Patents

Literature

100results about How to "Improve polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

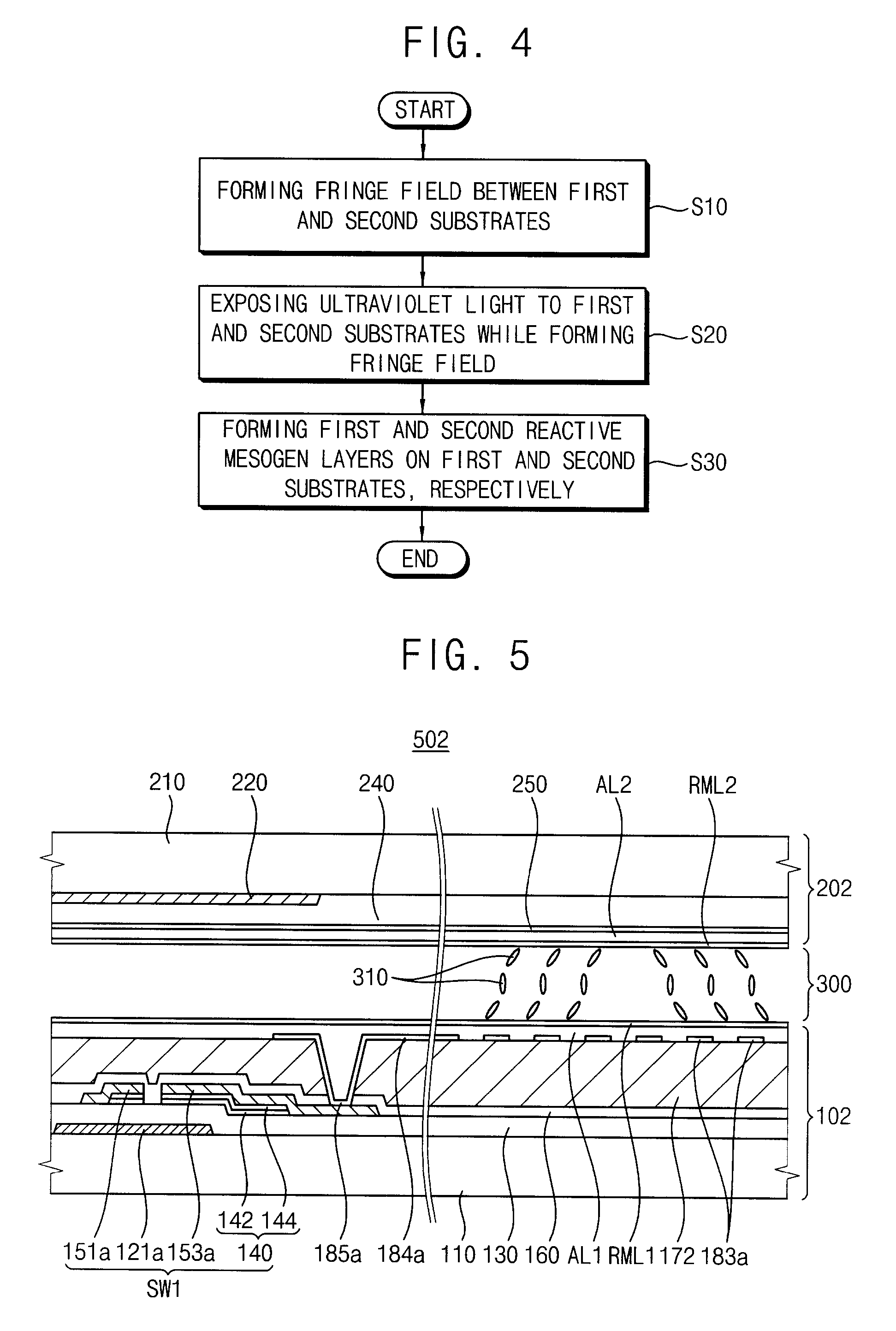

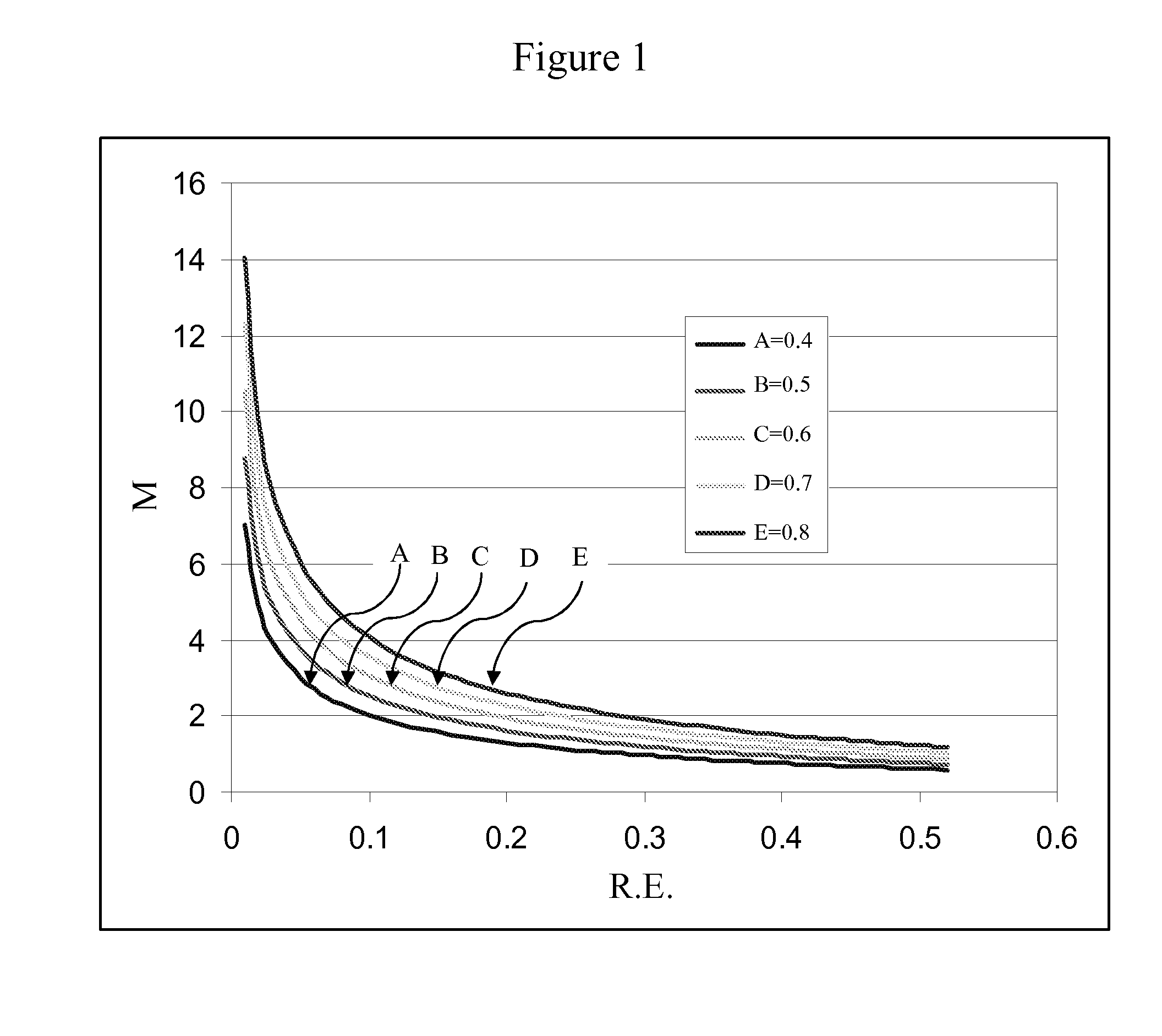

High melting thermoplastic elastomeric alpha-olefin polymers (PRE/EPE effect) and catalysts therefor

InactiveUS6559262B1Activity of fluxional unbridged metallocene polymerization catalystsHigh molecular weightGroup 4/14 element organic compoundsMetallocenesElastomerEthylene Homopolymers

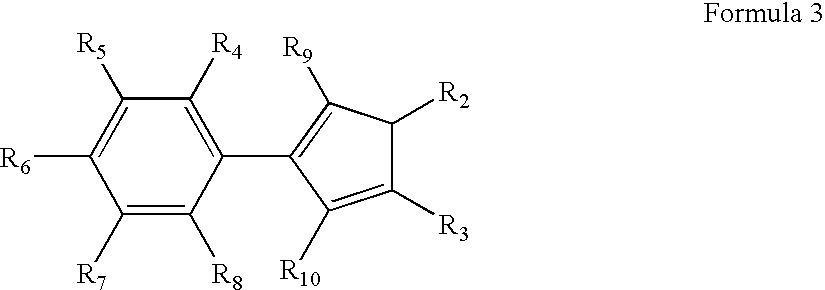

This invention relates generally to low ethylene insertions into I-olefin polymers and processes for production of such polymers using unbridged fluxional metallocenes, primarily substituted aryl indenyl metallocenes, and more particularly to use of unbridged, fluxional, cyclopentadienyl or indenyl metallocene catalyst systems in methods of production of high melting point I-olefin homo- and co-polymers, particularly elastomeric crystalline and amorphous block homo- and co-polymers of I-olefins. The activity of fluxional unbridged metallocene polymerization catalysts containing at least one 2-arylindene ligand is increased 10x or more by the addition of small (typically 0.1-10 wt. %) amounts of ethylene to the polymerization system, which increase is termed the Polymerization Rate-Enhancement effect (PRE), which is measured in terms of an Ethylene Enhancement Factor (EEF) as a dimensionless ratio in the range of from about 1.1 to about 10 or above. The amount of ethylene included in the reaction system can be selected and controlled to be so small as to result in essentially minimal (<2 mole %) incorporation of ethylene units into the resulting elastomeric polymer and the molecular weight may be increased. Amounts of ethylene to generate the PRE effect may be greater than 0.1 wt. % and preferably range up to about 2 wt. %. However, if a polymer with more ethylene is desired, additional ethylene may be incorporated into the polymerization feed, including up to 10 to about 50 mole % based on olefin units. A second important aspect of this invention is the ability to use a PRE activity-enhancing amount of ethylene in an olefin polymerization without substantially affecting the physical properties of the elastomer. In a third important aspect of this invention, I-olefin elastomers are produced through incorporation of ethylene using unbridged fluxional catalyst systems which may not otherwise produce acceptable elastomeric homopolymers. This effect is termed the EPE effect, for Elastomeric Property-Enhancing effect. The EPE amount of ethylene required to produce such elastomers typically overlaps the PRE activity-enhancing amount. Incorporation of up to about 5 mole % or more of ethylene typically will produce an elastomeric polymer using such catalyst systems. Typical useful amounts of incorporated ethylene include about 1 to 3 mole %. Preferred polymers of this invention retain sufficient crystallinity to provide a high melting point (by DSC) of about 80° C., preferably above 100° C., including in the range of from about 120° C. to about 140° C. and above. Novel flexible alpha-olefin homo and copolymers having elongation in excess of 600% and substantially no retained force are disclosed.

Owner:BP CORP NORTH AMERICA INC

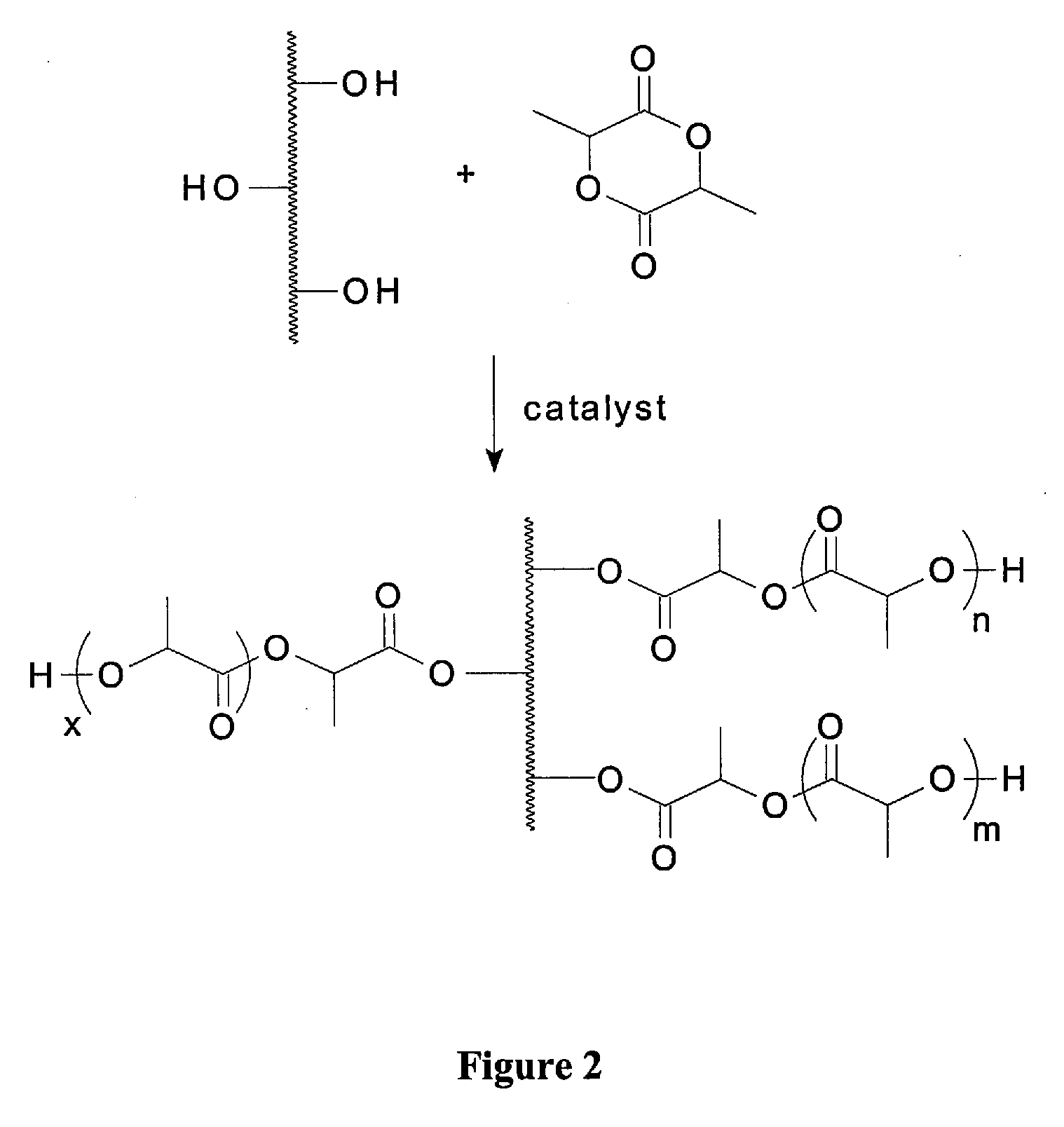

High modulus polymer composites and methods of making the same

InactiveUS20060235113A1Improve polymerizationIncrease ratingsThin material handlingPolymer compositesHigh molecular weight polymer

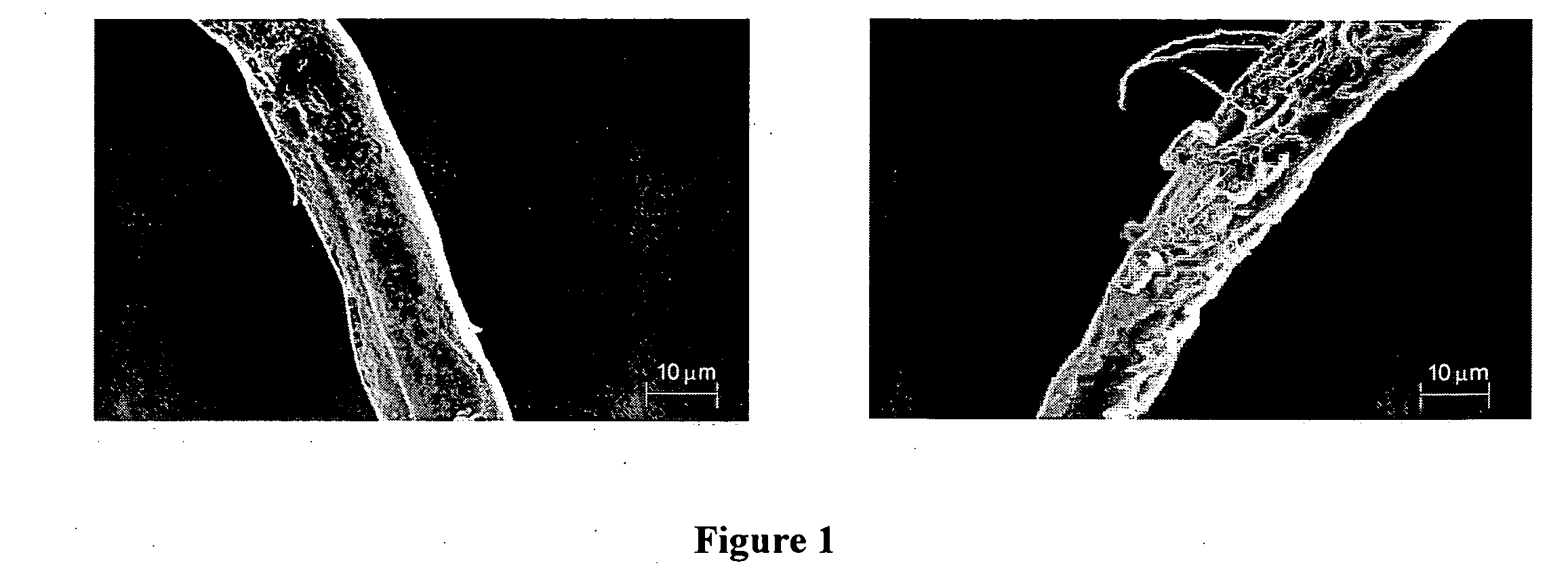

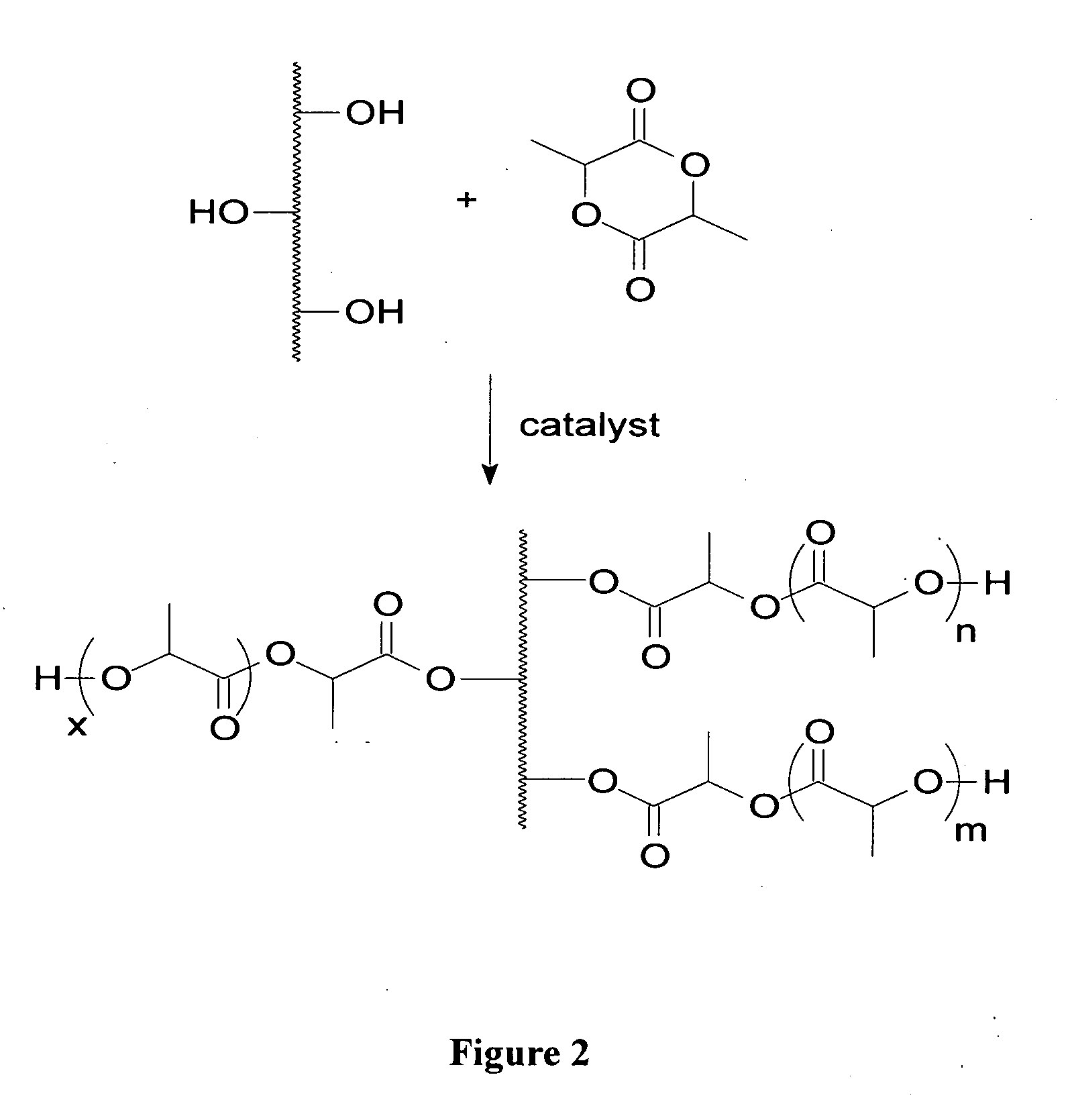

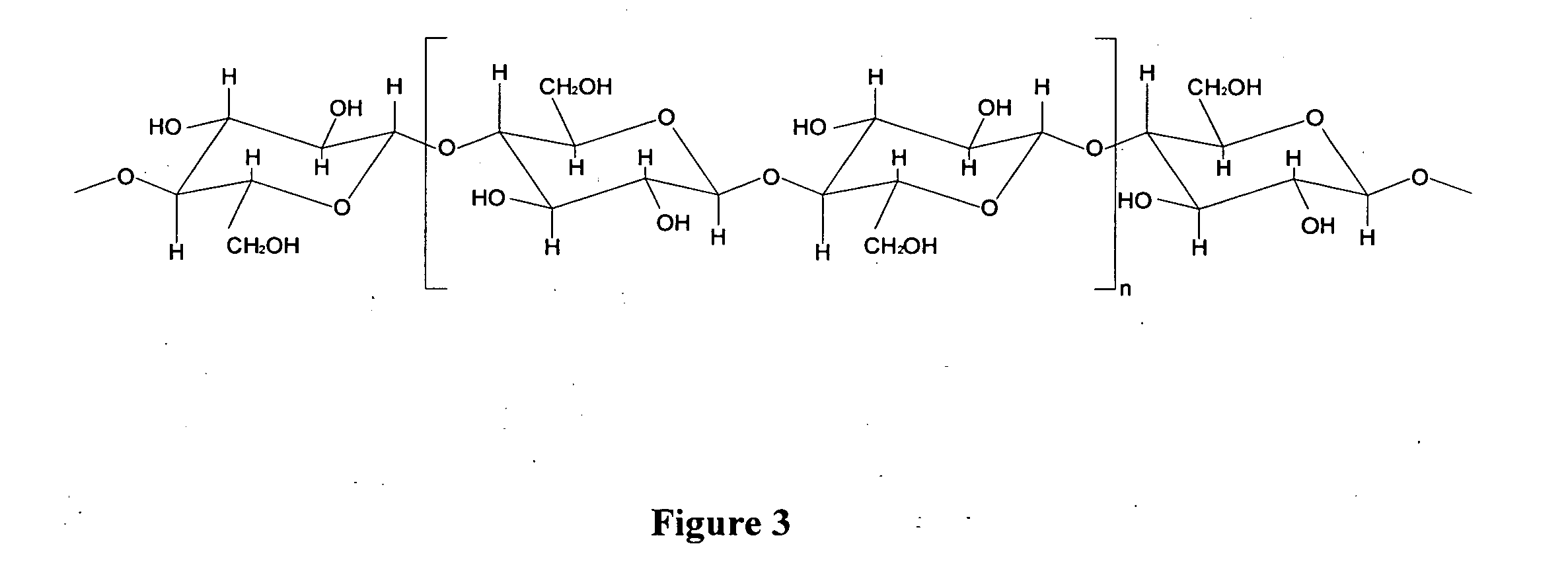

The invention provides methods of producing composite polymers by combining fillers with polymers in the presence of preformed high molecular weight polymer. Monomer polymerization can be initiated through the addition of initiators or by reactive chemical groups on the surface of the fibers. The composite materials formed possess superior mechanical properties compared to similar polymer composites made by either purely mechanical mixing or solely polymerization of monomers in the presence of the fillers.

Owner:COLORADO SCHOOL OF MINES

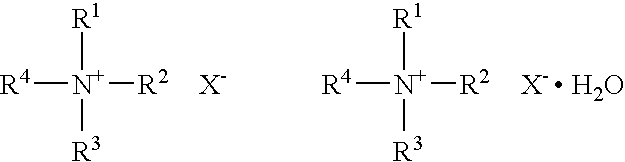

Adhesive applicators with improved polymerization initiators

InactiveUS20050147457A1Improved polymerization initiator and rate modifierImprove polymerizationLiquid surface applicatorsSurgical adhesivesPhase-transfer catalystChemistry

An article of manufacture for dispensing a liquid adhesive includes an applicator body, a liquid adhesive contained within the applicator body, a porous applicator tip attached to the applicator body and in a non-contacting relationship with the liquid adhesive, and a polymerization initiator or rate modifier loaded in or on the applicator tip, wherein the polymerization initiator or rate modifier is selected from quaternary ammonium salts and tertiary amines. The liquid adhesive can also include a phase transfer catalyst.

