Mask sponge bar laminating machine

A sponge strip and laminating machine technology, which is applied in the field of equipment for laminating sponge strips on masks, can solve the problems of affecting the quality of mask protection, increasing production costs, and low production efficiency, so as to improve the protection effect and reduce labor costs and production costs, and the effect of improving the bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

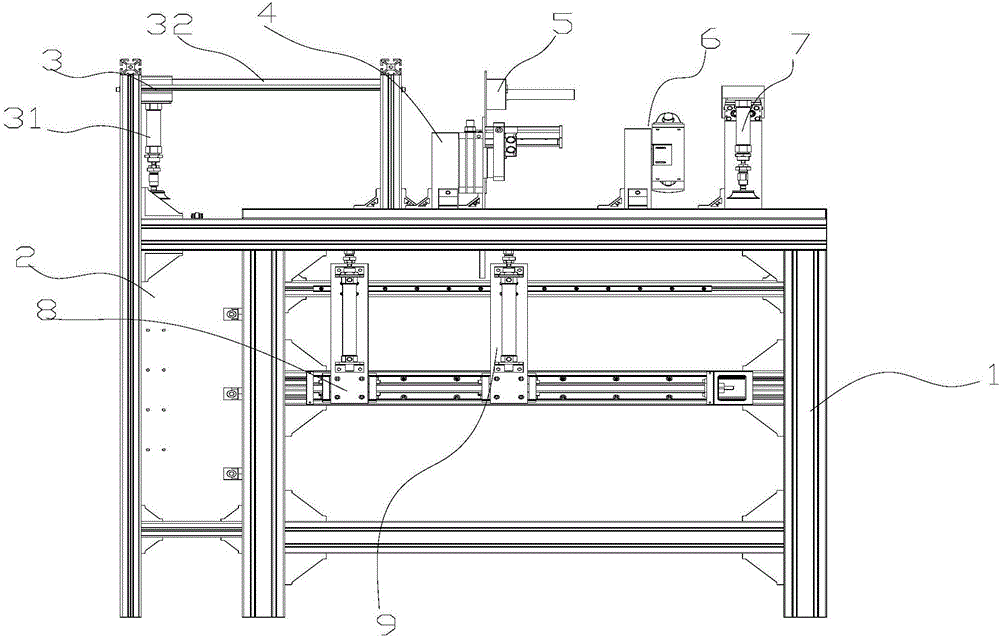

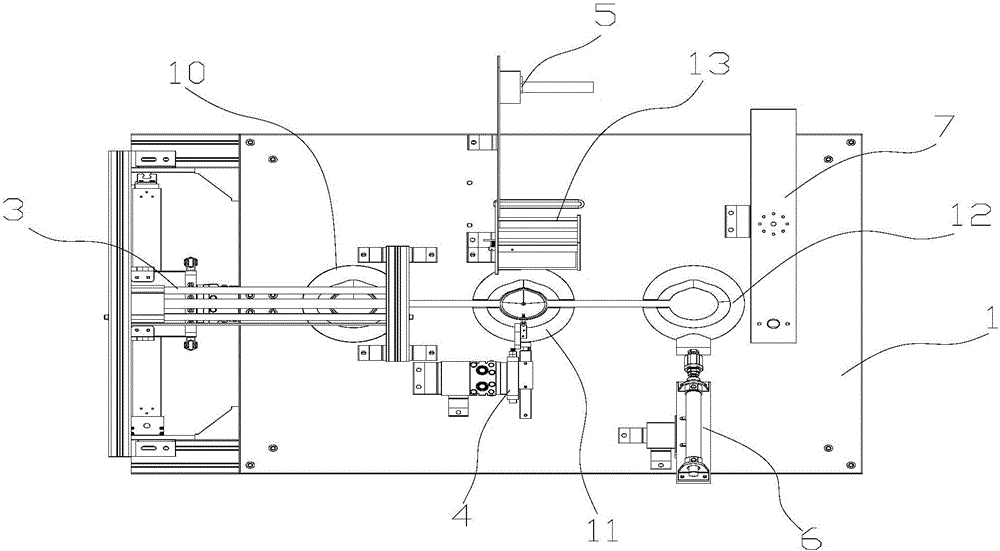

[0023] As a specific embodiment, the first mask transfer mechanism 3 includes two parts, the screw female mechanism 31 and the mask grabbing mechanism 32, the mask grabbing mechanism 32 is connected with the nut of the screw nut mechanism 31, and the mask grabbing mechanism 32 can move along the The direction of the screw rod moves back and forth. The mask grabbing mechanism 32 includes a mask grabbing head and a lifting mechanism, and the lifting mechanism can drive the mask grabbing head to move up and down.

[0024] In order to facilitate the processing of the subsequent process, automatic feeding can be carried out for the subsequent process. The mask transfer system can also be provided with a fourth mask transfer mechanism 7, through which the compressed sponge strip can be compressed from the sponge strip to the mask transfer mechanism 7. Press the die and transfer to the next process.

[0025] The mask sponge strip laminating machine is equipped with a position finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com