Patents

Literature

108results about "PH-change processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

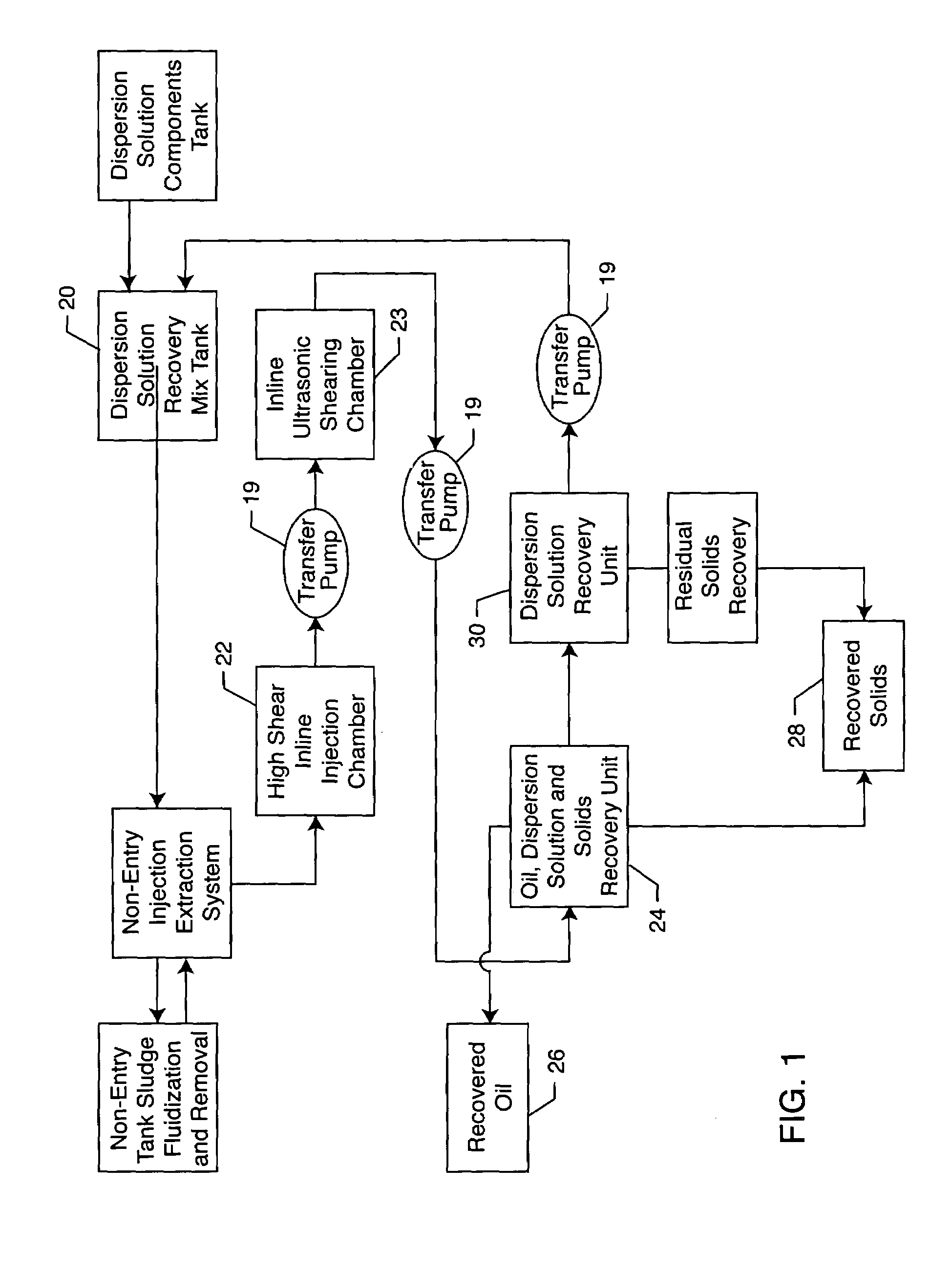

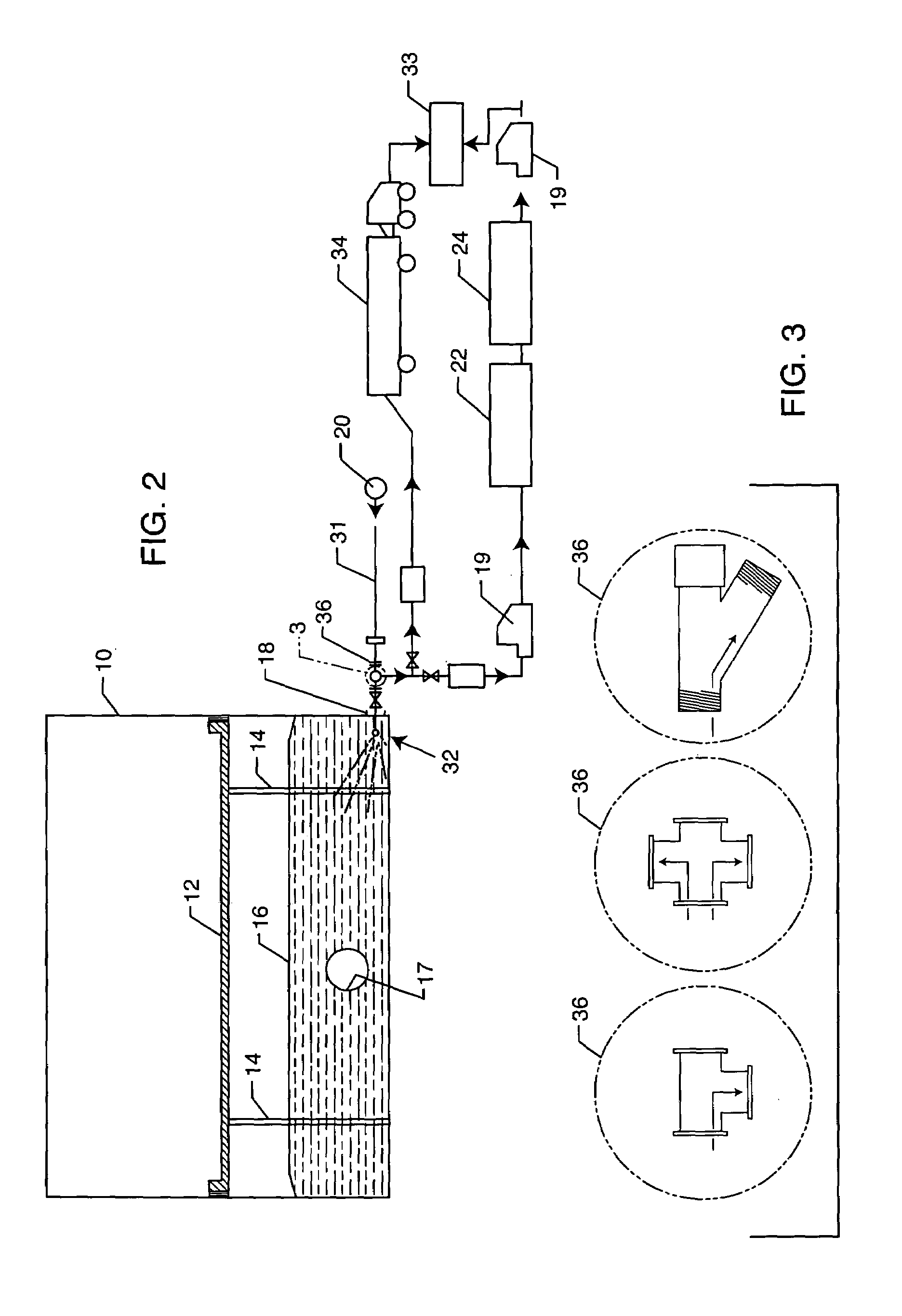

Petroleum recovery and cleaning system and process

InactiveUS20050161372A1Enhancing petroleum recoveryIncrease productionInorganic/elemental detergent compounding agentsLiquid separation auxillary apparatusProcess equipmentPetroleum product

Owner:AQUA TECH LLC

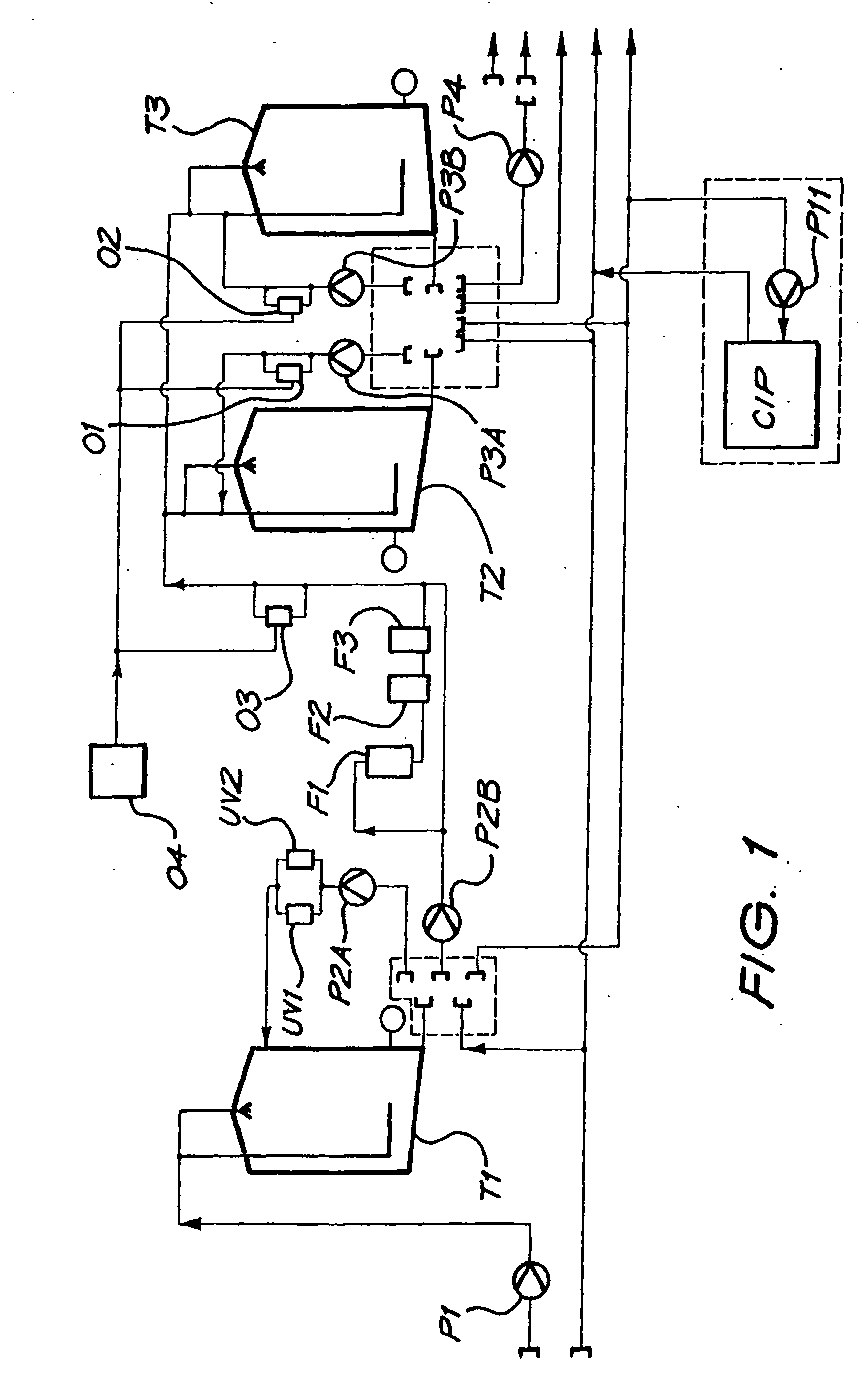

Process and appratus for use in preparing an aqueous magnesium bicarbonate solution

InactiveUS20050255174A1Rate of dissolutionFast dissolutionBiocideMagnesium carbonatesDissolutionMagnesium bicarbonate