Owner:CLOSURE MEDICAL

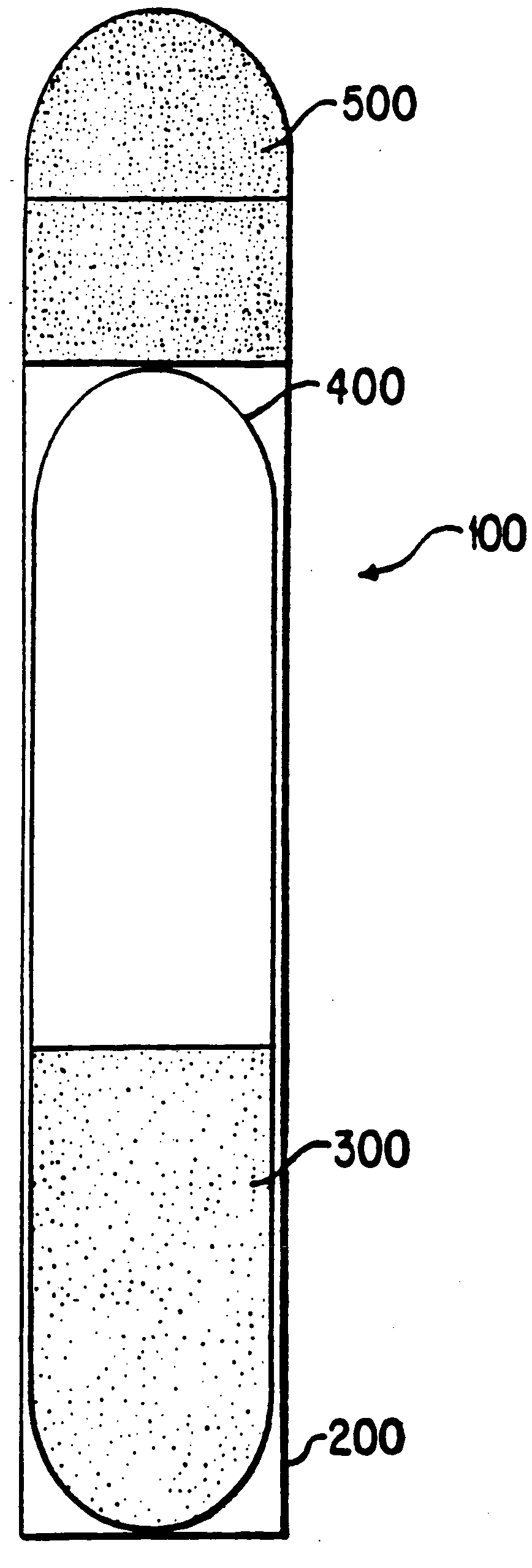

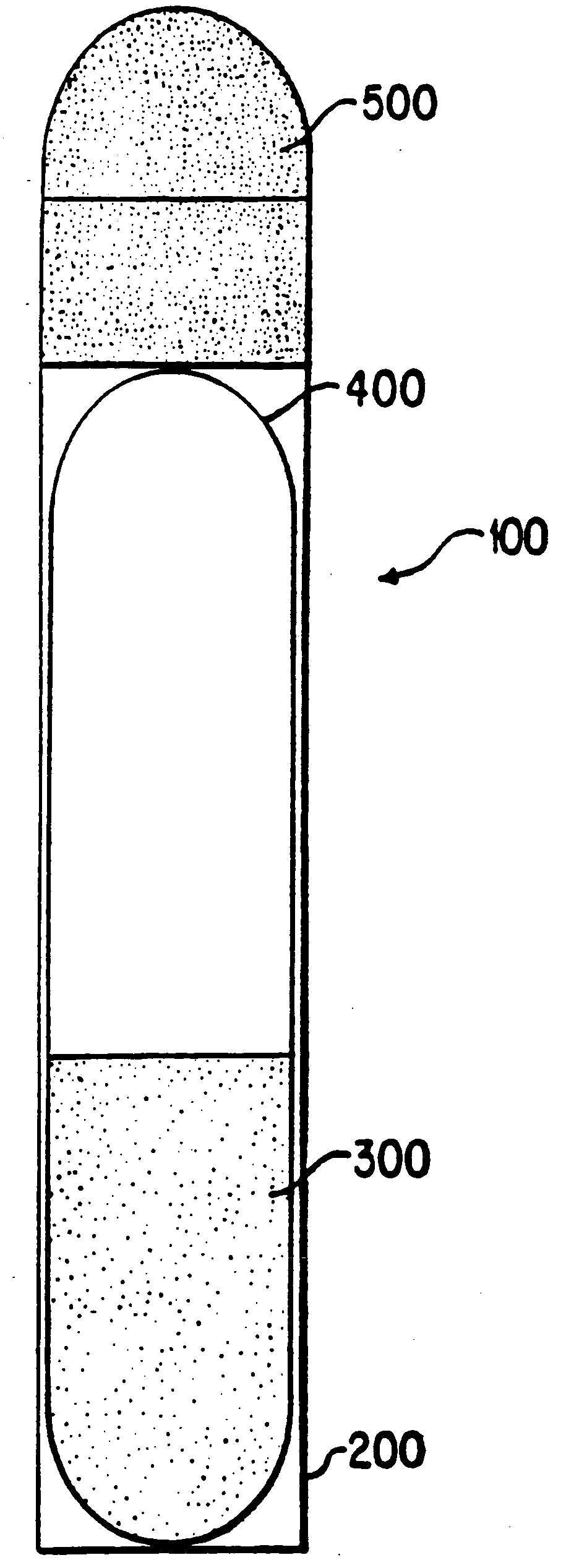

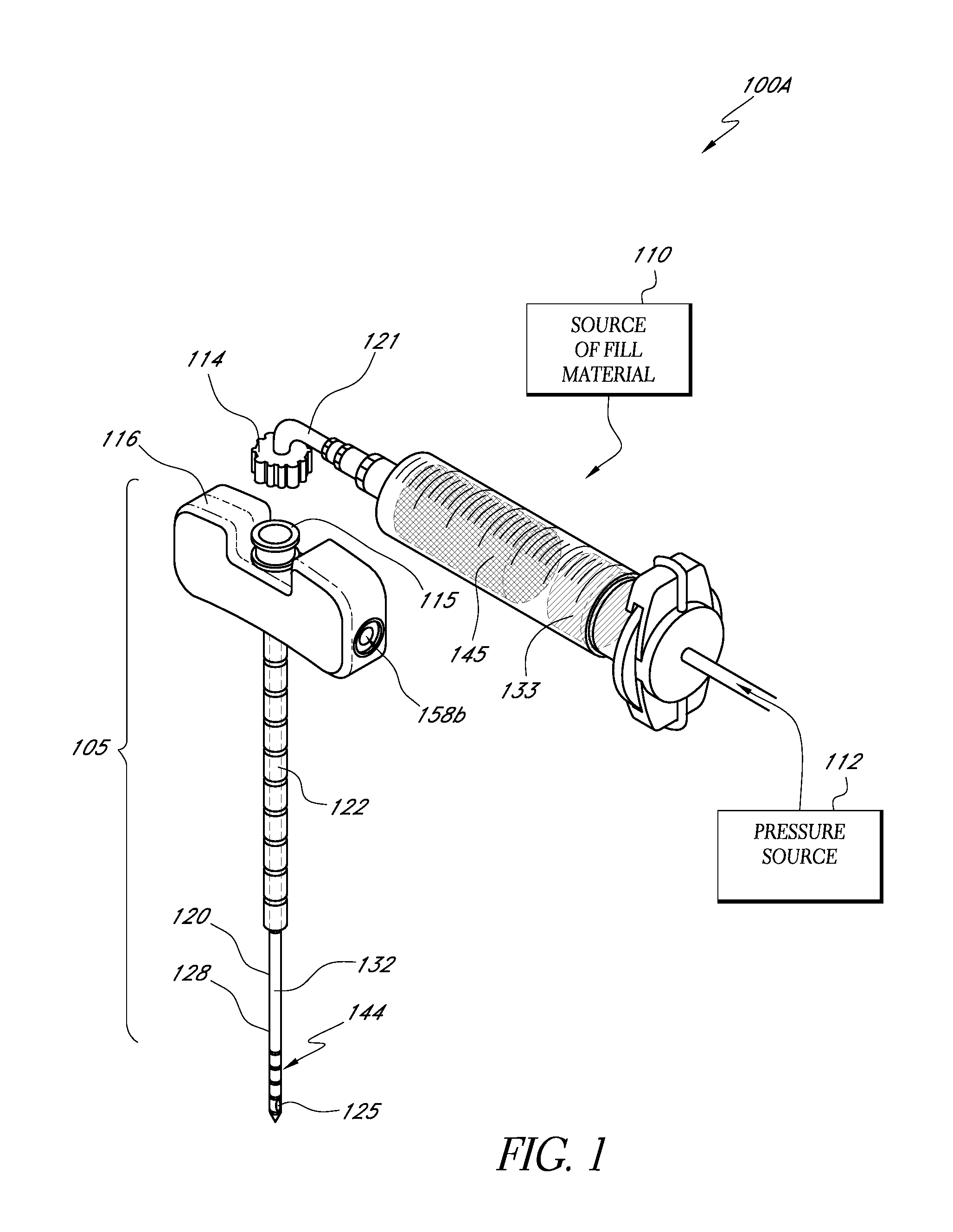

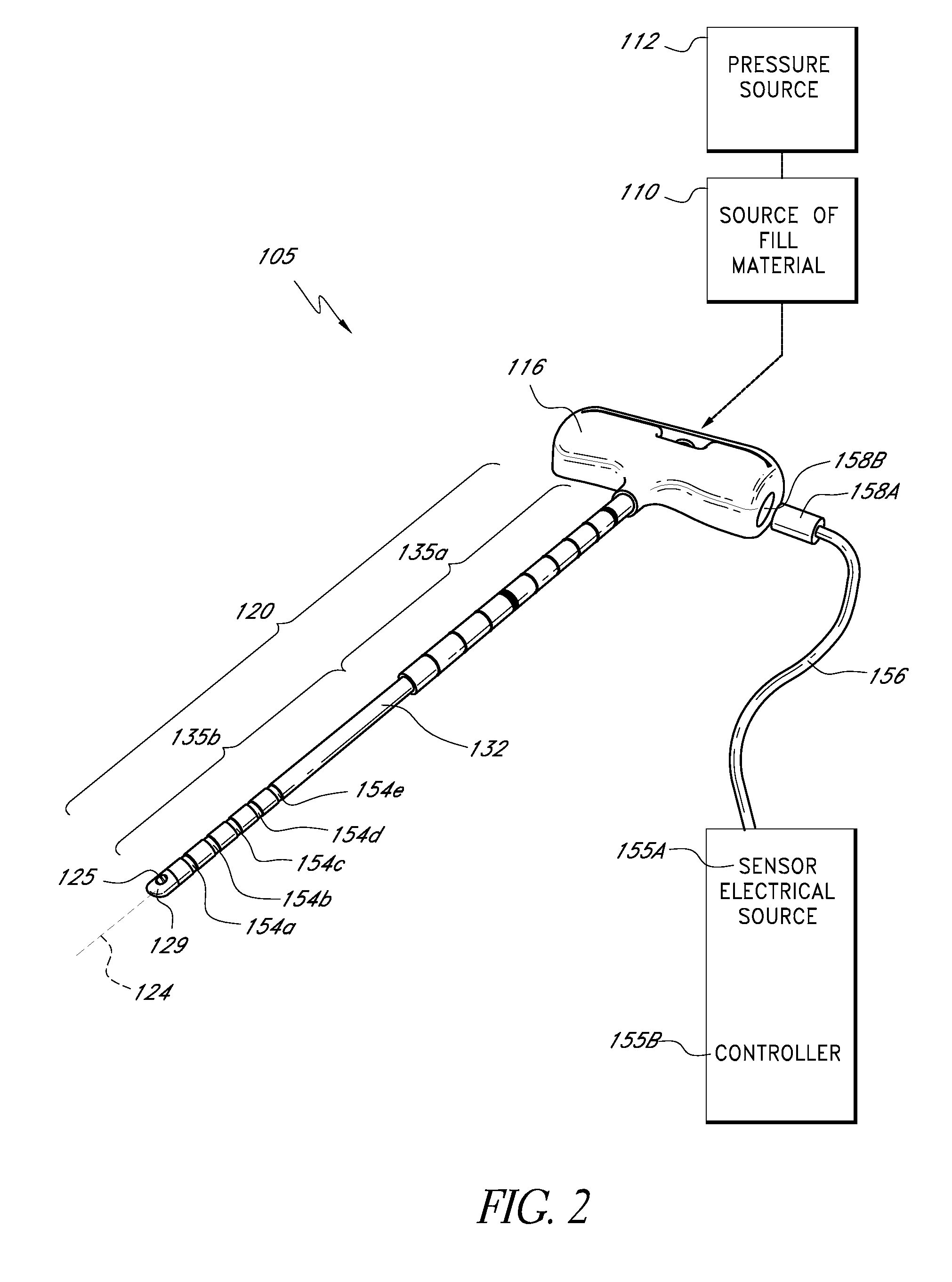

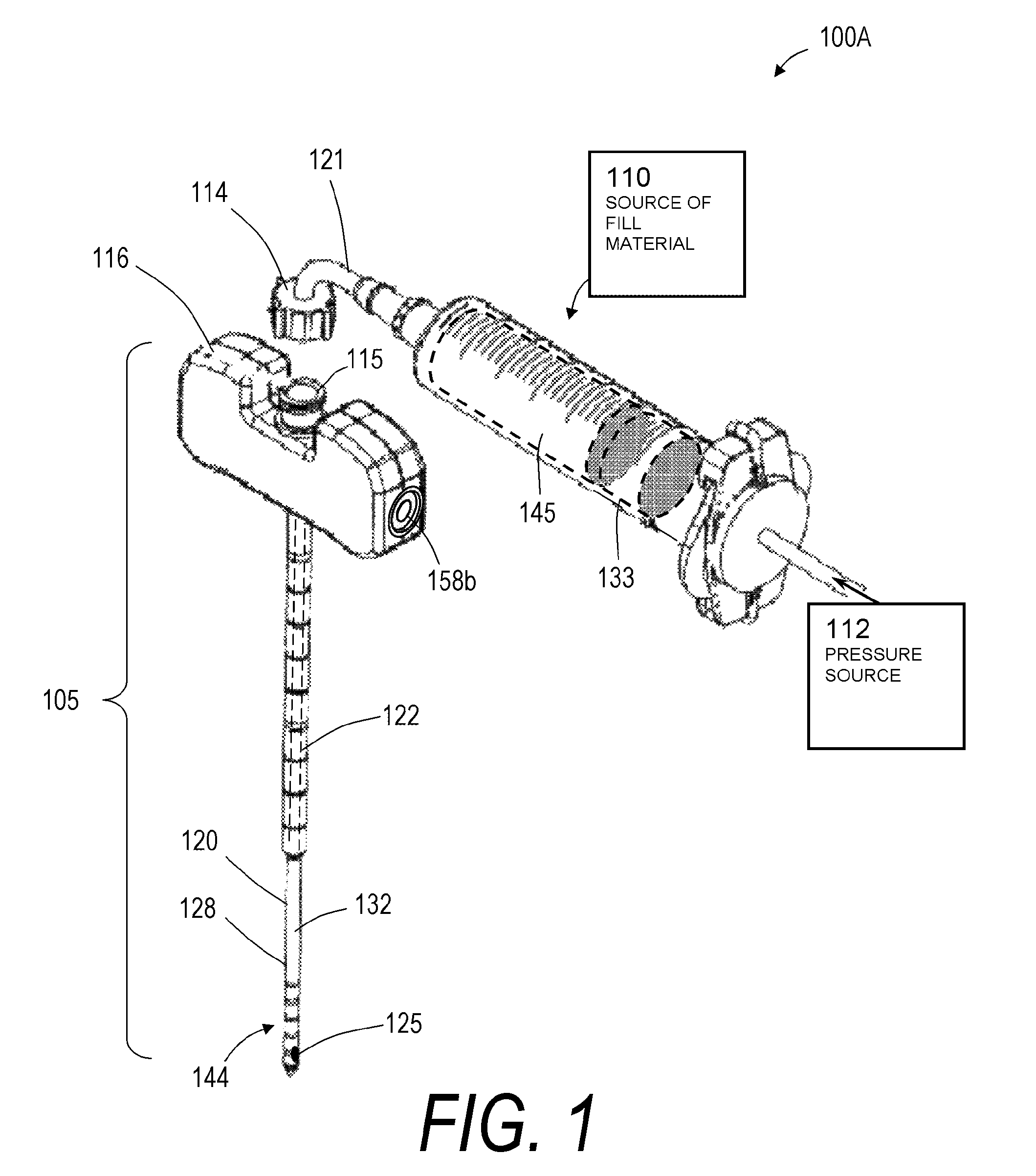

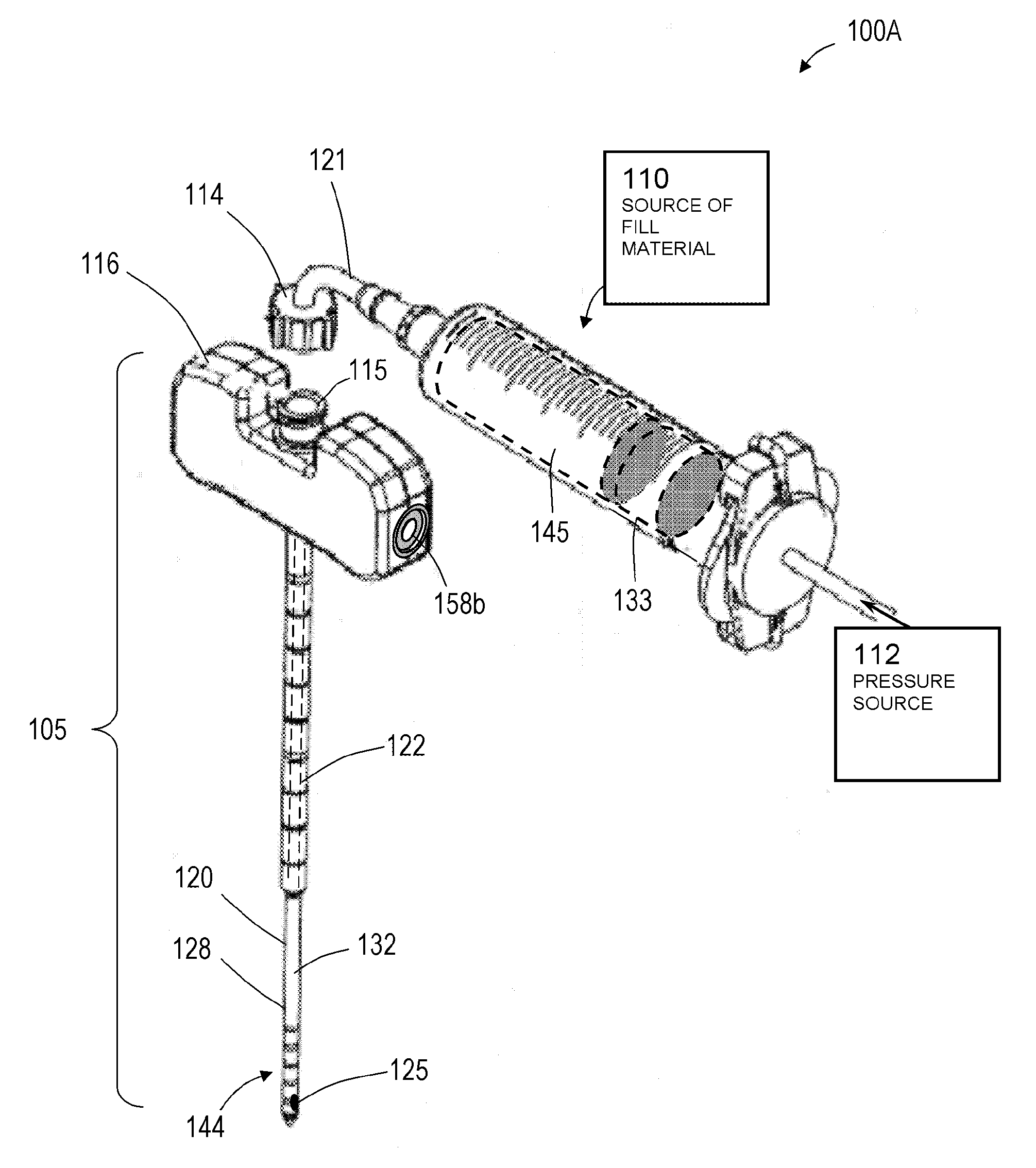

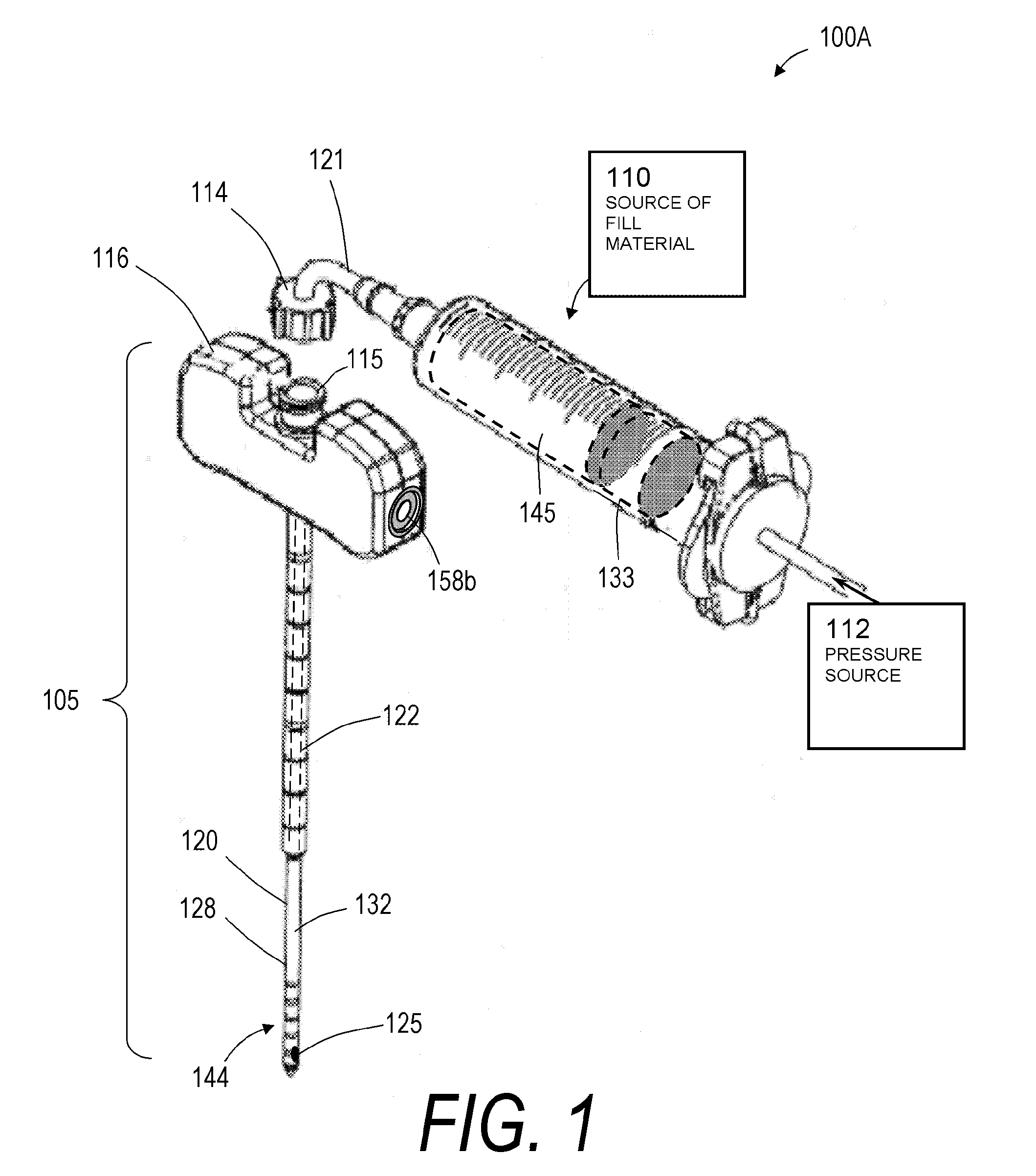

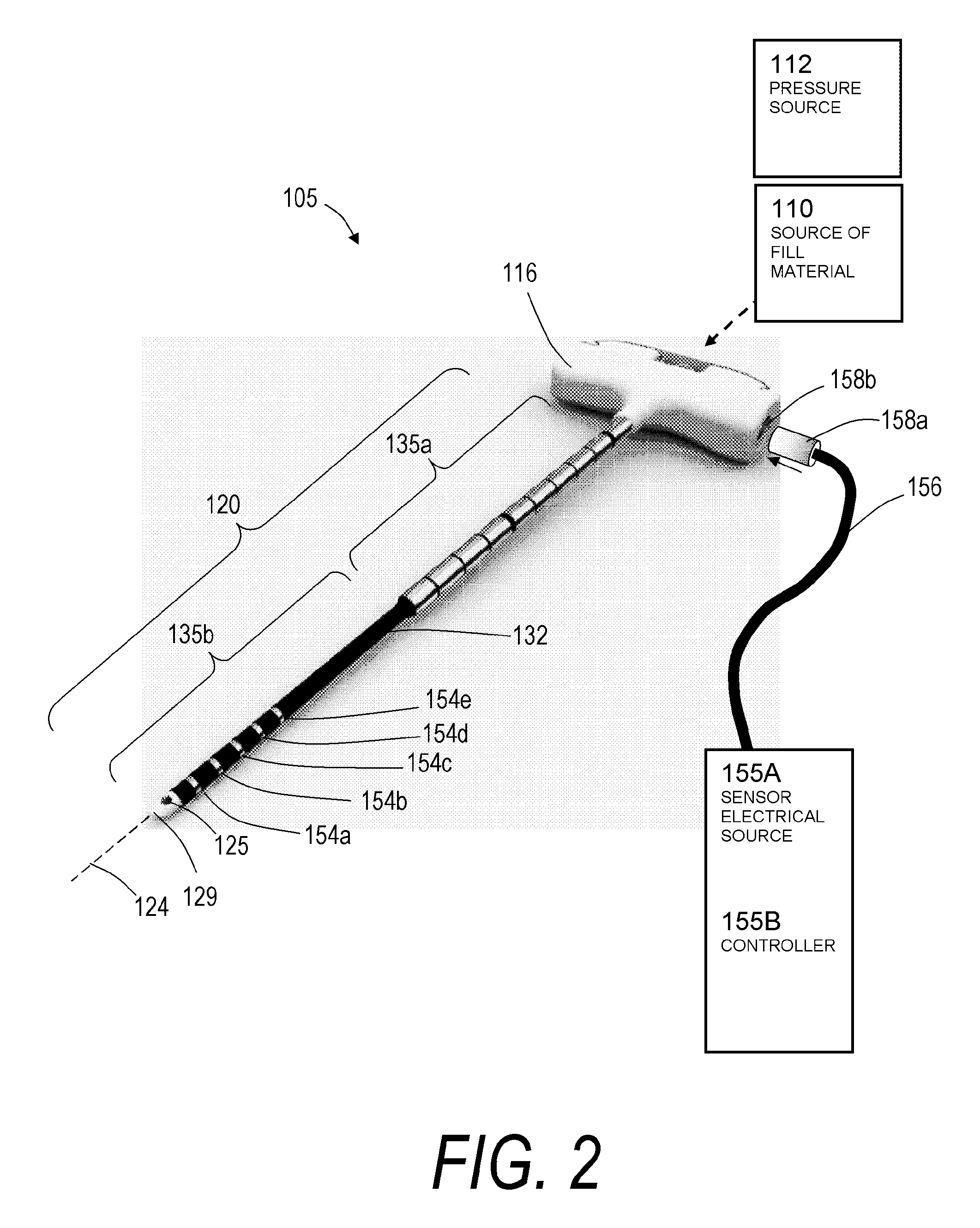

Bone treatment systems and methods

InactiveUS20090149878A1High viscosityInhibit migrationSurgical needlesProsthesisThermal energyFilling materials

The present invention relates in certain embodiments to systems for treating vertebral compression fractures. In one embodiment, a trocar with a flexible tip is provided to create a curved path in cancellous bone. An injector can be introduced into the vertebra in communication with the curved path for delivery of bone fill material into the curved path. Optionally, thermal energy can be applied to the bone fill material prior to injection into the curved path in cancellous bone to alter a property (e.g., viscosity) of the bone fill material.

Owner:DFINE INC

Electrolyte for lithium ion secondary battery and lithium ion secondary battery comprising the same

InactiveUS20140356734A1Avoid reactionImprove polymerizationCell electrodesOrganic electrolyte cellsLithiumOrganic solvent

An electrolyte for a lithium ion secondary battery and a lithium ion secondary battery including the same are provide. The electrolyte includes a non-aqueous organic solvent, a lithium salt which is dissolved in the non-aqueous solvent and a additive shown as general formula I. Wherein R1, R2 and R3 are each independently selected from H, alkyl group including from 1 to 12 carbon atoms, cycloalkyl group including from 3 to 8 carbon atoms and aromatic group including 6 to 12 carbon atoms; n represents an integer from 0 to 7. This additive in electrolyte can passivate cathode and anode effectively, restrain their reaction with electrolyte, reduce gases generation and battery's expansion in high temperature surrounding, provide as safety lithium ion secondary batteries.

