Foam attaching device for mobile phone touch screen

A technology of laminating device and touch screen, applied in applications, household components, household appliances, etc., can solve problems such as non-compliance with the continuous operation of the factory production process, inability to meet supply requirements, inaccurate lamination position, etc., to reduce the use limitations. , The effect of reducing economic cost and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

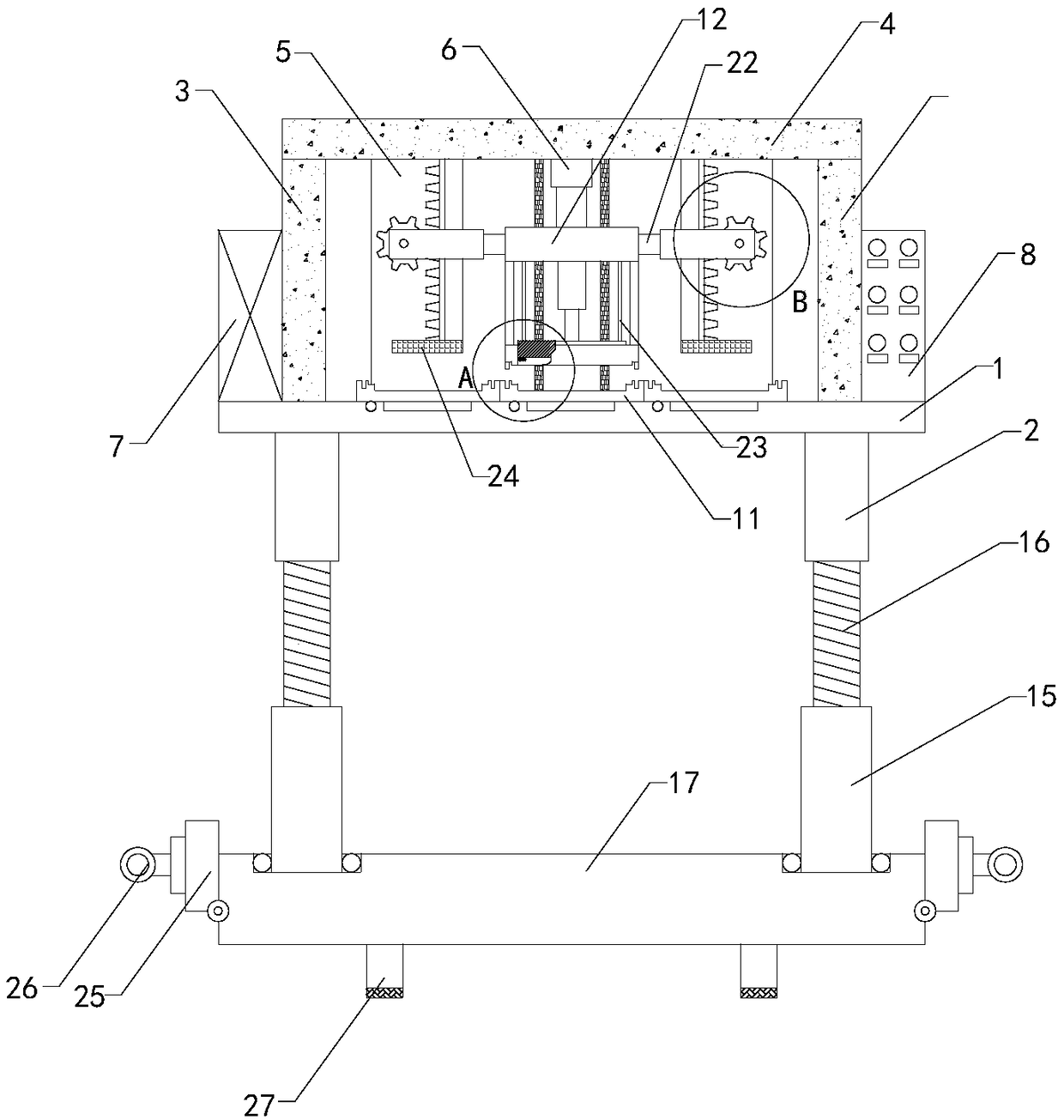

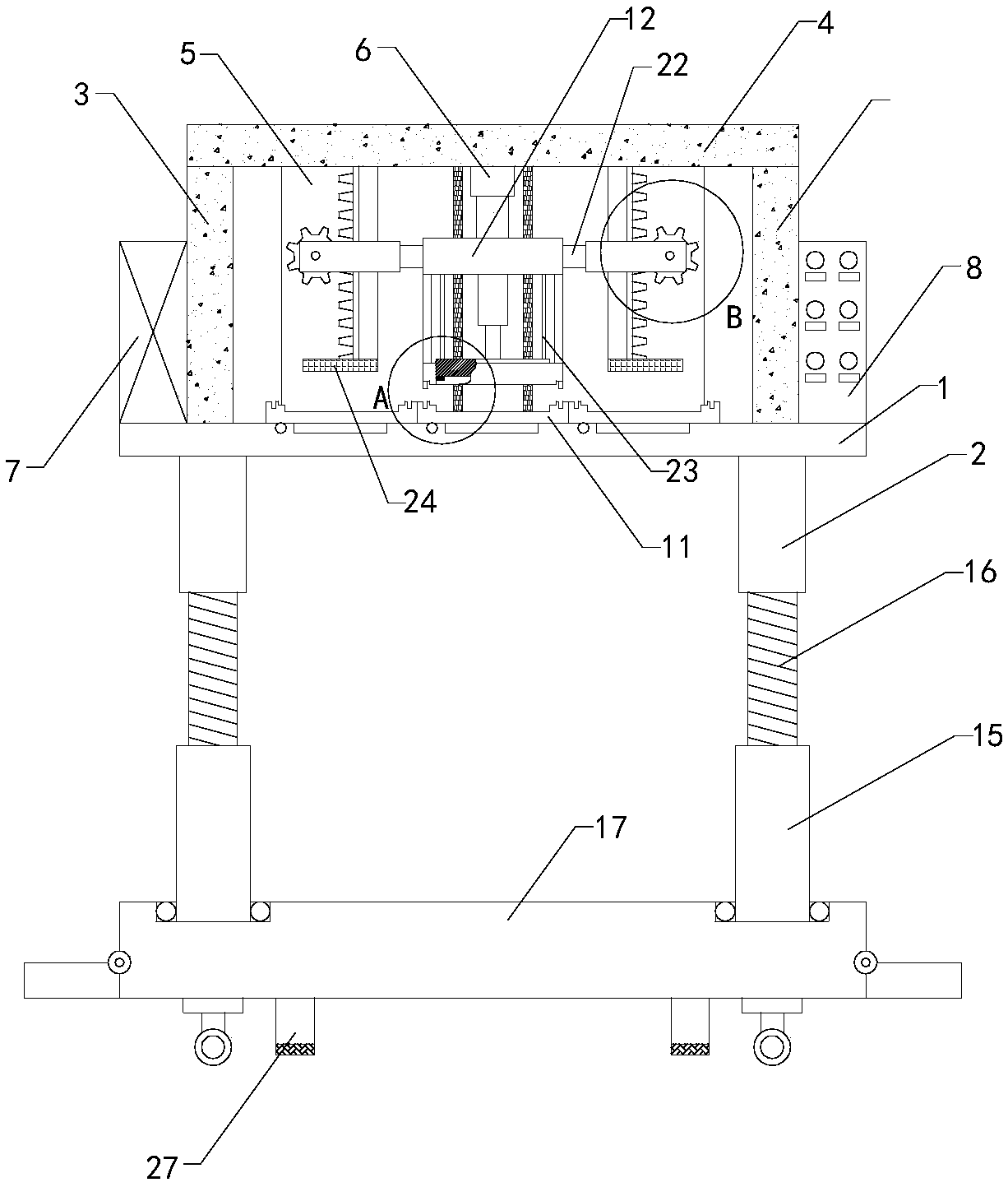

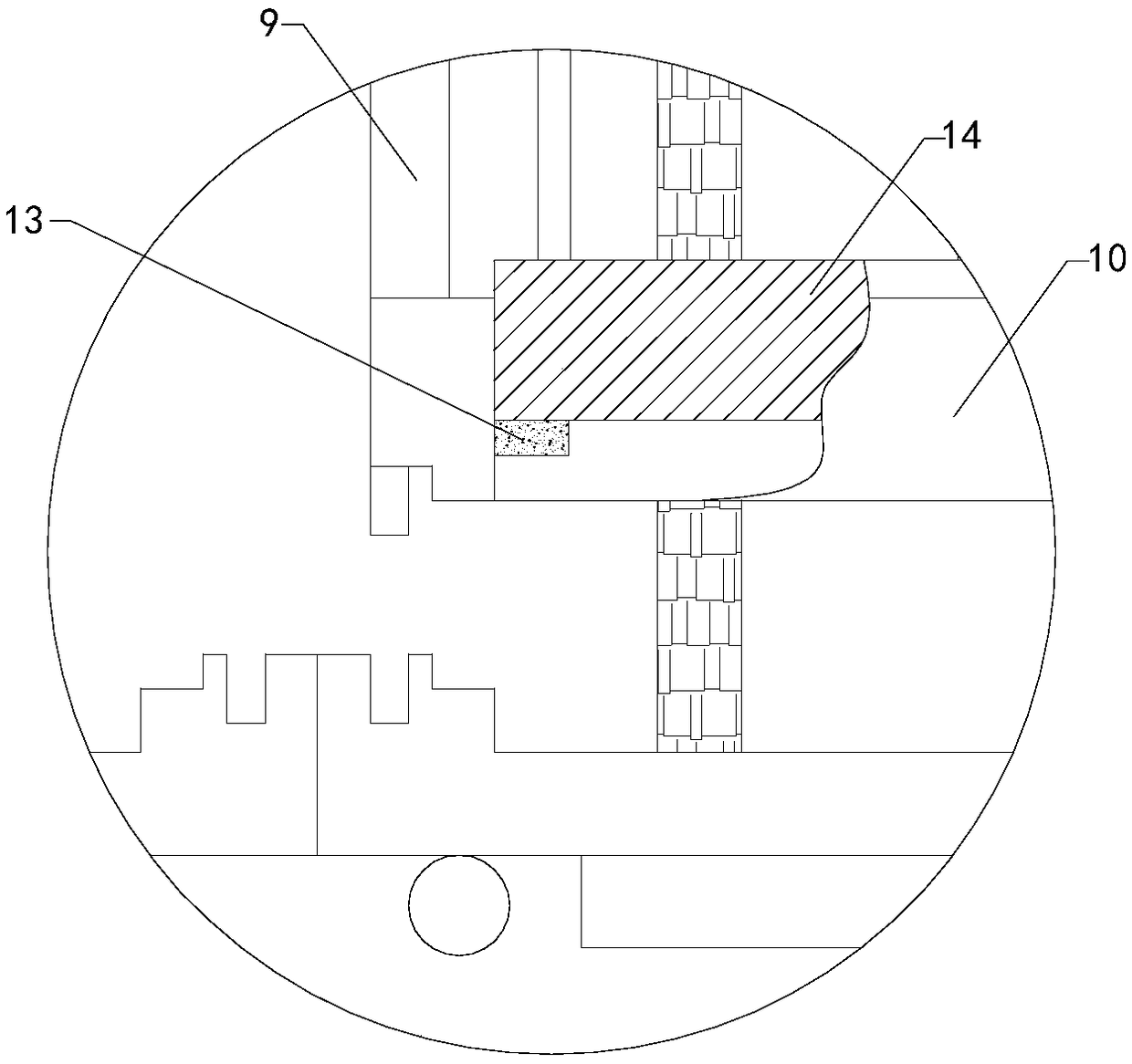

[0020] Such as Figure 1 to Figure 5As shown, a kind of foam pasting device for mobile phone touch screen of the present invention comprises workbench 1, four sets of legs 2, left support plate 3, right support plate and top plate 4, and the tops of four sets of legs are respectively connected with The left front side, the left rear side, the right front side and the right rear side of the bottom end of the workbench are connected, the bottom end of the left support plate is connected with the left side of the workbench top, the bottom end of the right support plate is connected with the right side of the workbench top, and The tops of the left support plate and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com