Horizontal mould parting static pressure molding machine and static pressure molding machine set capable of achieving automatic mould assembly

A technology of horizontal parting and molding machines, which is applied in the direction of molding machines, manufacturing tools, casting molding equipment, etc., which can solve the problems of unboxing and sand box flipping without manipulators, etc., and achieve the effect of continuous production of sand molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

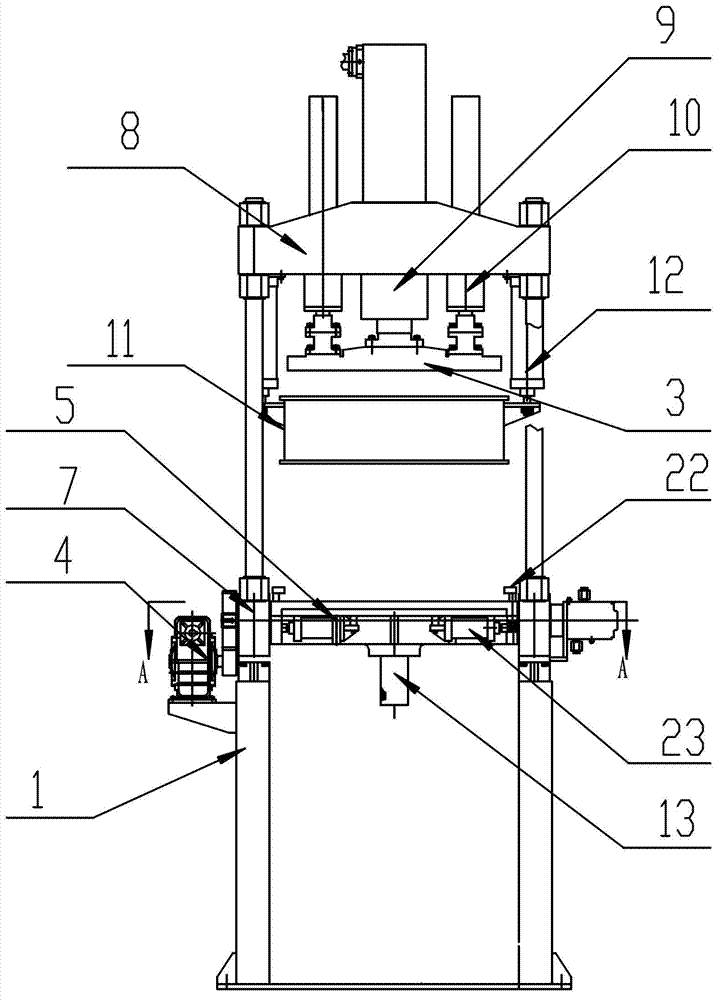

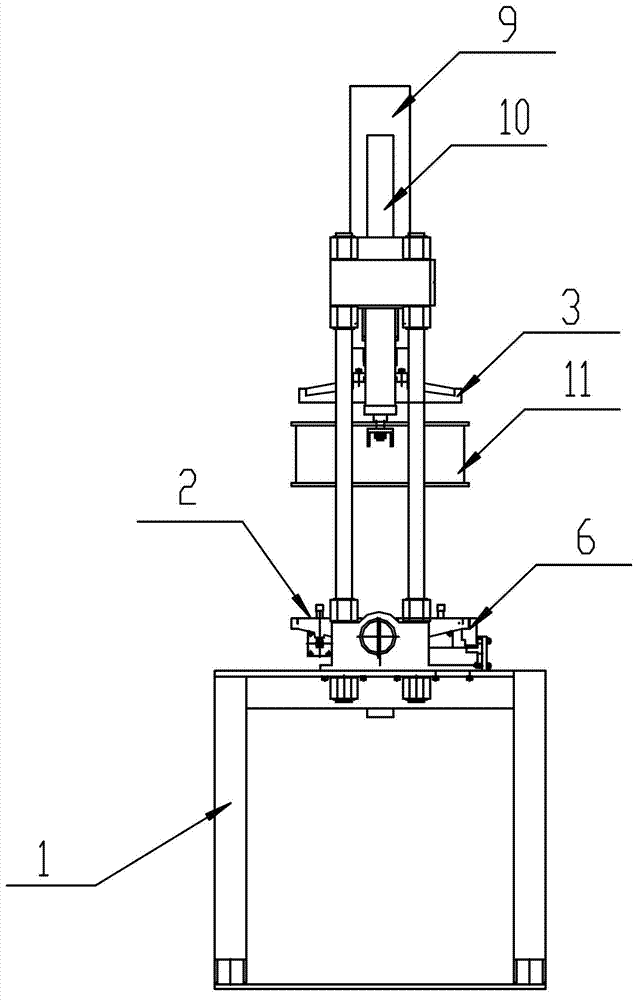

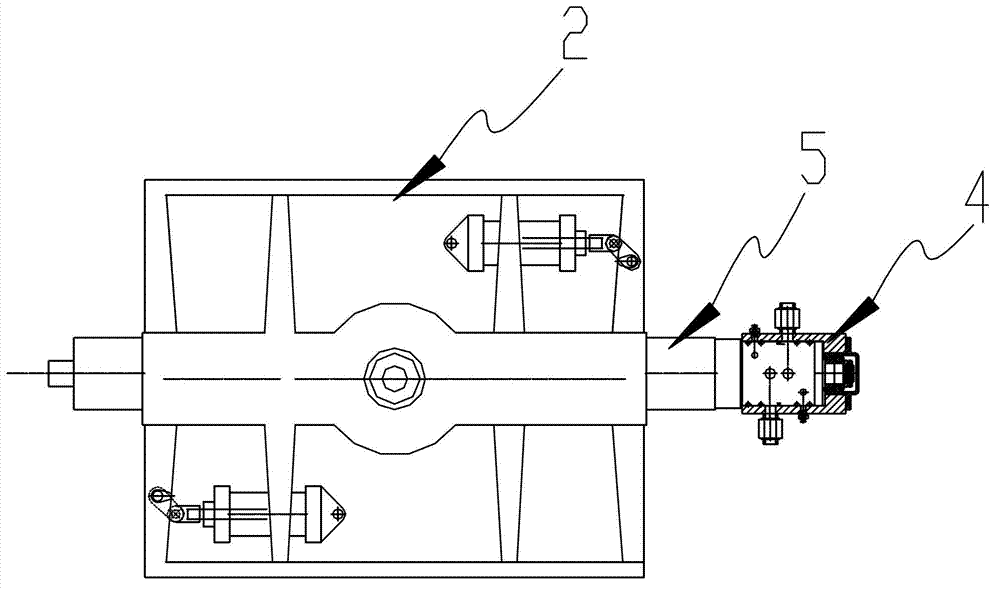

[0037] see figure 1 , figure 2 and image 3 , a horizontal type static pressure molding machine, comprising a frame 1, a horizontal workbench 2 arranged at the middle and lower part of the frame, an upper movable platen 3 arranged at the upper part of the frame and capable of moving up and down, and a Deputy sand box 11. The above-mentioned horizontal workbench is provided with a workbench turning mechanism that can drive it to turn back and forth 180°, and the workbench turning mechanism includes a workbench turning drive device 4, a workbench spindle 5 and a workbench positioning block 6. The horizontal workbench is hinged on the main shaft block 7 fixed on the corresponding position of the frame by the workbench main shaft, and the axis line of the workbench main shaft deviates slightly from the central axis of the horizontal workbench, such as deviating from a few millimeters. The above-mentioned workbench turning drive device can have multiple design methods, such as: S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com