Owner:NINGDE AMPEREX TECH

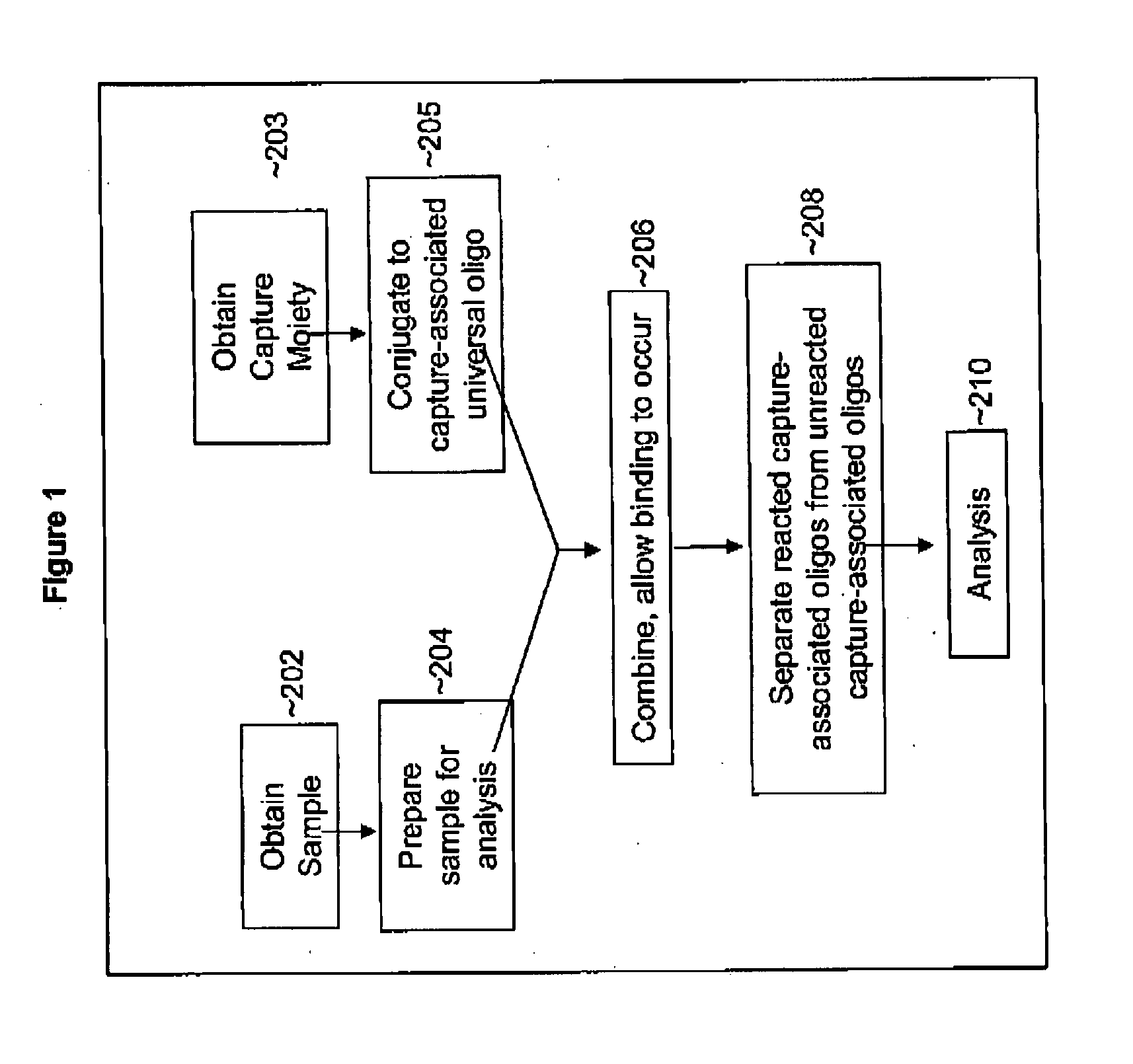

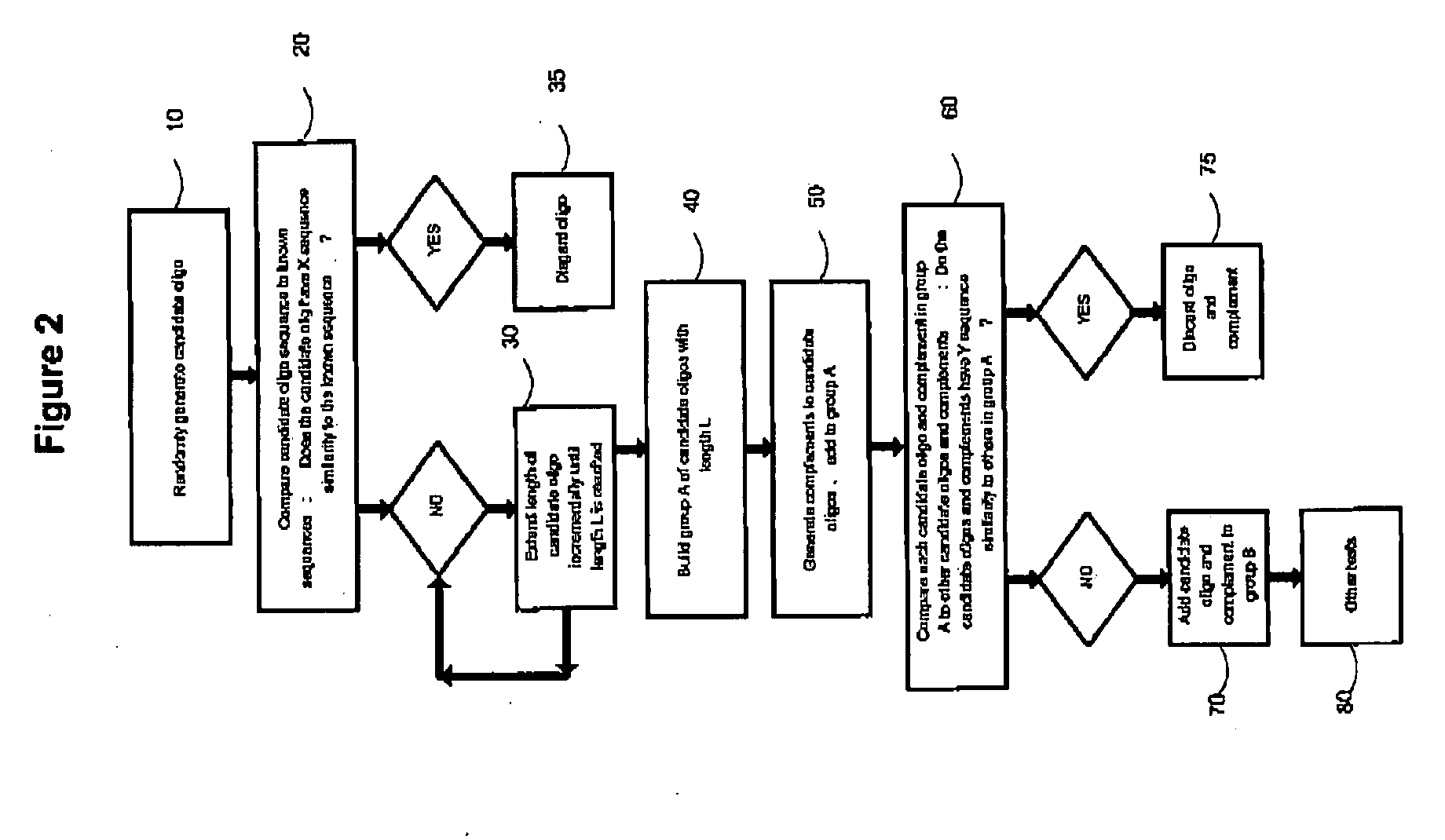

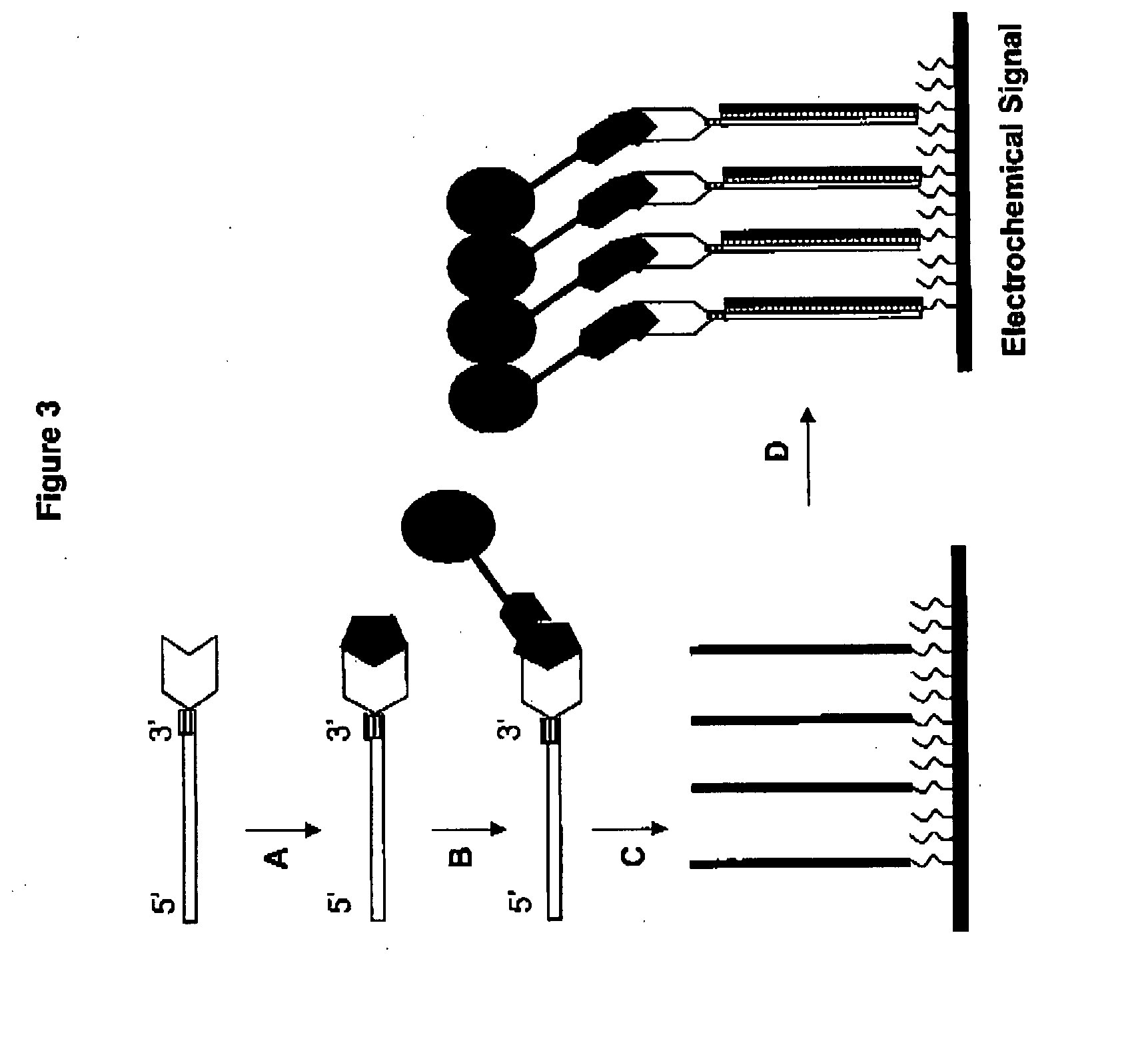

Methods of detecting one or more cancer markers

InactiveUS20080026394A1High selectivityHigh sensitivityMicrobiological testing/measurementSpecific detectionBiology

The present invention provides a methods and compositions for early diagnosis of cancer by rapid and specific detection of one or more cancer markers in a sample.

Owner:ANTARA BIOSCI

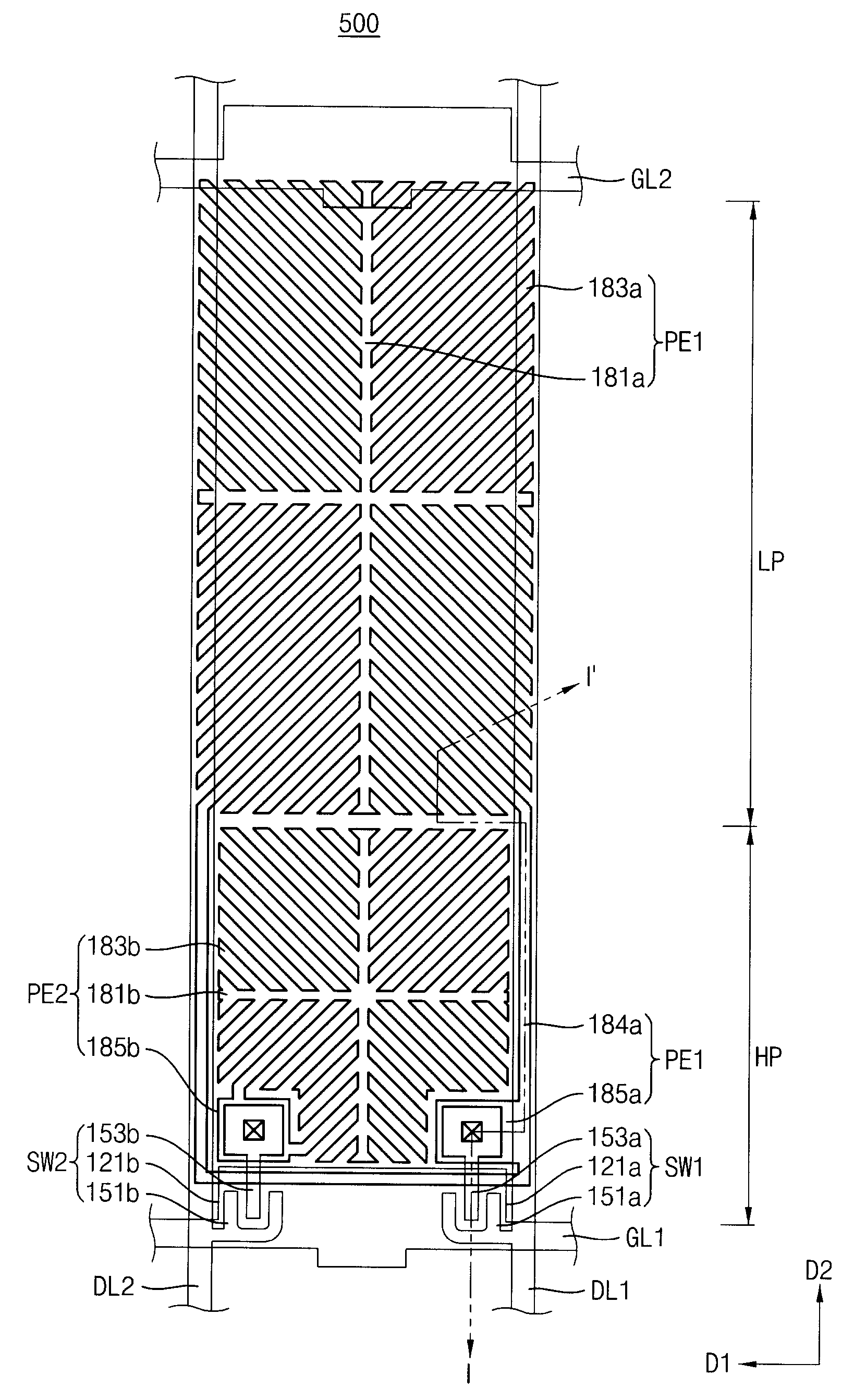

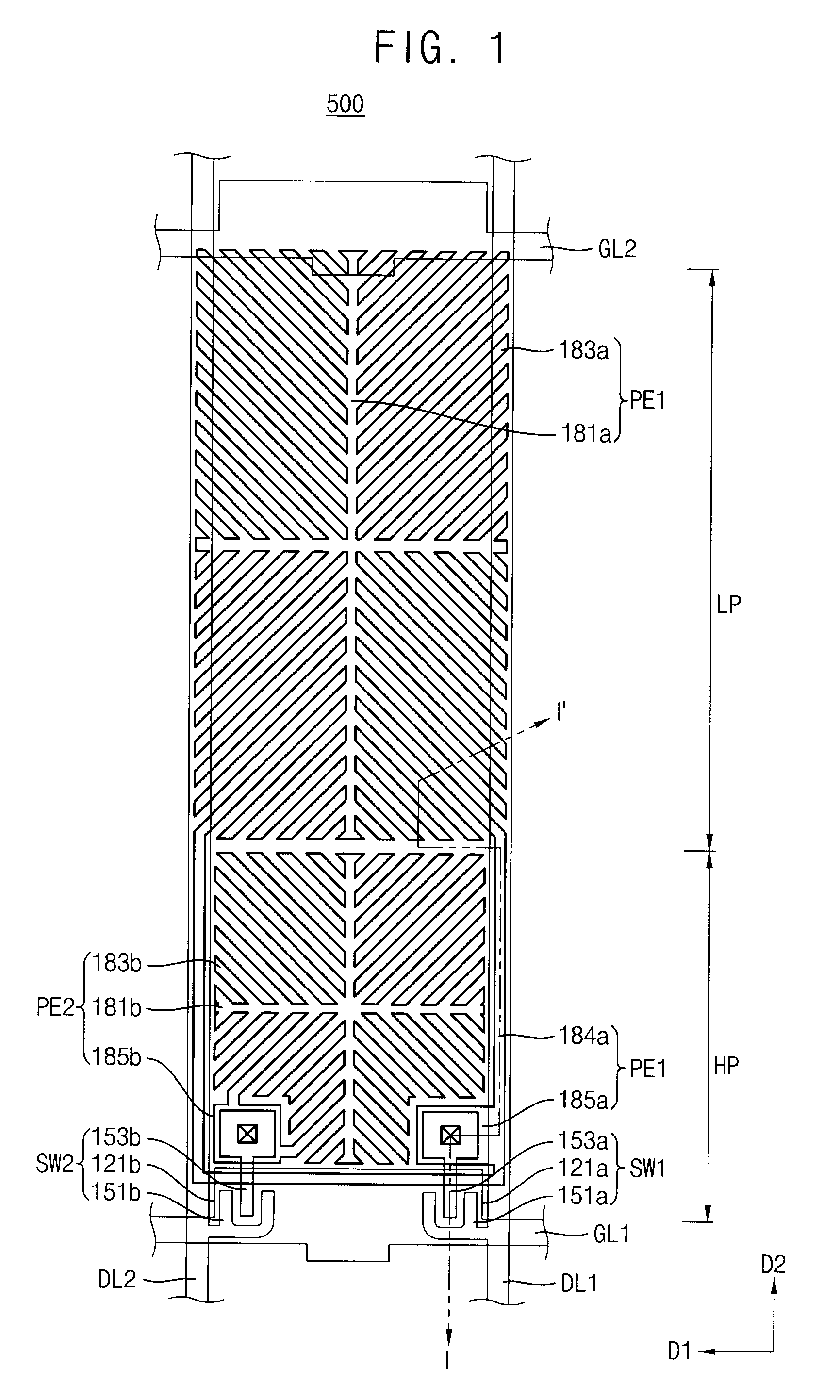

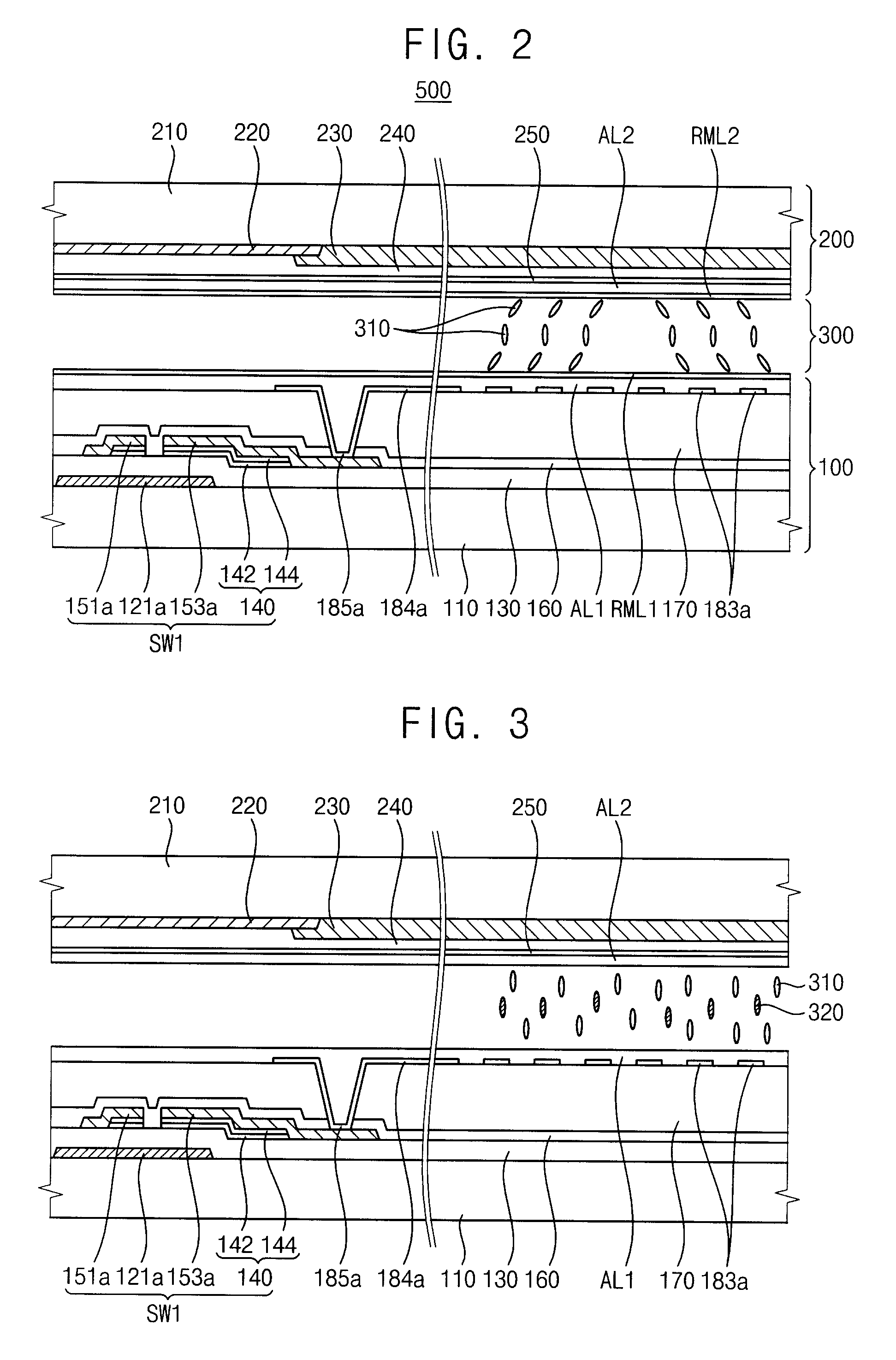

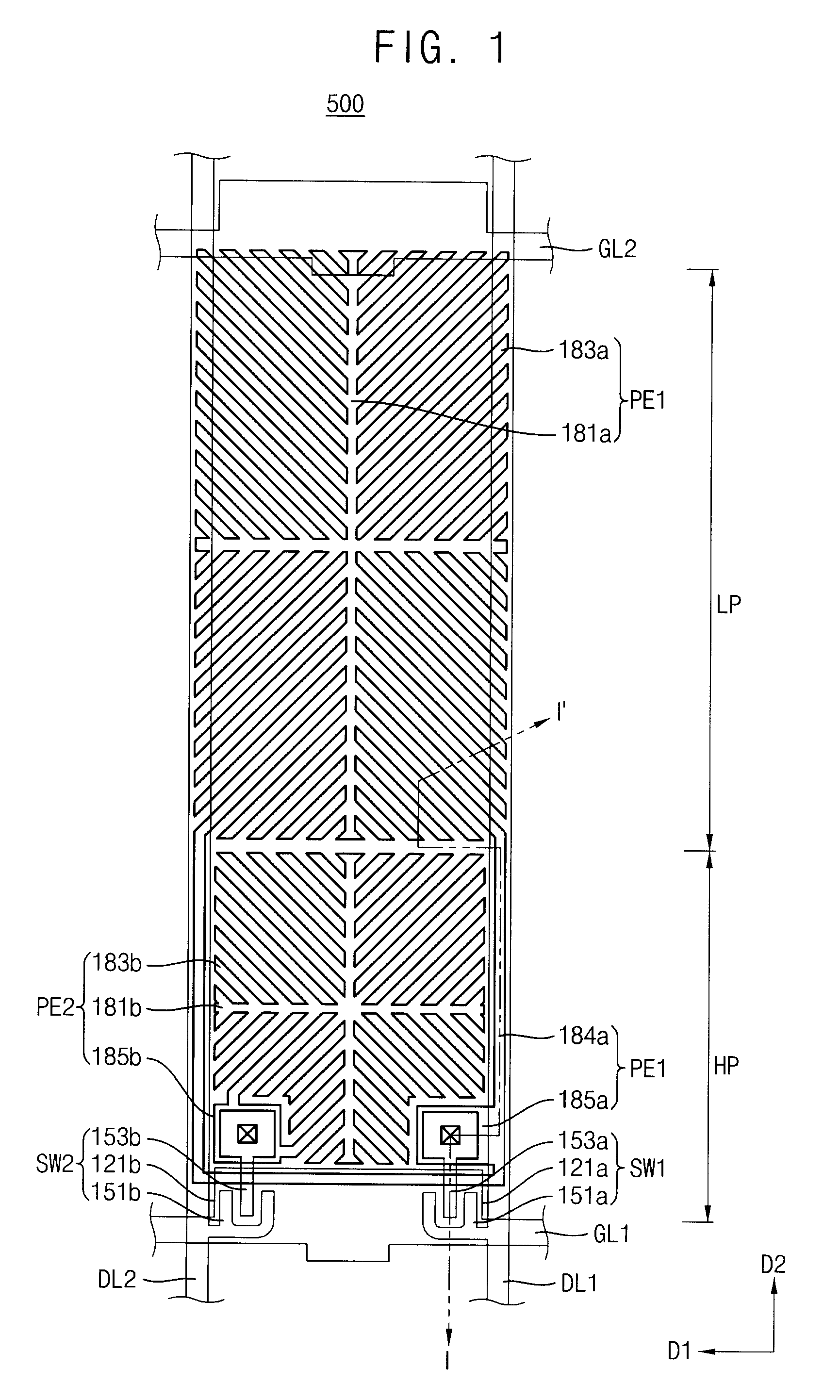

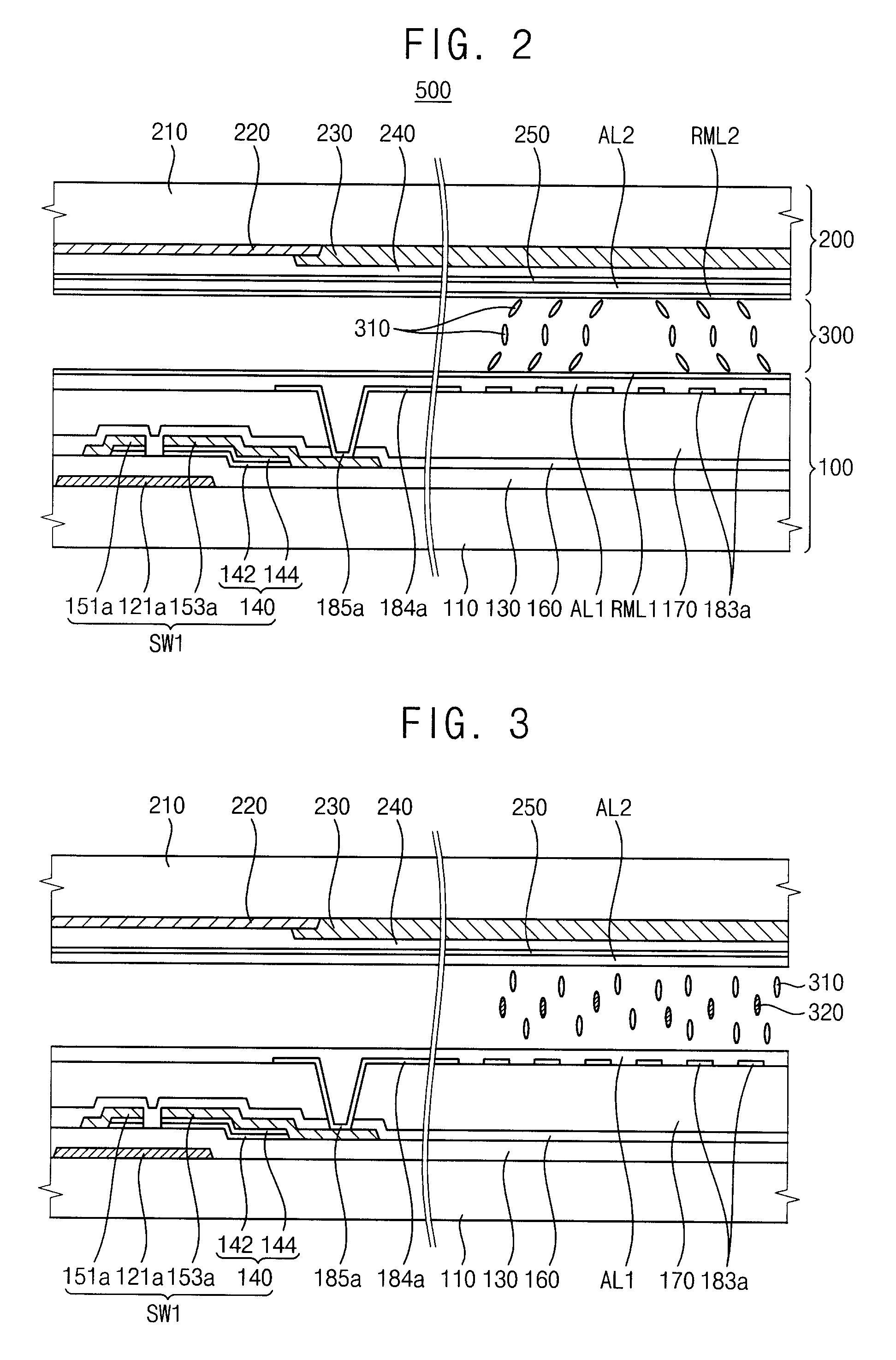

Liquid crystal display panel and method of manufacturing the liquid crystal display panel

InactiveUS20100231845A1Simple structureStabilize free radicalLiquid crystal compositionsThin material handlingLiquid-crystal displayEngineering

A liquid crystal display (“LCD”) panel includes a first substrate including a pixel electrode defining pixel areas, a first alignment layer disposed on the pixel electrode and a first reactive mesogen layer disposed on the first alignment layer, a second substrate including a common electrode layer disposed on an entire portion of the second substrate facing the first substrate, a second alignment layer disposed on the common electrode layer and a second reactive mesogen layer disposed on the second alignment layer, and a liquid crystal layer disposed between the first and second substrates and including a first liquid crystal compound represented by Chemical Formula 1, a second liquid crystal compound represented by Chemical Formula 2 and a third liquid crystal compound represented by Chemical Formula 3:

Owner:SAMSUNG DISPLAY CO LTD

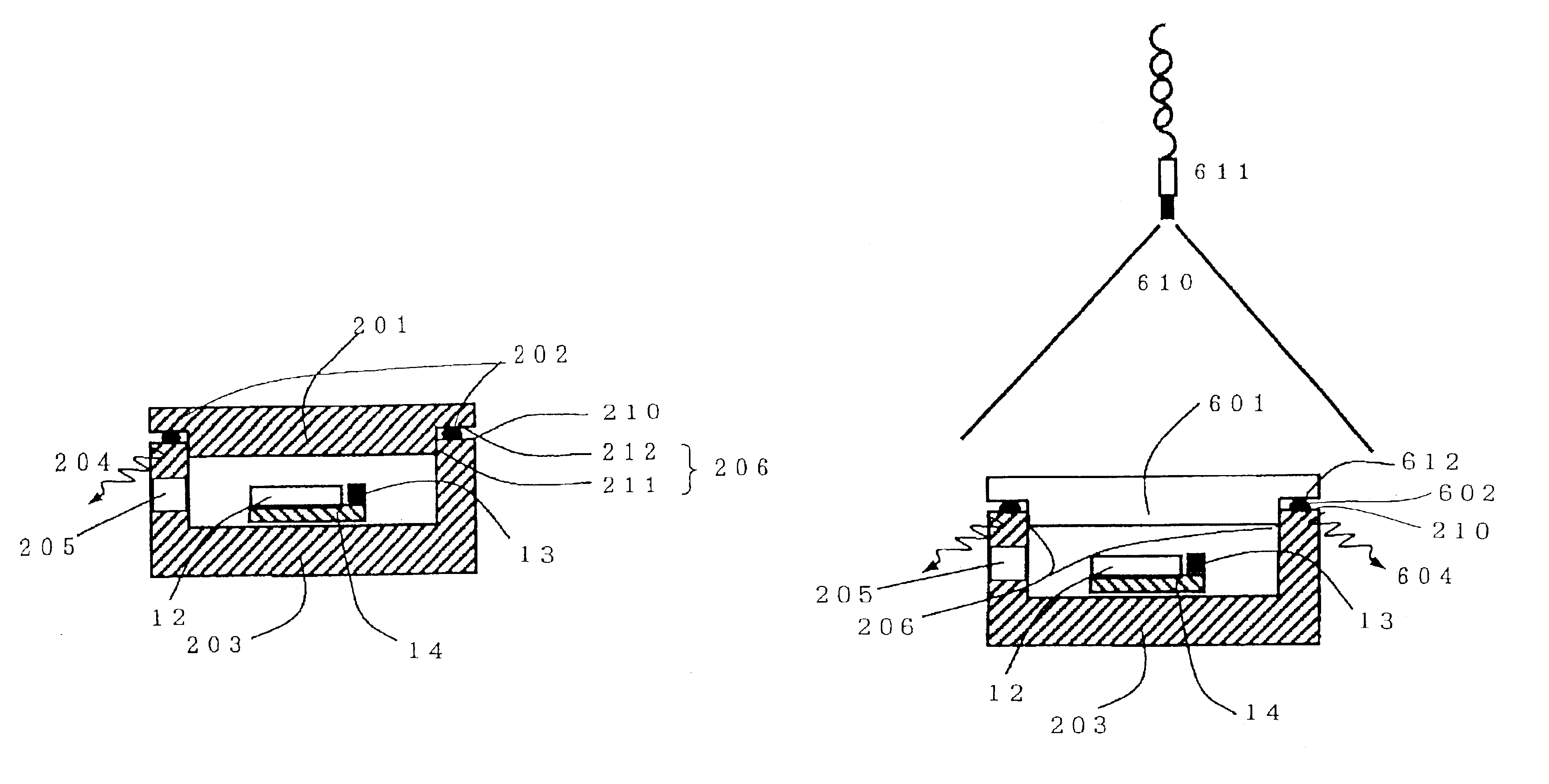

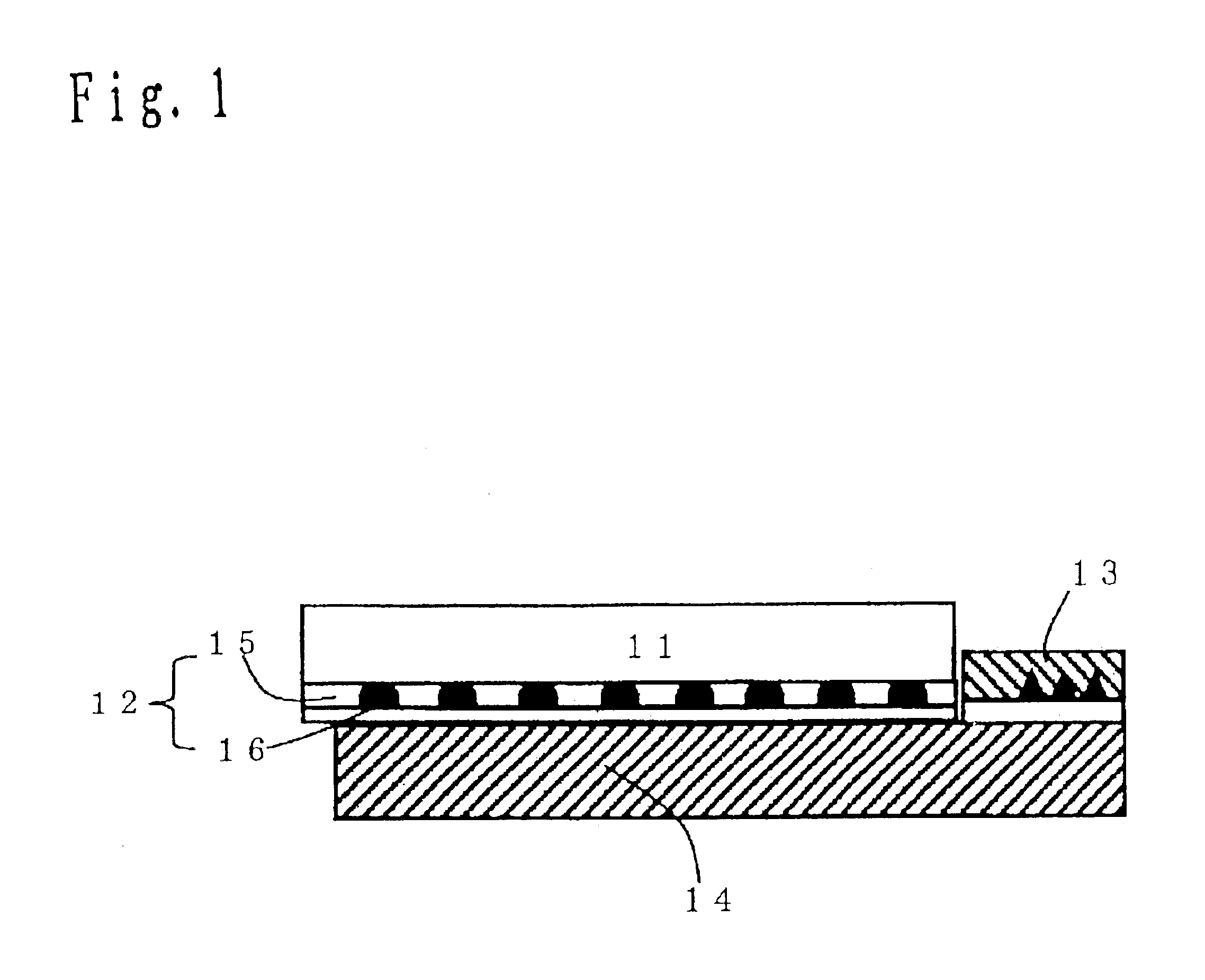

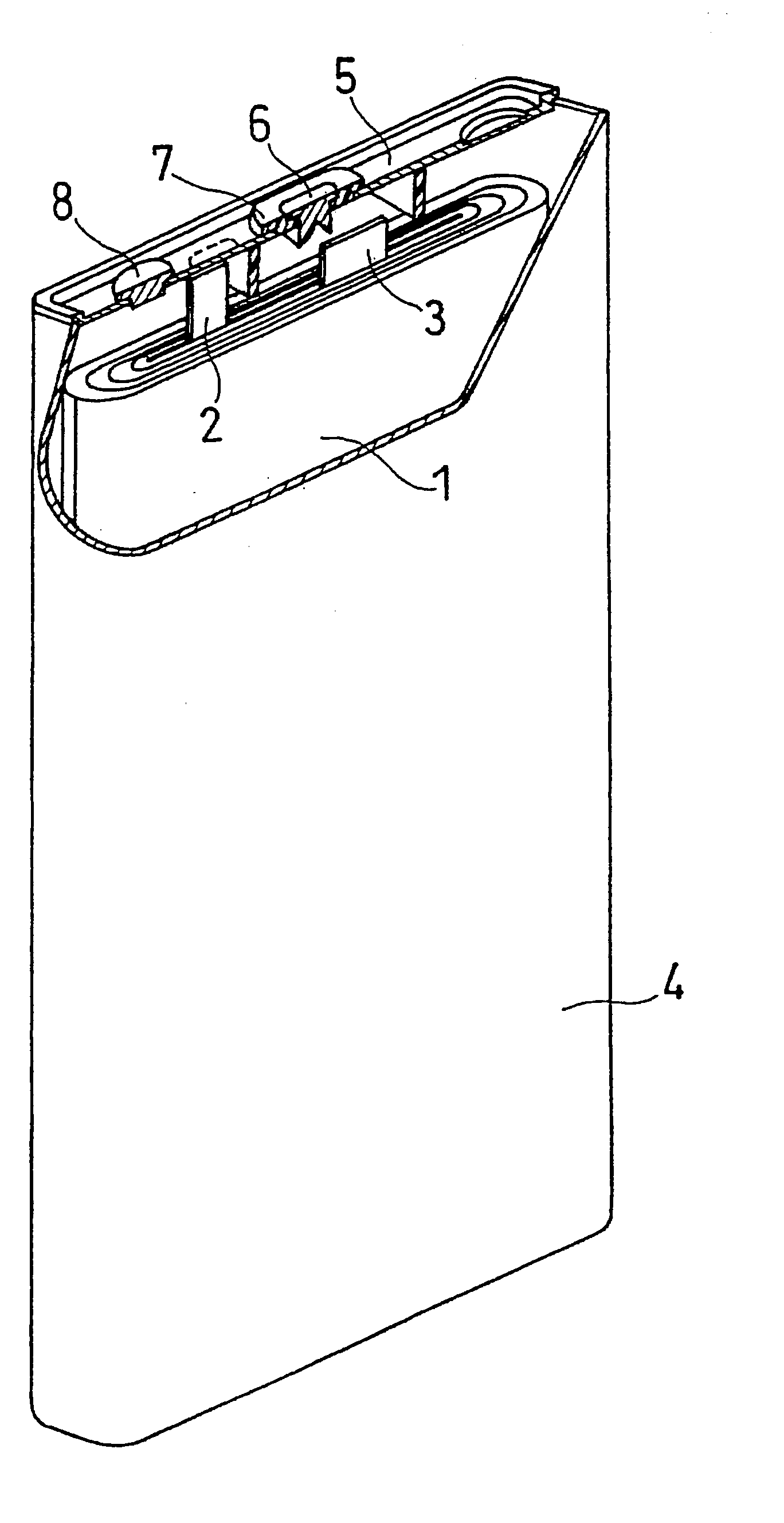

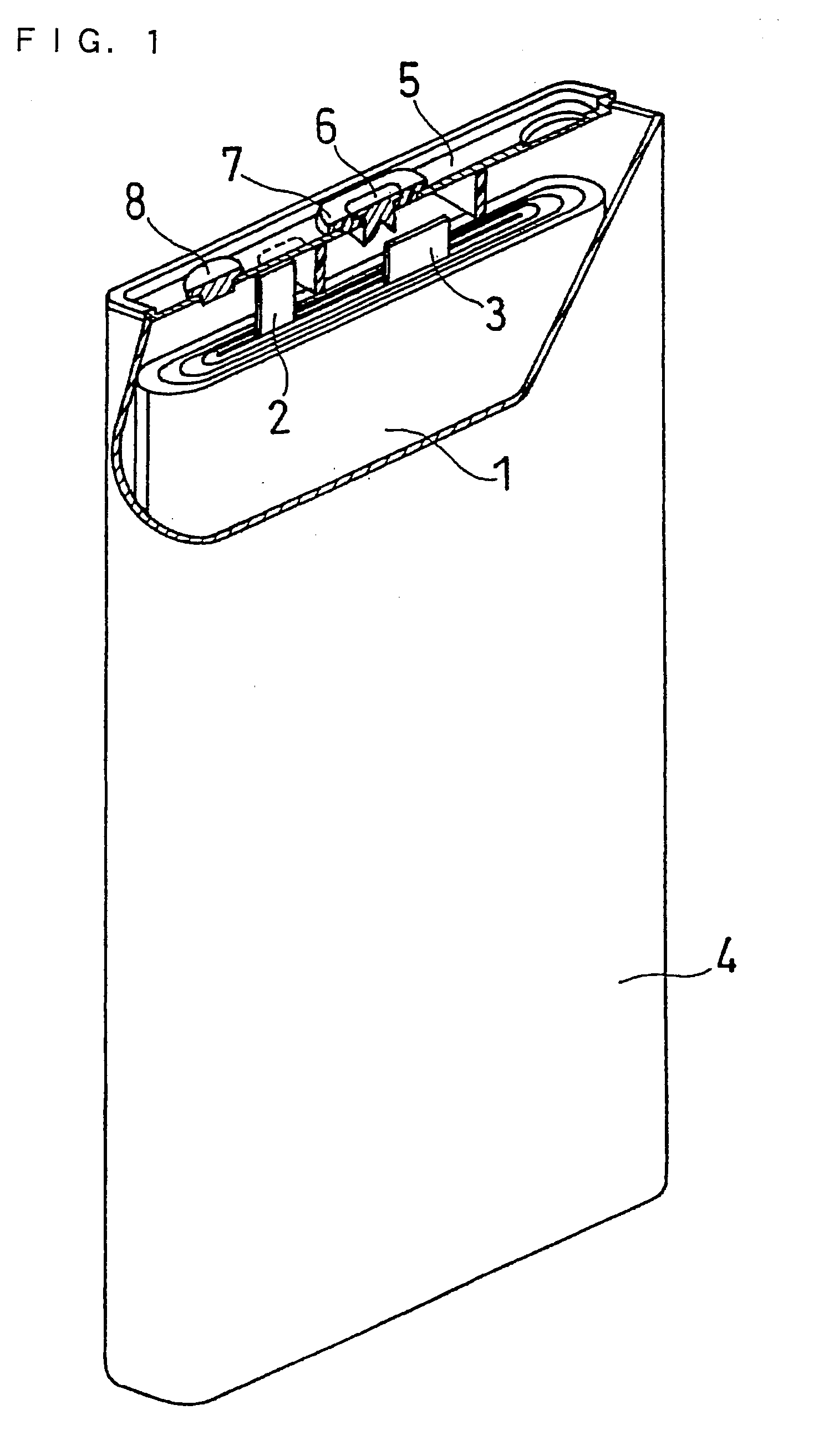

Short-wavelength laser module and method of producing the same

InactiveUS6847660B2Slowly loweredAttaining output stabilityLaser using scattering effectsOptical resonator shape and constructionHermetic sealComputer module

In a short-wavelength laser module, long-term reliability is lost because of unnecessary gas deposited on the end face of its optical waveguide.A short-wavelength laser module has a package structure wherein a package lid used when the short-wavelength laser module is hermetically sealed does not make contact with internal gas, and a process of accelerating the polymerization of a securing agent used inside the package is incorporated, whereby unnecessary gas from the securing agent is eliminated and the long-term reliability of the output is attained.

Owner:PANASONIC CORP

Ethylene enhancement of processes for synthesis of high melting theromoplastic elastomeric alpha -olefin polymers (PRE/EPE effects)

InactiveUS6160064AImprove productivityProduct can be usedGroup 4/14 element organic compoundsMetallocenesElastomerEthylene Homopolymers

This invention relates generally to low ethylene insertions into alpha -olefin polymers and processes for production of such polymers using unbridged fluxional metallocenes, primarily substituted aryl indenyl metallocenes, and more particularly to use of unbridged, fluxional, cyclopentadienyl or indenyl metallocene catalyst systems in methods of production of high melting point alpha -olefin homo- and co-polymers, particularly elastomeric crystalline and amorphous block homo- and co-polymers of alpha -olefins. The activity of fluxional unbridged metallocene polymerization catalysts containing at least one 2-arylindene ligand is increased 10x or more by the addition of small (typically 0.1-10 wt. %) amounts of ethylene to the polymerization system, which increase is termed the Polymerization Rate-Enhancement effect (PRE), which is measured in terms of an Ethylene Enhancement Factor (EEF) as a dimensionless ratio in the range of from about 1.1 to about 10 or above. A second important aspect of this invention is the ability to use a PRE activity-enhancing amount of ethylene in an olefin polymerization without substantially affecting the physical properties of the elastomer. In a third important aspect of this invention, alpha -olefin elastomers are produced through incorporation of ethylene using unbridged fluxional catalyst systems which may not otherwise produce acceptable elastomeric homopolymers. Preferred polymers of this invention retain sufficient crystallinity to provide a high melting point (by DSC) of about 80 DEG C., preferably above 100 DEG C., including in the range of from about 120 DEG C. to about 140 DEG C. and above. Novel flexible alpha -olefin homo and copolymers having elongation in excess of 600% and substantially no retained force are disclosed.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