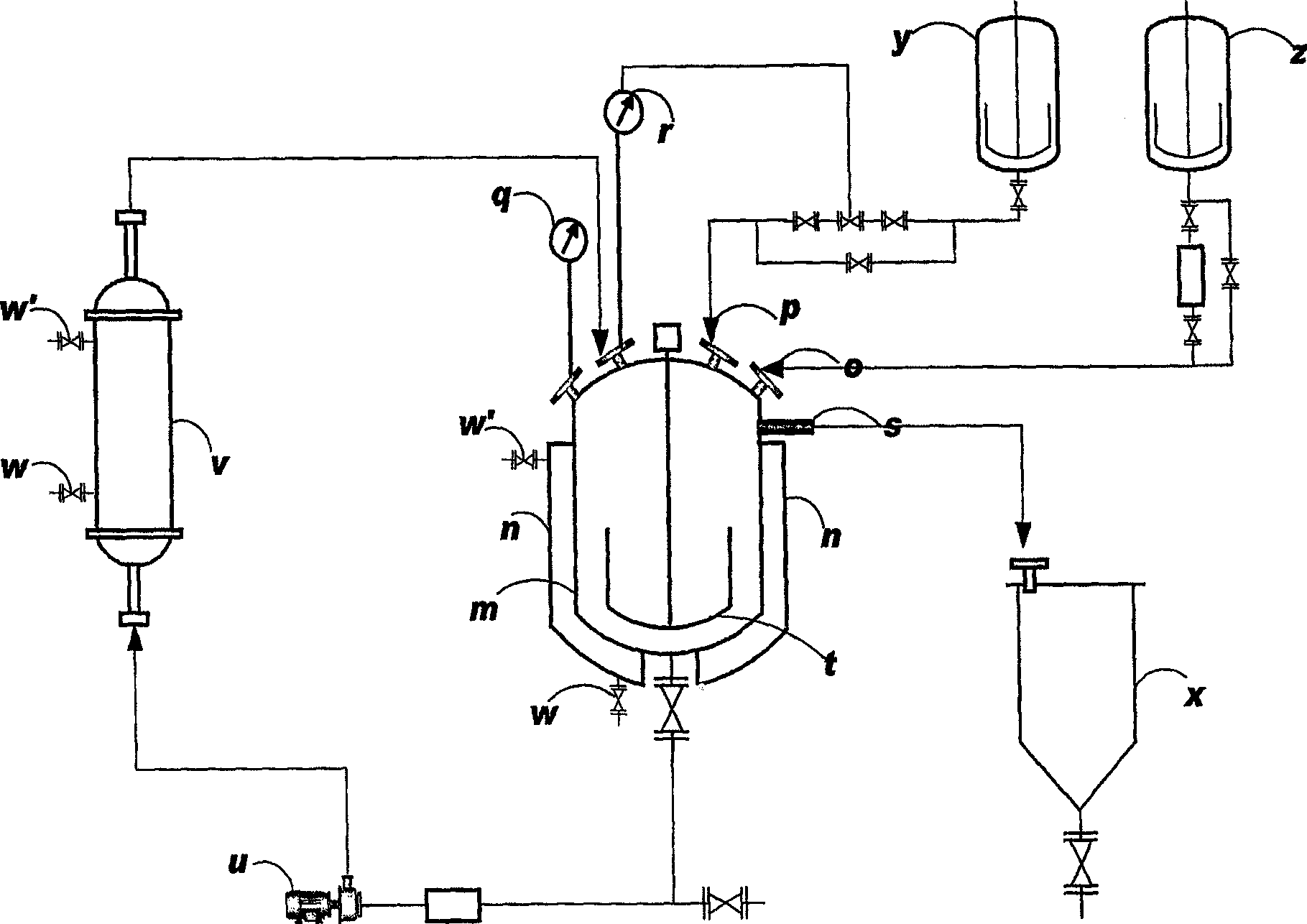

A method and an apparatus for preparing a substantially clear aqueous solution containing magnesium bicarbonate are disclosed. One method of preparing a substantially clear aqueous solution containing magnesium bicarbonate, includes contacting, with species resulting from the dissolution of carbon dioxide in water, an aqueous suspension of magnesium carbonate, at suitable conditions of pressure and temperature, so as to obtain an aqueous solution of magnesium bicarbonate and controlling the pH of the said solution so that, after reaction of the said species with the magnesium carbonate, the final pH falls within a range of from about 8.0 to about 8.8. One apparatus suitable for preparing an aqueous solution of magnesium bicarbonate, comprises means for contacting, with species resulting from the dissolution of carbon dioxide in water, a suspension of powdered magnesium carbonate in water so as to form an aqueous solution of magnesium bicarbonate and means for controlling the pH of the solution between about 7 and about 9 by adjusting the amount of at least one of the said species and said powdered magnesium carbonate that is contacted with the other.

