Automatic attaching machine for mobile phone auxiliary materials and operating method of automatic attaching machine

A technology for laminating accessories and laminating machines, applied in the directions of material gluing, mechanical equipment, connecting components, etc., can solve the problems of difficulty in debugging flatness, high flatness requirements, waste of space, etc., so as to achieve small occupied space and improve production. quality, improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

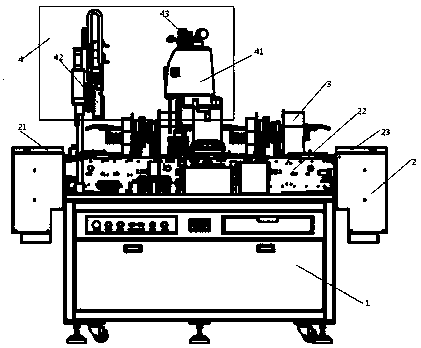

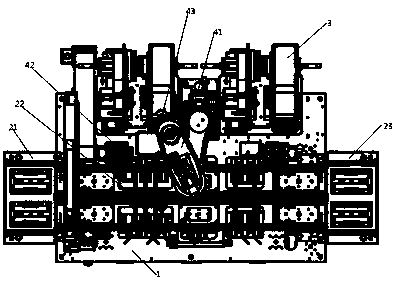

[0034] see Figure 1-Figure 2 , the embodiments of the present invention include:

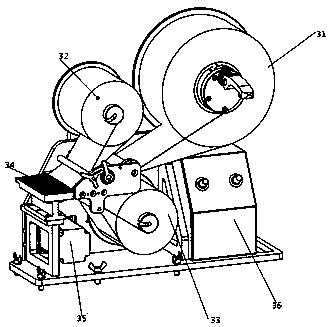

[0035] An automatic laminating machine for mobile phone accessories, comprising: a frame 1, a loading and unloading mechanism 2, an auxiliary material peeling mechanism 3 and an auxiliary material laminating mechanism 4;

[0036] The auxiliary material fitting mechanism 4 is fixedly installed in the middle of the surface of the rack 1, and is used to perform auxiliary material fitting processing on the product, and the auxiliary material fitting mechanism 4 includes an actuator 41, a suction mechanism 42 and a positioning mechanism that cooperate with each other....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com