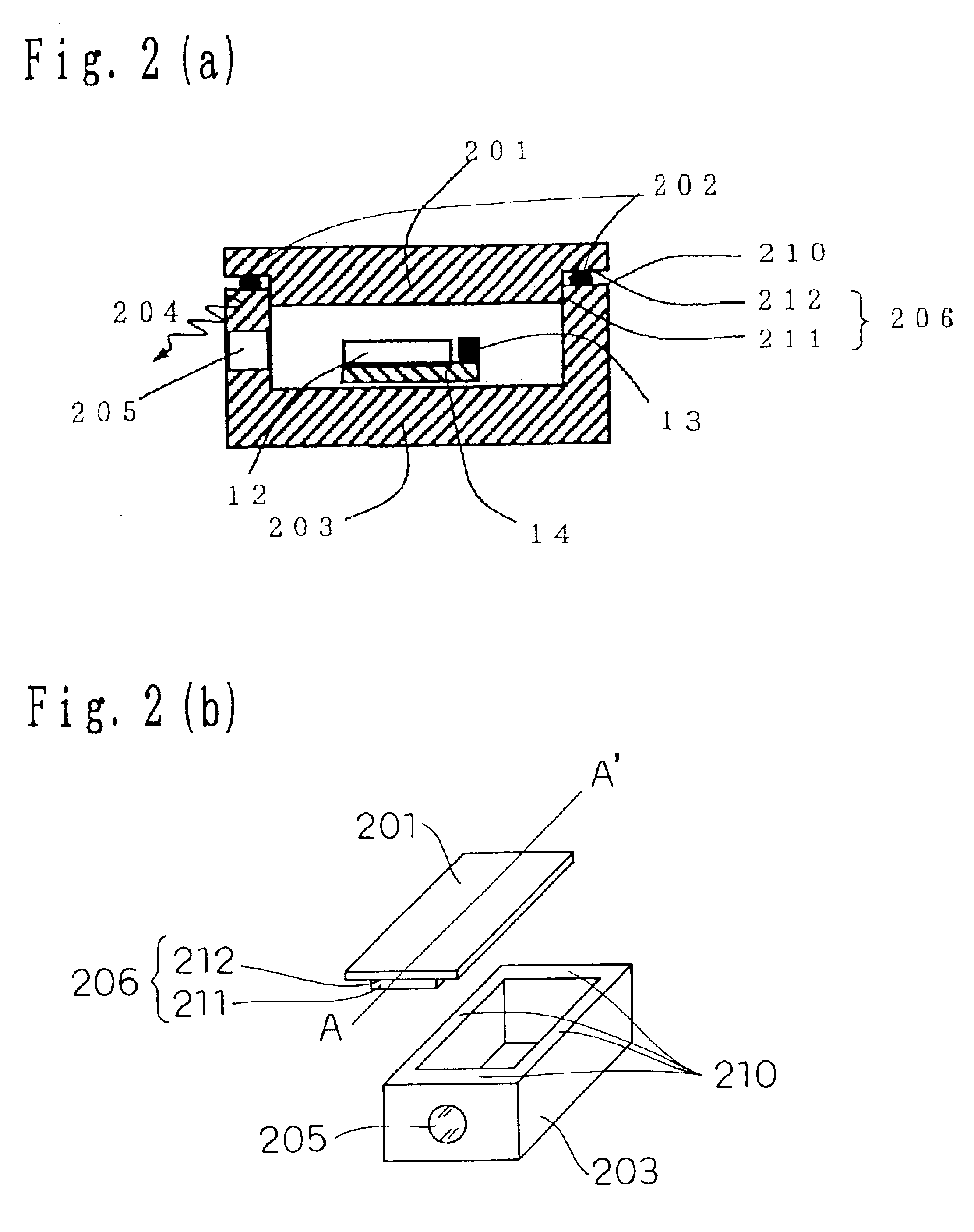

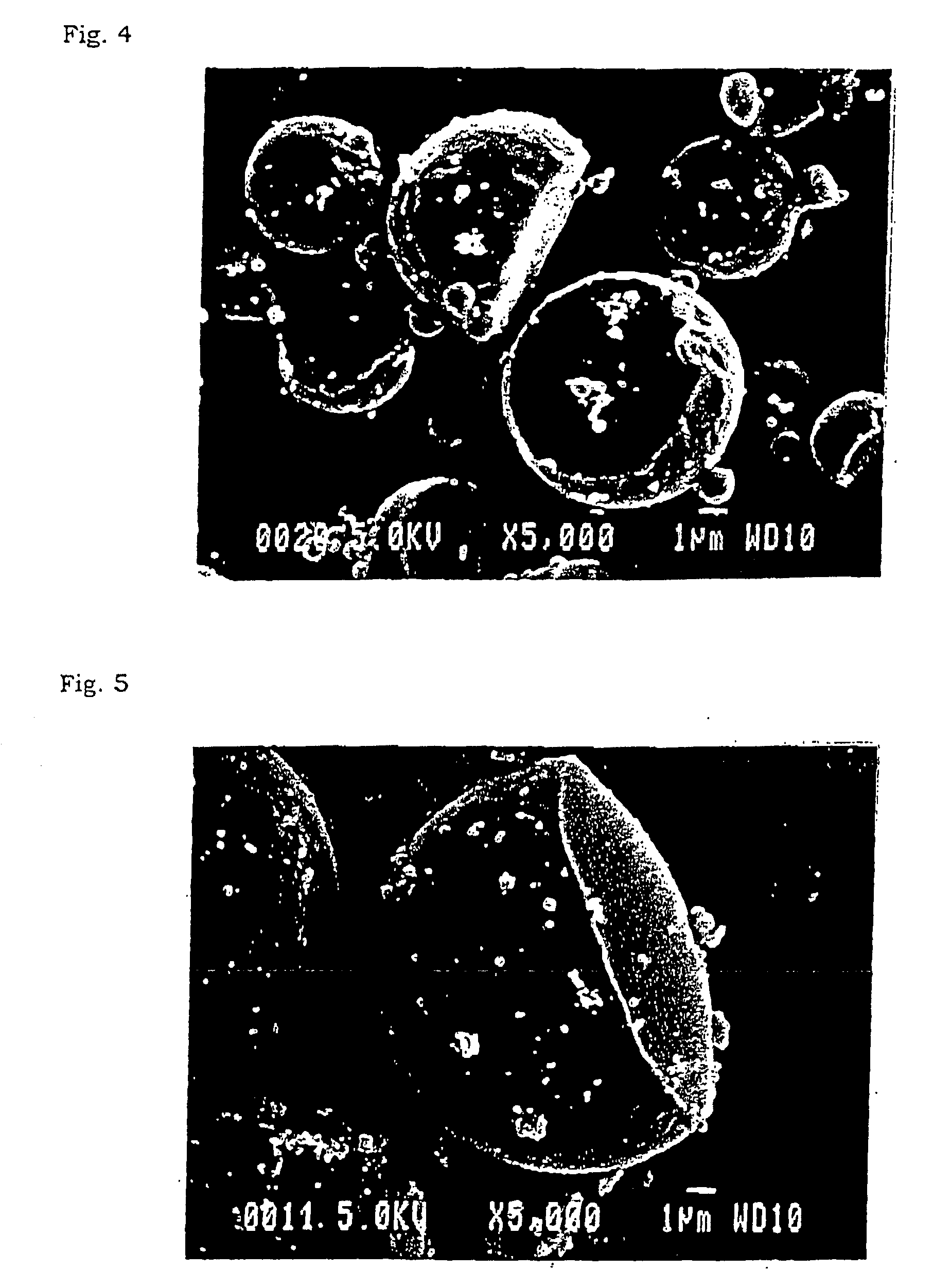

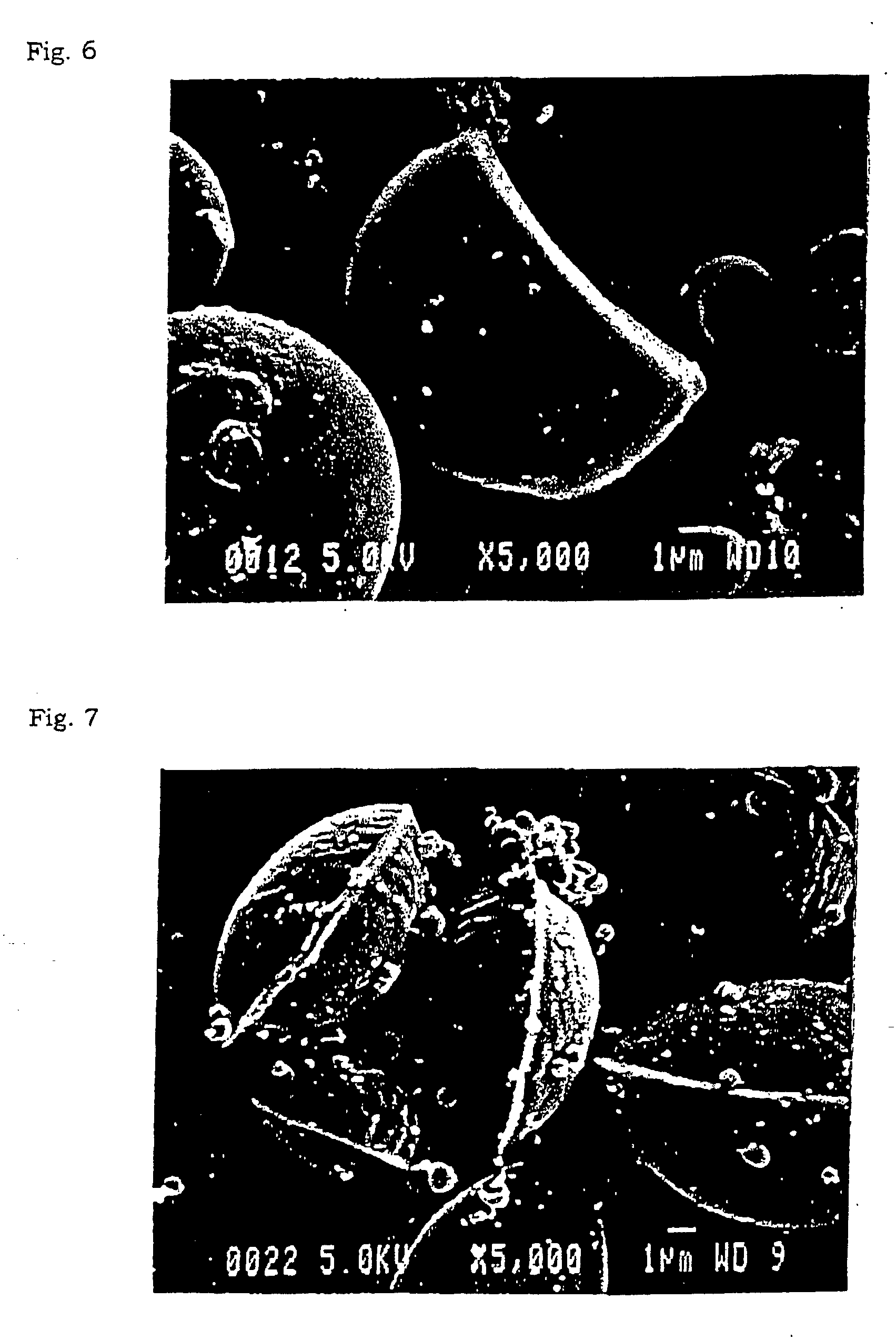

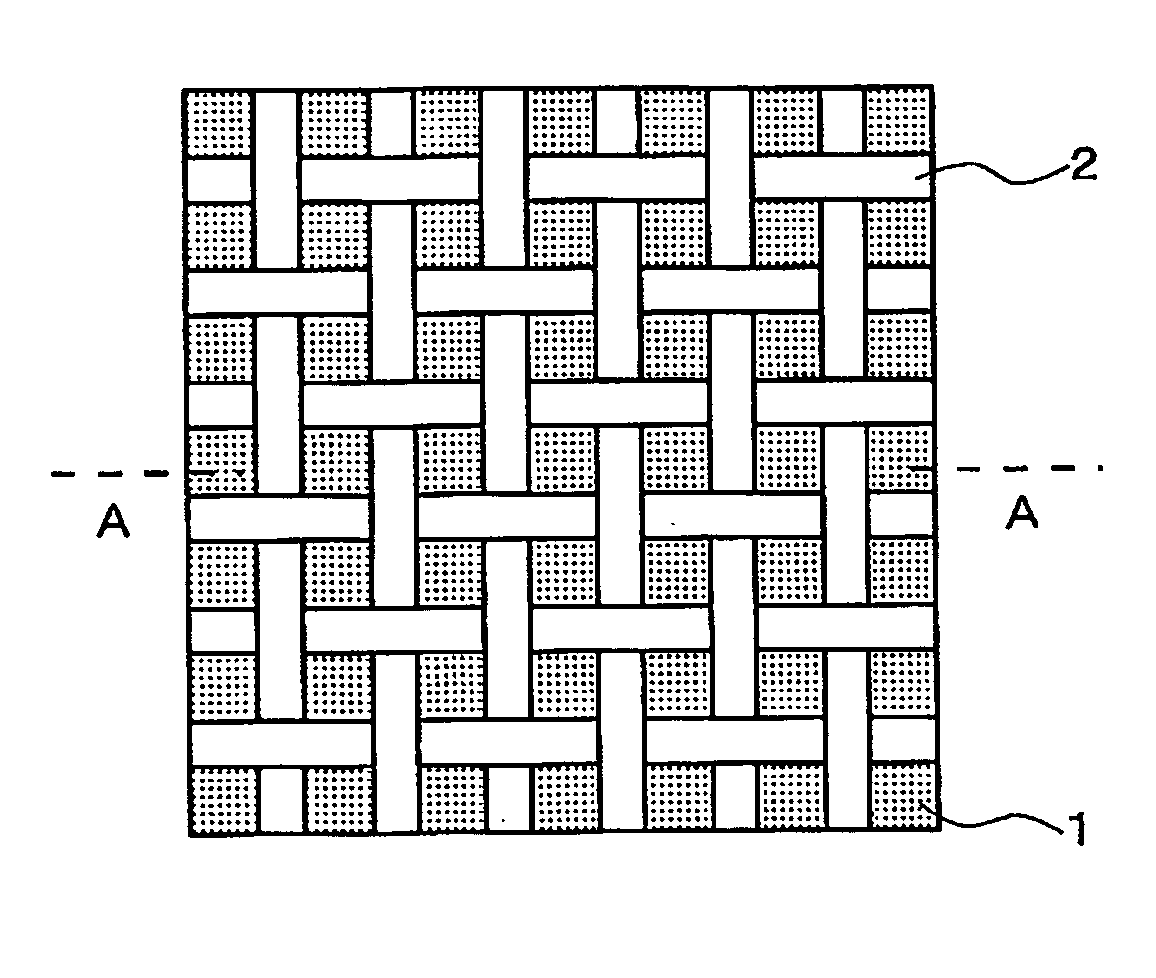

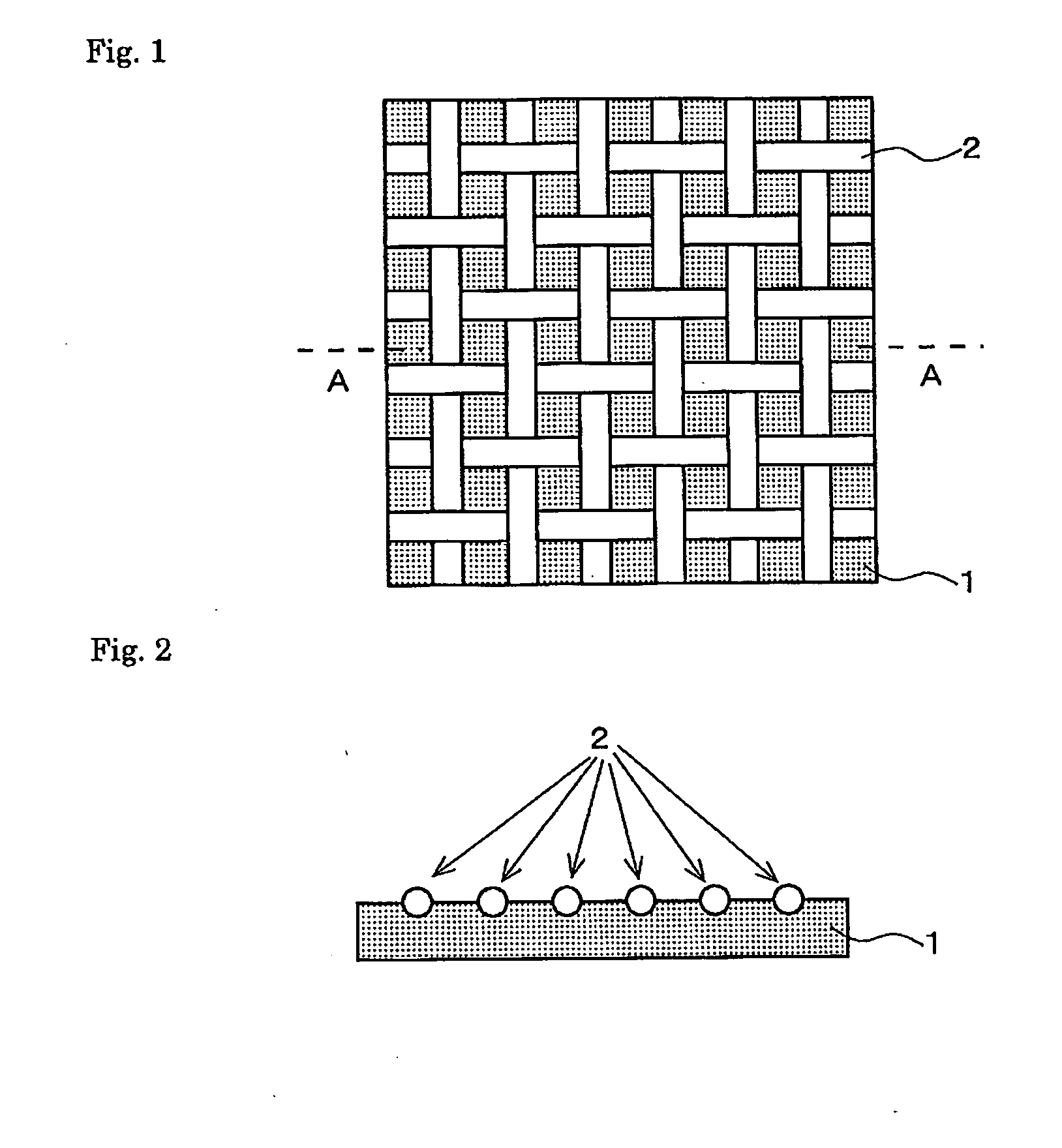

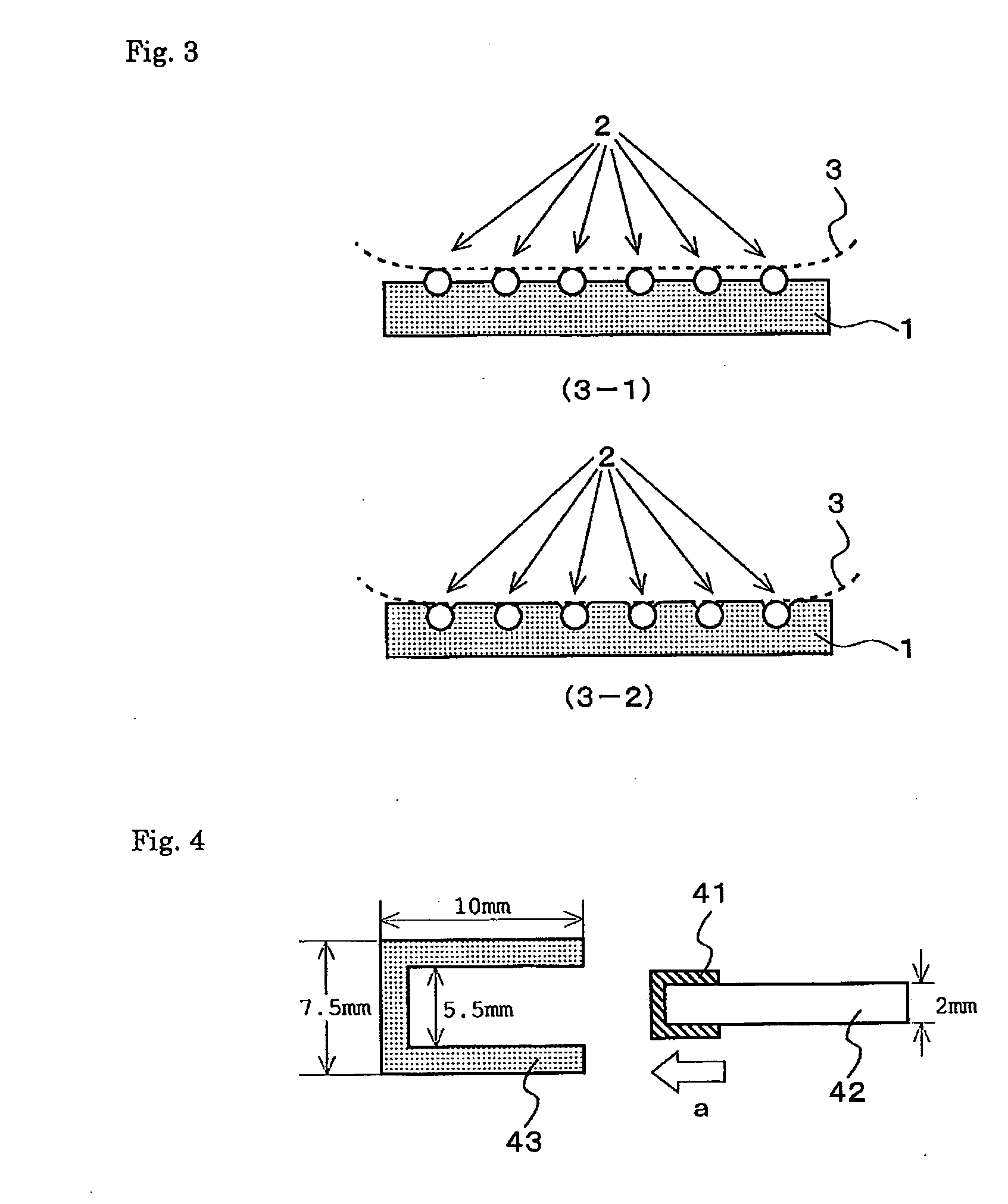

Resin particles and process for producing the same

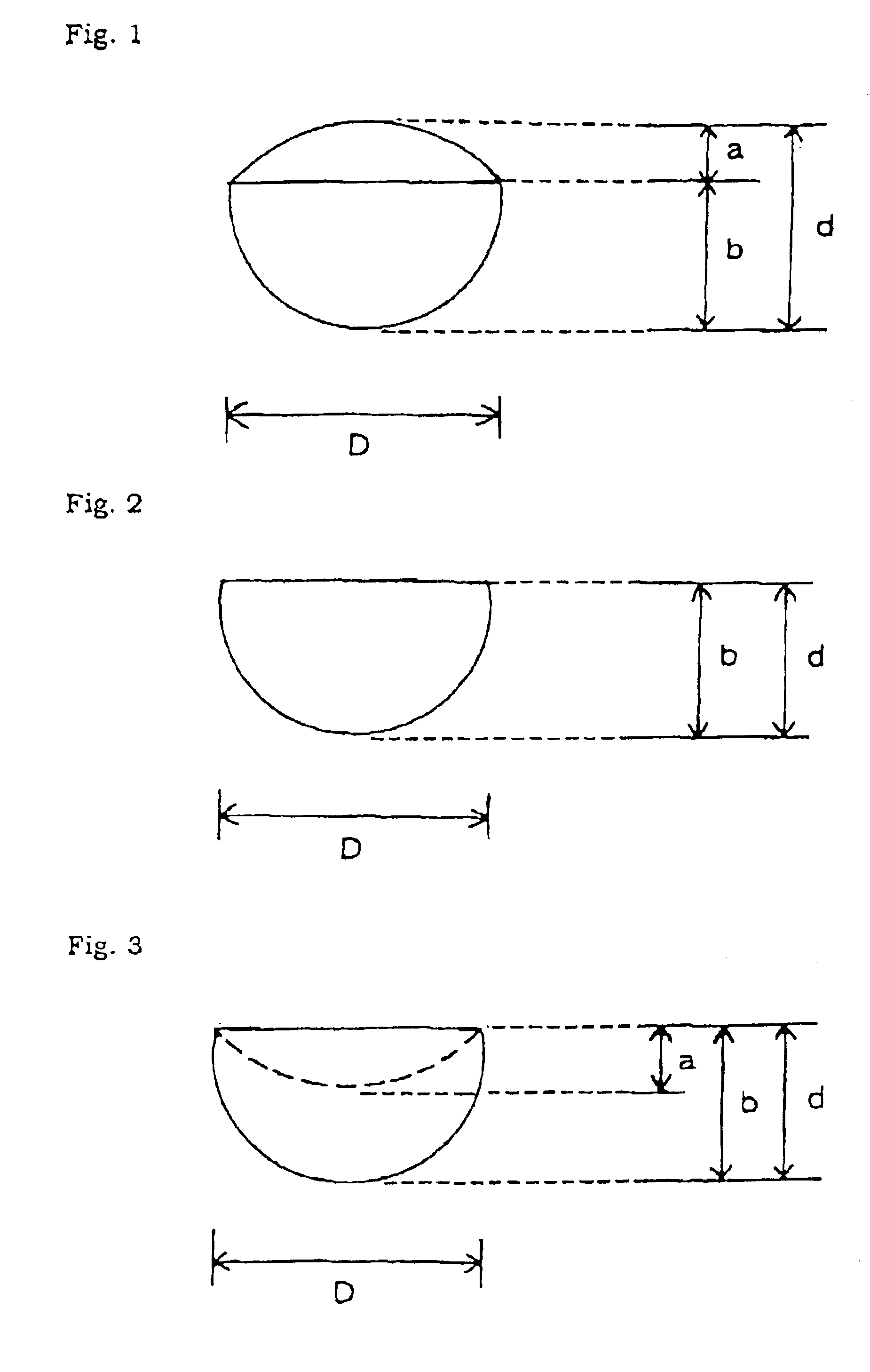

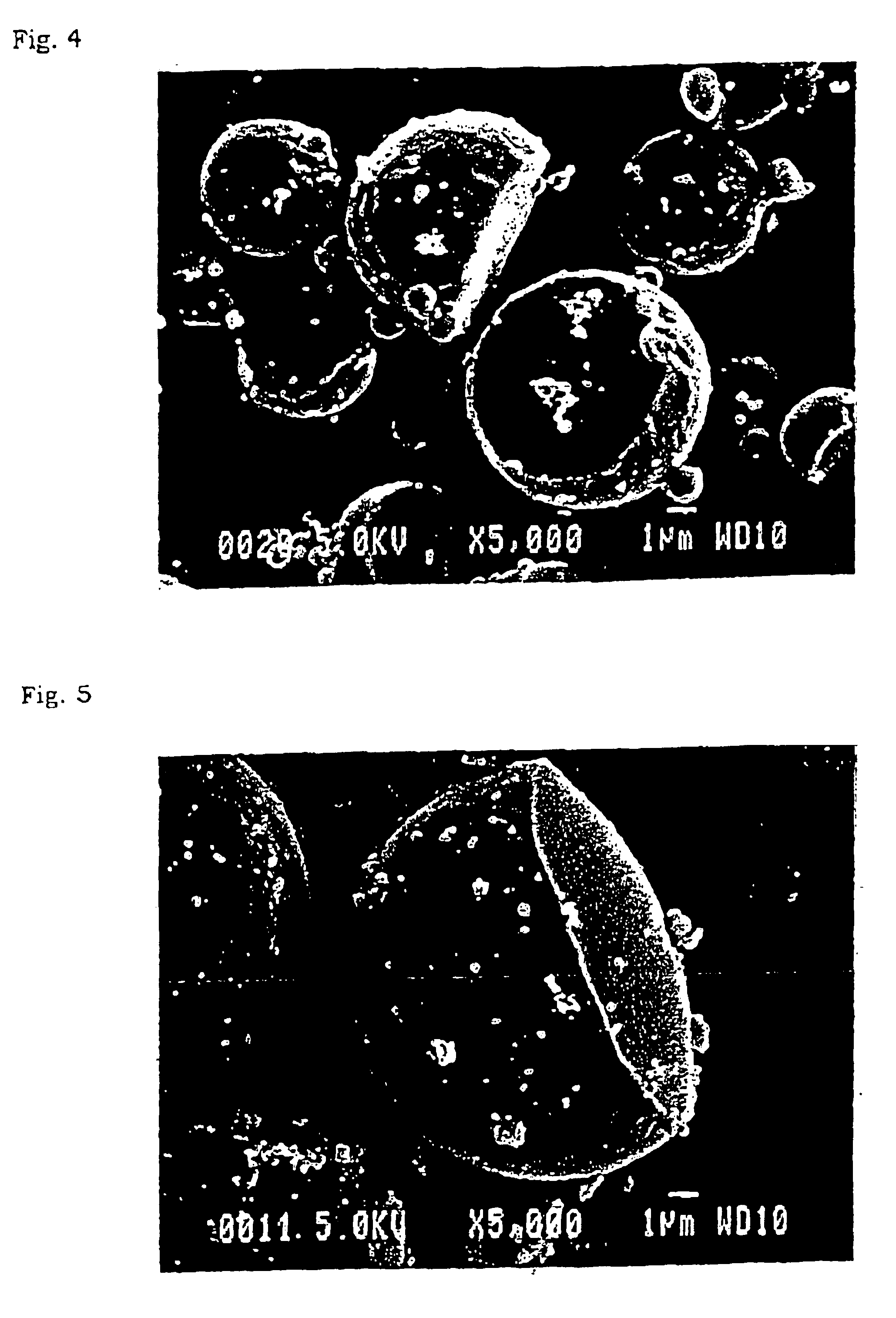

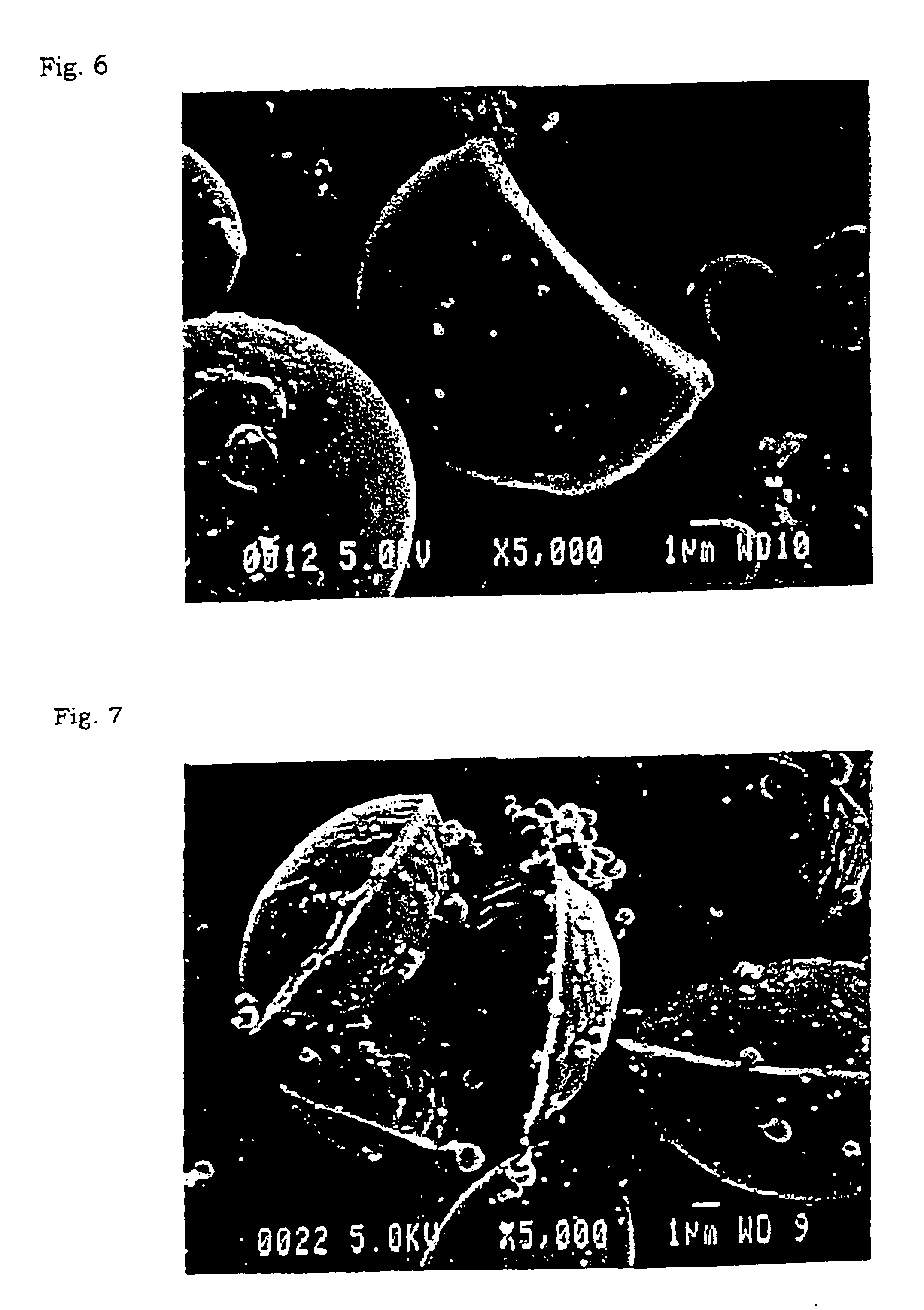

Subjects of the present invention are to provide resin particles having high ability and suitable for various purposes and to provide preparation method thereof. This invention provides resin particles each of which is formed by two curved surfaces or by one curved surface and one plane surface, has a boundary line between these two surfaces and satisfies the relationships: <paragraph lvl="0"><in-line-formula>0.1 mum<=D<=500 mum (I) < / in-line-formula><paragraph lvl="0"><in-line-formula>0.05<=d / D<=0.8 (II) < / in-line-formula>wherein D is particle diameter in horizontal direction and d is the maximum height in longitudinal direction in a side view in which the boundary line is placed in horizontal direction.

Owner:SEKISUI PLASTICS CO LTD

Macromer composition including light activated initiator

InactiveUS20060287410A1Restore and improve and functionRestore and improve tissue growthImpression capsTeeth fillingLight activatedLighting spectrum

The invention provides compositions that include macromers and visible light-activated polymerization initiators, and methods for forming a matrix using these compositions in conjunction with a light source that emits light primarily in the visible light spectrum.

Owner:SURMODICS INC

Bone treatment systems and methods

ActiveUS8696679B2High viscosityInhibit migrationInternal osteosythesisProsthesisFilling materialsVertebra compression fracture

Owner:DFINE INC

Heavy metal passivator for reducing bio-availability of cadmium in soil

ActiveCN105295938AAchieve sustained releasePrevent volatilizationAgriculture tools and machinesOther chemical processesHydrogenSoil porosity

The invention discloses a heavy metal passivator for reducing the bio-availability of cadmium in soil. The heavy metal passivator is prepared by mixing the following components in percentage by weight: 70 to 90 percent of biochar and 10 to 30 percent of modified sodium alginate. The heavy metal passivator disclosed by the invention not only has a function of passivating the heavy metal in the soil in situ, but also is capable of improving the soil structure and increasing the soil porosity, the pH (Potential of Hydrogen) of the soil is increased to a larger extent, and the function of repairing acidified soil is also obtained.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

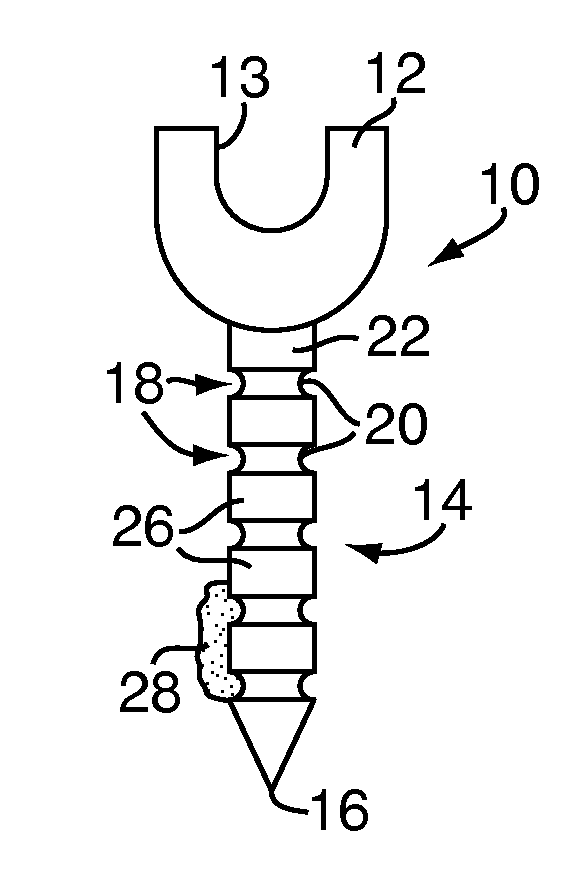

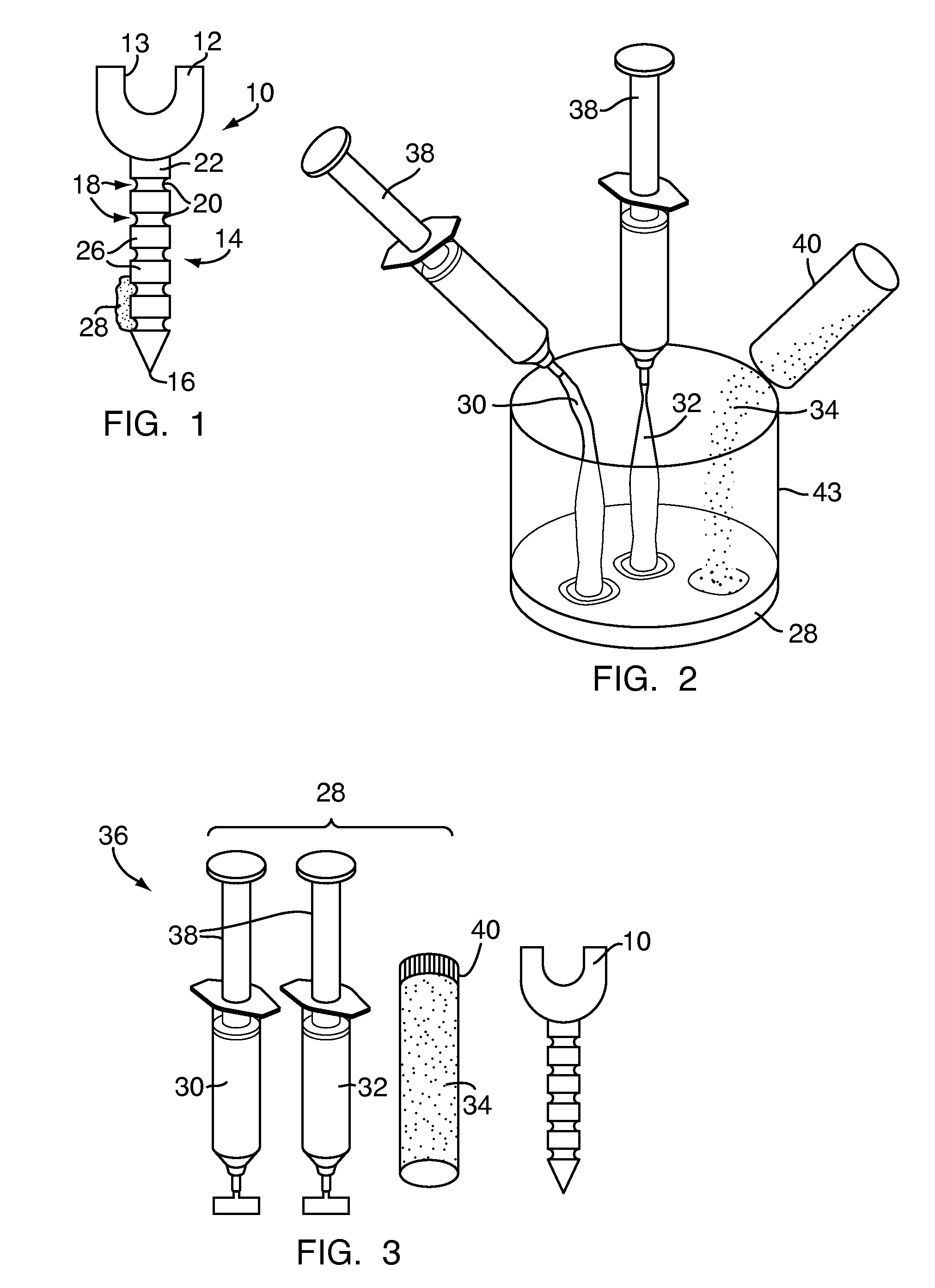

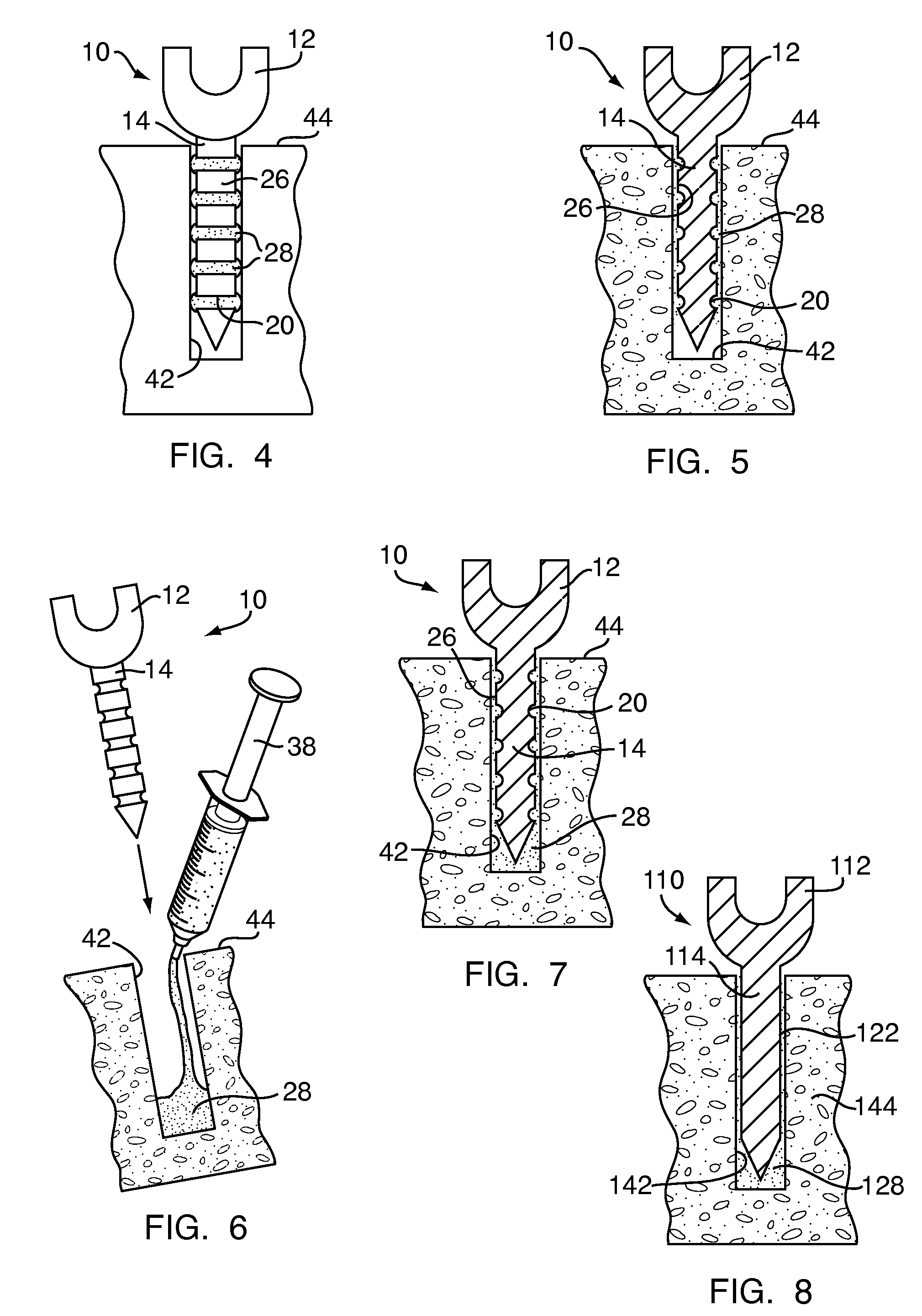

Methods and devices for spinal fusion

InactiveUS20120046698A1Improve implant strengthIncrease stiffnessSuture equipmentsInternal osteosythesisAdhesiveUltimate tensile strength

A pedicle fastener for implantation during a spinal fusion procedure includes a head and shank, the shank being connectable to the head and extending outwardly therefrom. The shank may include a shielding feature formed therein for accommodating an adhesive augmenting the pedicle fastener and improving implantation strength and stiffness thereof. A method for implanting the pedicle fastener includes forming a hole in a pedicle, applying the adhesive to the hole and sliding the shank of the pedicle fastener into the hole. The adhesive may also be applied to the hole through direct injection, injection through a longitudinal cannula formed in the pedicle fastener or by depositing the adhesive on the shank and inserting the shank into the hole. Polymerization of the adhesive may be accelerated by heating the pedicle fastener.

Owner:DOCTORS RES GROUP

Non-Aqueous Electrolyte and Secondary Battery Containing the Same

InactiveUS20070254215A1Increase resistance of batteryInhibit reactionCell electrodesOrganic electrolyte cellsSolventHydrogenated terphenyls

Disclosed is a non-aqueous electrolyte containing a non-aqueous solvent, a solute dissolved in the non-aqueous solvent, and a hydrogenated terphenyl. The solute comprises an alkali salt containing boron and an alkali salt containing no boron. An amount of the hydrogenated terphenyl contained in the non-aqueous electrolyte is preferably 0.5 mass % to 3.5 mass %. For example, LiBF4, NaBF4 or KBF4 is used as the alkali salt containing boron, while LiPF6, LiClO4, LiAsF6, LiCF3SO3, LiN(SO2CF3)2, LiN(SO2C2F5)2 or LiC(SO2CF3)3 is used as the alkali salt containing no boron.

Owner:PANASONIC CORP +1

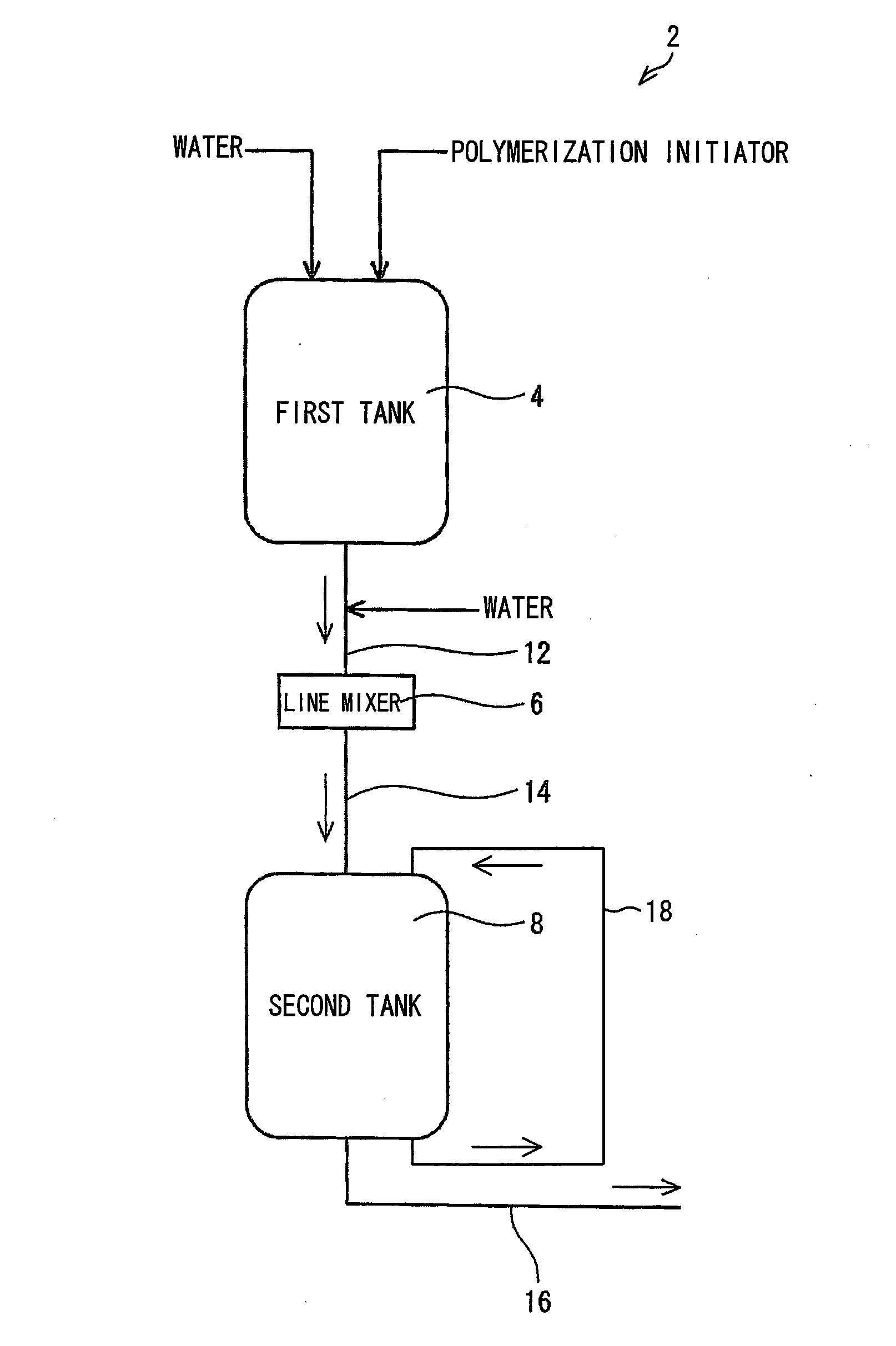

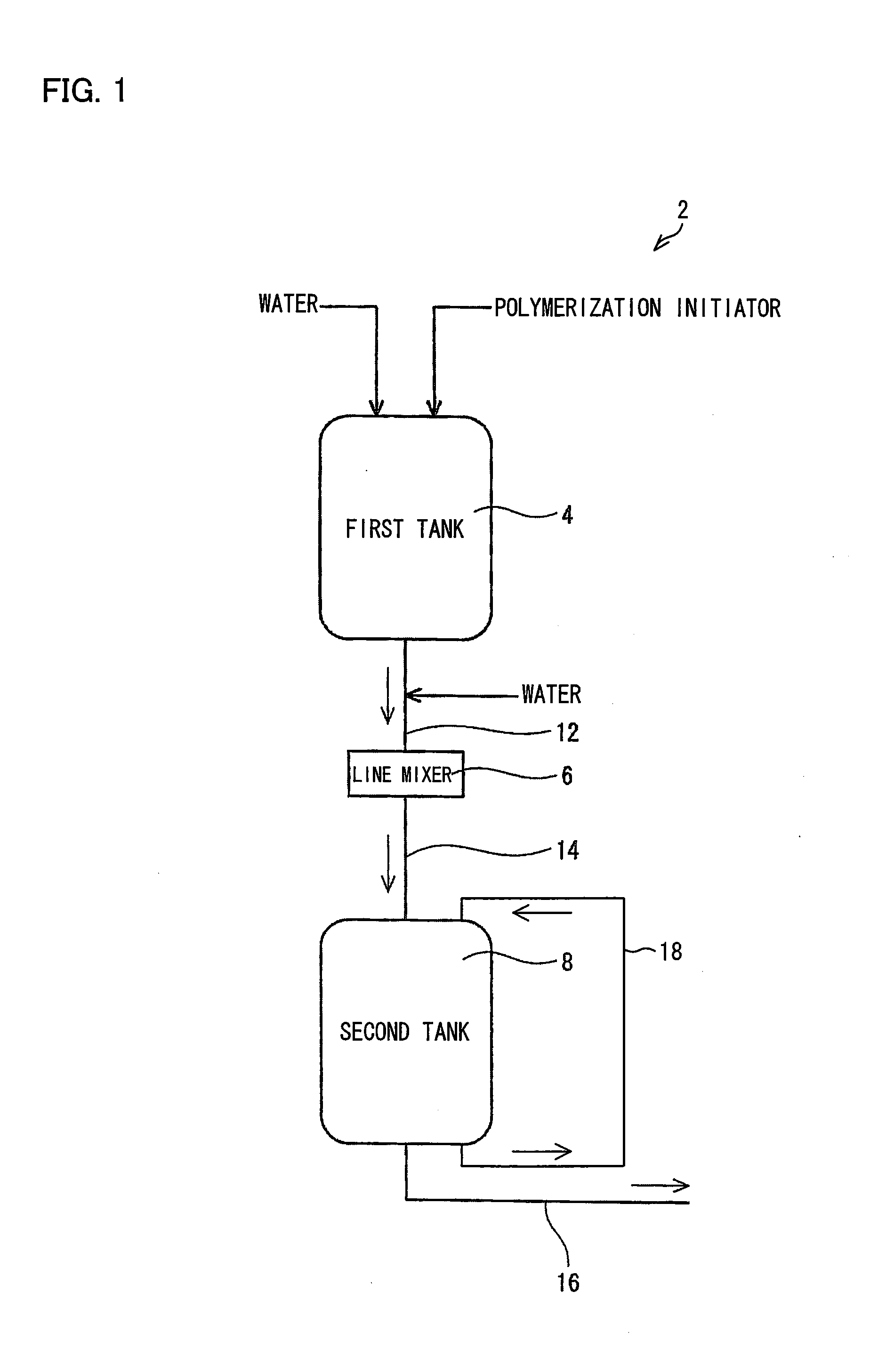

Method for producing particulate water absorbing agent containing water absorbent resin as main component