Owner:SHELLEY ARTHUR +2

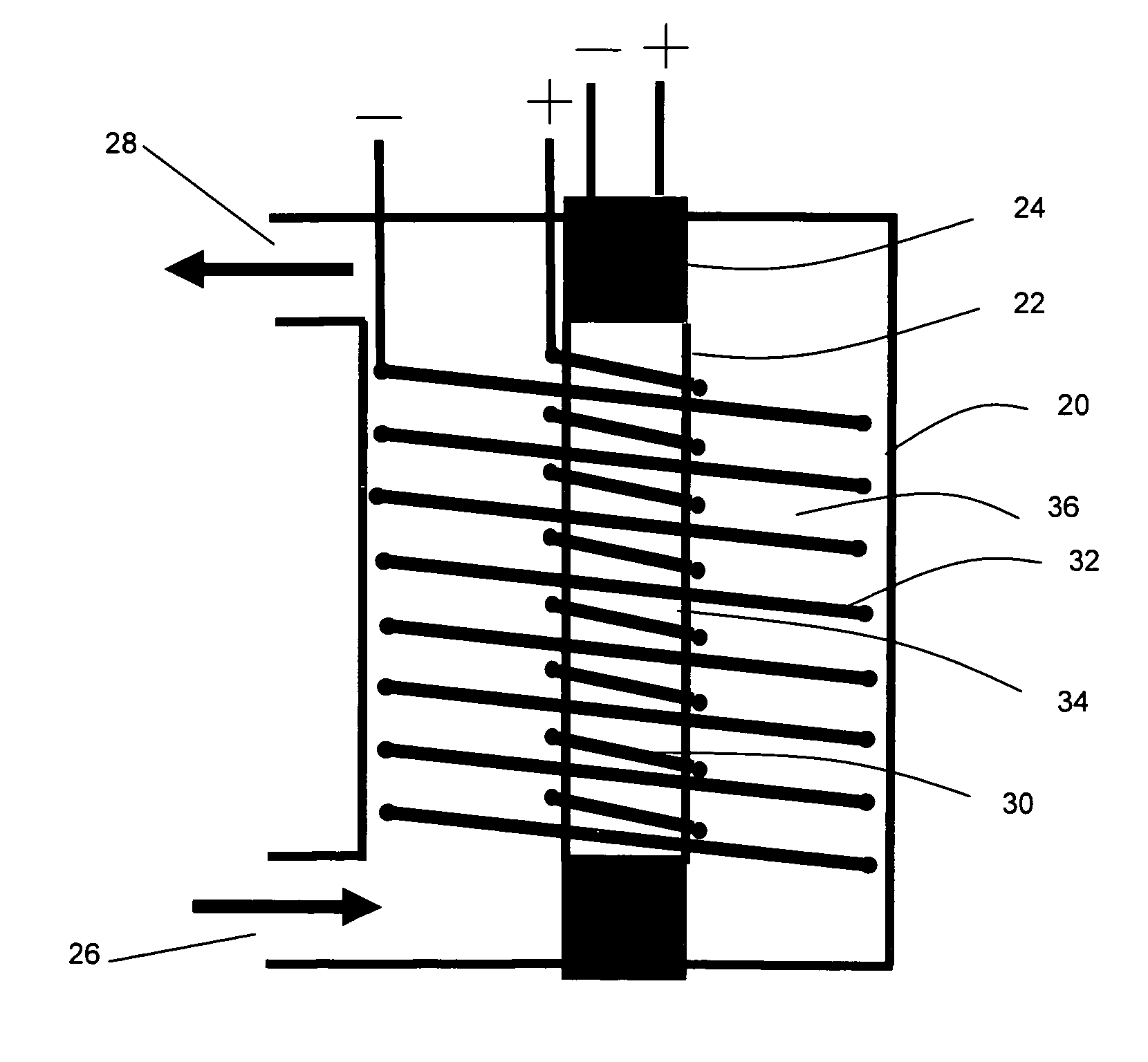

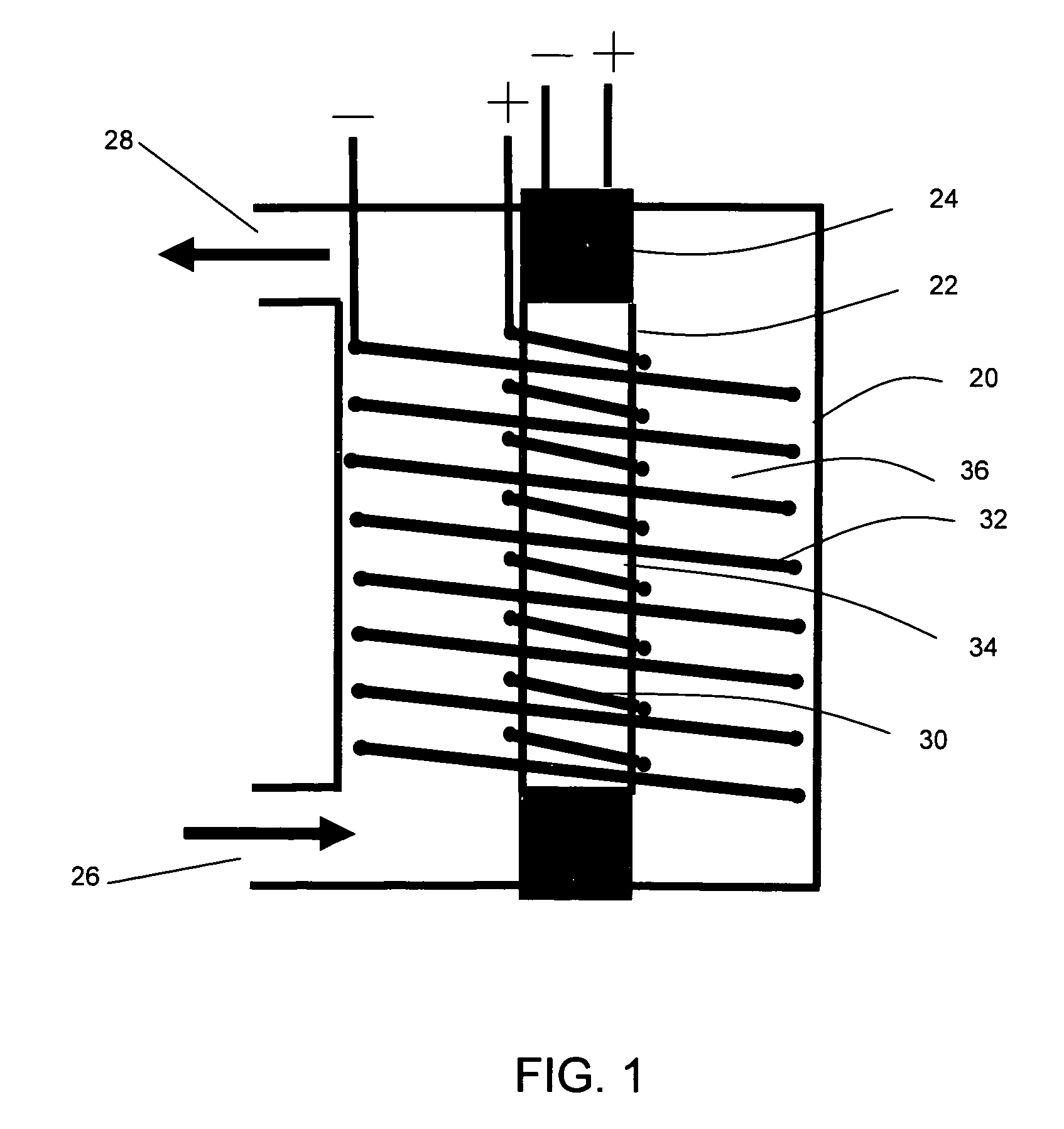

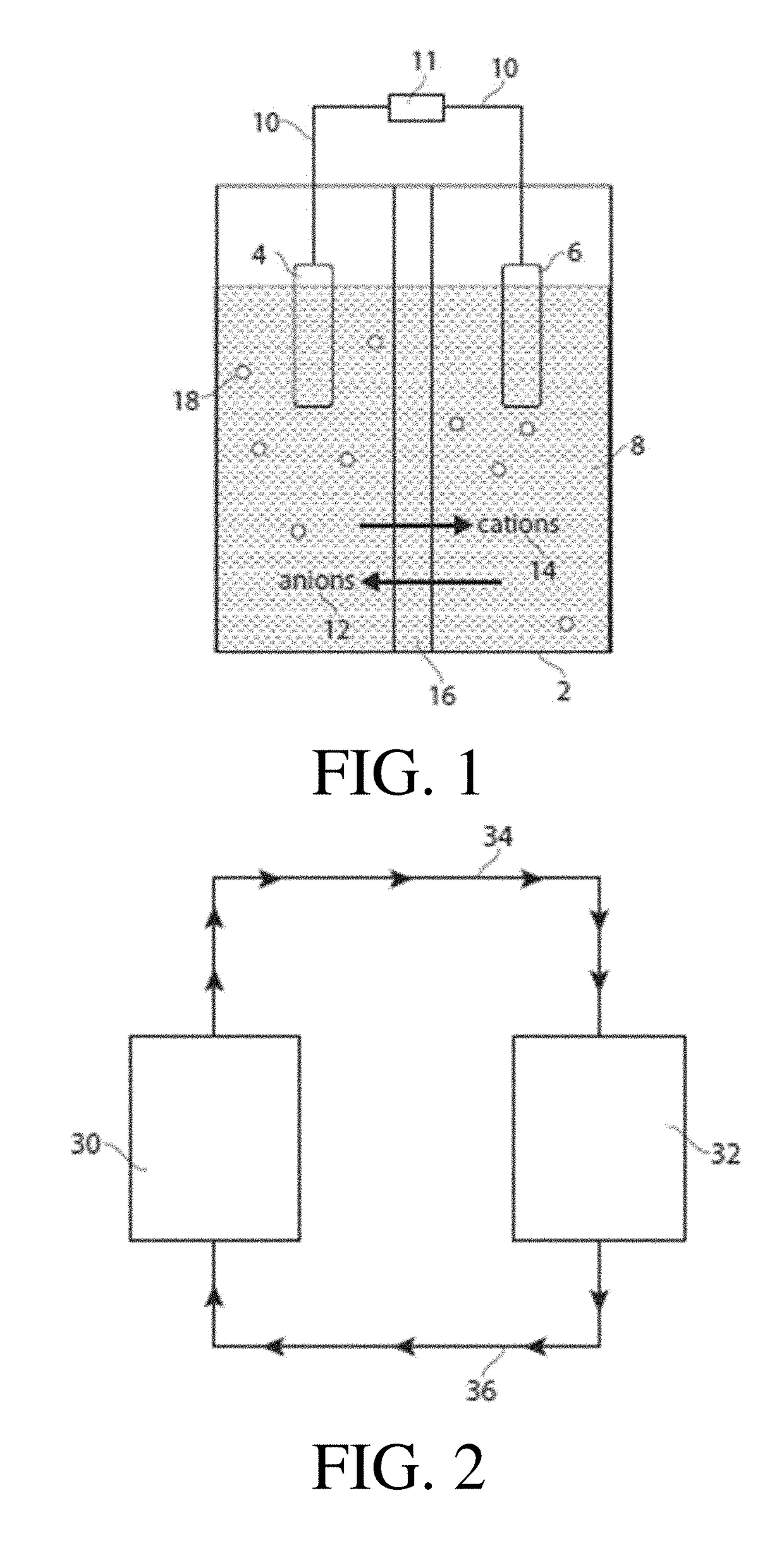

Method and apparatus for scale and biofilm control

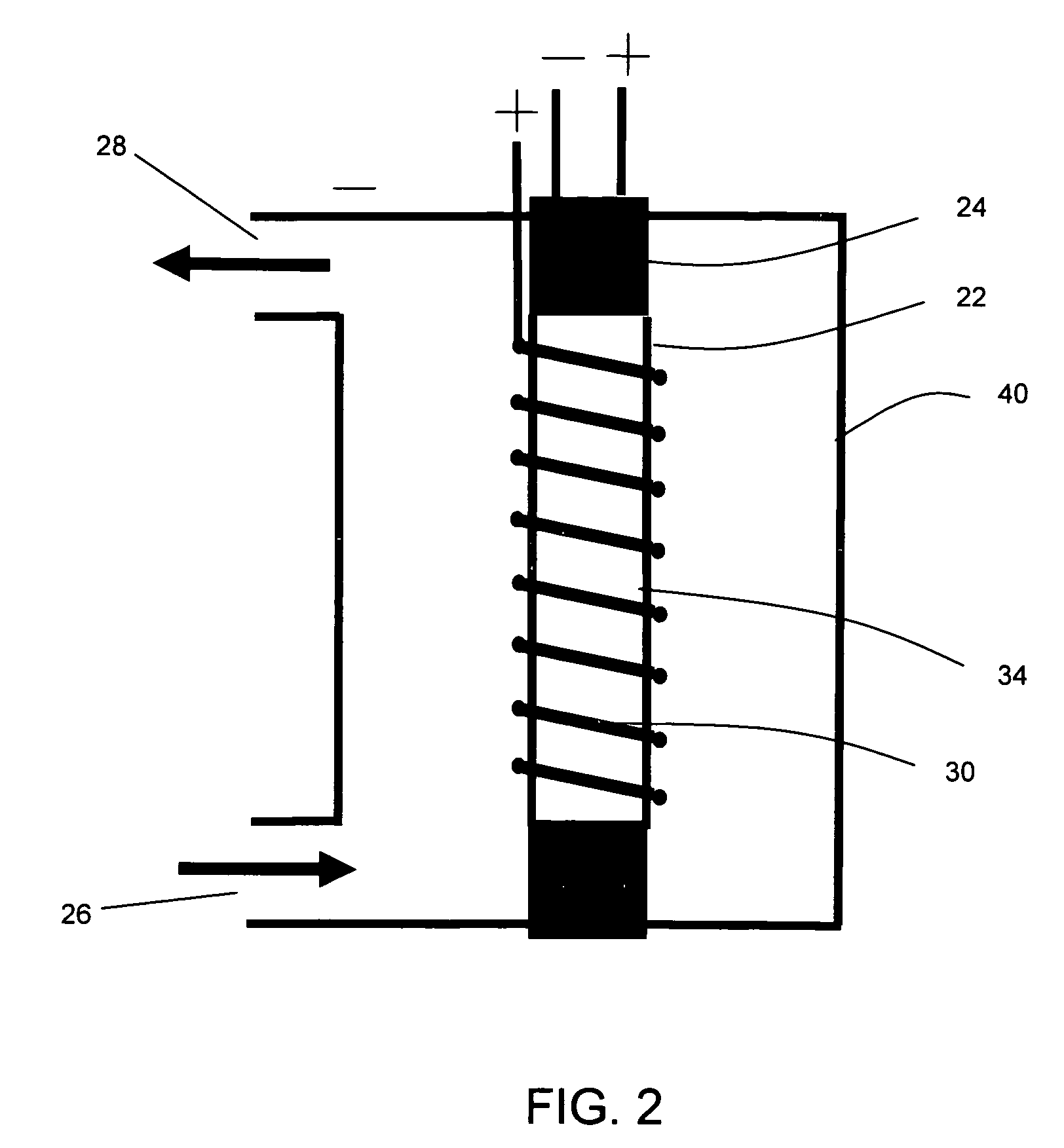

InactiveUS7326330B2Avoid formingSignificant laborFrom normal temperature solutionsElectrolysis componentsBiological membraneQuartz

Method and apparatus for electrolytically controlling the formation of scale and biofilm in water purification and other systems. An anode is deposited on or disposed on or adjacent to a surface, such as that of a quartz UV tube, providing a low pH environment which inhibits the formation of carbonate scale and biofilm.

Owner:ABQ UV POLLUTION SOLUTIONS +1

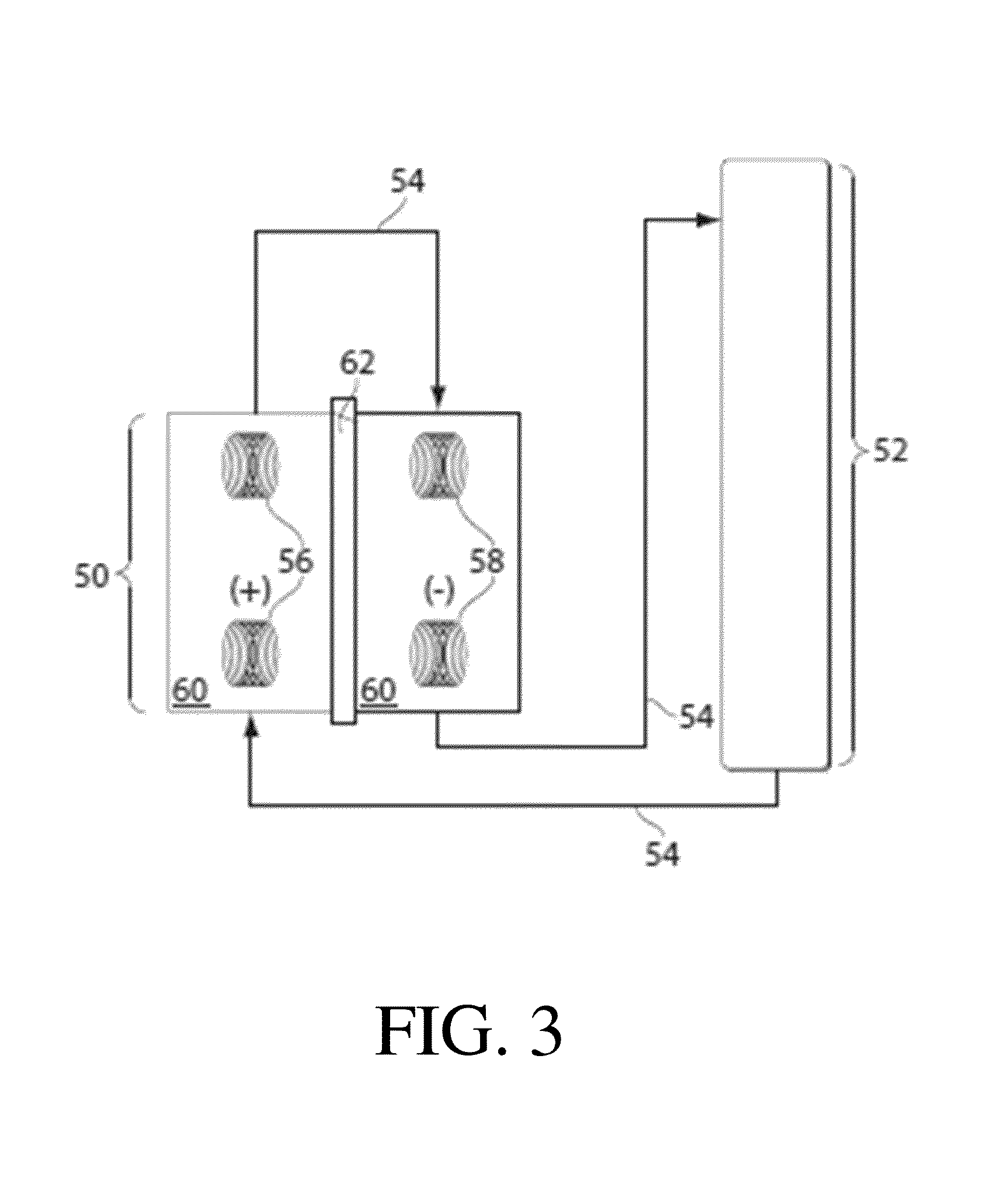

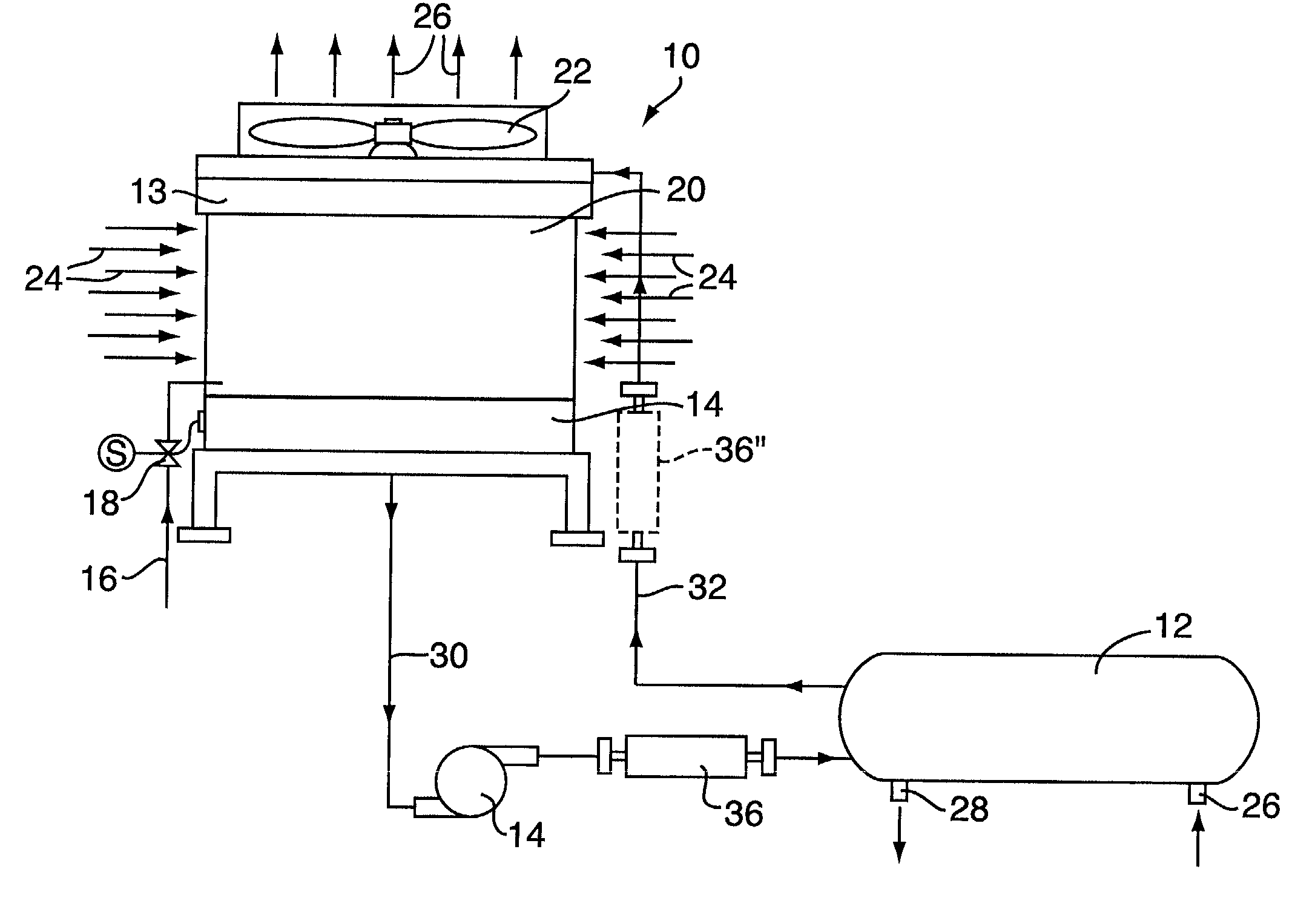

Process of forming an oxidizing agent in liquid by use of ringing magnetic flux

InactiveUS6641739B2Avoid depositionReduce the populationLiquid separation auxillary apparatusLiquid separation by electricityMagnetic fluxOxidizing agent

