Automatic feeding device for belt filling adhesive of tyre building machine

A tire building machine and automatic material feeding technology, which is applied in the field of machinery and molding, can solve the problems of high labor intensity, inability to complete the automatic separation of filling rubber semi-finished materials, lamination and fixed-length cutting, and unstable lamination accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

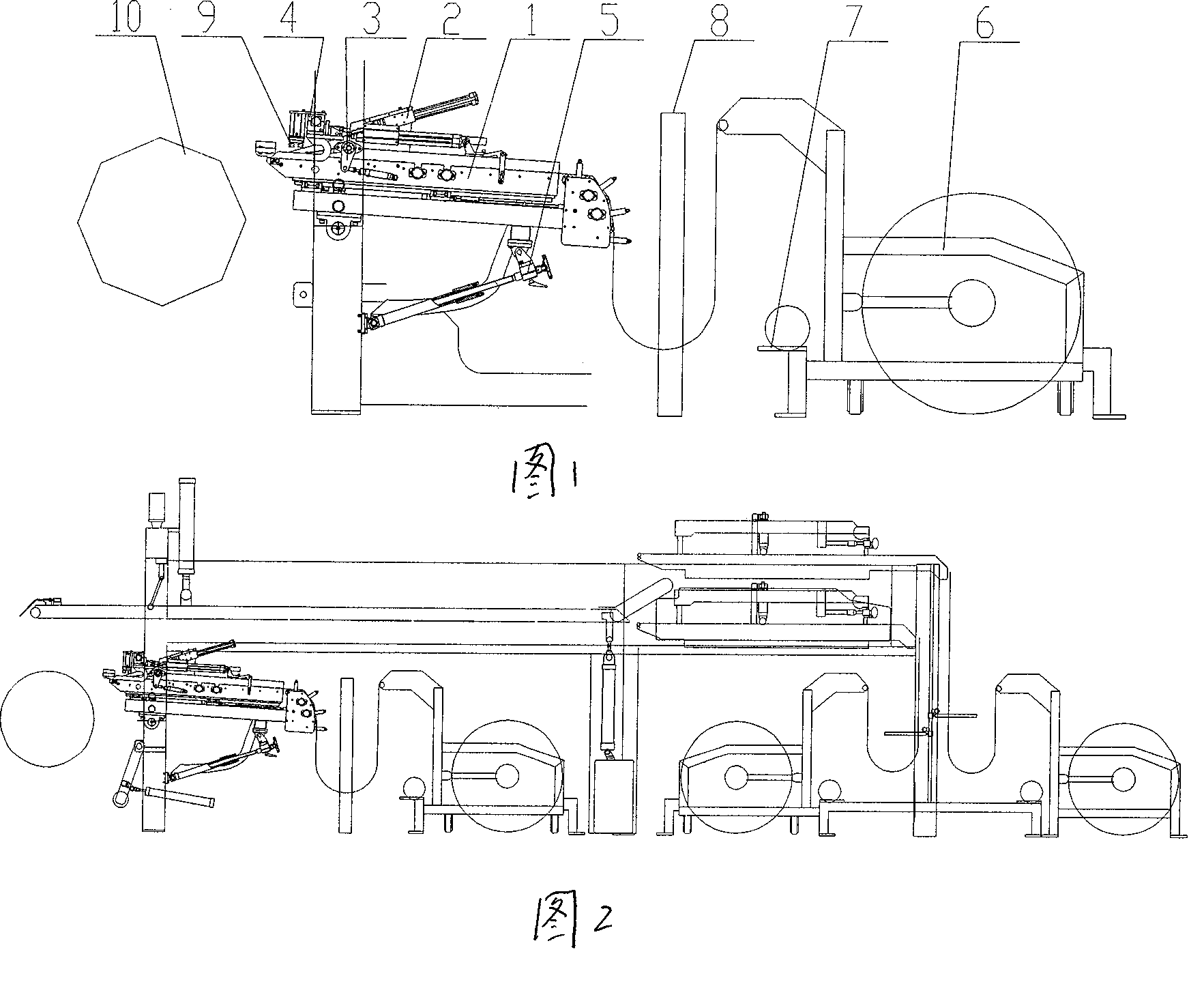