ActiveUS20110039961A1Accelerating polymerizationResidue reductionPH-change processesAbsorbent padsAqueous solutionPolymer chemistry

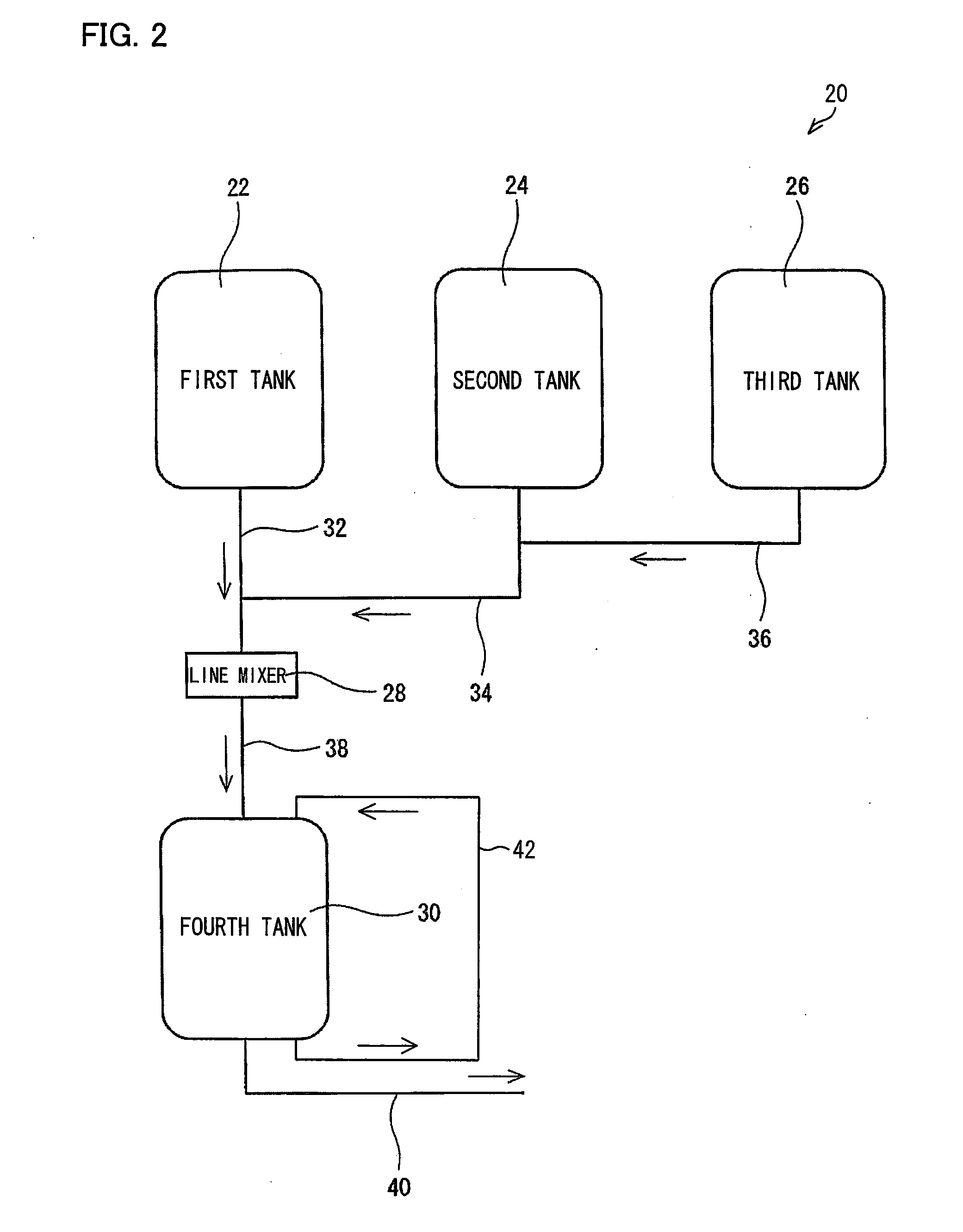

An apparatus (2) includes: a first tank (4); a line mixer (6); a second tank (8); a cooling jacket (10); a first tube (12); a second tube (14); and a third tube (16). In the first tank (4), (i) sodium persulfate serving as a polymerization initiator and (ii) water are fed so as to obtained an aqueous solution. The aqueous solution is continuously taken out and transferred via the first tube (12) to the line mixer (6). Between the first tank (4) and the line mixer (6), water is injected into the first tube (12). The water and the sodium persulfate aqueous solution are stirred together in the line mixer (6). This stirring decreases a concentration of the aqueous solution. The resulting aqueous solution is continuously fed to the second tank (8) via the second tube (14). The aqueous solution is then continuously taken out via the third tube (16) and is continuously added to an acrylic acid (salt) aqueous solution. This provides a production method which allows a high-quality water absorbing agent to be obtained with a compact apparatus.

Owner:NIPPON SHOKUBAI CO LTD

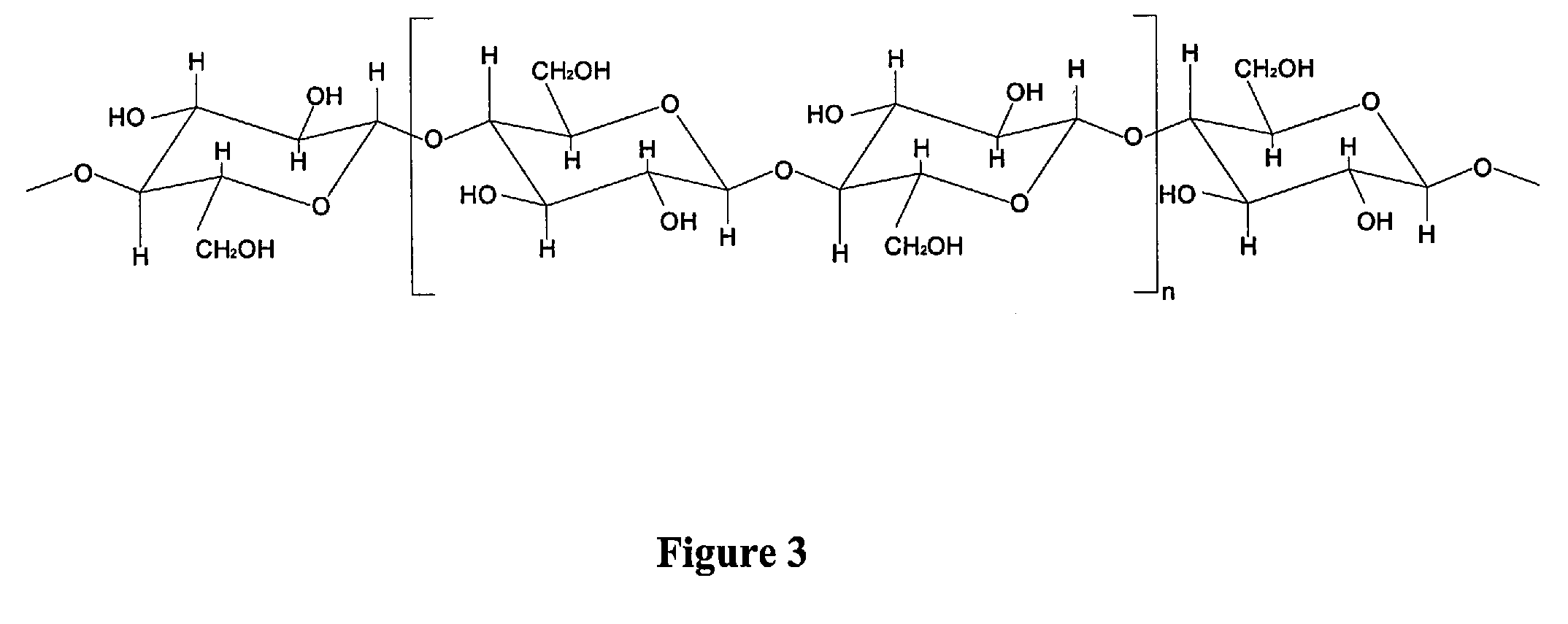

Preparation method of bamboo dissolving pulp

InactiveCN102121201AHigh removal rateReduce pollution loadPulp bleachingPulping with inorganic basesSulfateDissolving pulp

The invention discloses a preparation method of bamboo dissolving pulp. The method comprises the following steps of: (1) preparing materials; (2) stewing with sulfate; (3) bleaching with OO-X-D1-E-D2; and (4) treating with acid. The purity and the content of type A cellulose in the bamboo dissolving pulp prepared with the preparation method of the bamboo dissolving pulp are increased in a certain degree compared with those in the prior art, the purity and the content of alpha cellulose are increased by 1.5-2.5 percent compared with those in the prior art, the yield can be further increased, the dosage of chemical preparations and energy consumption are reduced, and environmental pollution can be further reduced.

Owner:FUJIAN AGRI & FORESTRY UNIV

High modulus polymer composites and methods of making the same

InactiveUS20090292046A1Improve polymerizationIncrease ratingsPigmenting treatmentWood treatment detailsFiberPolymer science

Owner:DORGAN JOHN R +1

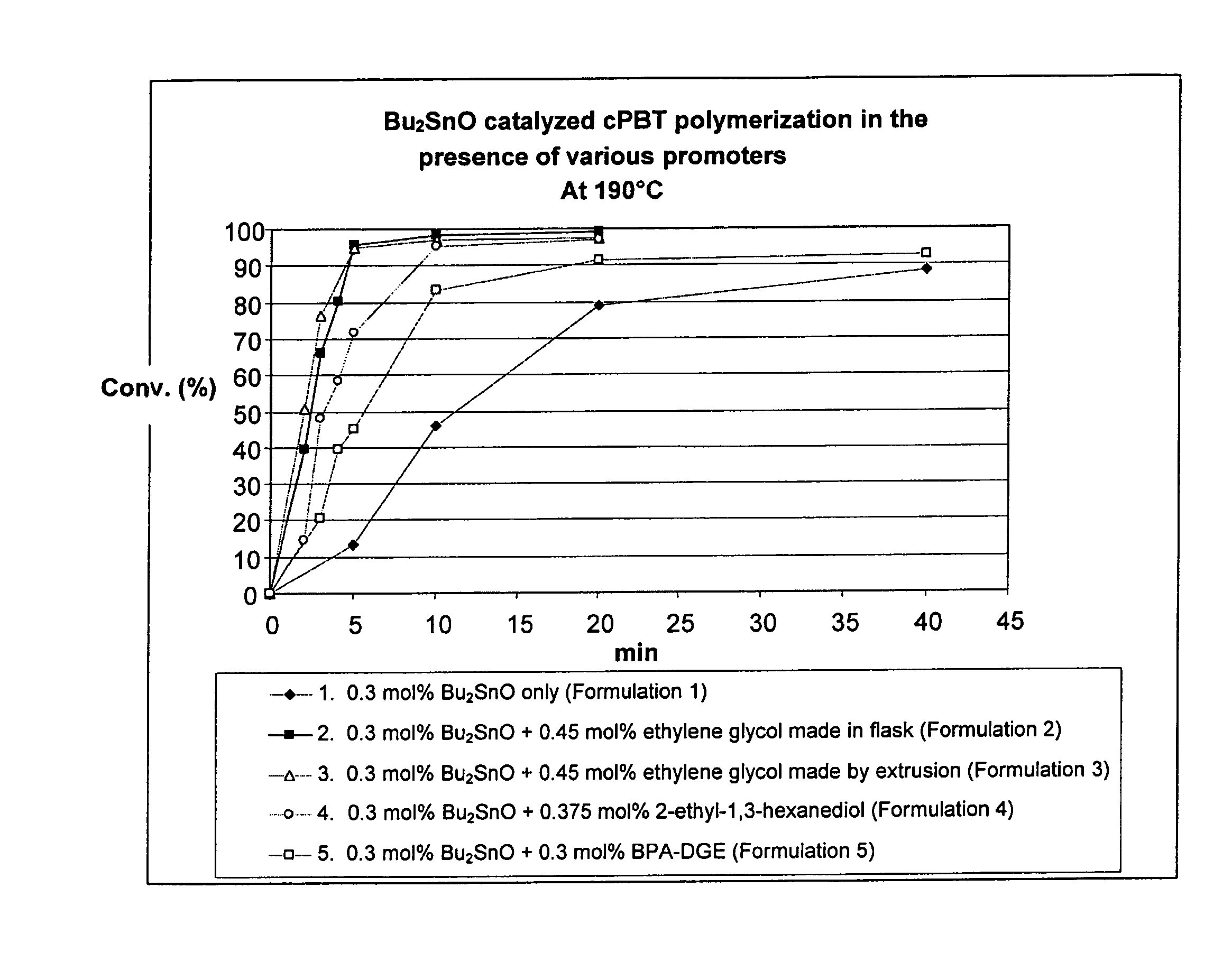

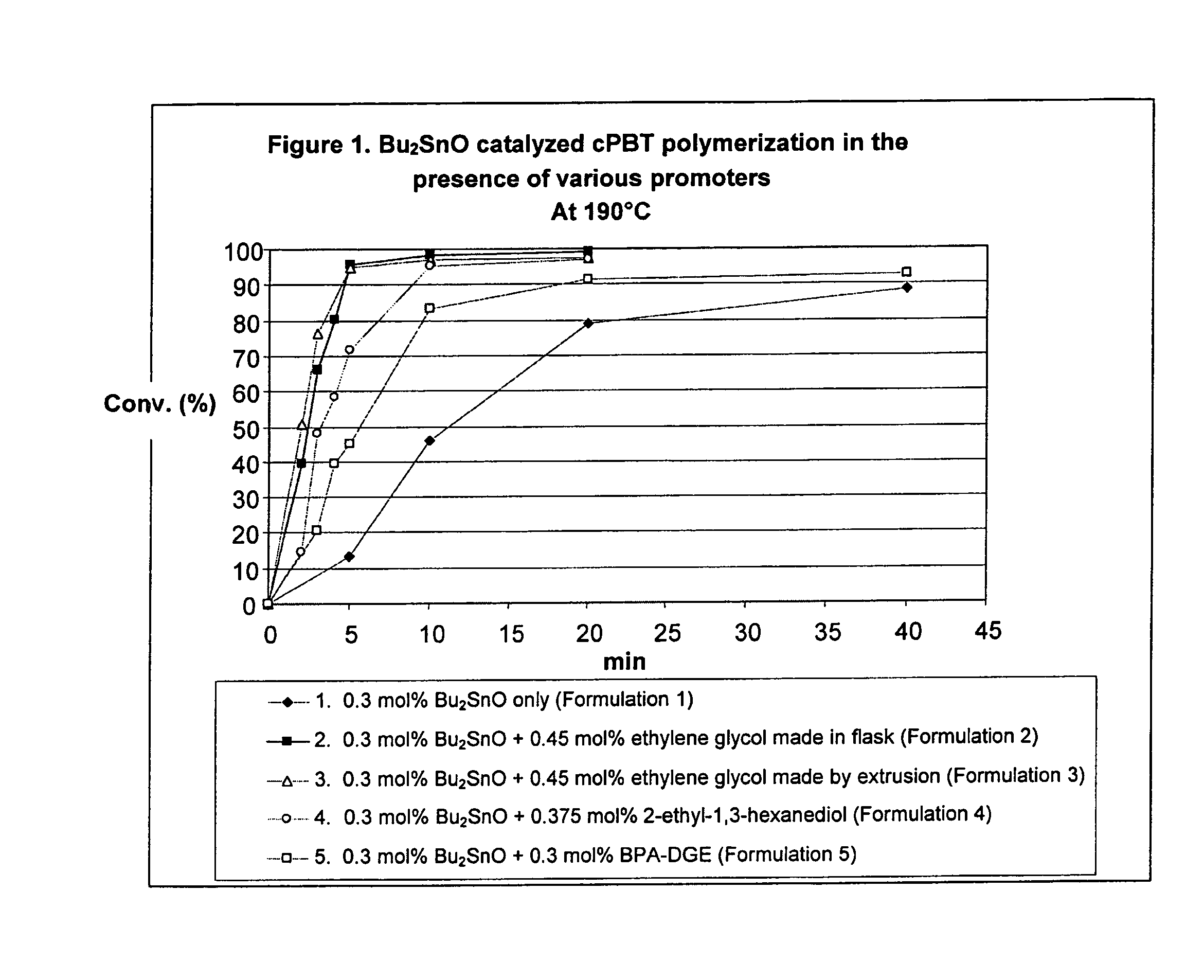

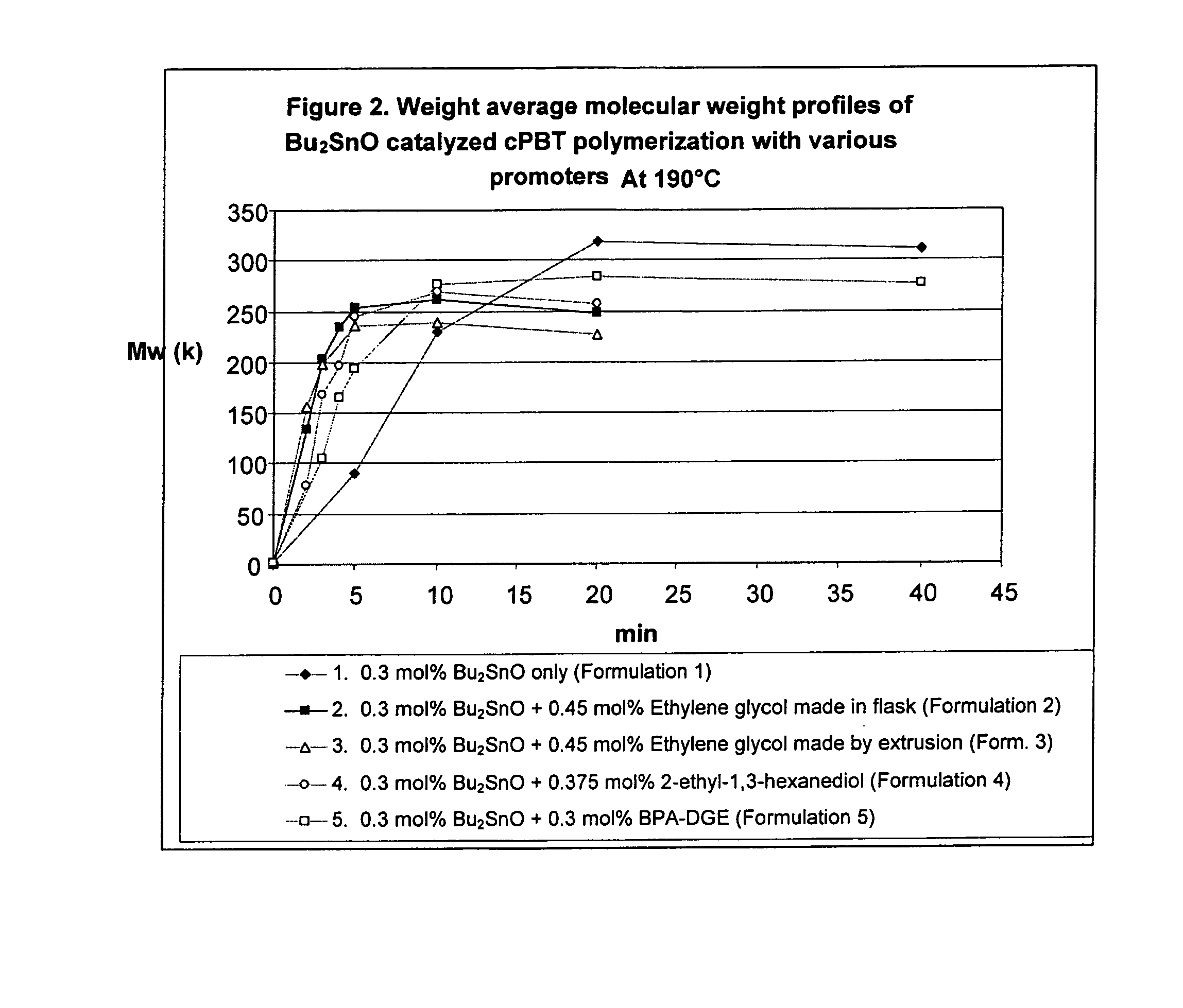

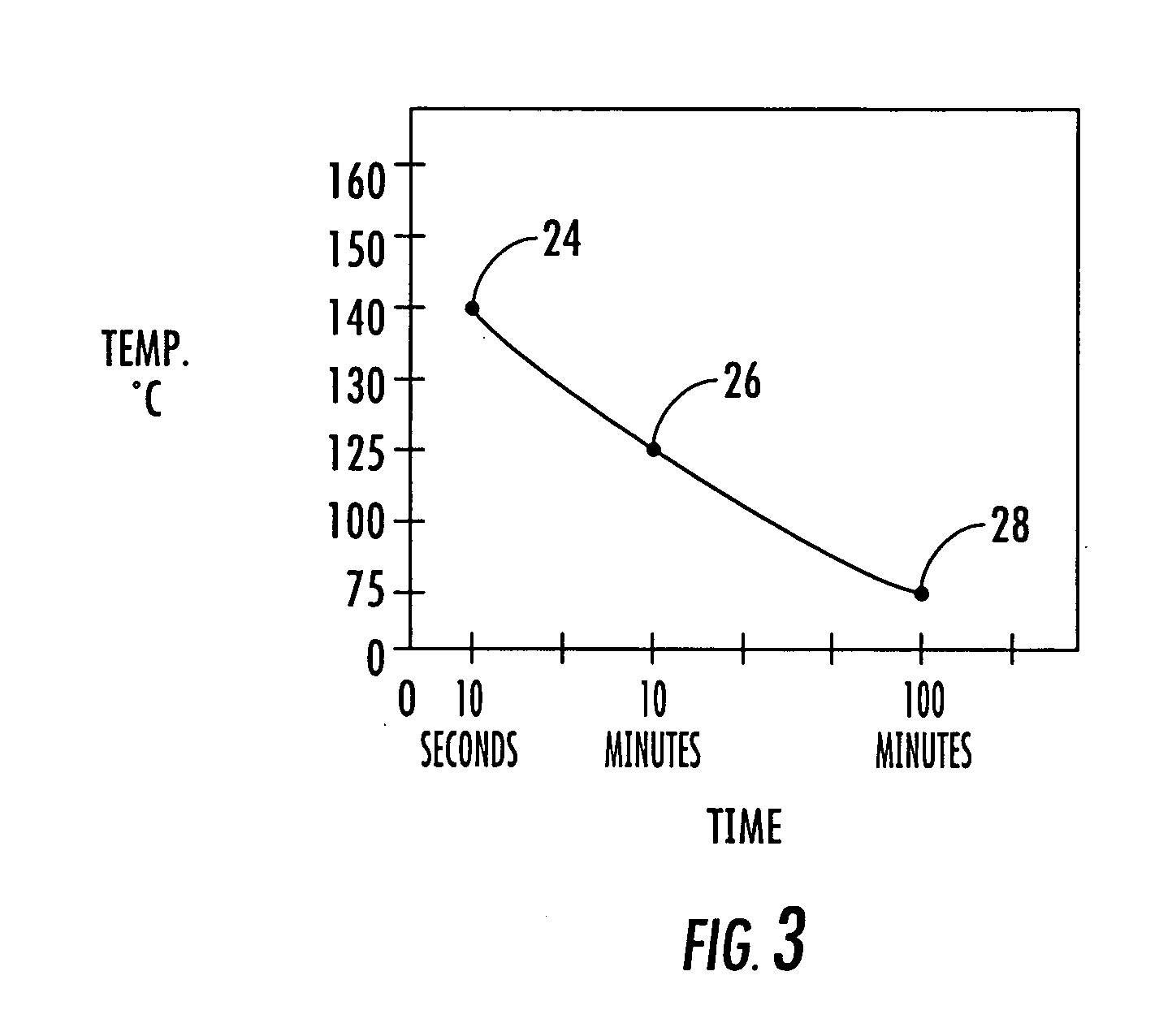

Methods for polymerizing macrocyclic polyester oligomers using catalyst promoters

InactiveUS7256241B2Extended shelf lifeGood processing characteristicsOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsPolyesterOligomer

The invention provides methods and formulations involving the use of promoters that accelerate the polymerization of macrocyclic polyester oligomers (MPOs). For example, in certain embodiments, the invention provides blends of macrocyclic polyester oligomer (MPO), catalyst, and promoter that are substantially stable at ambient temperature for a period of time. The blend material may be stored without premature polymerization of MPO or deactivation of catalyst. The invention also provides processes employing one-part, ready-to-polymerize blends that contain MPO, catalyst, and promoter, as well as processes in which the catalyst and promoter are used in separate streams and are contacted when it is desired to accelerate polymerization of MPO. Methods of the invention offer advantages in the manufacture of thermoplastic parts and composites, due at least in part to the unique properties of MPO.

Owner:LIQUID THERMO PLASTICS

Liquid crystal display panel and method of manufacturing the liquid crystal display panel

InactiveUS8318270B2Improve reliabilityShorten production timeLiquid crystal compositionsThin material handlingLiquid-crystal displayEngineering

A liquid crystal display (“LCD”) panel includes a first substrate including a pixel electrode defining pixel areas, a first alignment layer disposed on the pixel electrode and a first reactive mesogen layer disposed on the first alignment layer, a second substrate including a common electrode layer disposed on an entire portion of the second substrate facing the first substrate, a second alignment layer disposed on the common electrode layer and a second reactive mesogen layer disposed on the second alignment layer, and a liquid crystal layer disposed between the first and second substrates and including a first liquid crystal compound represented by Chemical Formula 1, a second liquid crystal compound represented by Chemical Formula 2 and a third liquid crystal compound represented by Chemical Formula 3:

Owner:SAMSUNG DISPLAY CO LTD

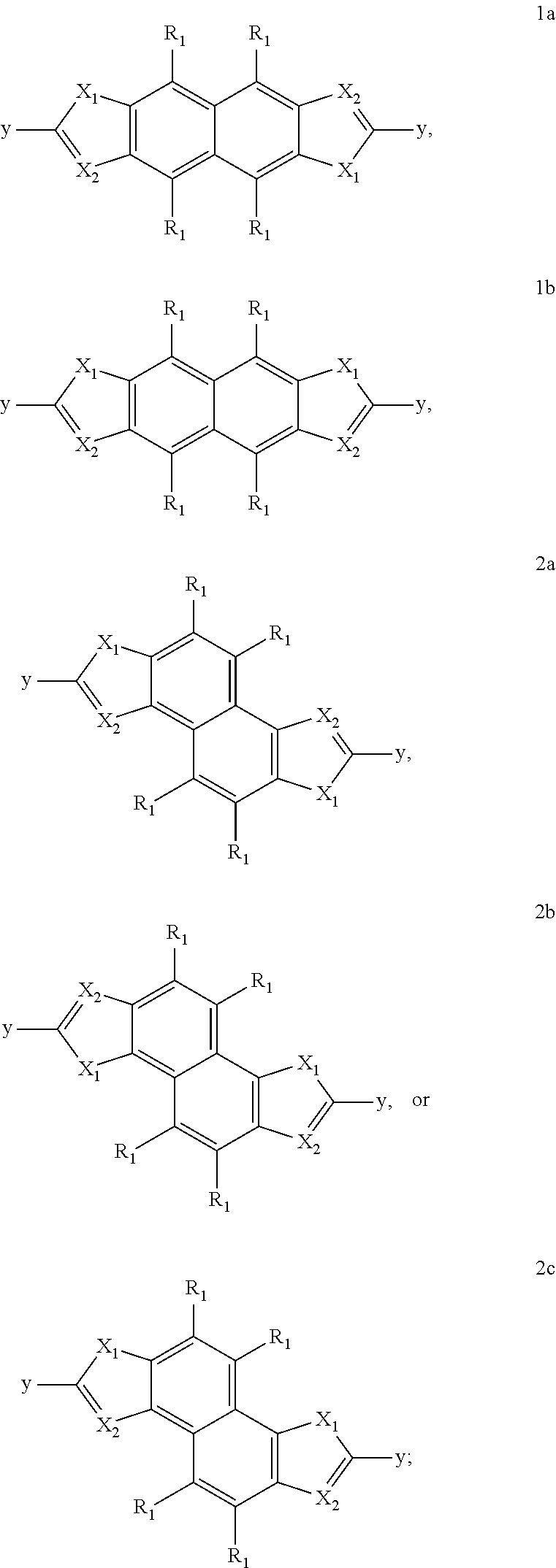

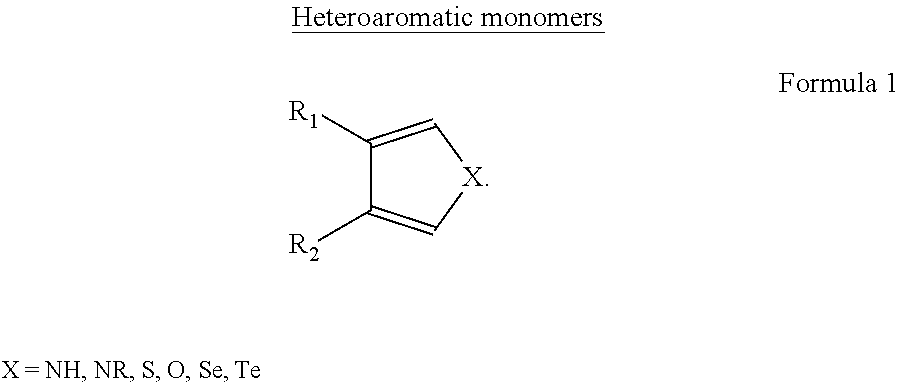

Novel fused naphthalene cyclohetero ring compounds, and methods and uses thereof

InactiveUS20150045560A1Easy to introduceImprove polymerizationSilicon organic compoundsOrganic compound preparationSimple Organic CompoundsOrganic semiconductor

Described herein are heterocyclic organic compounds of following formulae: More specifically, described herein are fused heterocyclic naphthalene compounds, polymers based on fused heterocyclic naphthalene compounds, methods for making these compounds, and uses thereof. The compounds described have improved polymerization and stability properties that allow for improved material processibility for use as organic semiconductors (OSCs).