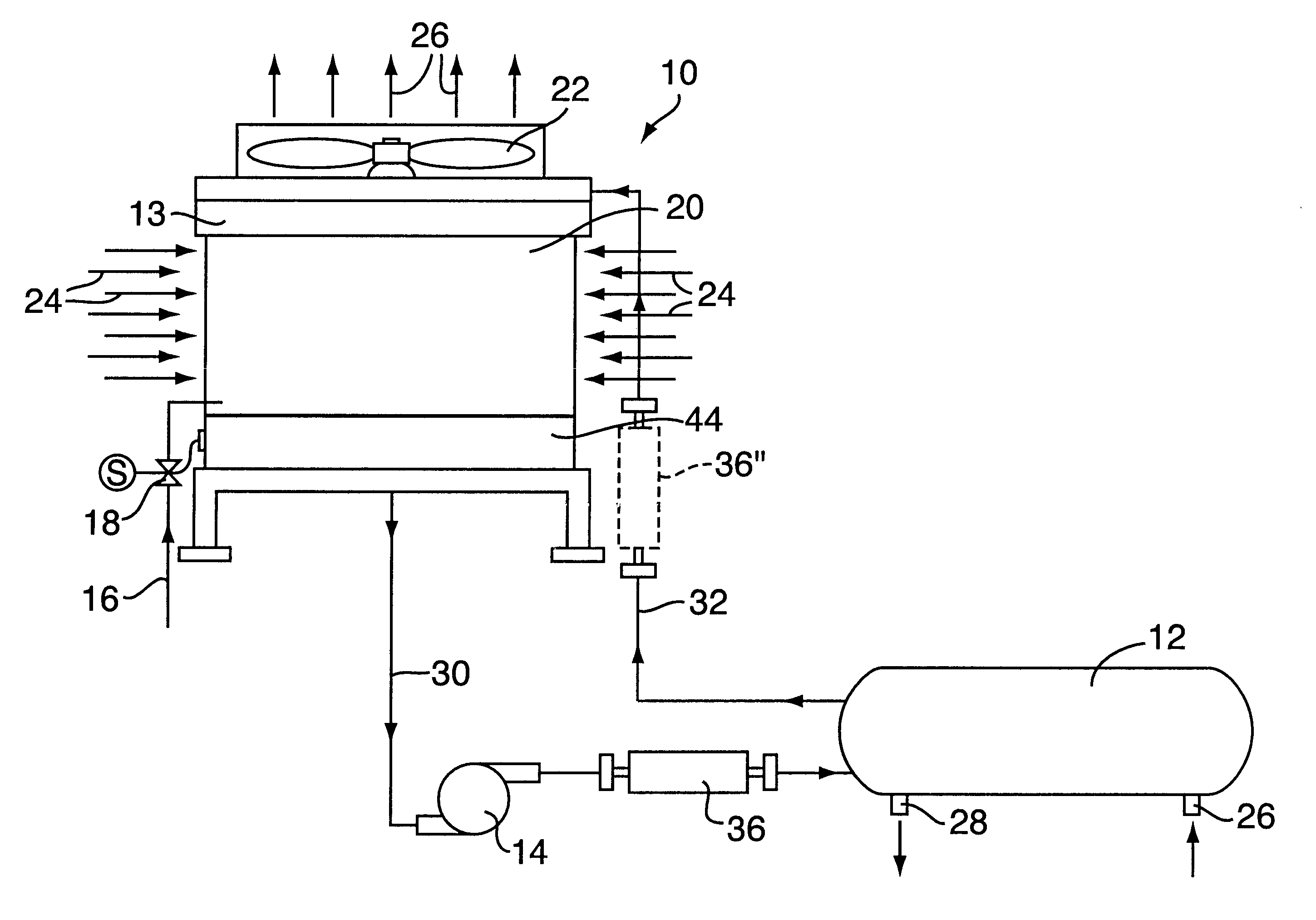

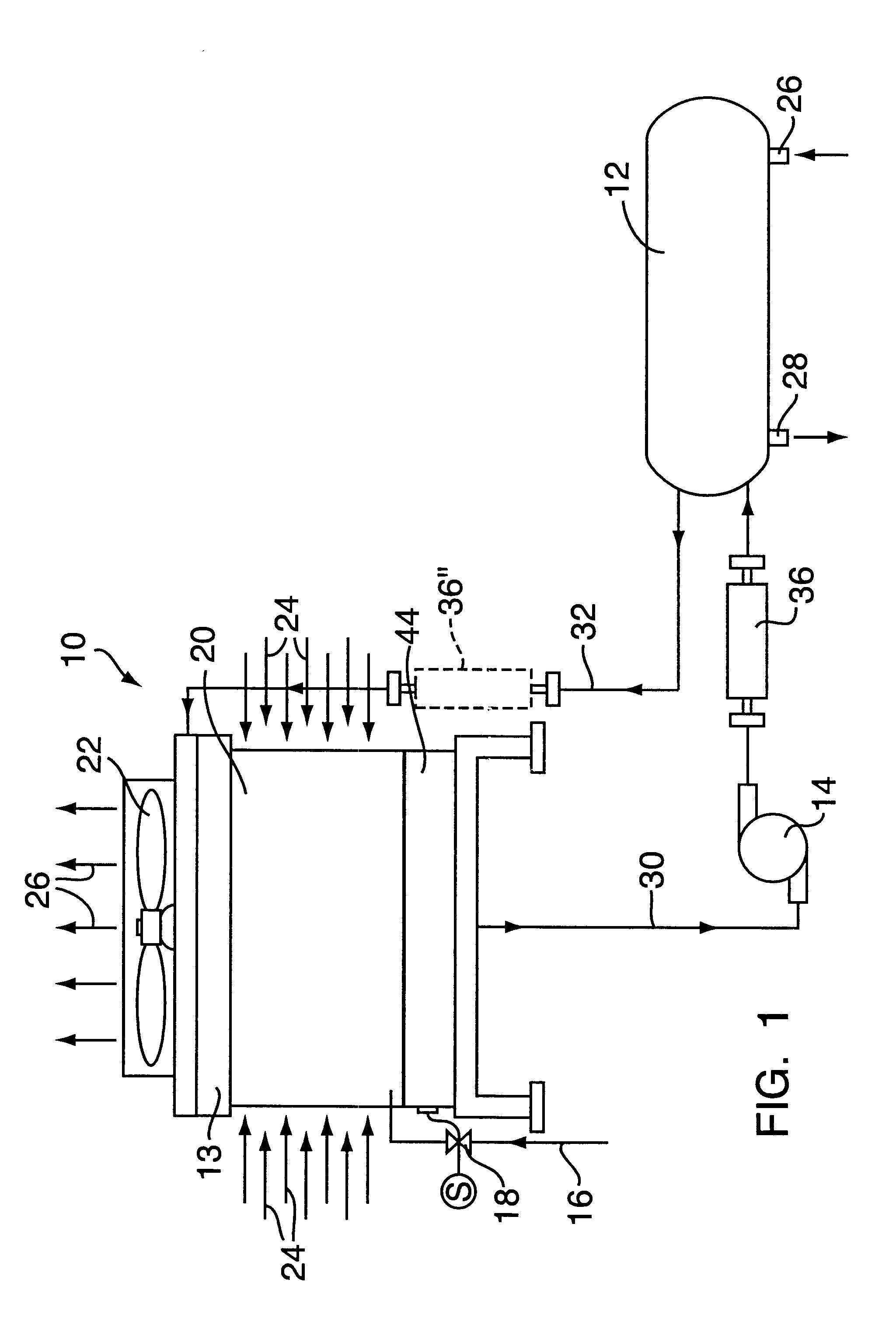

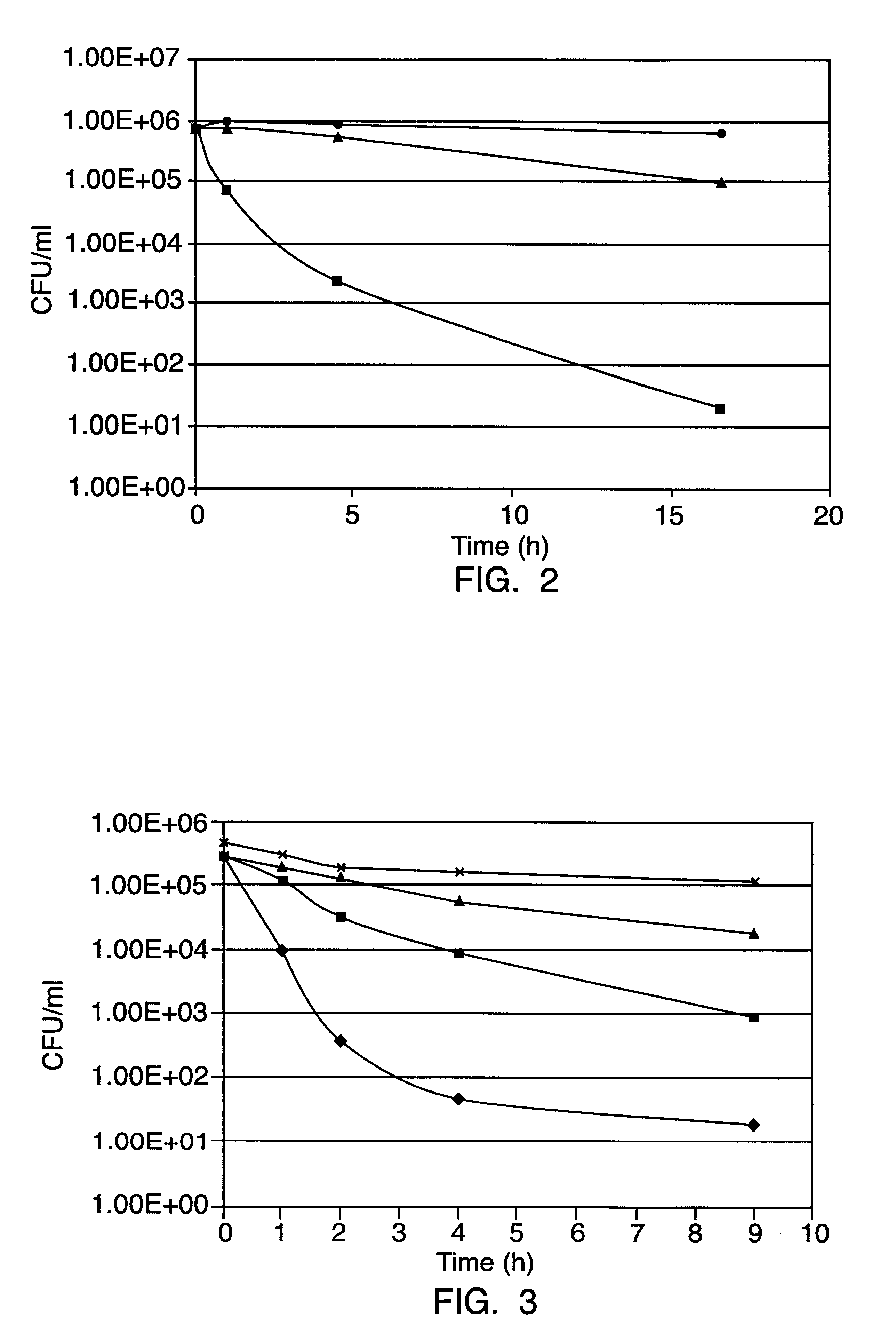

A method of making an oxygen-rich and stabilized oxidizing agent in a liquid, preferably water, involves exposure of aerated liquid to repeated bursts of ringing magnetic flux having a primary frequency of 10 kHz to 80 kHz, with the bursts repeated at a frequency of 1 Hz to 100 Hz, and with the water being kept basic at a pH level between pH 7 to pH 10. The oxidizing agent is believed to be a relatively stable complex of hydrogen peroxide, and has a significant anti-microbial effect on microorganisms, including biofilms, in the water achieved by oxidation of the oxidizing agent with chemical components of the microorganisms.