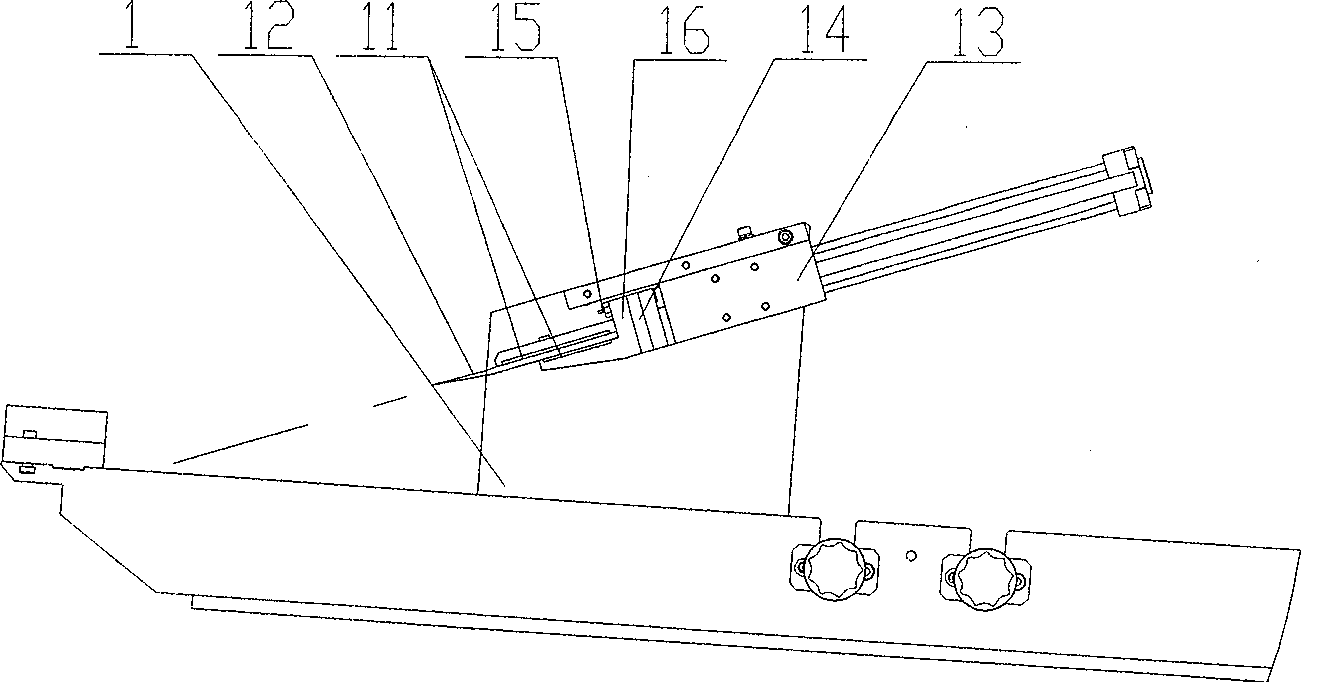

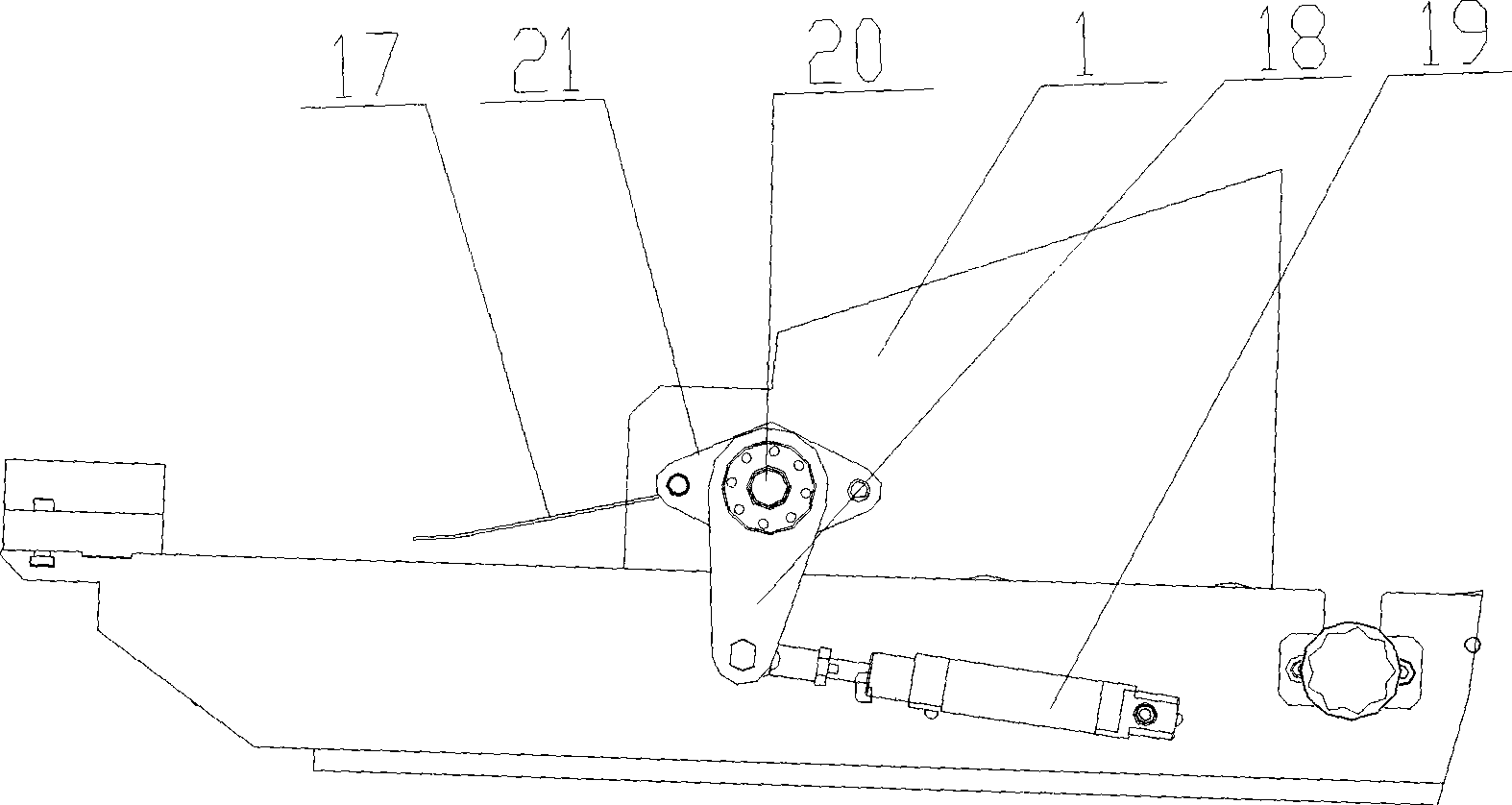

[0015] Referring to the accompanying drawings 1 to 5, the belt filling rubber automatic feeding device of this kind of tire building machine includes a conveying frame 1, an angle adjustment device 5 and a feeding device that is sequentially arranged at the rear end of the conveying frame 1 and feeds it. The trolley 6, the opening device 7 and the cloth storage mechanism 8 are characterized in that a hot knife cutting assembly 2 for cutting semi-finished materials is installed above the conveying frame 1, and it is composed of a knife body 12, a knife seat 16, and a heating plate 11. , a heat shield 14, a thermistor 15 for temperature control, and a guide rod cylinder 13. The hot knife cutting assembly 2 is installed at an angle of 20 degrees to the conveying frame 1. The rear end is a guide rod cylinder 13, and the front end is a knife. The body 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com