Owner:CORNING INC

Double-faced pressure-sensitive adhesive tape

InactiveUS20100143711A1Improve cohesionImprove polymerizationFilm/foil adhesivesEster polymer adhesivesPressure sensitiveChemistry

Provided is a double-faced pressure-sensitive adhesive tape superior in processability and workability during operation in solar cell modules.The double-faced pressure-sensitive adhesive tape according to the present invention is a double-faced pressure-sensitive adhesive tape having an acrylic pressure-sensitive adhesive layer containing bubbles and / or hollow microspheres, characterized in that the frictional force, which is defined as the stress applied when a sample of 2 cm×2 cm in size having a 30 g load fixed on at least one side of the acrylic pressure-sensitive adhesive layer containing bubbles and / or hollow microspheres, is pulled on an aluminum plate in the horizontal direction at a speed of 300 mm / min, is 0.01 to 1.0 N / cm2.

Owner:NITTO DENKO CORP

Resin particles and process for producing the same

Subjects of the present invention are to provide resin particles having high ability and suitable for various purposes and to provide preparation method thereof.This invention provides resin particles each of which is formed by two curved surfaces or by one curved surface and one plane surface, has a boundary line between these two surfaces and satisfies the relationships:wherein D is particle diameter in horizontal direction and d is the maximum height in longitudinal direction in a side view in which the boundary line is placed in horizontal direction.

Owner:SEKISUI PLASTICS CO LTD

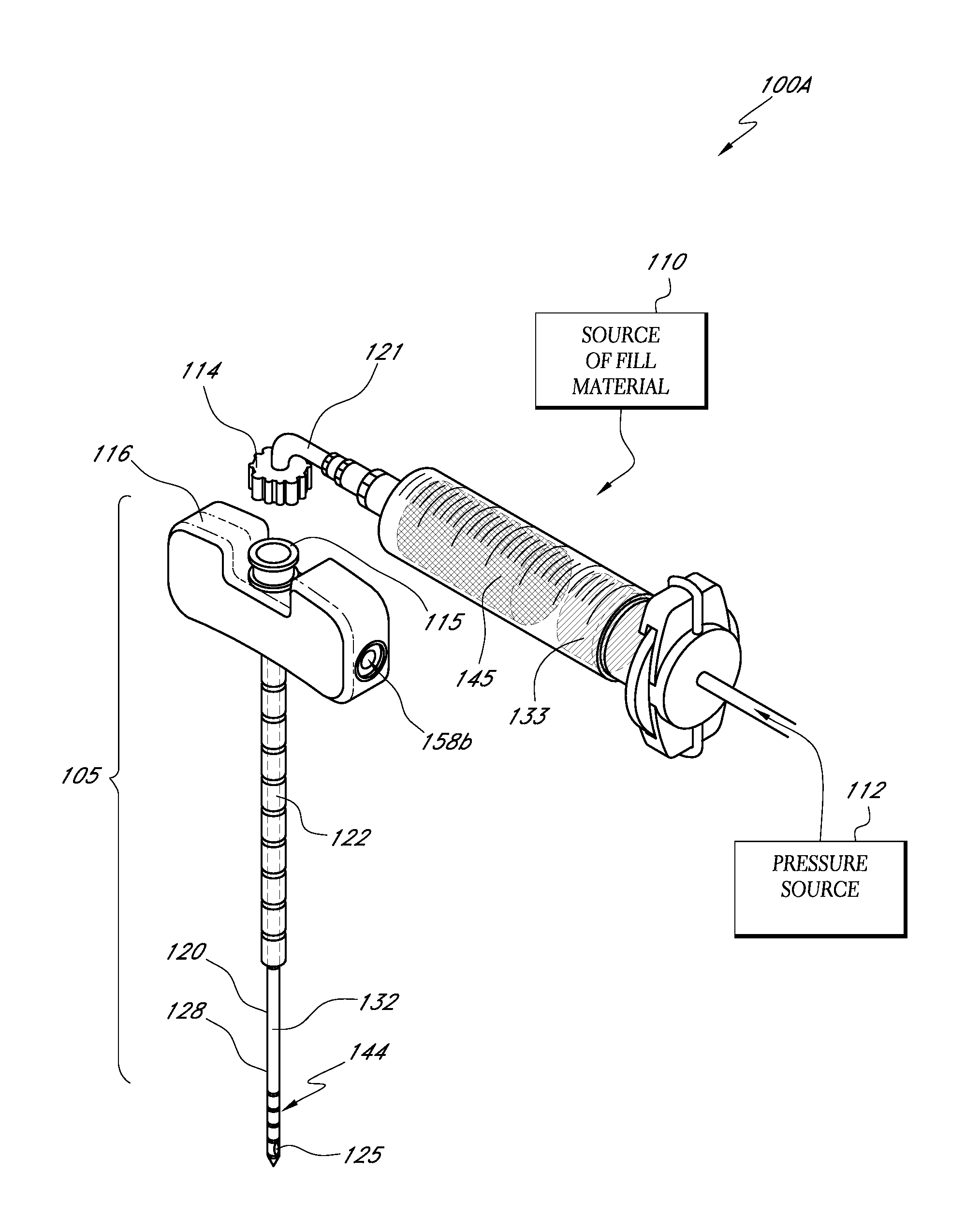

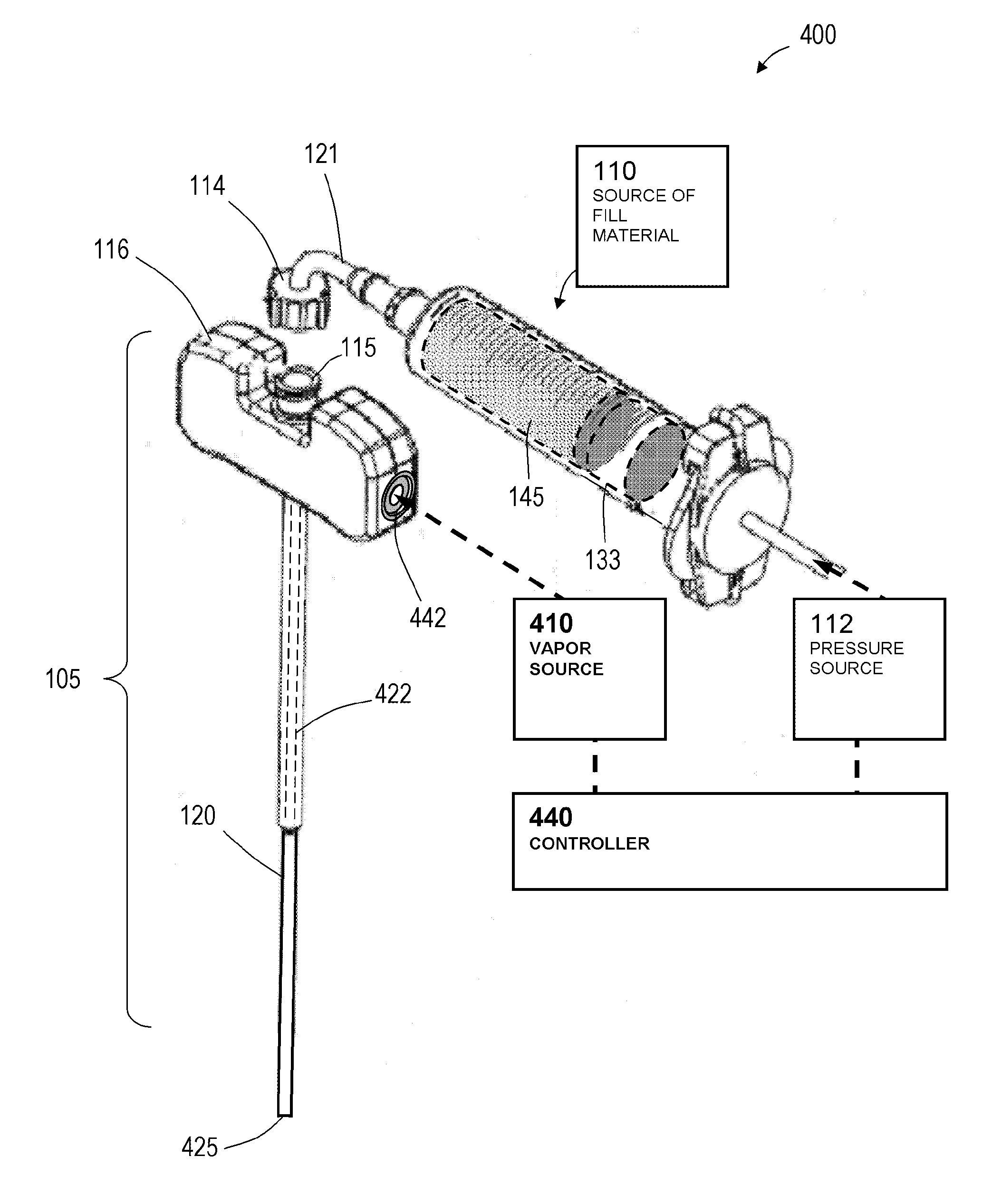

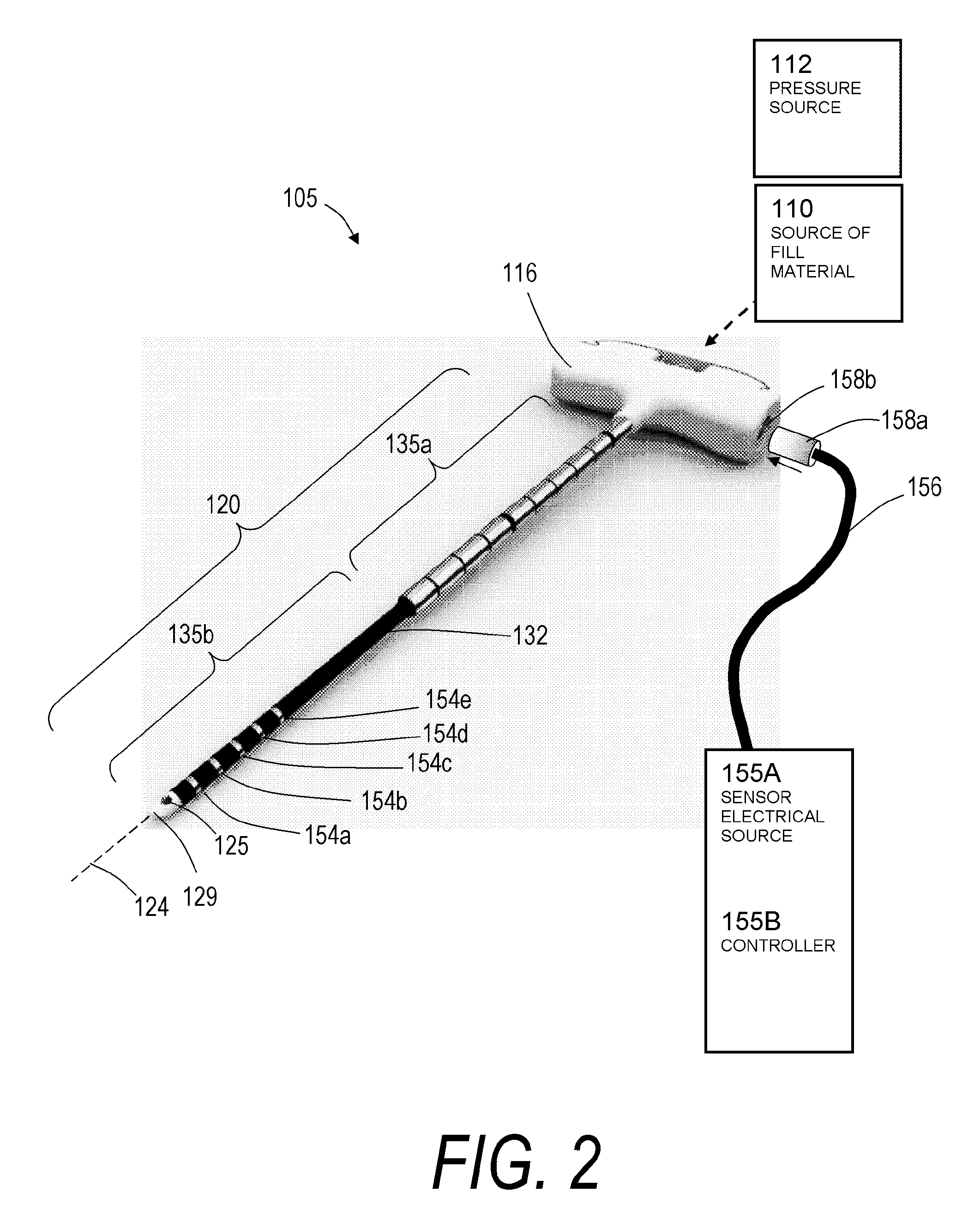

Bone treatment systems and methods

ActiveUS20080154273A1High viscosityInhibit migrationInternal osteosythesisMedical devicesFilling materialsVertebra compression fracture

The present invention relates in certain embodiments to methods, systems, and devices for treating vertebral compression fractures. In one embodiment, a bone cement injector is advanced into bone and injects a bone cement flow through the injector and a vapor flow from at least one vapor outlet in the injector. In another embodiment, the bone treatment system comprises an elongated member having a flow passageway, a bone fill material source, and a vapor source coupleable to the flow passageway. Still another embodiment describes a vapor injection device having an elongated member with a flow passageway, the elongated member configured for insertion into a bone and for delivering a bone fill material through the flow passageway, and having at least one vapor channel in communication with the flow passageway to deliver a vapor into the flow passageway to heat a bone fill material flow.

Owner:DFINE INC

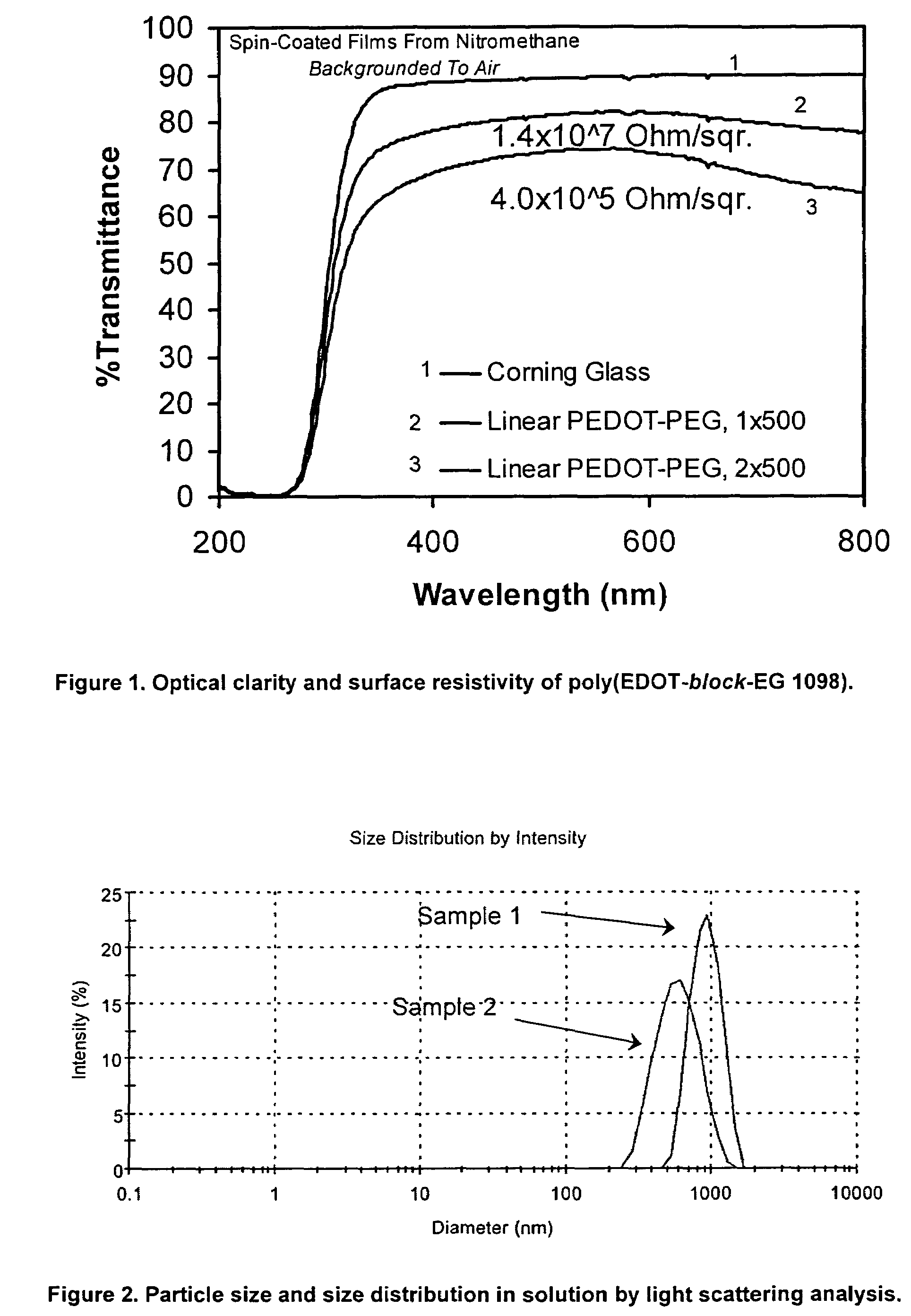

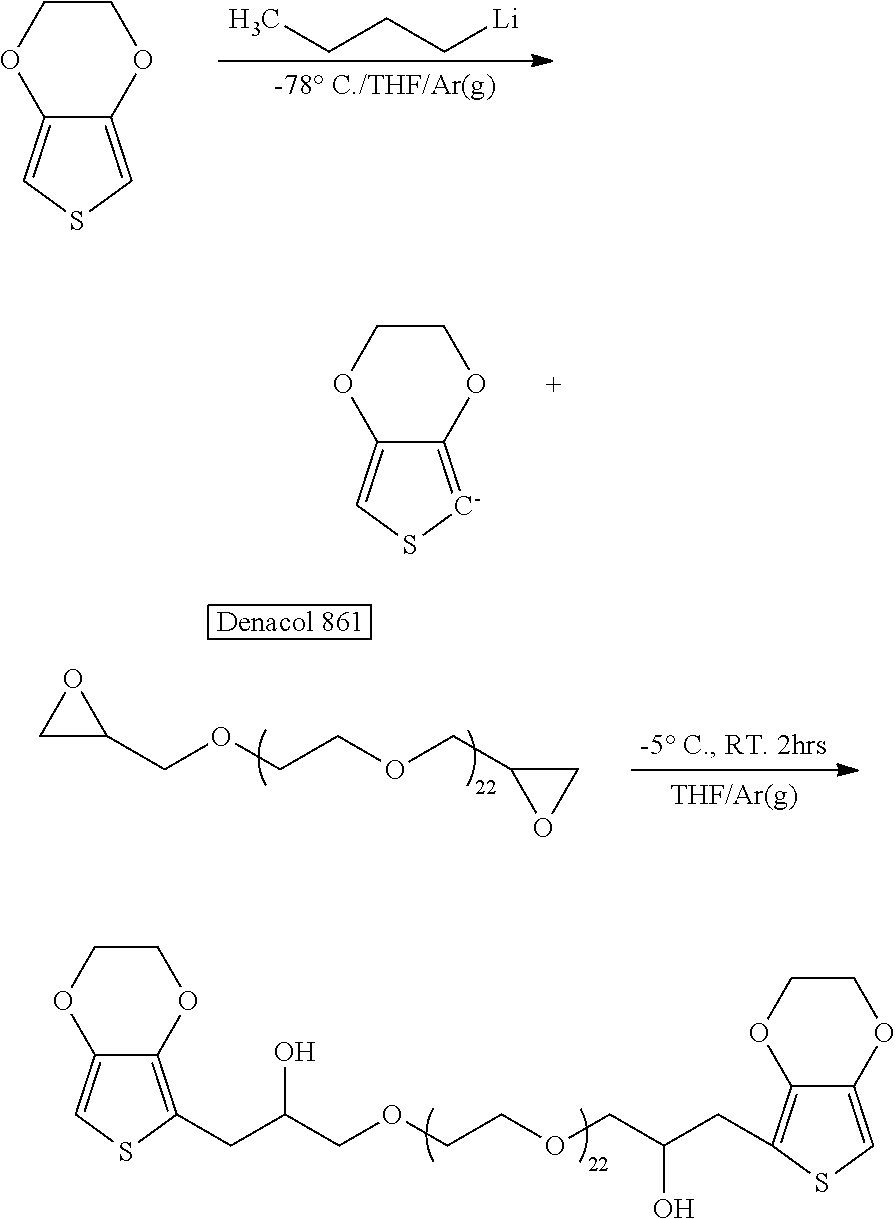

Methods of production, purification, and processing of poly(heteroaromatic) block copolymers with improved solubility or dispersability

This invention relates to improved methods for the preparation, purification, and processing of poly(heteroaromatic) block copolymers, as well as compositions prepared by these methods. Methods relate to preparation of multiblock and triblock copolymers of intrinsically conducting polymers (ICPs) containing at least one block of a poly(heteroaromatic) polymer and at least two blocks of a non-conducting polymer. This invention provides polymer solutions or dispersions of improved stability and better film-forming properties. The poly(heteroaromatic) block copolymers are obtained in their conducting or doped form, and are retained in a solvated, wet form throughout the production and purification processes. Stable solutions or dispersions of the purified copolymers in organic solvents, water, or mixtures thereof are provided. Stable solutions or dispersions of ICPs are useful in the preparation of semiconducting and conducting films, blends, and coatings on a variety of substrates using standard processing and coating techniques.

Owner:TDA RES

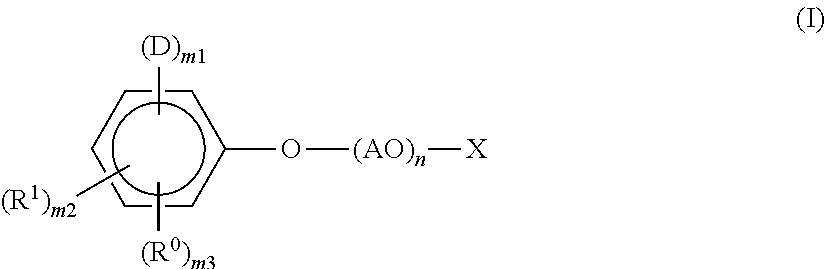

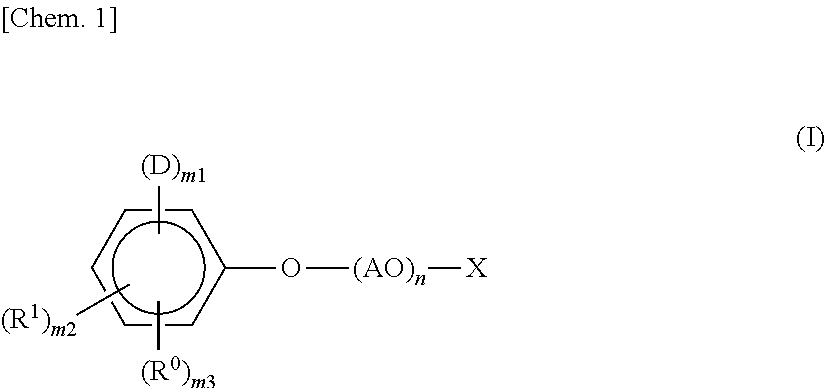

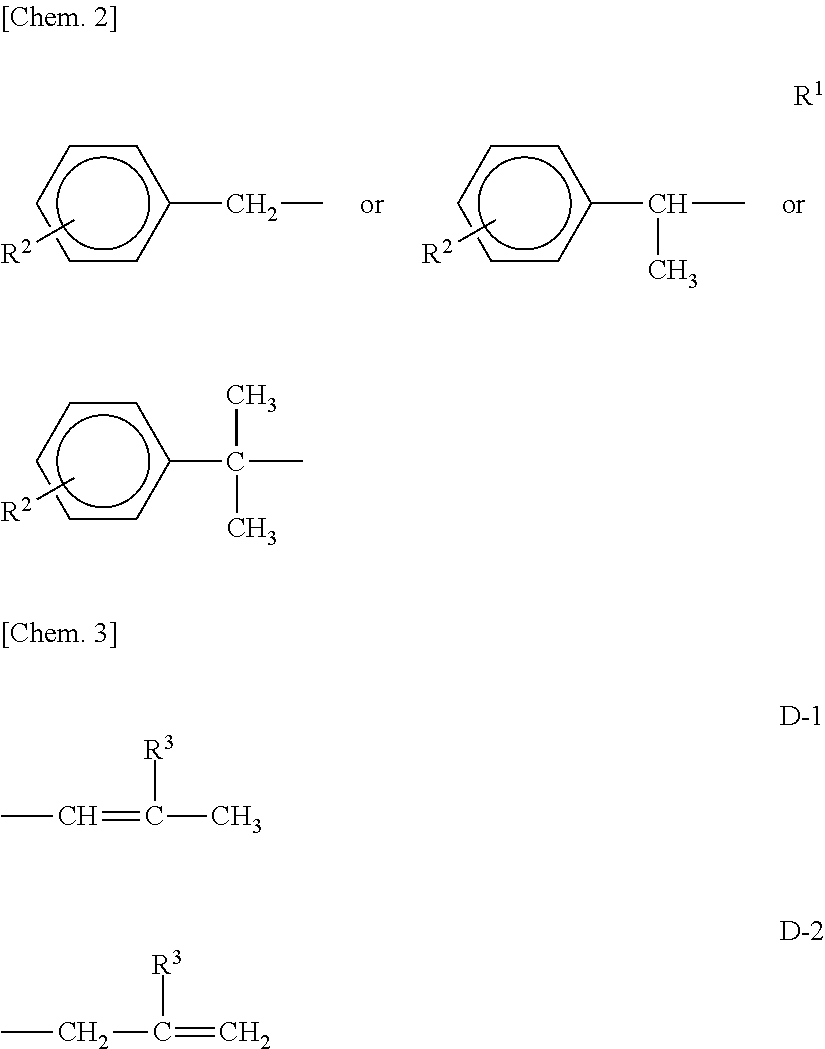

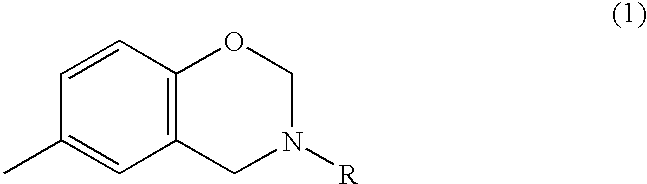

Emulsifier for emulsion polymerization

ActiveUS20140323753A1Accelerating polymerizationImprove polymerizationTransportation and packagingMixingPolymer chemistryEmulsion polymerization

An emulsifier for emulsion polymerization contains a compound represented by the following general formula (I).

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

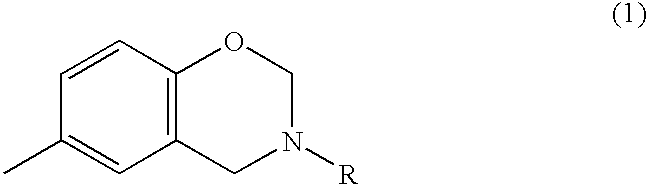

Coating composition containing benzoxazine compound

InactiveUS20030038031A1Improve corrosion resistanceImprove surface smoothnessElectrolysis componentsVolume/mass flow measurementCompound aSolid matter

A novel method for improving the coating film smoothness and a cationic electrodeposition coating composition containing no heavy metal-based rust prevention agents such as lead compounds and capable of forming a coating film with a high corrosion resistance are provided. A coating composition forming a coating film under heating, which comprises, relative to a resin solid matter, 0.5 to 20% by weight of a compound having an N-substituted benzoxazine ring represented by the following general formula (1): in the formula, R is a hydrocarbon group having 1 to 8 carbon atoms.

