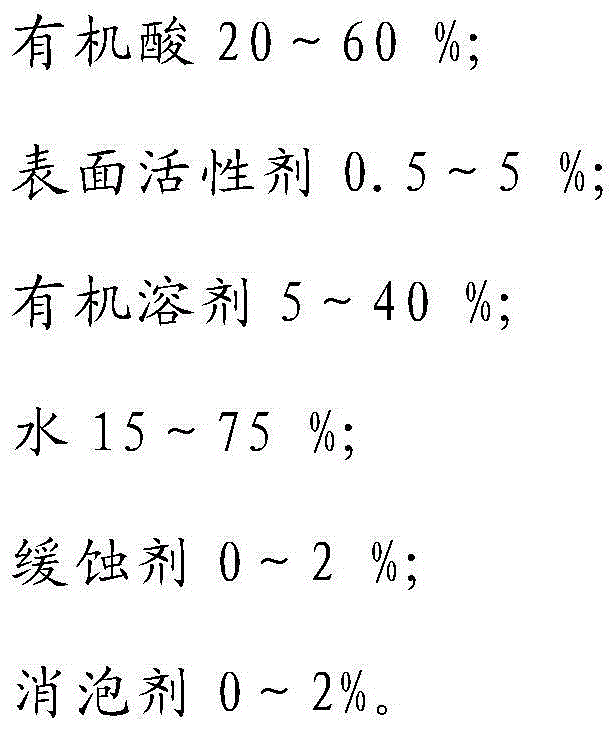

Embodiment 1

[0028] What this embodiment adopts is a kind of silicon wafer degumming agent, according to percentage by weight, it comprises 2-hydroxysuccinic acid 30%; Isomerized alcohol polyoxyethylene ether 2%; Dipropylene glycol 15%; Water 52%; Imidazole 0.5% of morphine; 0.5% of polyoxyethylene polyoxypropylene pentaerythritol ether.

[0029] The present invention also provides a method for preparing a silicon wafer degumming agent, which is to put the materials in the above ratio into a reaction kettle, fully stir and mix them at room temperature for 3 hours, and obtain the silicon wafer degumming agent A1 of the present invention until uniformly mixed.

Embodiment 2

[0031] What the present embodiment adopts is a kind of silicon wafer degumming agent, according to percentage by weight, it comprises 2,3-dihydroxysuccinic acid 25%; Sodium lauryl sulfate 3%; 2,2-dimethylol butanol 20%; water 51%; imidazoline 0.5%; polyoxypropylene glyceryl ether 0.5%.

[0032] The present invention also provides a method for preparing the silicon wafer degumming agent, which is to put the materials in the above ratio into a reaction kettle, and carry out sufficient stirring and mixing at room temperature for 3 hours until the silicon wafer degumming agent A2 of the present invention is obtained through uniform mixing.

Embodiment 3

[0034] What the present embodiment adopts is a kind of silicon wafer degumming agent, according to percentage by weight, it comprises glycolic acid 55%; Octylphenol polyoxyethylene ether 3%; Diacetone alcohol 25%; Water 16%; Methanol 0.5% ; Polyoxyethylene polyoxypropylene pentaerythritol ether 0.5%.

[0035] The present invention also provides a method for preparing the silicon wafer degumming agent, which is to put the materials in the above ratio into a reaction kettle, and carry out sufficient stirring and mixing at room temperature for 3 hours until the silicon wafer degumming agent A3 of the present invention is obtained through uniform mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com