Non-Aqueous Electrolyte and Secondary Battery Containing the Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

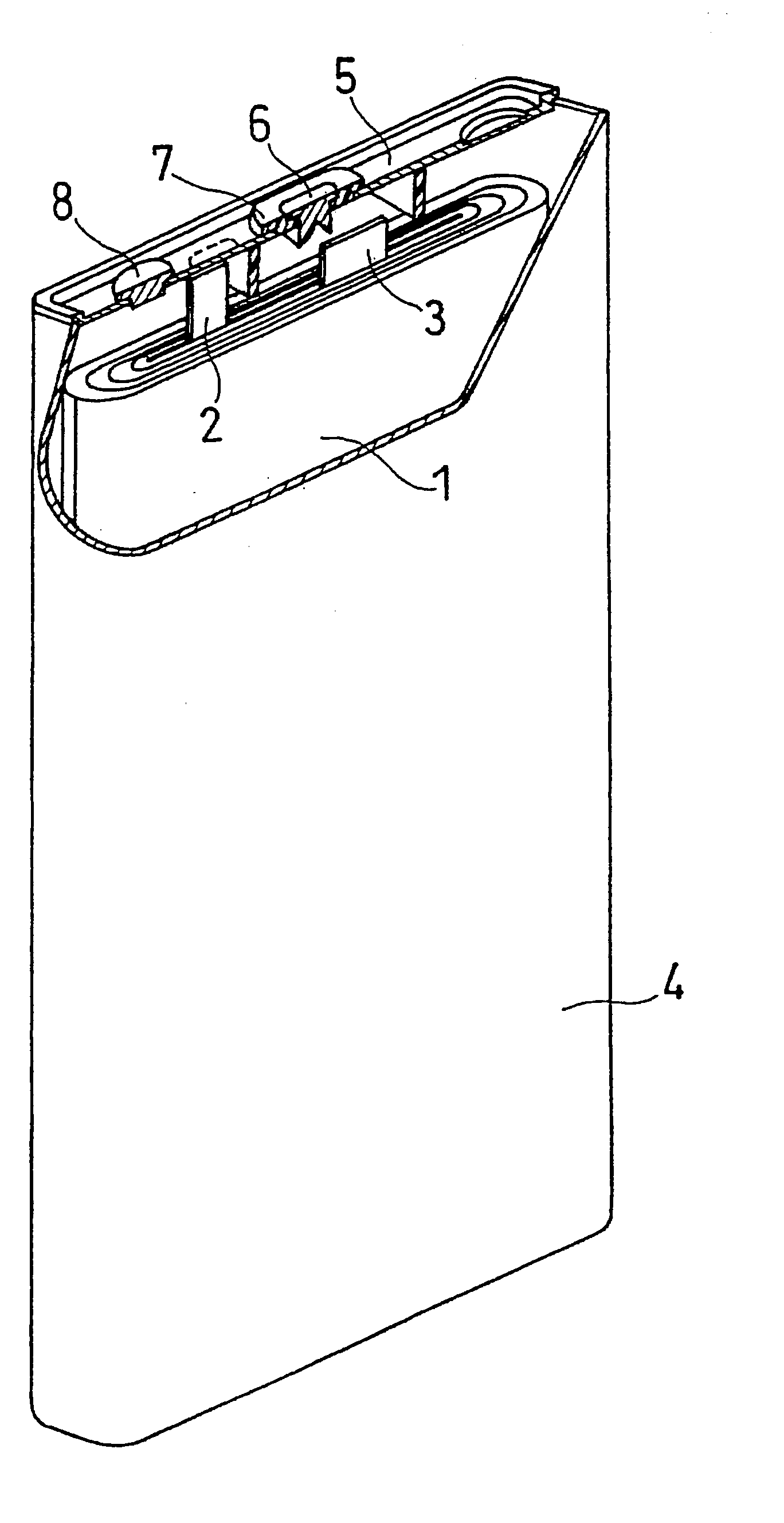

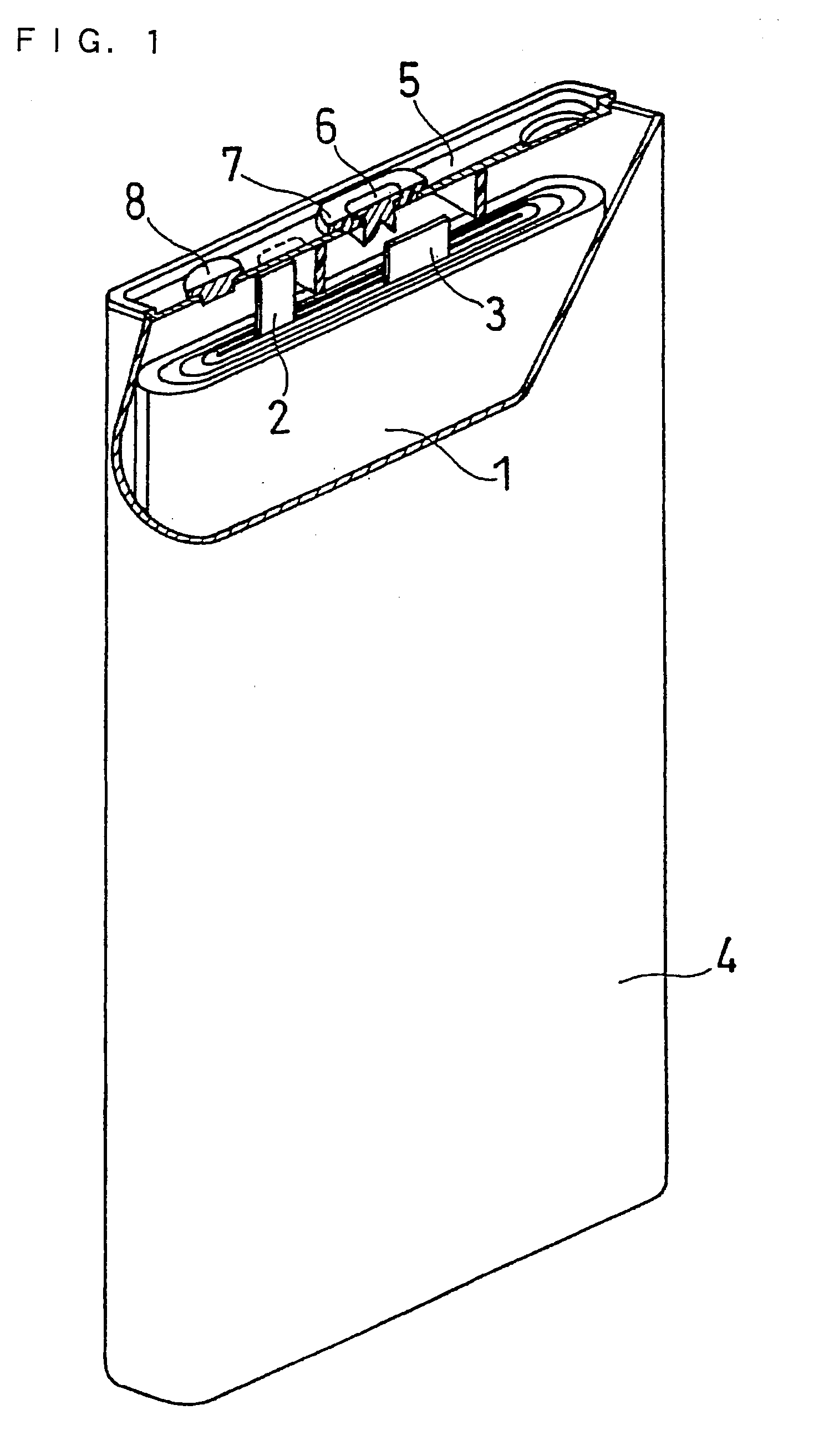

Image

Examples

example 1

[0087] (i) Fabrication of a Positive Electrode Plate

[0088] LiCoO2 (mean particle size 10 μm) serving as a positive electrode active material, carbon black serving as a conductive agent, and polyvinylidene fluoride (PVdF) serving as a binder were blended at a mass ratio of 100:3:4, then kneaded with an appropriate amount of N-methyl-2-pyrrolidone (NMP) to give a positive electrode material mixture paste.

[0089] The positive electrode material mixture paste was applied on both faces of a positive electrode current collector formed of an aluminum foil having a thickness of 30 μm by means of a doctor blade method so that a thickness after drying became approximately 230 μm. Then the current collector with paste was pressed so that a dry coating membrane had a thickness of 180 μm, and was cut into a predetermined size to obtain a positive electrode plate. To the positive electrode plate, a positive electrode lead made of aluminum was welded.

[0090] (ii) Fabrication of a Negative Electro...

example 2

[0108] A rectangular lithium ion secondary battery was fabricated in the same manner as in Example 1 except that the content of the hydrogenated m-terphenyl in the non-aqueous electrolyte was changed to 0.2 mass %.

example 3

[0109] A rectangular lithium ion secondary battery was fabricated in the same manner as in Example 1 except that the content of the hydrogenated m-terphenyl in the non-aqueous electrolyte was changed to 0.5 mass %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com