Non-stick wheel modified emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and non-stick wheels, which is applied in the field of industrial chemicals, can solve problems such as the failure of the sticky layer, achieve a good degree of polymerization, avoid sticking wheels, and improve road performance and construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

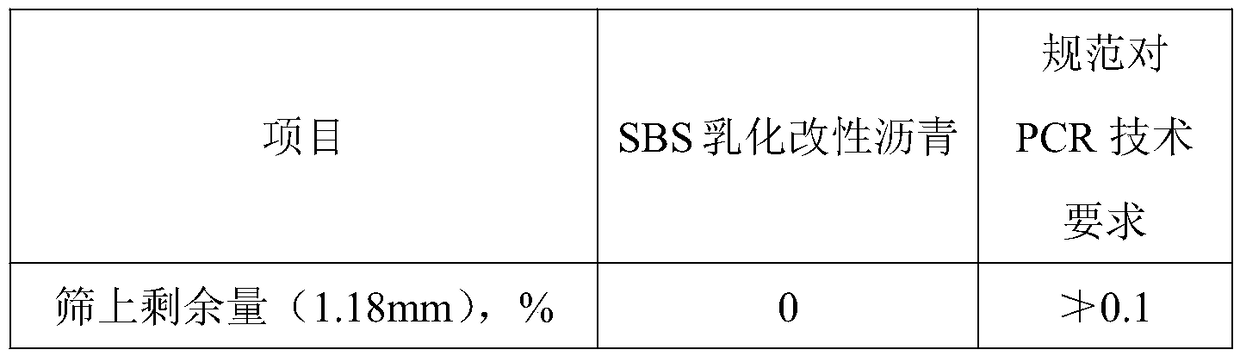

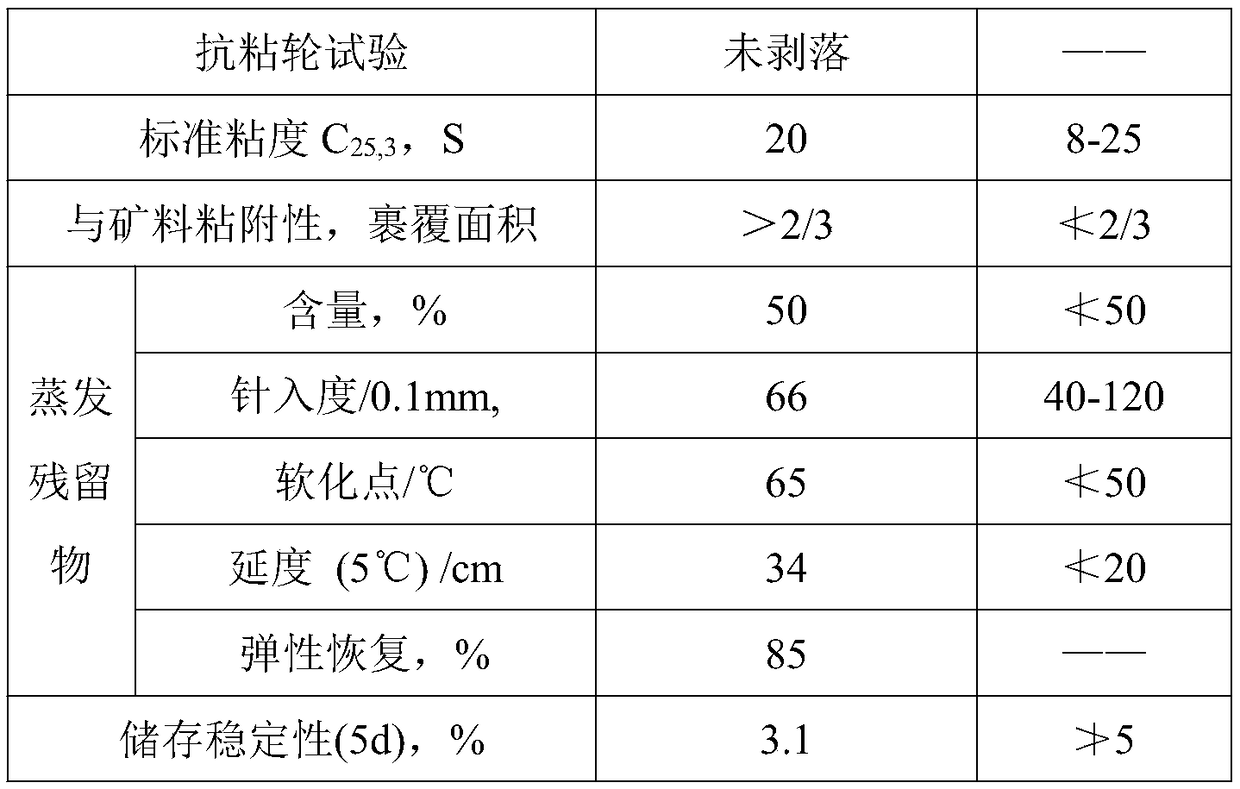

[0035] A non-stick wheel SBS modified emulsified asphalt,

[0036] 100 parts of asphalt, 1.5 parts of furfural oil, 3.8 parts of SBS polymer modifier, 0.3 parts of fast-cracking and fast-setting emulsifier, 0.1 part of emulsified asphalt stabilizer, 100 parts of water, highly cross-linked silicone resin 3 copies.

[0037] Asphalt: 70A road petroleum asphalt produced by China Shipping Asphalt Co., Ltd.;

[0038] Furfural extraction oil: four-line furfural extraction oil produced by Maoming Haoda Petrochemical Co., Ltd.;

[0039] Polymer modifier: 3501SBS produced by Taiwan Li Changrong Chemical Industry Co., Ltd.;

[0040] Fast-cracking emulsifier: DF-62E emulsifier produced by Shanghai Longfu Material Technology Co., Ltd.;

[0041] Emulsified asphalt stabilizer: JY-WD2 emulsified asphalt stabilizer produced by Jiangsu Jinyang New Material Technology Co., Ltd.;

[0042] Silicone resin: SH-9501 type silicone resin produced by Shenzhen Jipeng Silicon Fluorine Materials Co., L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com