Owner:EVAPCO PROD INC

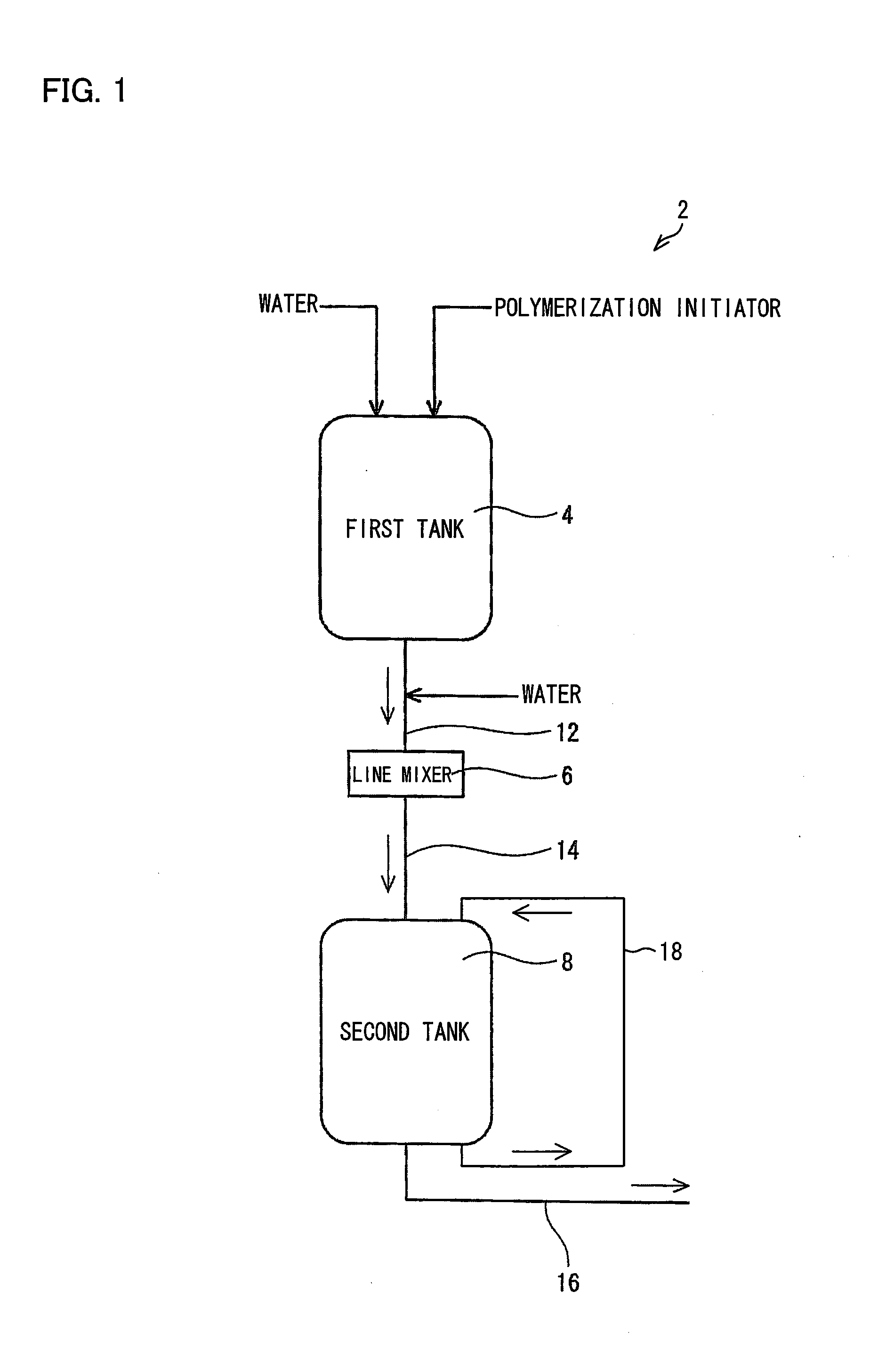

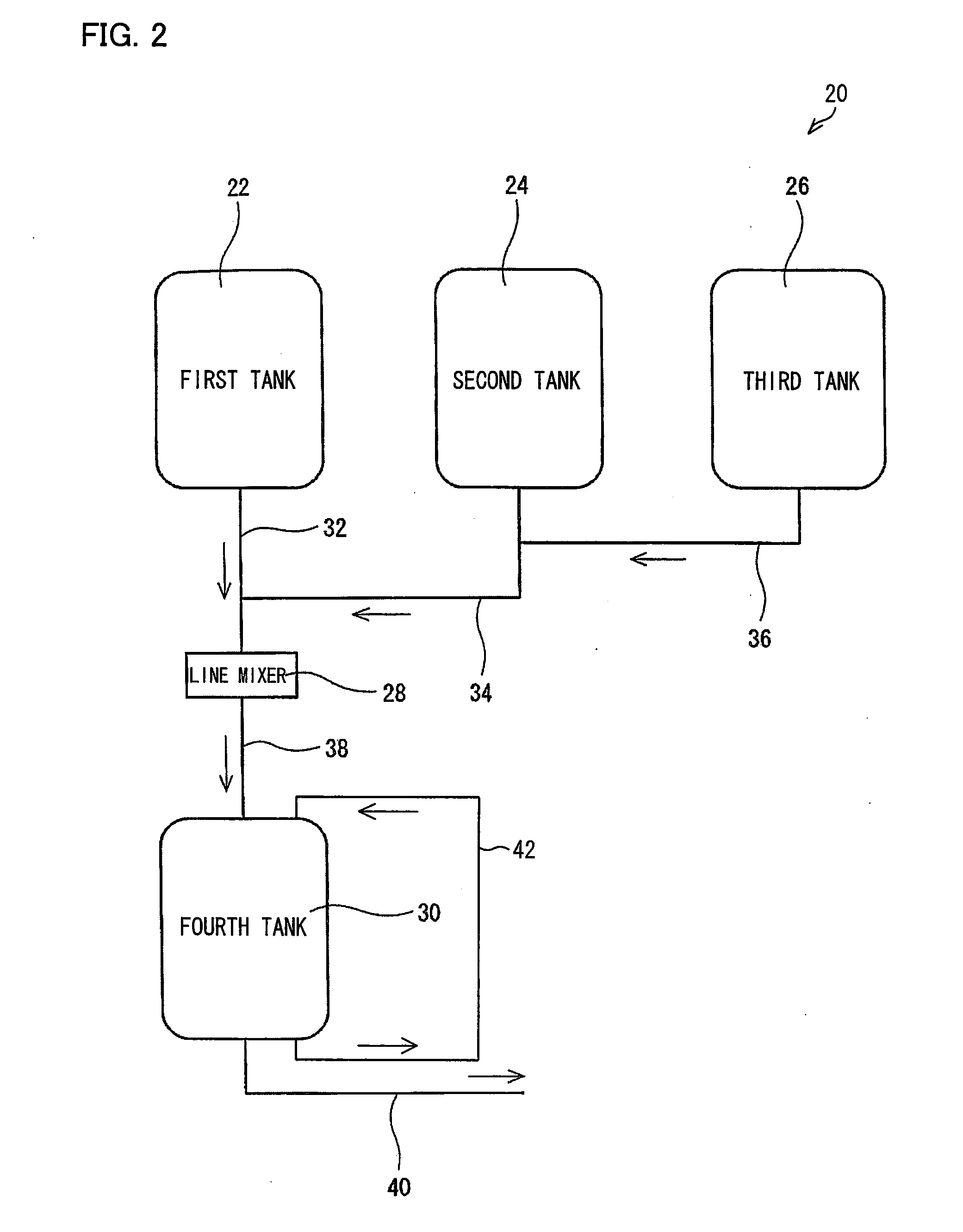

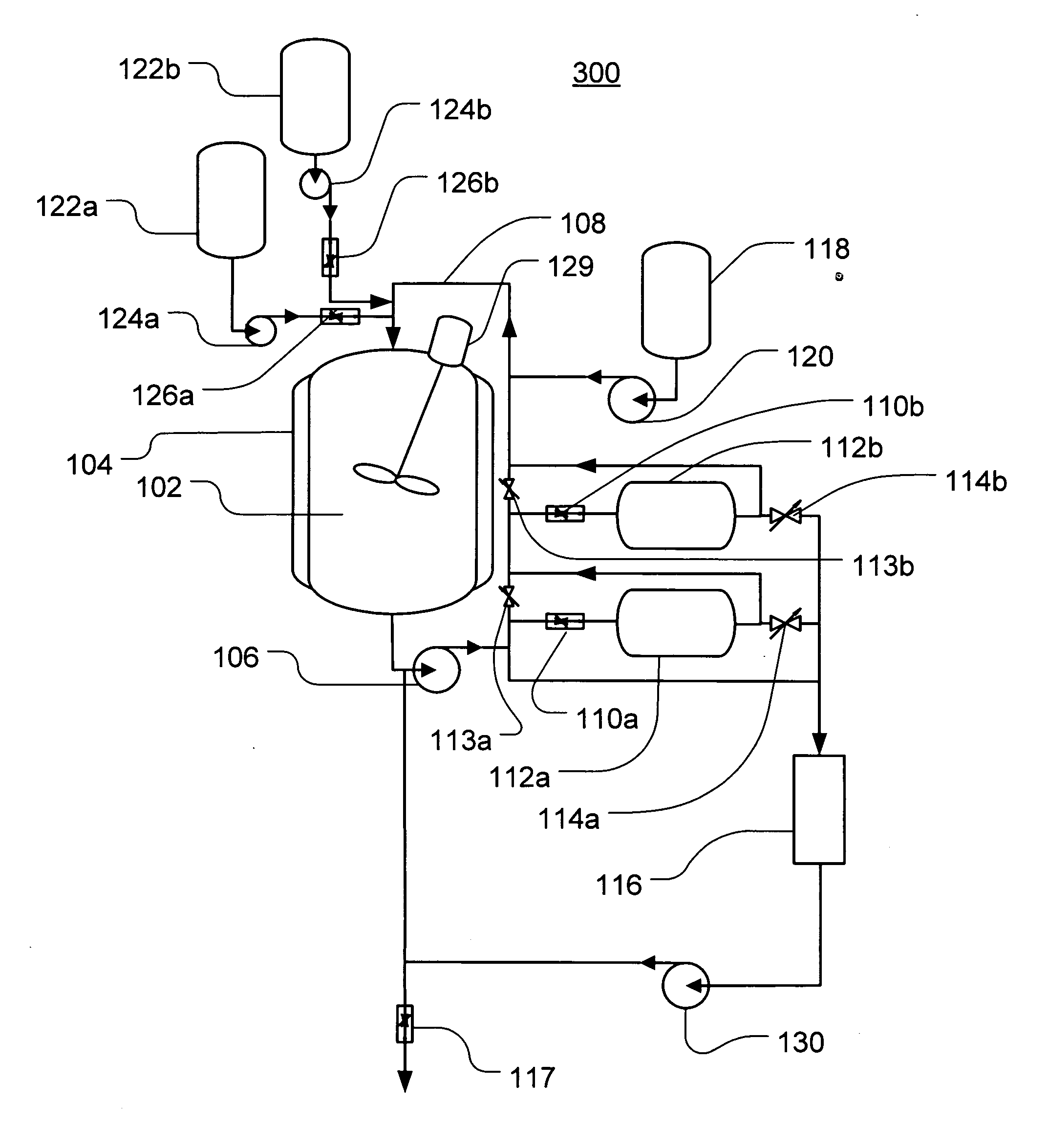

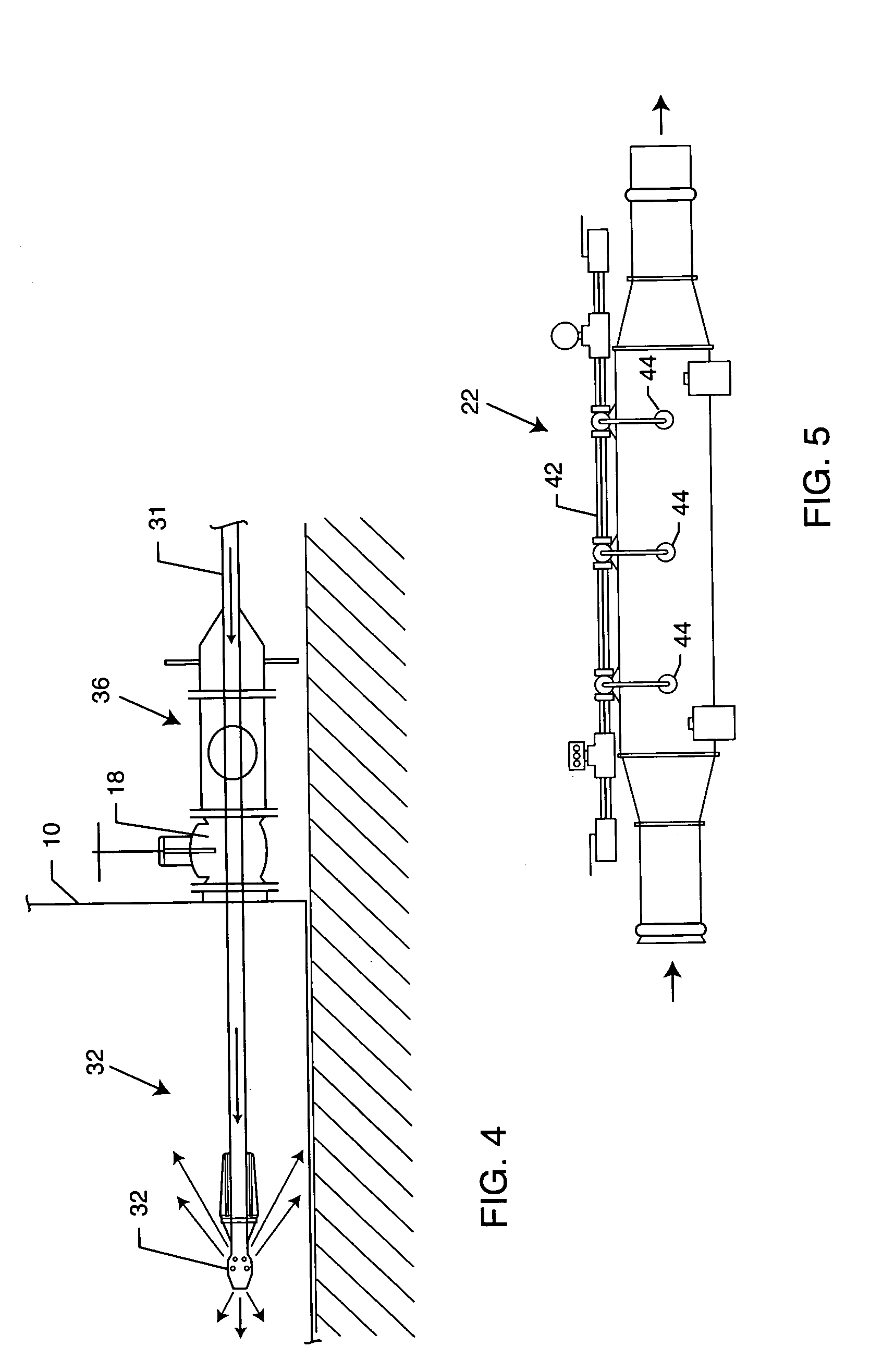

Production method and production apparatus of particulate water absorbing agent containing water absorbent resin as main component

