Steel disc reinforcement installation sticking machine of flexible circuit board in manufacture procedure

A flexible circuit board and steel sheet technology, which is applied in the manufacture of printed circuits, printed circuits, electrical components, etc., can solve the problems of difficult parameter control, poor efficiency of pre-applied reinforcing plates, and weak reinforcing plates, and achieves simple and convenient operation. , Improve production efficiency and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

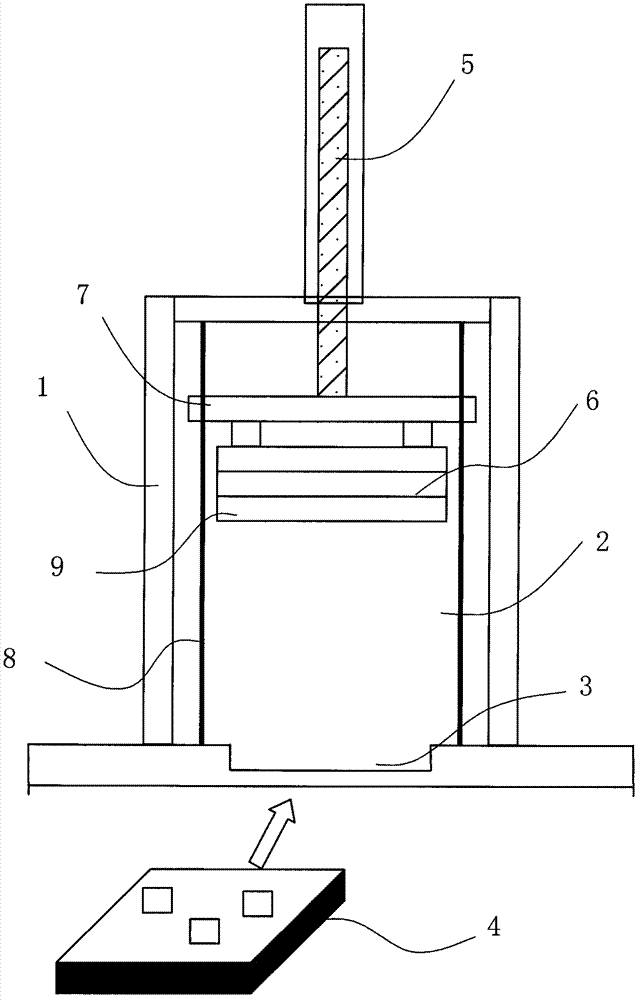

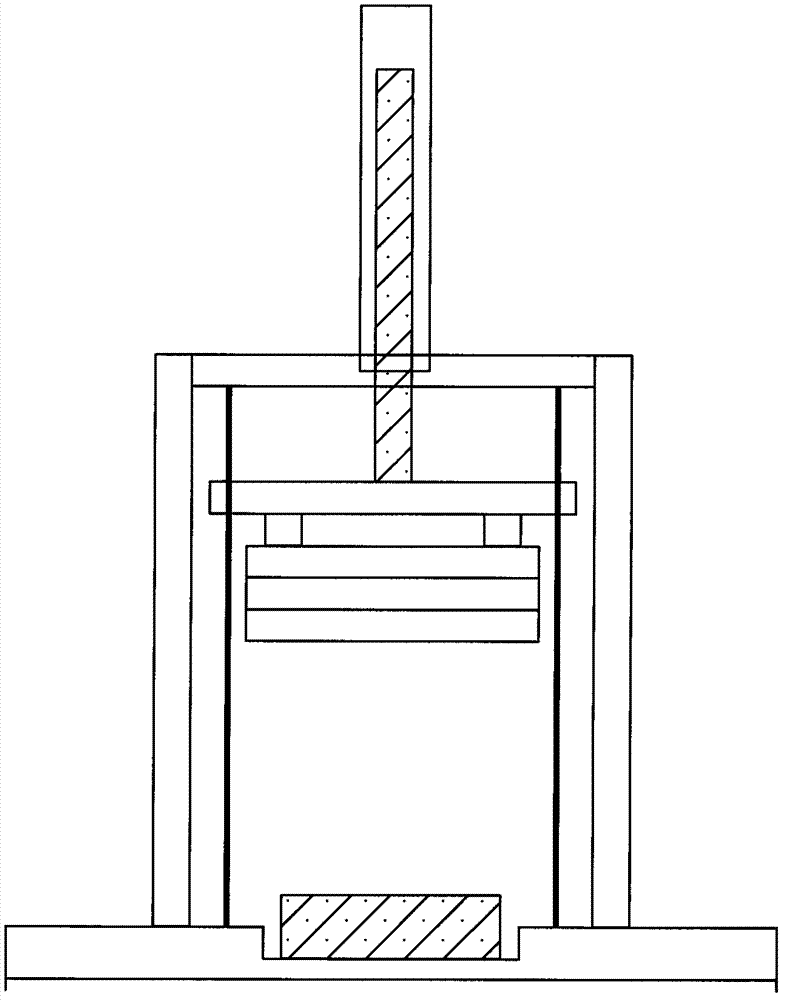

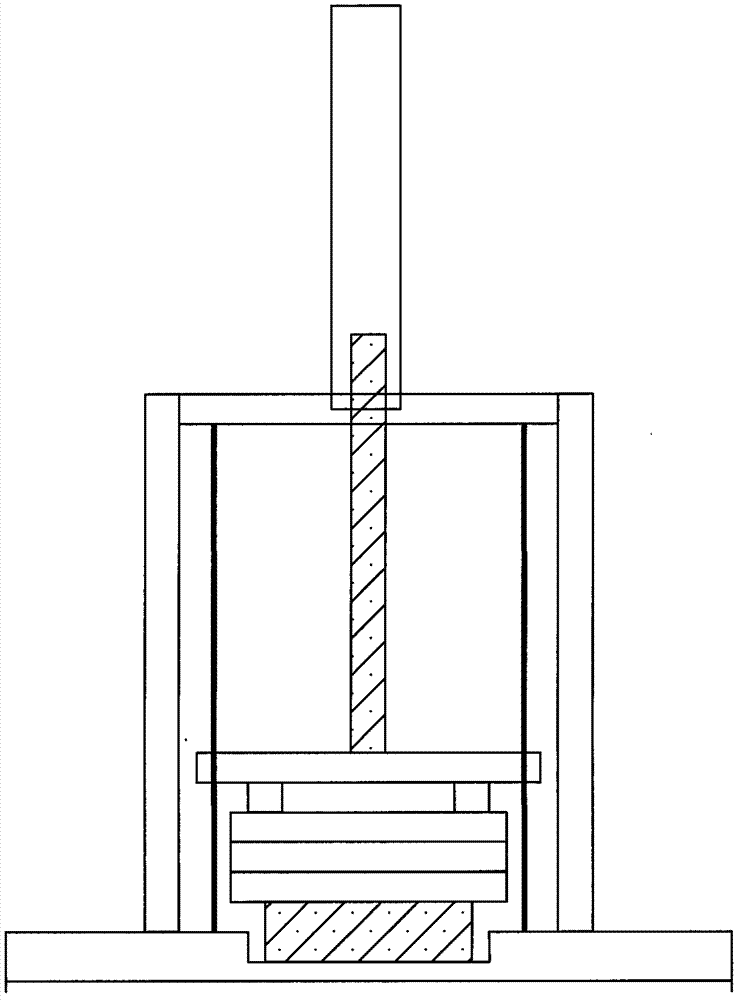

[0016] A steel sheet reinforcement mounting machine for flexible circuit boards in the manufacturing process, including a machine body 1, an operating chamber 2 is provided in the body, and a fixing groove 3 for placing a jig 4 is opened at the bottom of the operating chamber 2, The depth of this fixed groove 3 is less than the height of jig 4, is provided with cylinder 5 on the top of operating cavity 2, is provided with an upper mold template 6 directly above fixed groove 3, and its upper end is connected with cylinder 5 through connecting plate 7, and It can move up and down with the cylinder 5, and a control system for automatically adjusting pressure, temperature and time is also provided in the body 1, 100, wherein the control system 100 has a temperature controller 40, a time controller 30 and a pressure controller such as an air pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com