Clean jute fiber degumming method

A degumming method, hemp fiber technology, applied in biological and environmental protection, textile fields, can solve the problems of high cost of chemical degumming, poor stability of enzyme activity, poor cohesion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

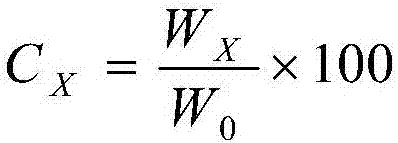

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1 Application of Plant Cellulose Extractant in Hemp Fiber Degumming Project

[0060] 1. Preparation of cooking liquid: preparation of cellulose extracting agent—the volume ratio of liquid A to liquid B is 5:1; then dilute with water at a ratio of 1:10 to prepare cooking liquid.

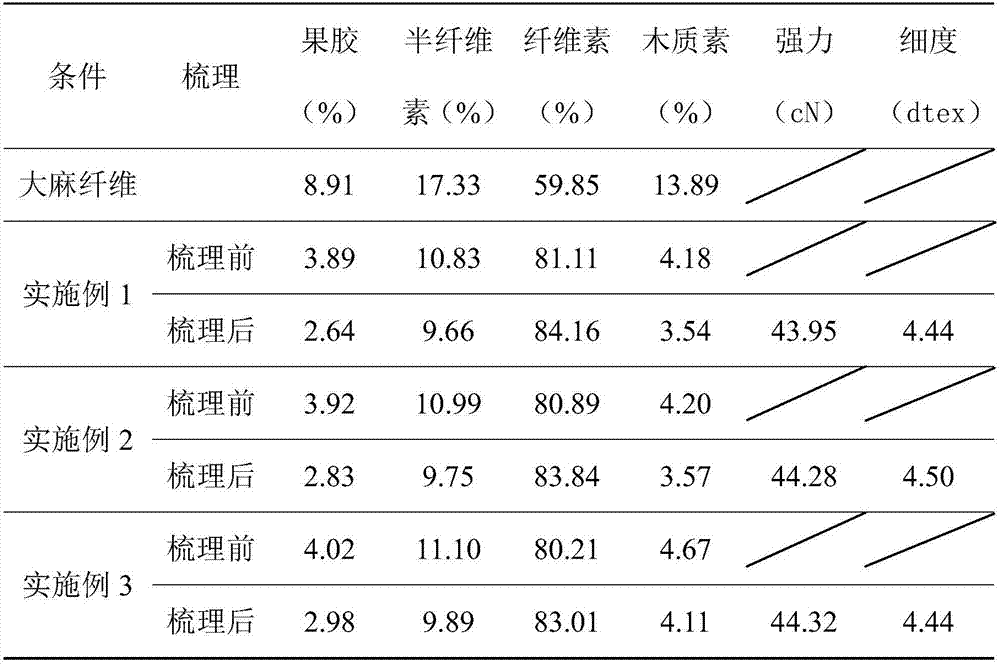

[0061] 2. Process: Combing 5kg of hemp fiber raw material for impurity removal; liquor ratio of 1:10; adding cooking liquid and cooking for 50 minutes; cooking temperature at 80°C; hemp fiber components before and after washing, bleaching, drying, health preservation, and fine carding The test results are shown in Table 1, specifically:

[0062] Step 1: Opening, removing impurities and combing the hemp fiber.

[0063] Step 2: put 5 kg of the preliminarily carded hemp fiber into a cooking pot, and add the prepared cooking liquid; the cooking bath ratio is 1:10; normal pressure, cooking temperature 80°C; cooking time 50min.

[0064] Step 3: send the hemp fiber after cooking into the was...

Embodiment 2

[0067] 1. Cooking liquor preparation: all the cooking raffinate (the raffinate containing solid content≦10%) in the embodiment 1 step 2 is used as a part of the cooking liquor, and according to the bath ratio requirement, the cooking liquor insufficient part is prepared with embodiment 1 Cooking liquid (that is, the volume ratio of liquid A and liquid B is 5:1; then diluted with water at a ratio of 1:10, the prepared cooking liquid) is supplemented (the newly prepared cooking liquid accounts for 30% of the total cooking liquid) .

[0068] 2. The process is the same as in Example 1, and the hemp fiber component test results are shown in Table 1.

Embodiment 3

[0070] 1. Cooking liquid preparation: all the cooking raffinate (solid content≤10%) of step 2 gained in embodiment 2 is used as a part of cooking liquid, and according to bath ratio requirement, the insufficient part of cooking liquid is prepared with embodiment 1 The cooking liquid is replenished (the newly prepared cooking liquid accounts for 30% of the whole cooking liquid).

[0071] 2. The process is the same as in Example 1, and the hemp fiber component test results are shown in Table 1.

[0072] See Table 1 for the degumming effect of the hemp fibers cooked in Example 1, Example 2, and Example 3—that is, fiber index detection (cellulose, hemicellulose, pectin, lignin, fineness, and strength). It can be seen from Table 1 that the cellulose content is greatly increased; lignin and pectin are effectively reduced; the fineness and strength meet the requirements of spinnable high-count blended yarn. The cooking liquor developed by this patent can be well applied in the degum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com