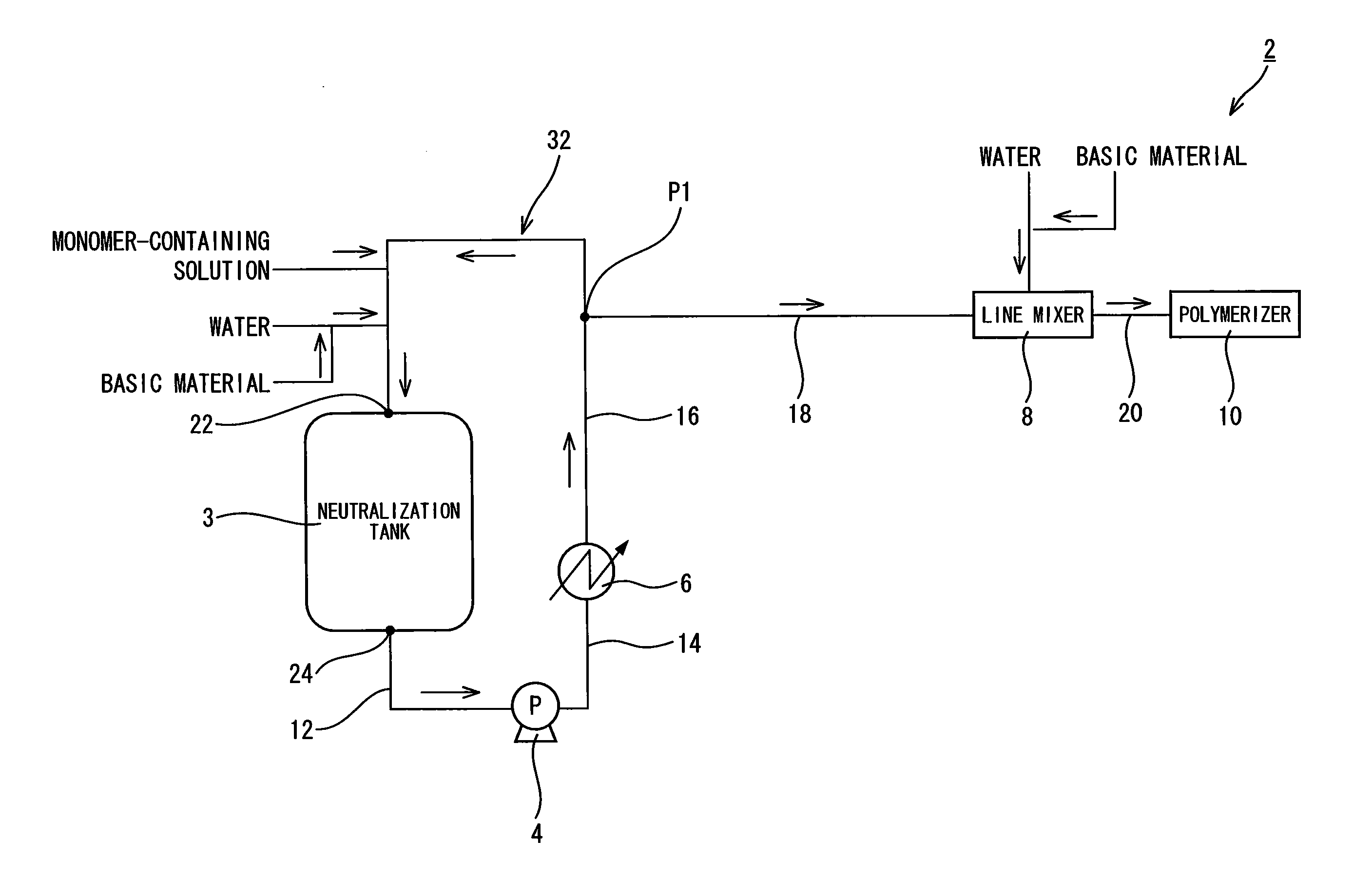

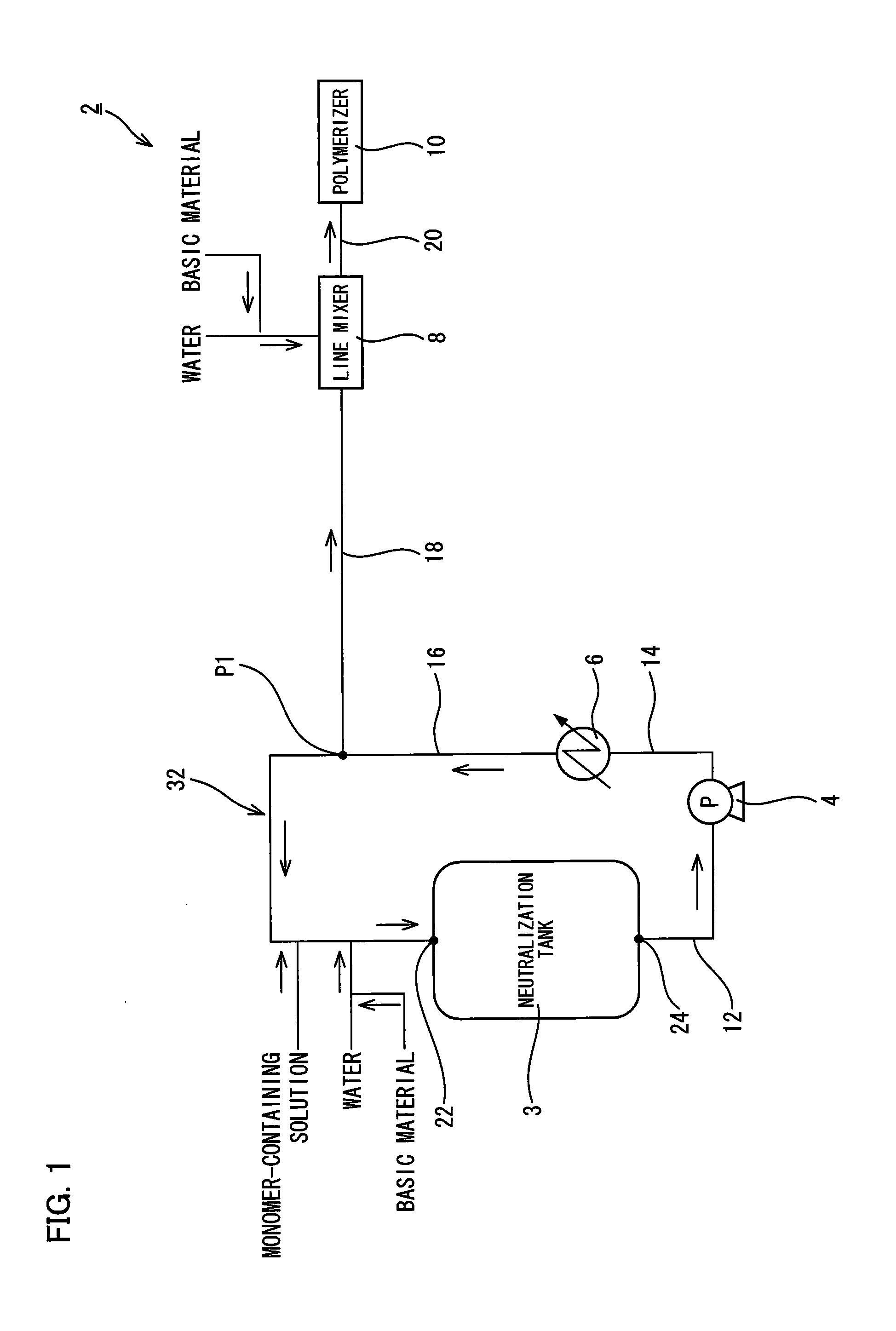

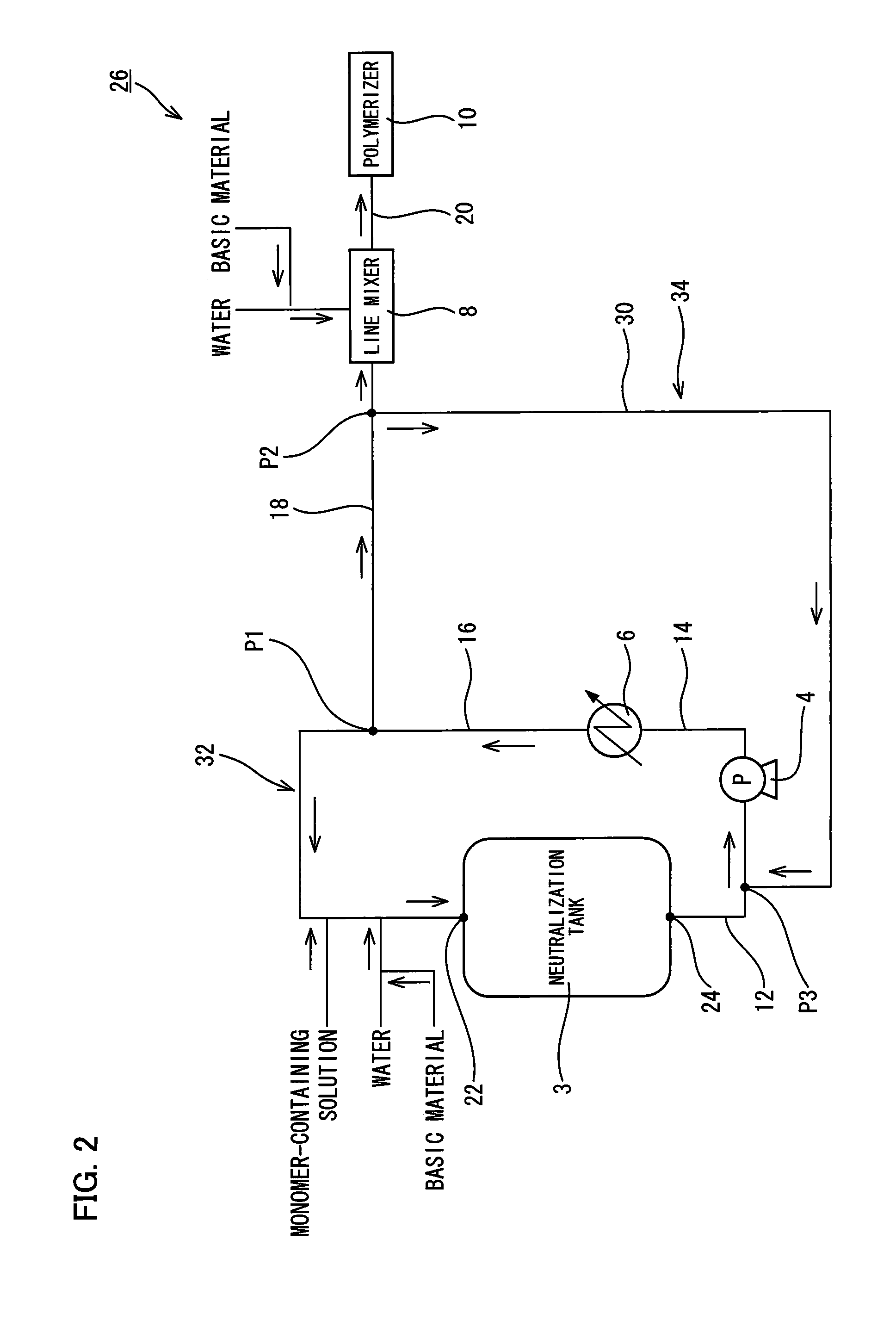

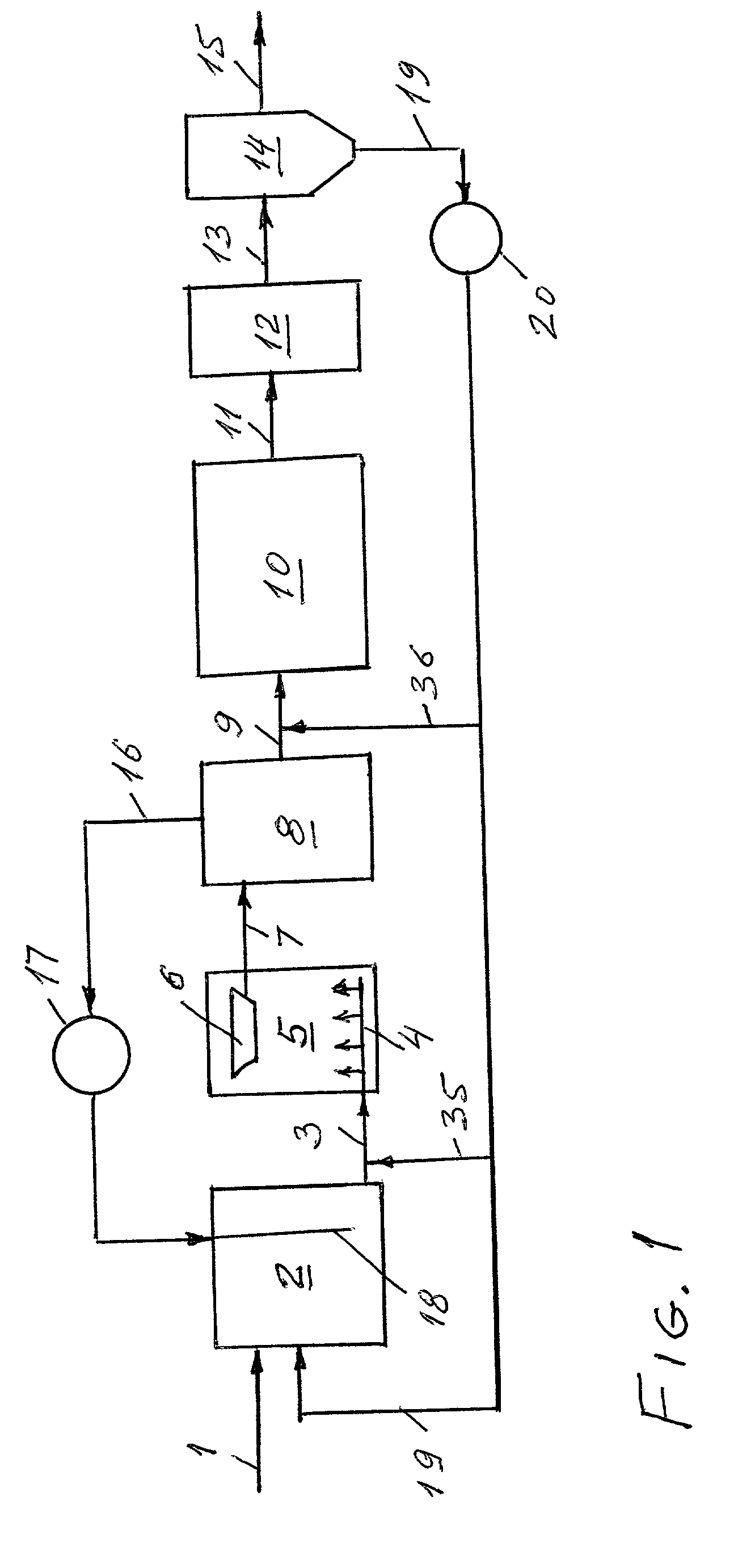

An apparatus (2) includes a neutralization tank (3), a pump (4), a heat exchanger (6), a line mixer (8), a polymerizer (10), a first pipe (12), a second pipe (14), a third pipe (16), a fourth pipe (18), and a fifth pipe (20). Continuously supplied into the neutralization tank (3) are a monomer aqueous solution and a basic aqueous solution, so as to prepare a mixture solution. The mixture solution is circulated through the first pipe (12), the pump (4), the second pipe (14), the heat exchanger (6), and the third pipe (16). The mixture solution is supplied to the polymerizer through the fourth pipe (18). The apparatus (2) satisfies a requirement that a value X is not more than 200, which value X is found according to the following expression: “X=(V / F)·A”, wherein V is a volume of the mixture solution present in a neutralization system, F is a flow volume of the mixture solution to be supplied to a polymerization system, and A is a contact area of the mixture solution present in the neutralization system with a device(s) and a pipe(s) constituting the neutralization system. With this arrangement, it is possible to provide a water absorbent resin having superior whiteness.

Owner:NIPPON SHOKUBAI CO LTD

Volatile acid transfer in biological-abiotic processes

InactiveUS20020158009A1Water treatment parameter controlWater contaminantsOrganismal ProcessWastewater

A method of a wastewater treatment in a system consisting of at least one acid consuming step and at least one volatile acid generating step and further comprising step of evacuating the volatile acid from that at least one step generating at least one volatile acid and step of transferring at least one volatile acid to that at least one acid consuming step.

