Processing method of super-thick special-shaped reinforcing sheet of flexible circuit

A technology of flexible circuits and processing methods, applied in the direction of bendable/stretchable components, printed circuits, printed circuits, etc., can solve problems such as the inability to guarantee the lamination progress and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

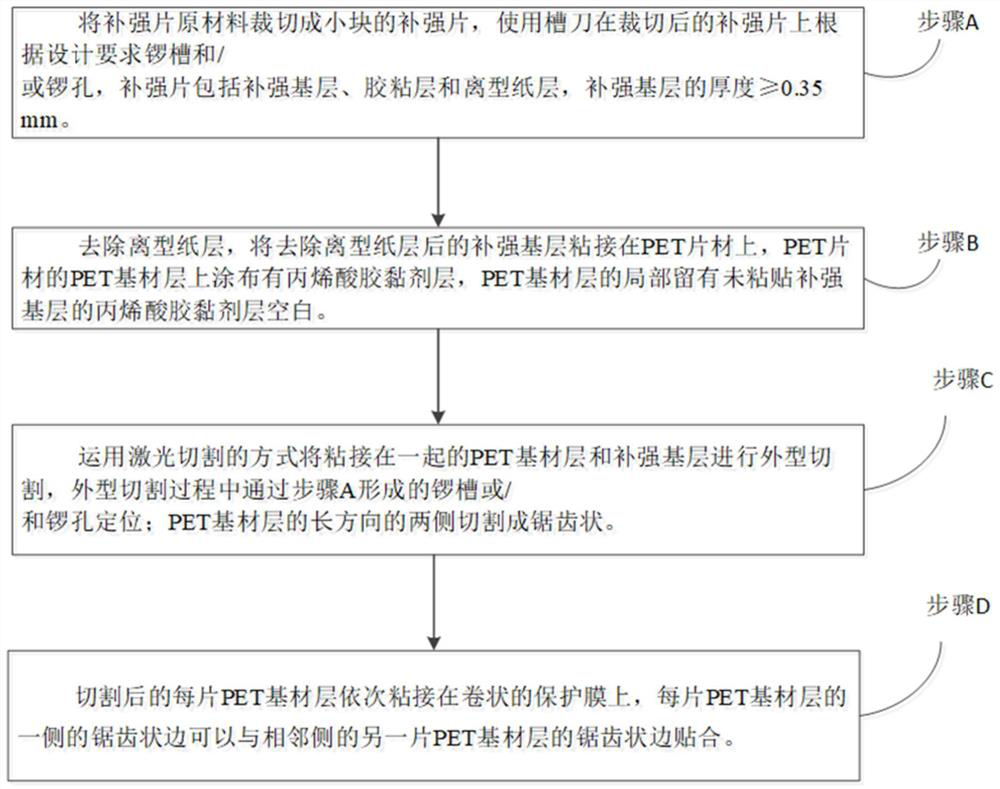

[0051] Attached below Figure 1-7 A processing method of an ultra-thick special-shaped reinforcing sheet for a flexible circuit of the present invention will be further described.

[0052] A method for processing an ultra-thick special-shaped reinforcing sheet for a flexible circuit, comprising:

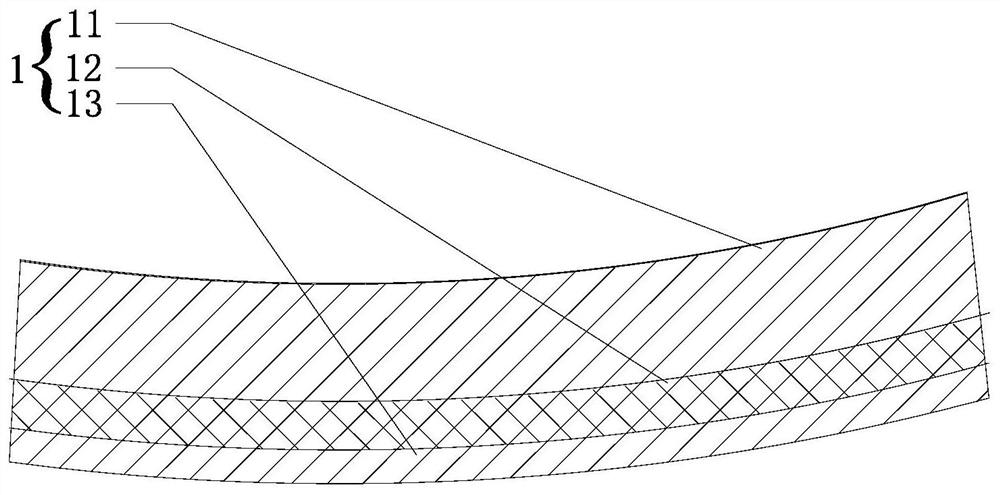

[0053] Step A. Cut the raw material of the reinforcement sheet into small pieces of the reinforcement sheet 1, and use a slotting knife to place grooves and / or holes on the cut reinforcement sheet 1 according to the design requirements. The reinforcement sheet 1 includes reinforcement The base layer 11, the adhesive layer 12 and the release paper layer 13, the thickness of the reinforcing base layer 11 is ≥0.35mm;

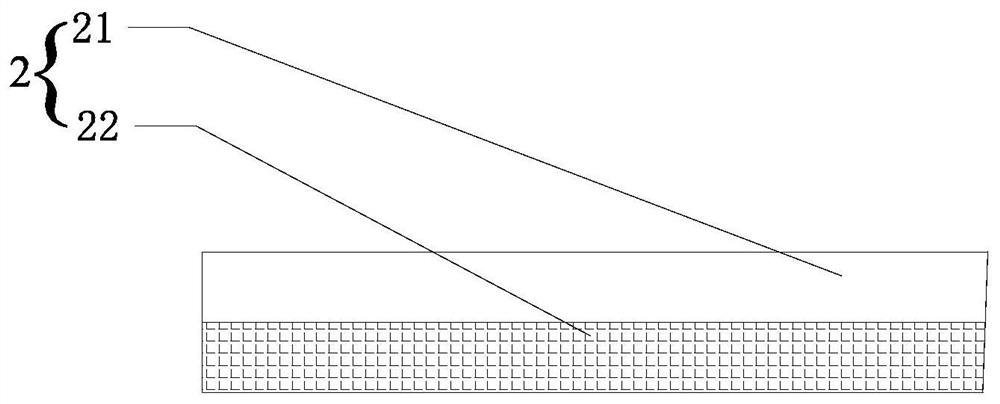

[0054] Step B. Remove the release paper layer 13, and bond the reinforcing base layer 11 after removing the release paper layer 13 on the PET sheet 2, and the PET substrate layer 21 of the PET sheet 2 is coated with an acrylic adhesive layer 22, the portion of the PET s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com