Owner:NIPPON PAINT CO LTD

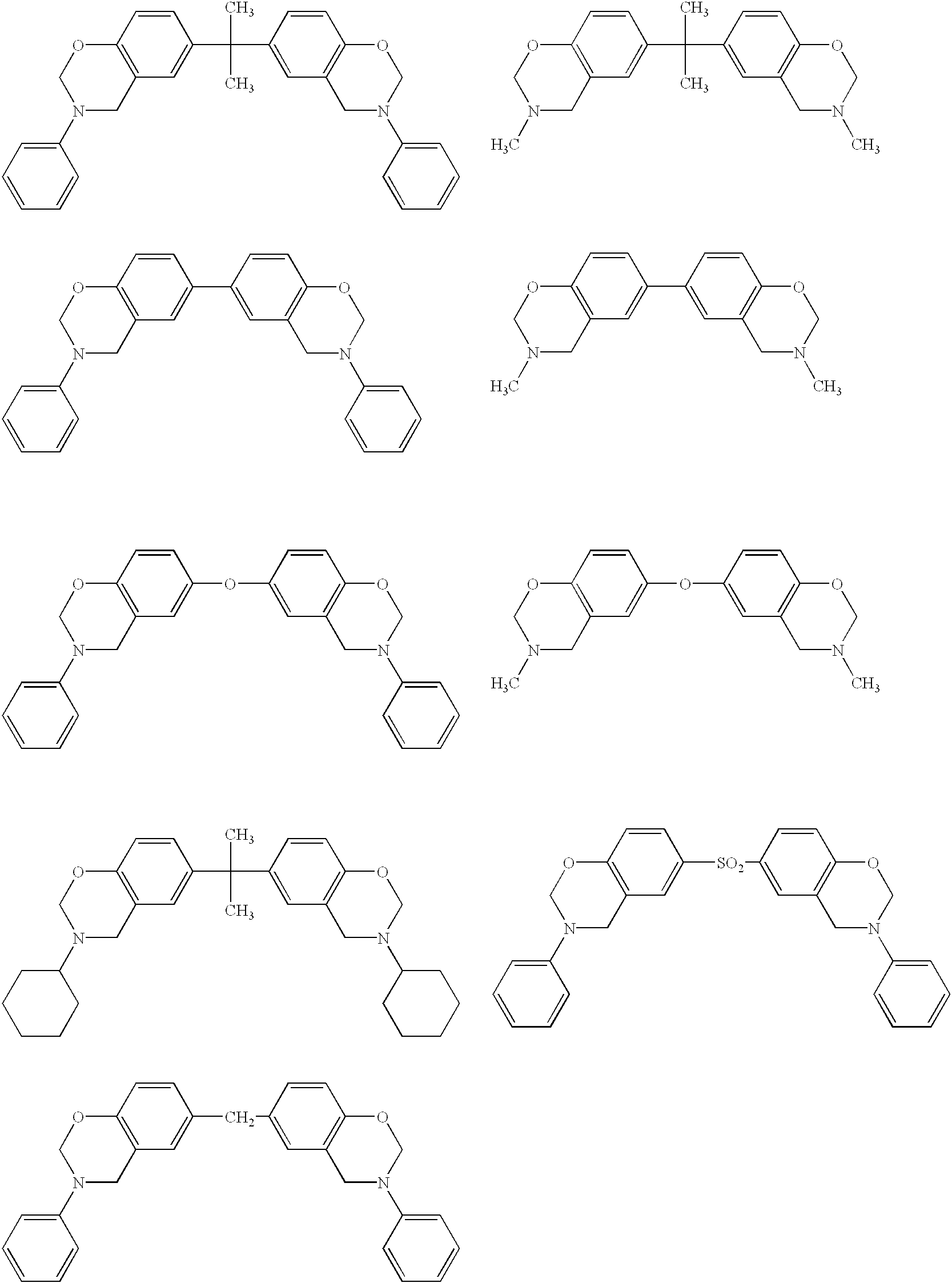

High-purity high-basicity nanoscale PACS flocculating agent and preparation method thereof

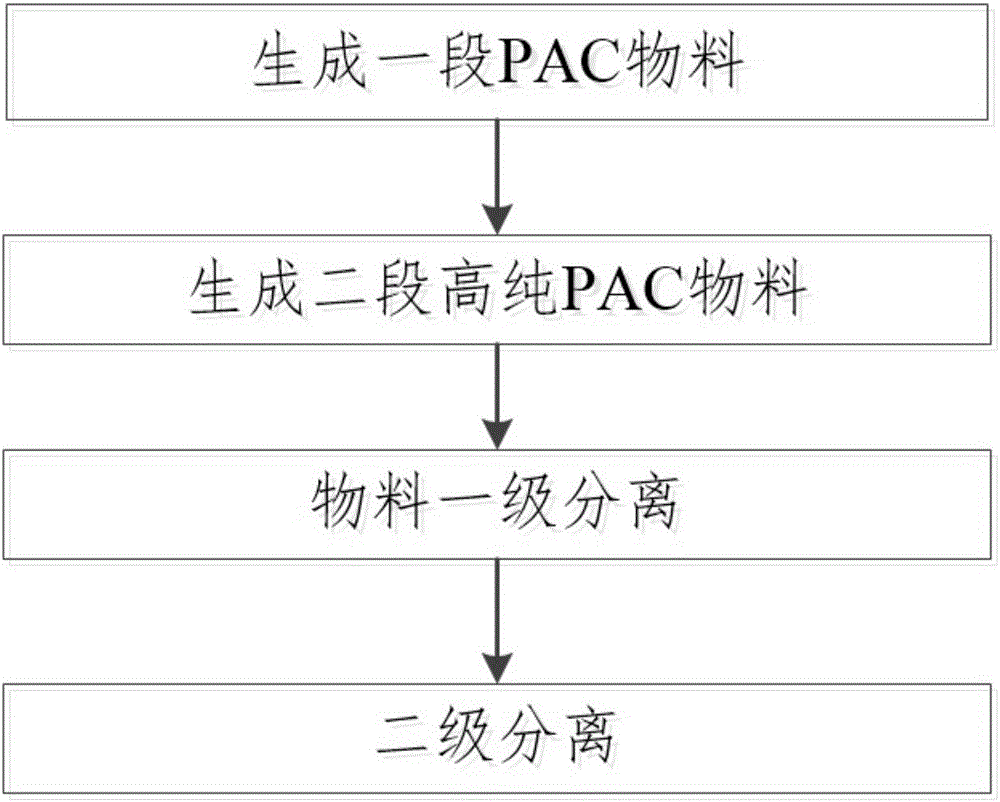

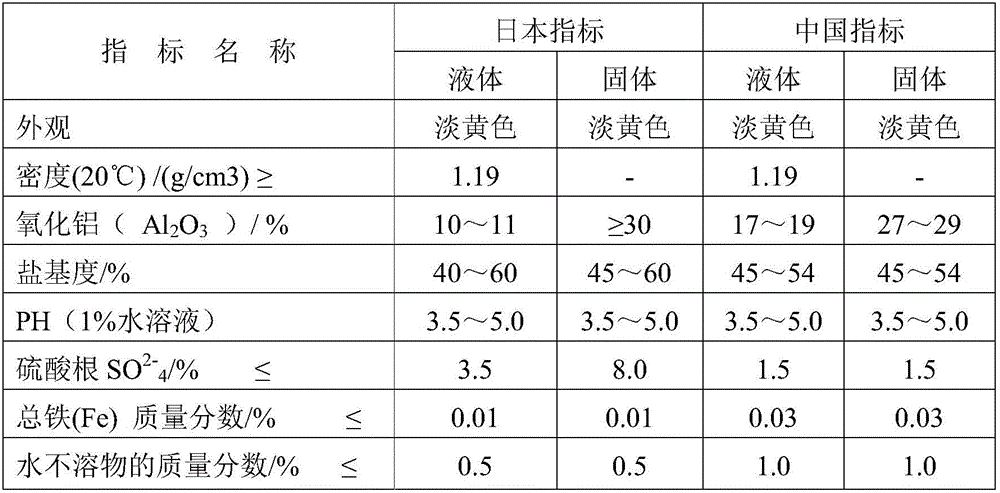

ActiveCN106517463ARaise the basicitySolve the degree of polymerization of hydroxyl groupsAluminium chloridesWater/sewage treatment by flocculation/precipitationPolymerizationHydroxy compound

The invention relates to a preparation method of a high-purity high-basicity nanoscale PACS flocculating agent. The method comprises the following steps: (1) generating a first-stage PAC material; (2) generating a second-stage high-purity PAC material; (3) performing primary separation on the materials; (4) performing secondary separation on the materials. The PACS flocculating agent prepared by the preparation method has a nanoscale crystal structural form, and the hydroxyl polymerization degree and basicity are increased remarkably, so that the organic high molecular weight is increased, and a very good water purifying effect is achieved.

Owner:广西继禹环保科技有限公司

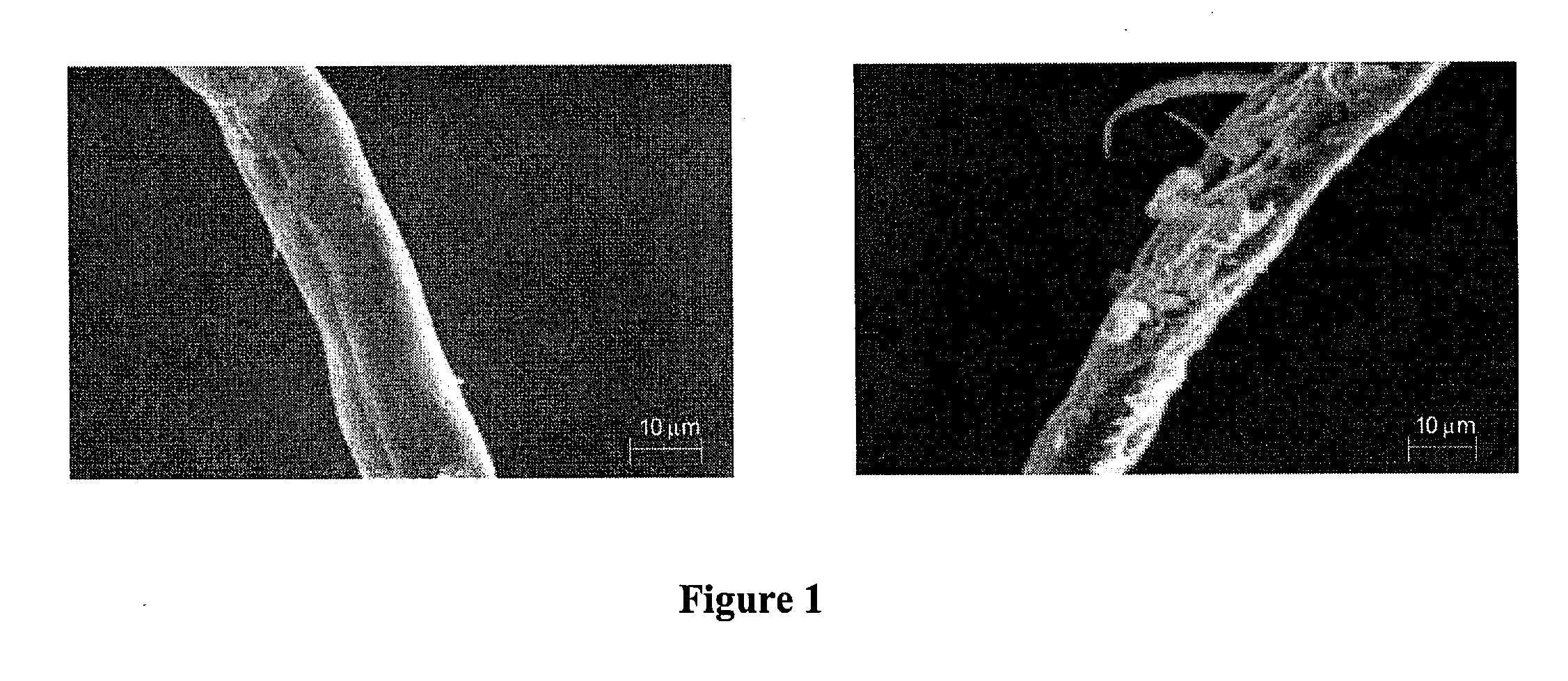

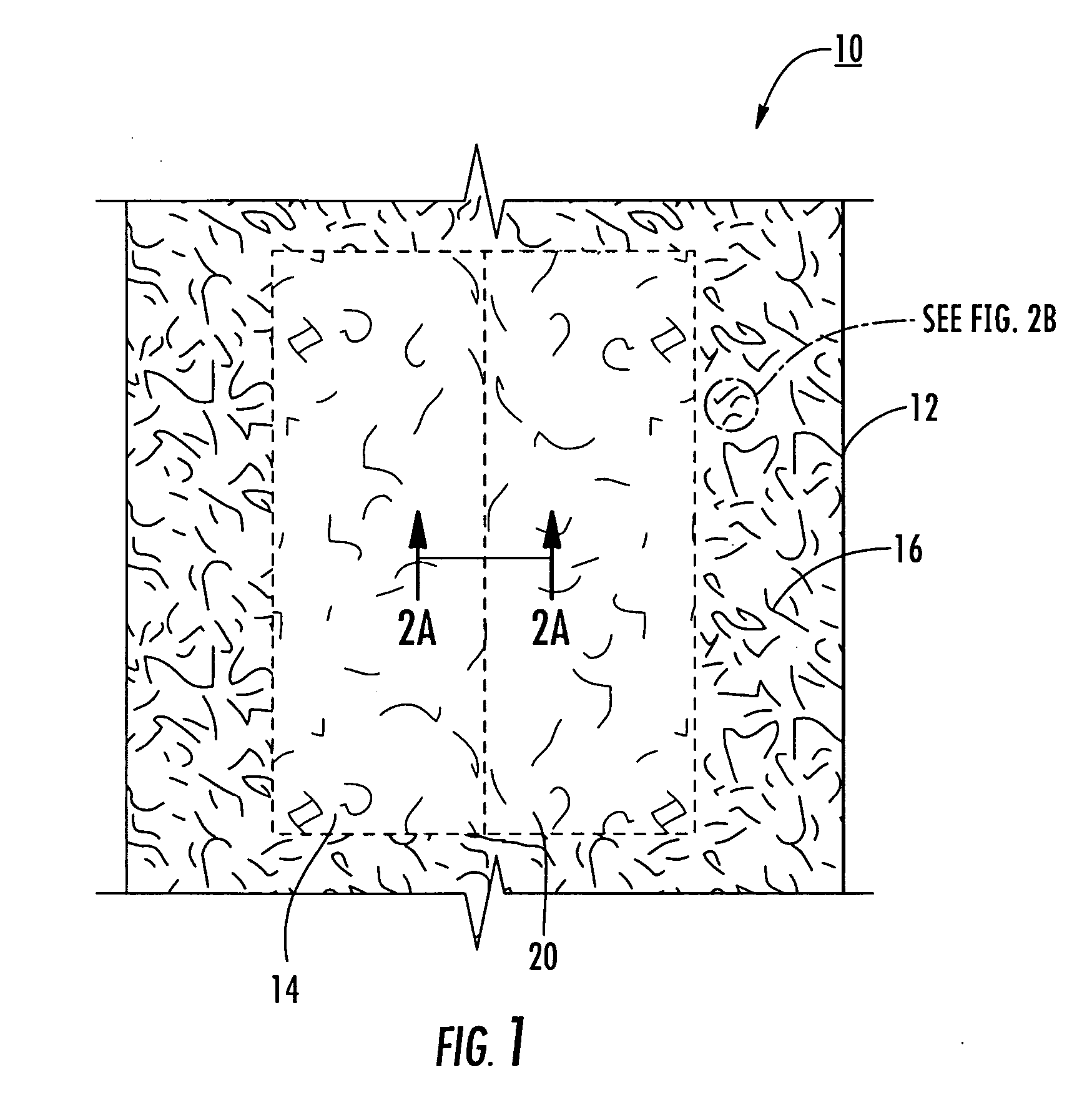

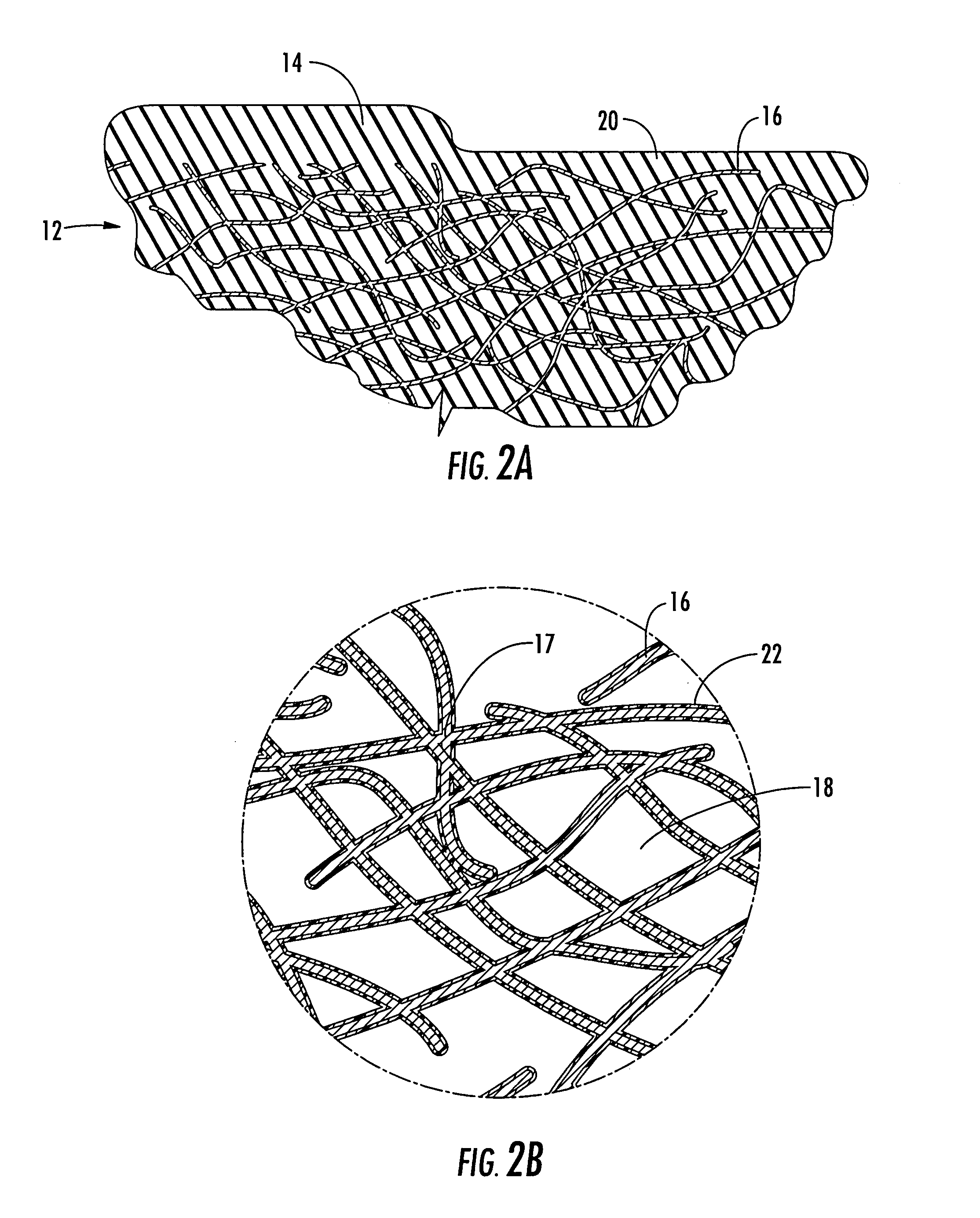

Reinforced elastic fiberous web

InactiveUS20060099871A1Resistant to tearingResistance to deformationFibre treatmentSynthetic resin layered productsFiberCross-link

The present invention is directed to a lubricated reinforced fibrous web having a plurality of fibers. A lubricant layer is cross-linked on the fibers to coat the fibers and to form a point-bearing surface on the fibrous web. The cross-linked lubricant layer imparts extensibility and elasticity to the fibrous web for use in a comfort-coated personal care article.

Owner:KIMBERLY-CLARK WORLDWIDE INC

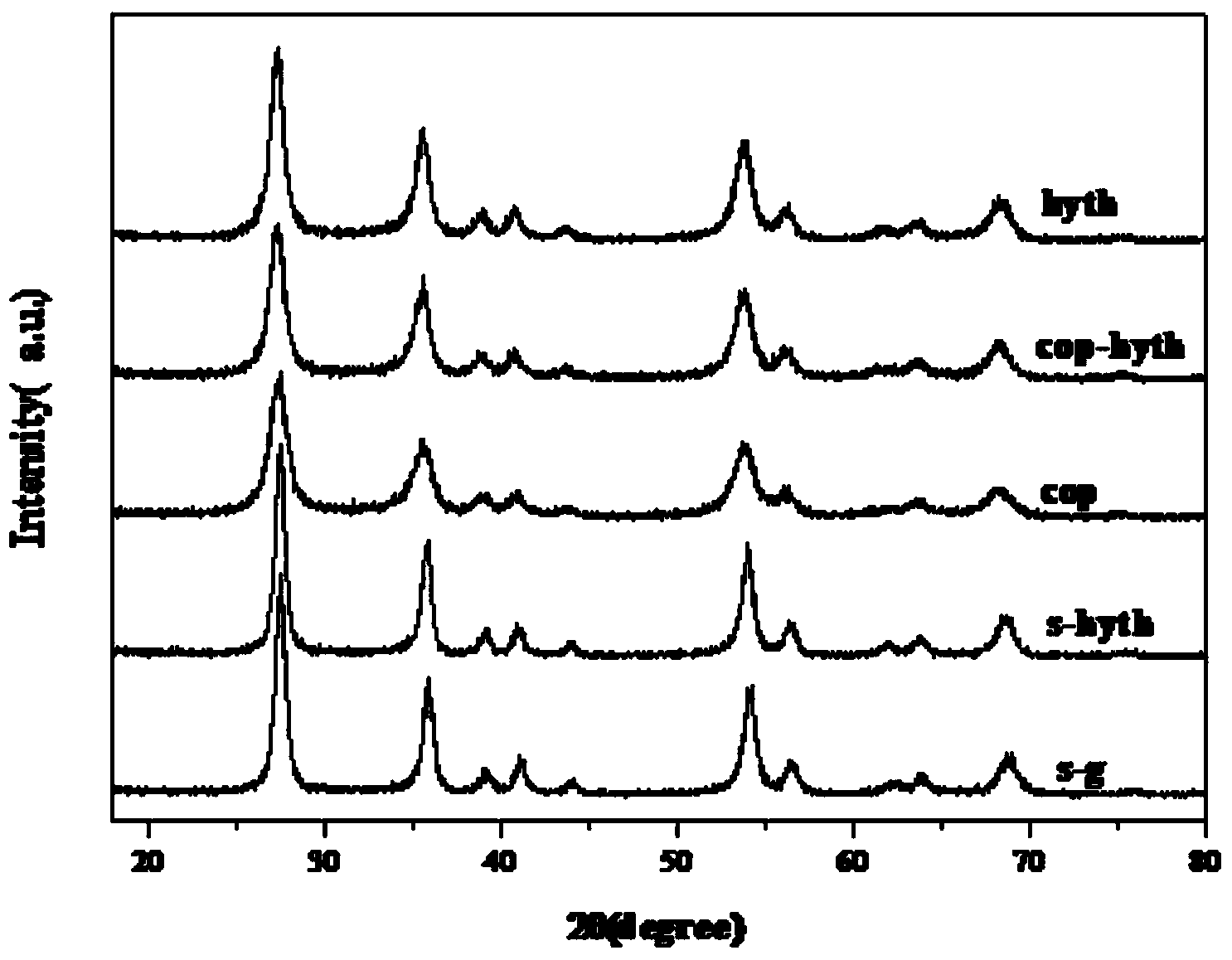

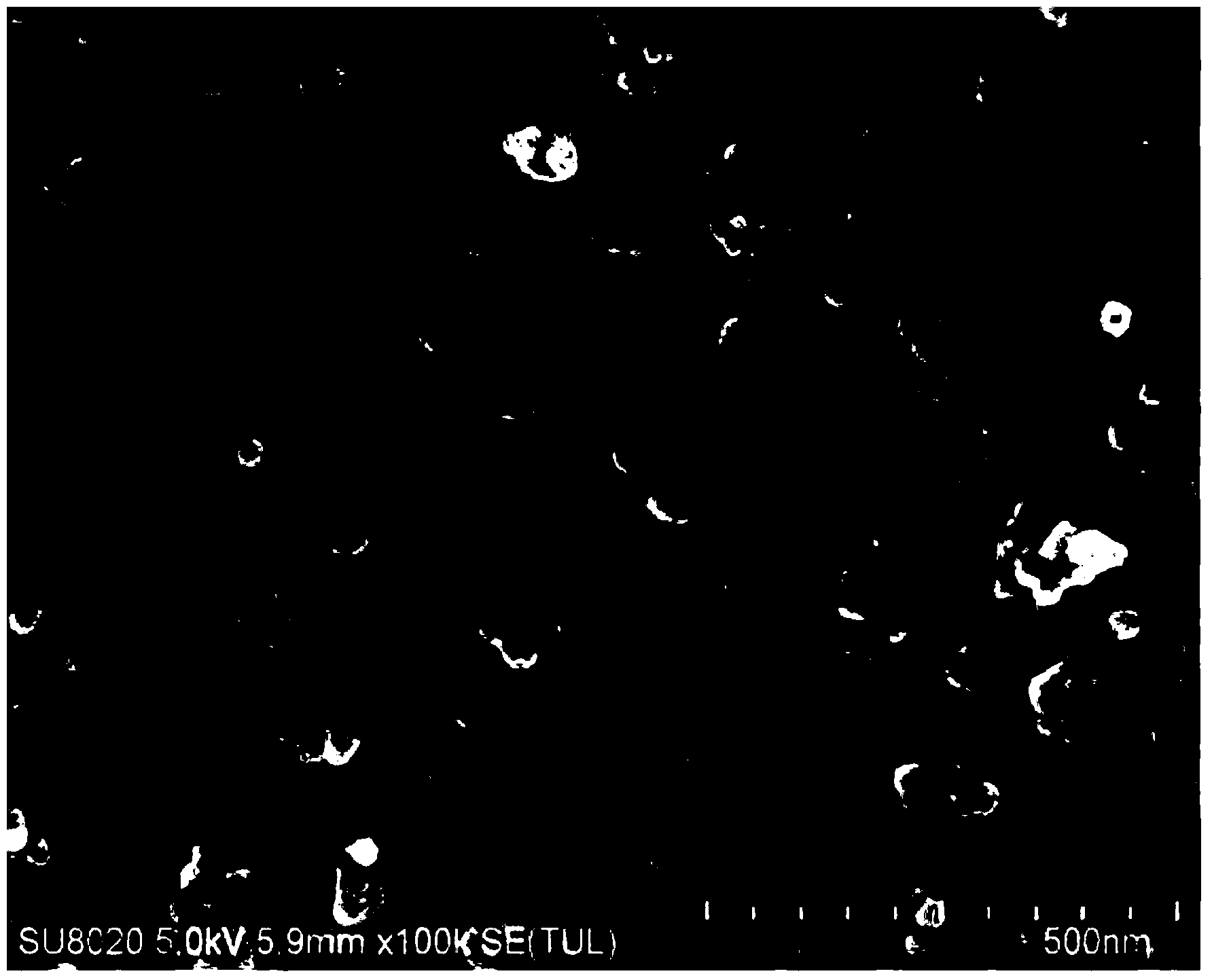

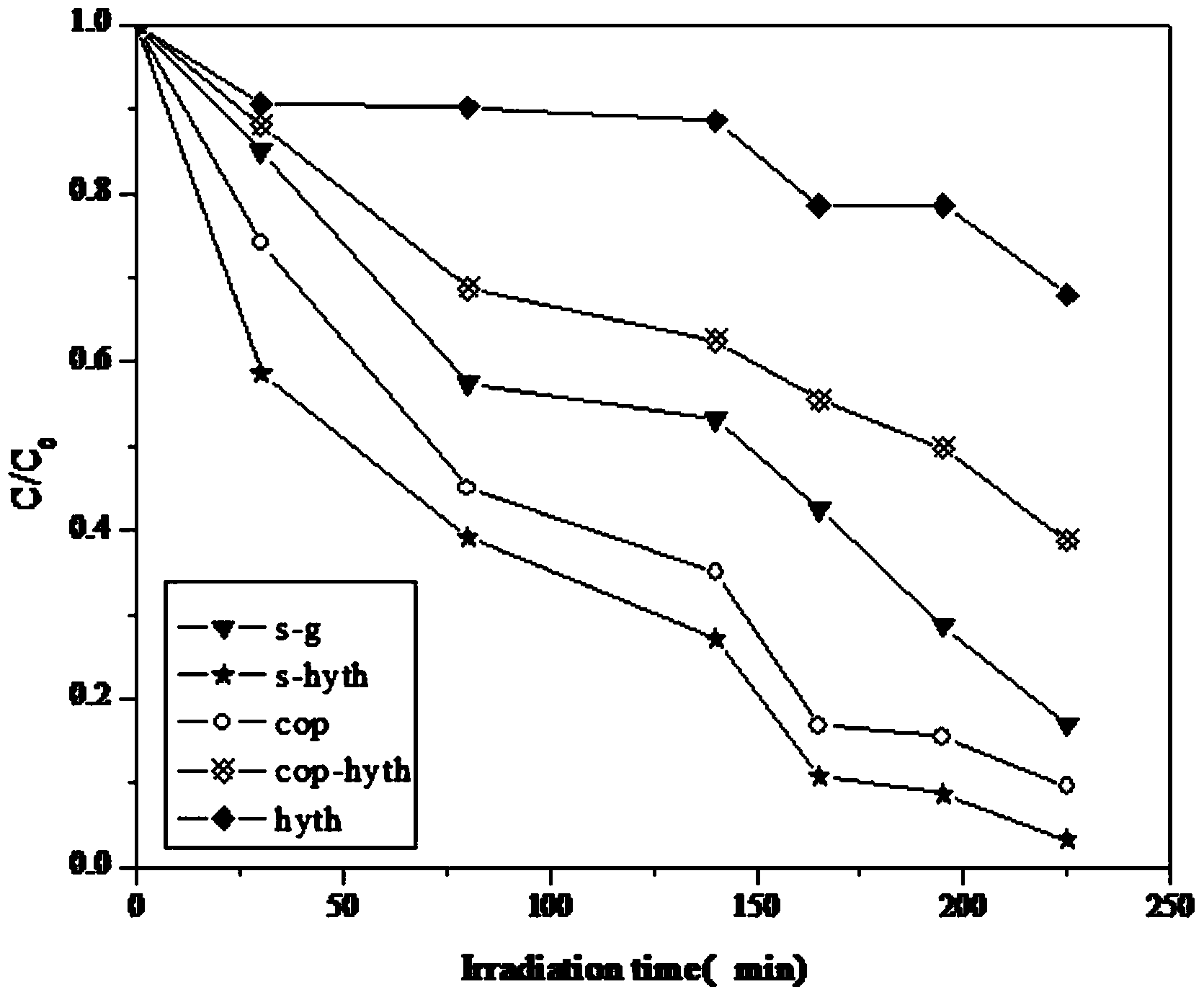

Preparation method of SnO2-TiO2 composite nano photocatalyst

InactiveCN103657628AHigh activityImprove stabilityMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsAcetic acidAlcohol

A preparation method of a SnO2-TiO2 composite nano photocatalyst comprises operation steps as follows: (1), mixing tetrabutyl titanate, absolute ethyl alcohol and glacial acetic acid, adding dilute nitric acid to regulate pH, stirring and adding water; (2) adding a SnCl4*5H2O solution into the mixed solution in a molar ratio of titanium to tin to be 3:1, stirring, and aging for 22-26 h; (3) placing the aged material into an autoclave for treatment for 22-25 h at the temperature of 175-185 DEG C, and cooling the material in the autoclave to the room temperature; and (4) performing centrifugal separation on a product, then drying the product at 95-110 DEG C and roasting the product for 2-6 h to obtain a finished product. The SnO2-TiO2 composite nano photocatalyst prepared with the method has higher purity and activity, good dispersibility, high thermostability and good repeatability; the method does not require addition of a surfactant and the like, so that the cost is lower, and the production cost is reduced greatly; and meanwhile, the production time is shortened to 2-3 d, and further, the operation is simple and safe.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com