Owner:KHUDENKO BORIS M

Continuous neutralizer mixer reactor and a continuous process for quenching chlorination reaction mixture in production of chlorinated sucrose

An improved process of production of a chlorinated sugar is described comprising chlorination of a partially protected sugar, wherein quenching as well as neutralization of chlorinated reaction mass is carried out concurrently and continuously in a reactor which is a continuous mixer as well as quencher providing continuous mixing of chlorination reaction mixture and pH adjusting solution and also provides for continuous quenching and continuous removal of quenched chlorinated reaction mixture.

Owner:V B MEDICARE PVT LTD

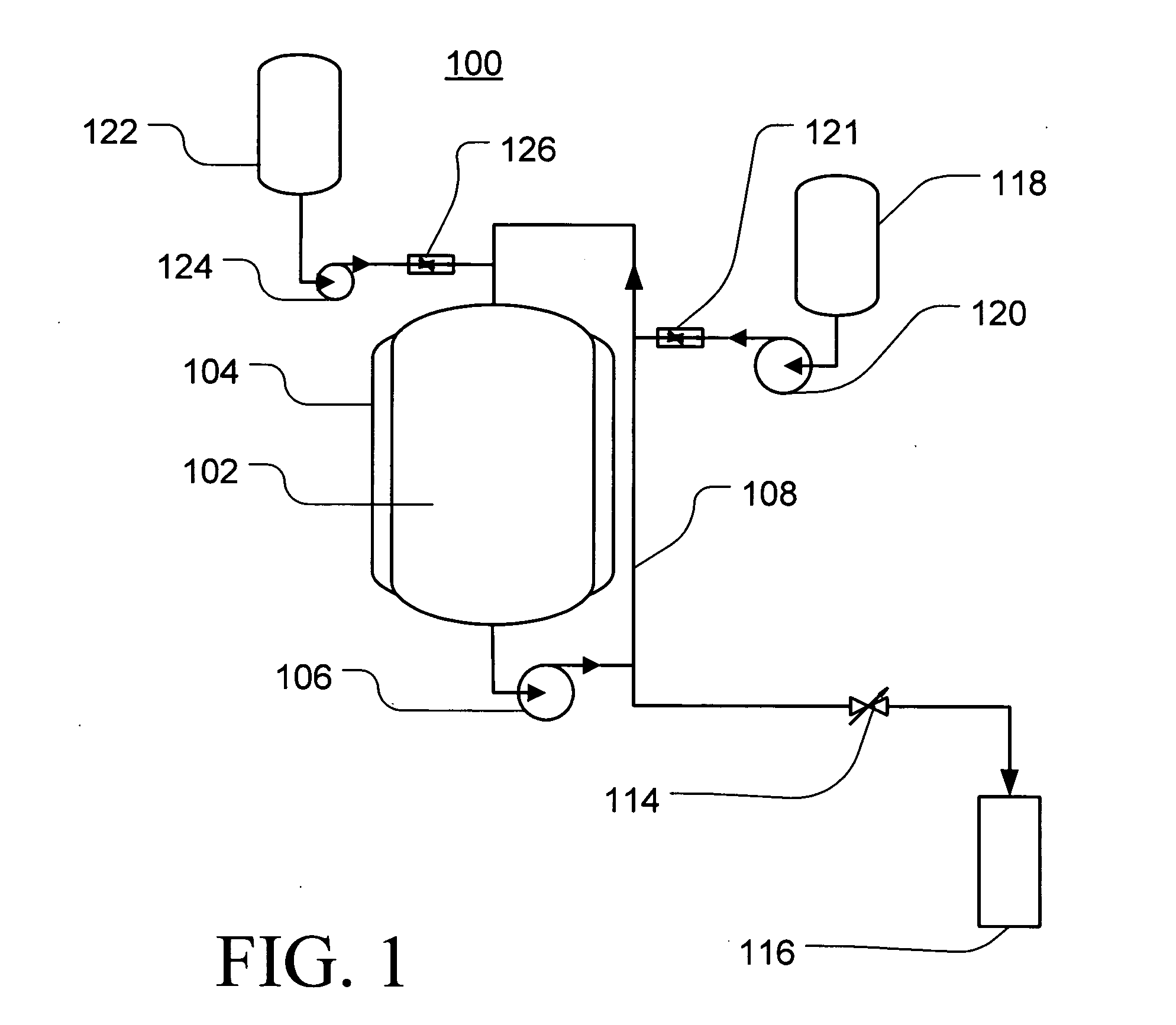

Method for producing particulate water absorbing agent containing water absorbent resin as main component

ActiveUS20110039961A1Accelerating polymerizationResidue reductionPH-change processesAbsorbent padsAqueous solutionPolymer chemistry

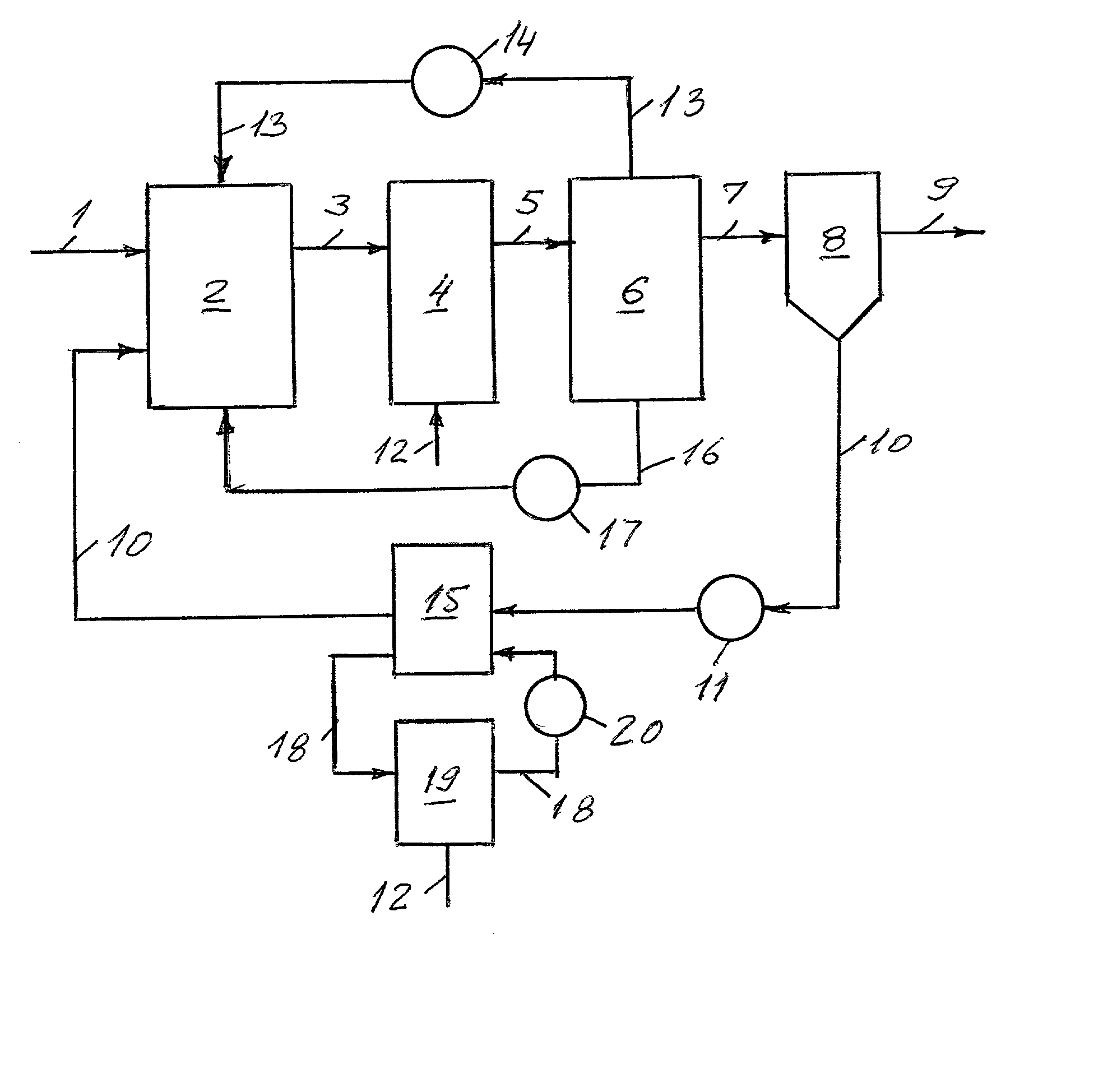

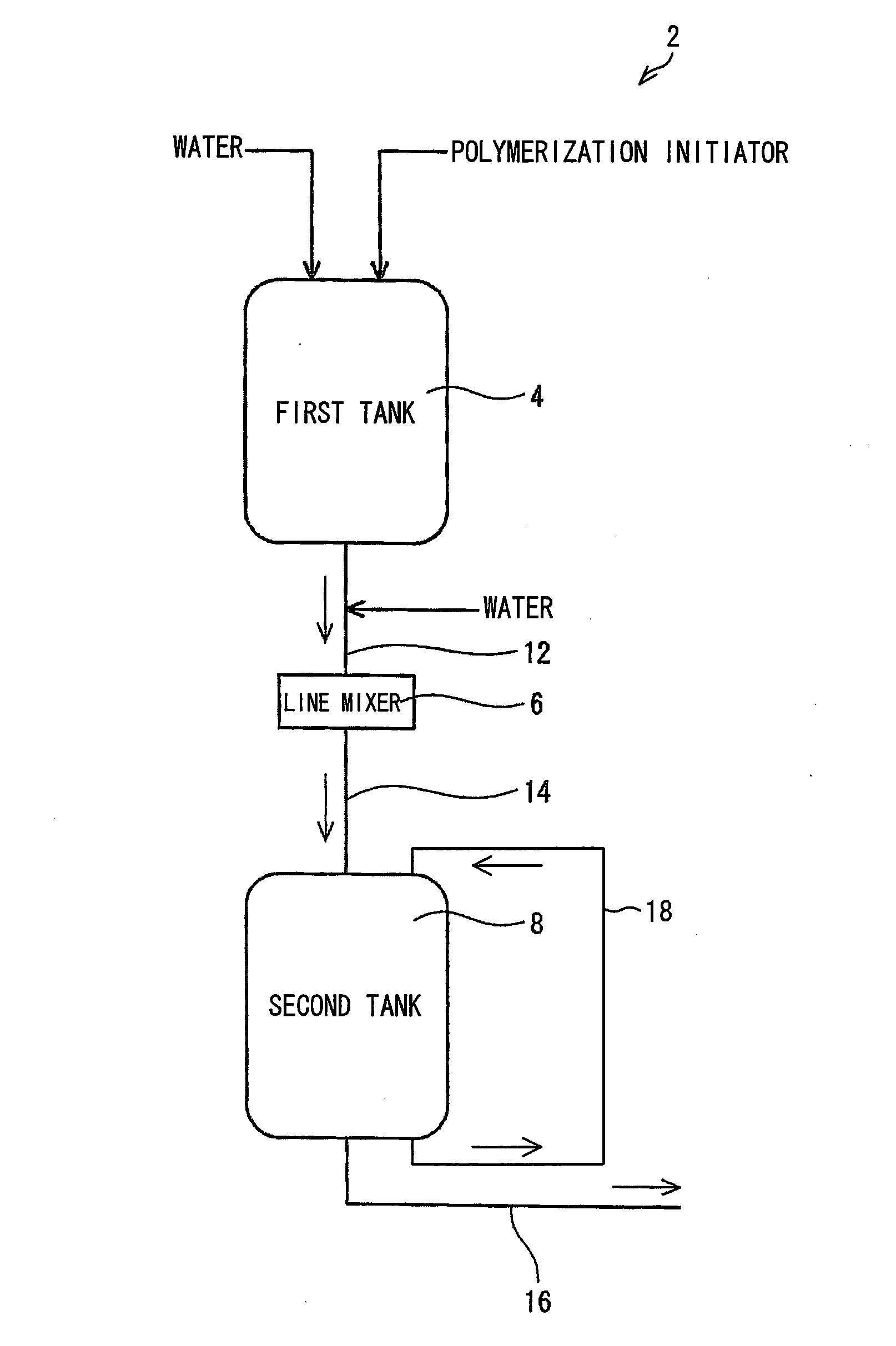

An apparatus (2) includes: a first tank (4); a line mixer (6); a second tank (8); a cooling jacket (10); a first tube (12); a second tube (14); and a third tube (16). In the first tank (4), (i) sodium persulfate serving as a polymerization initiator and (ii) water are fed so as to obtained an aqueous solution. The aqueous solution is continuously taken out and transferred via the first tube (12) to the line mixer (6). Between the first tank (4) and the line mixer (6), water is injected into the first tube (12). The water and the sodium persulfate aqueous solution are stirred together in the line mixer (6). This stirring decreases a concentration of the aqueous solution. The resulting aqueous solution is continuously fed to the second tank (8) via the second tube (14). The aqueous solution is then continuously taken out via the third tube (16) and is continuously added to an acrylic acid (salt) aqueous solution. This provides a production method which allows a high-quality water absorbing agent to be obtained with a compact apparatus.

