High-strength high-melting point low-mercury content amalgam

A high-melting-point, high-strength technology, applied in the parts of gas discharge lamps, etc., can solve the problems affecting the quality of energy-saving lamps, easy precipitation, and low compressive strength of alloy particles, to ensure the consistency of photoelectric parameters and particle flow. Good performance, ensure the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

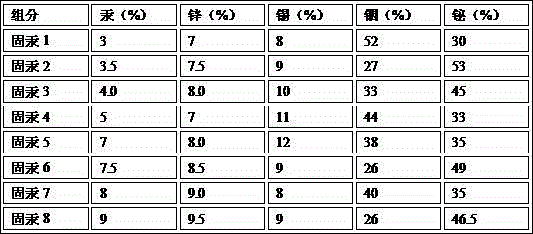

[0012] A high-strength, high-melting point, low-mercury solid mercury content, the weight percentage of each component is shown in Table 1.

[0013] The weight percentage of each component of table 1

[0014]

[0015] Choose any solid mercury in solid mercury 1-8, and study its mercury pressure and temperature characteristic curves. It can be found that the high strength, high melting point and low mercury content solid mercury of the present invention has high compressive strength of alloy particles, and can be used in product transportation. It is not easy to be damaged during use, which better guarantees the automatic production of circular platoon cars; 2) The mercury saturation of the alloy is high, and the particles do not precipitate mercury and do not stick together, so the particles have good fluidity; 3) The melting point of the alloy is as high as 300-340 ° C. When the energy-saving lamp is sealed off for the second time, the alloy particles placed on the exhaust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com