Owner:NIPPON SHOKUBAI CO LTD

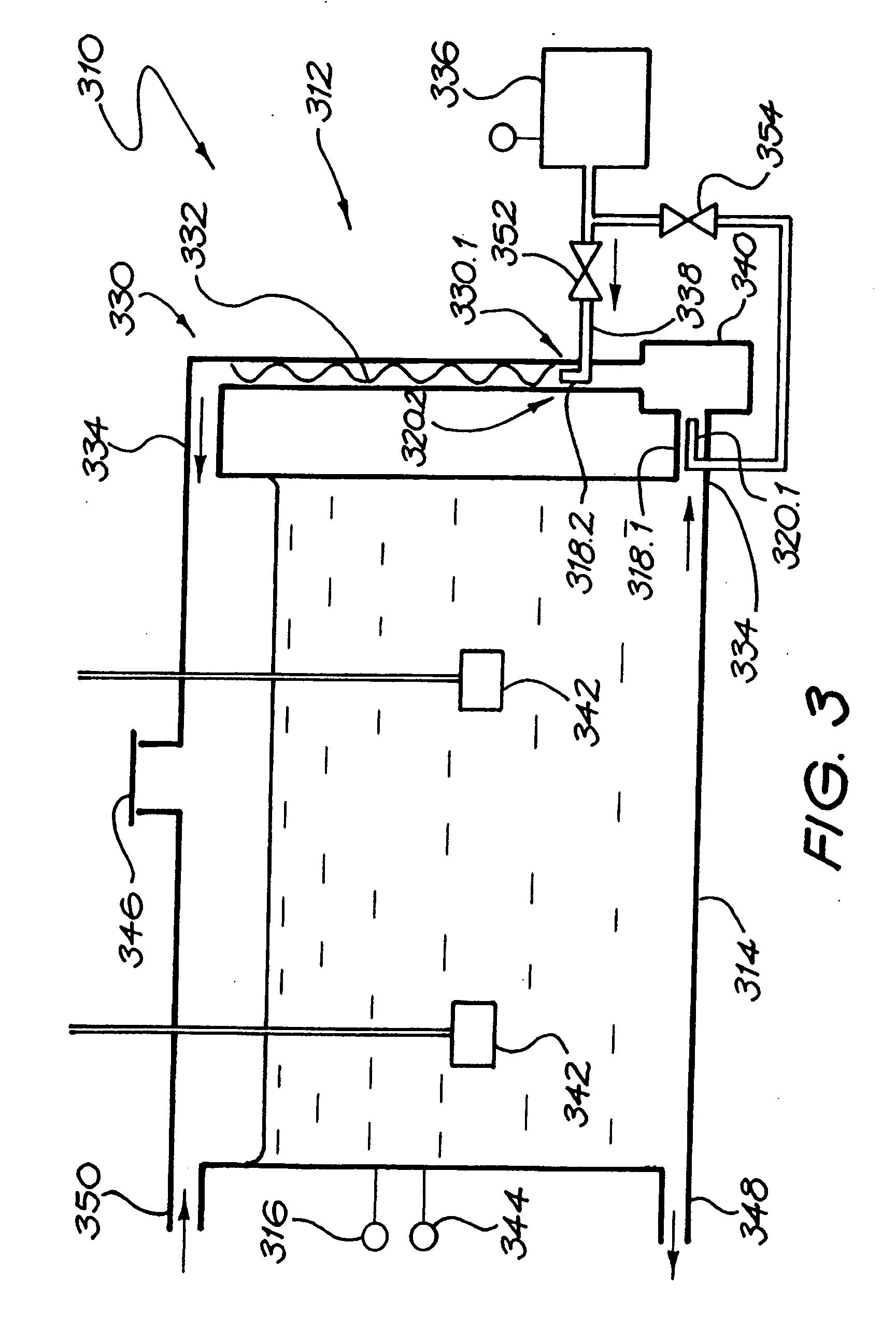

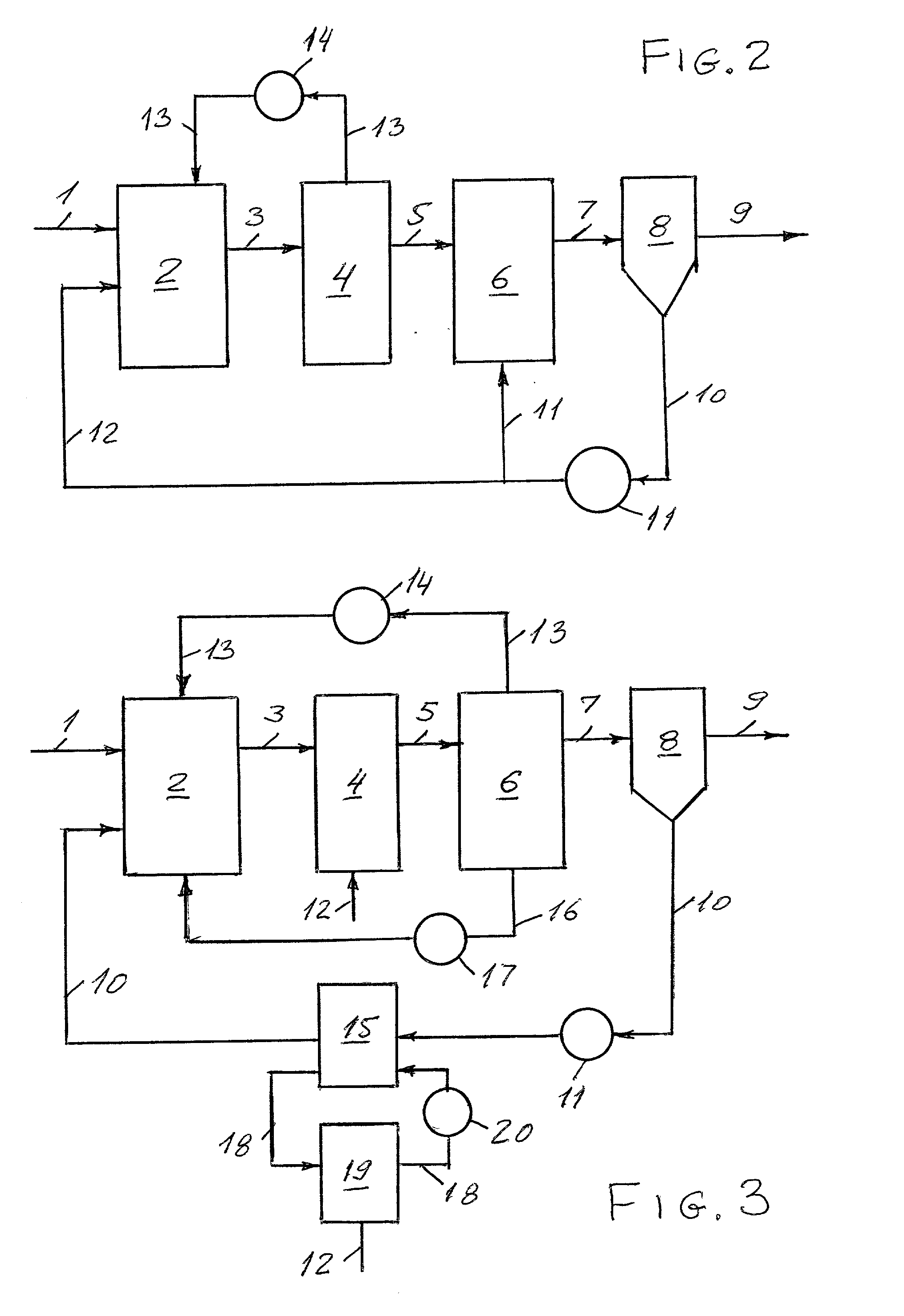

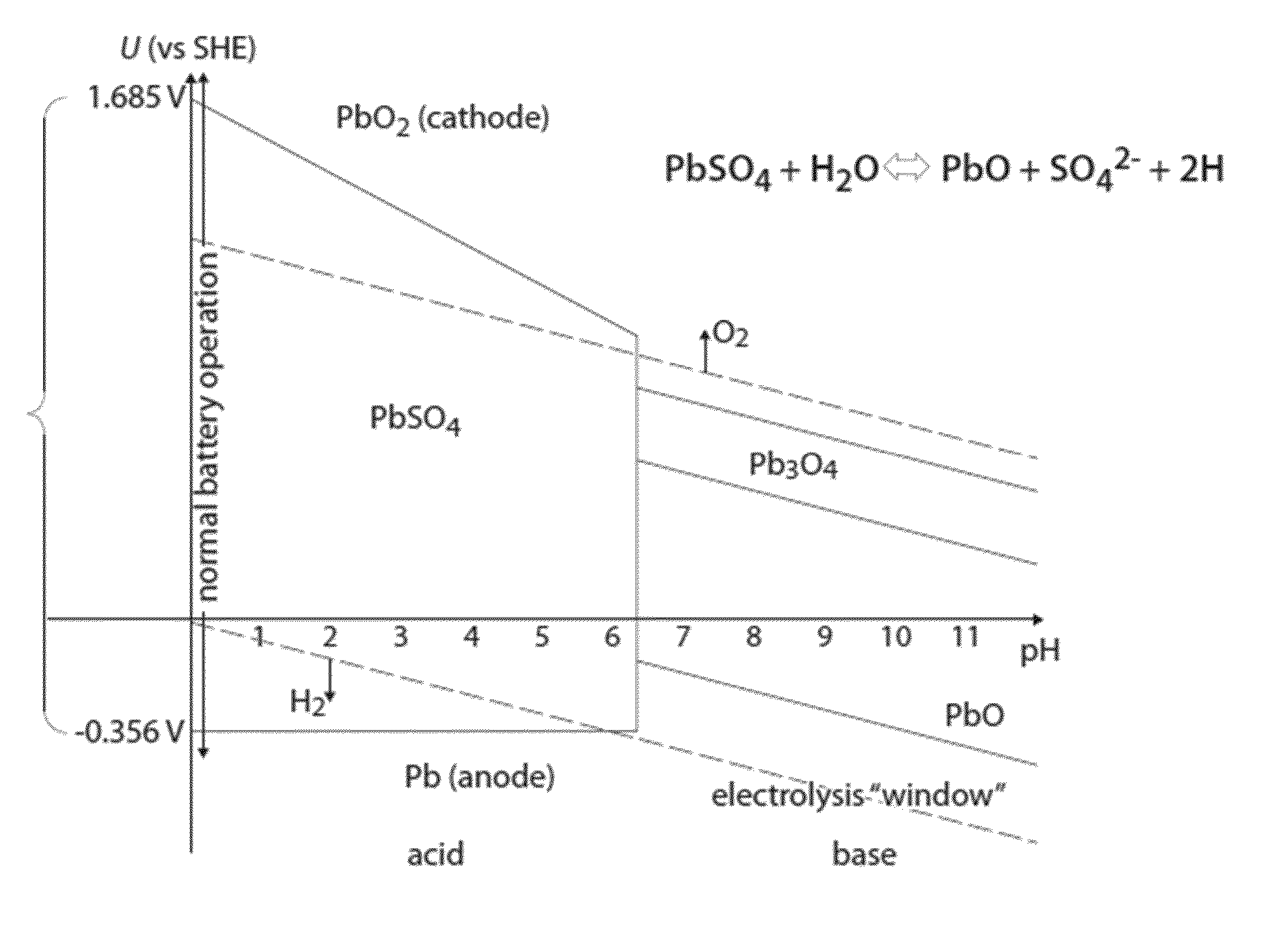

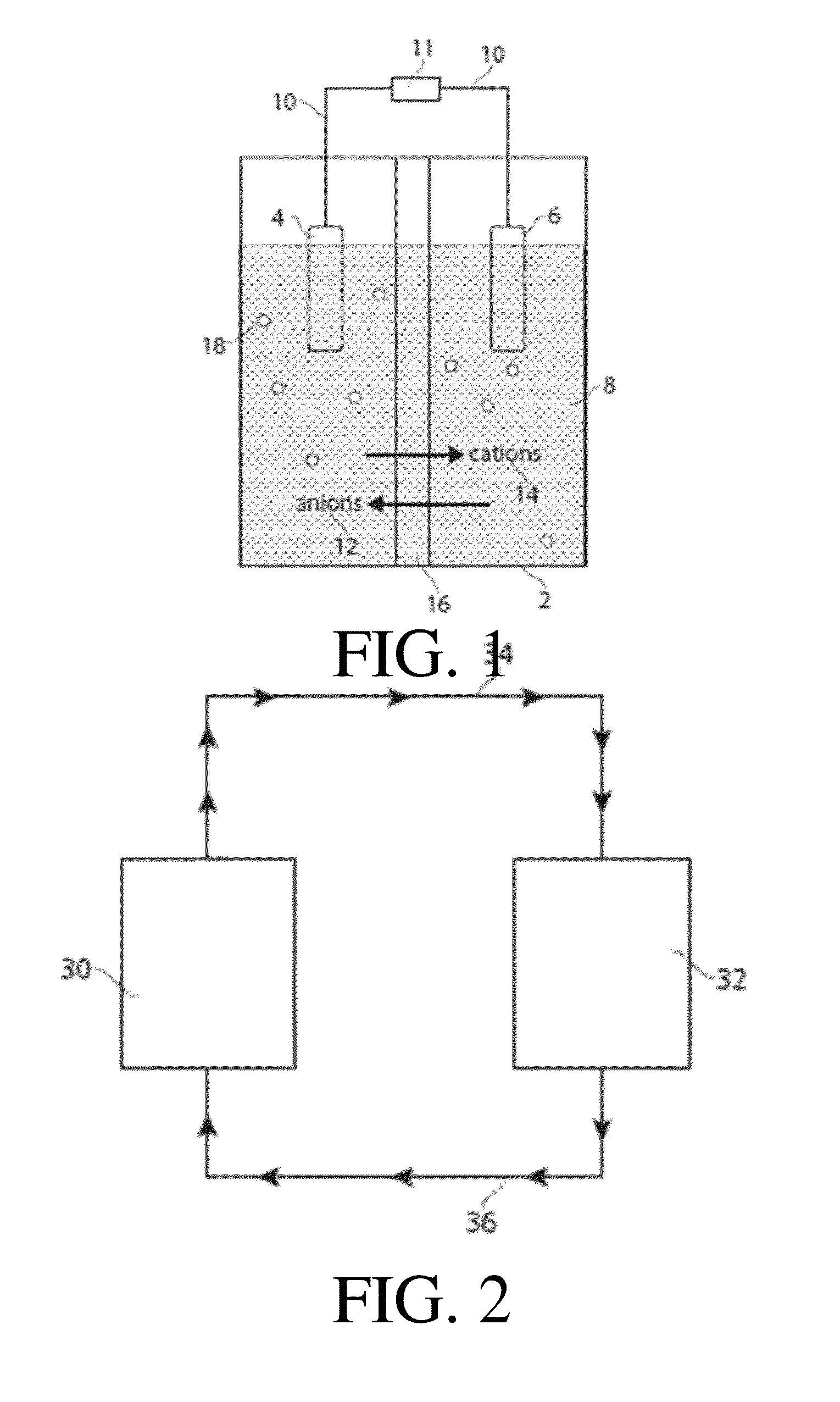

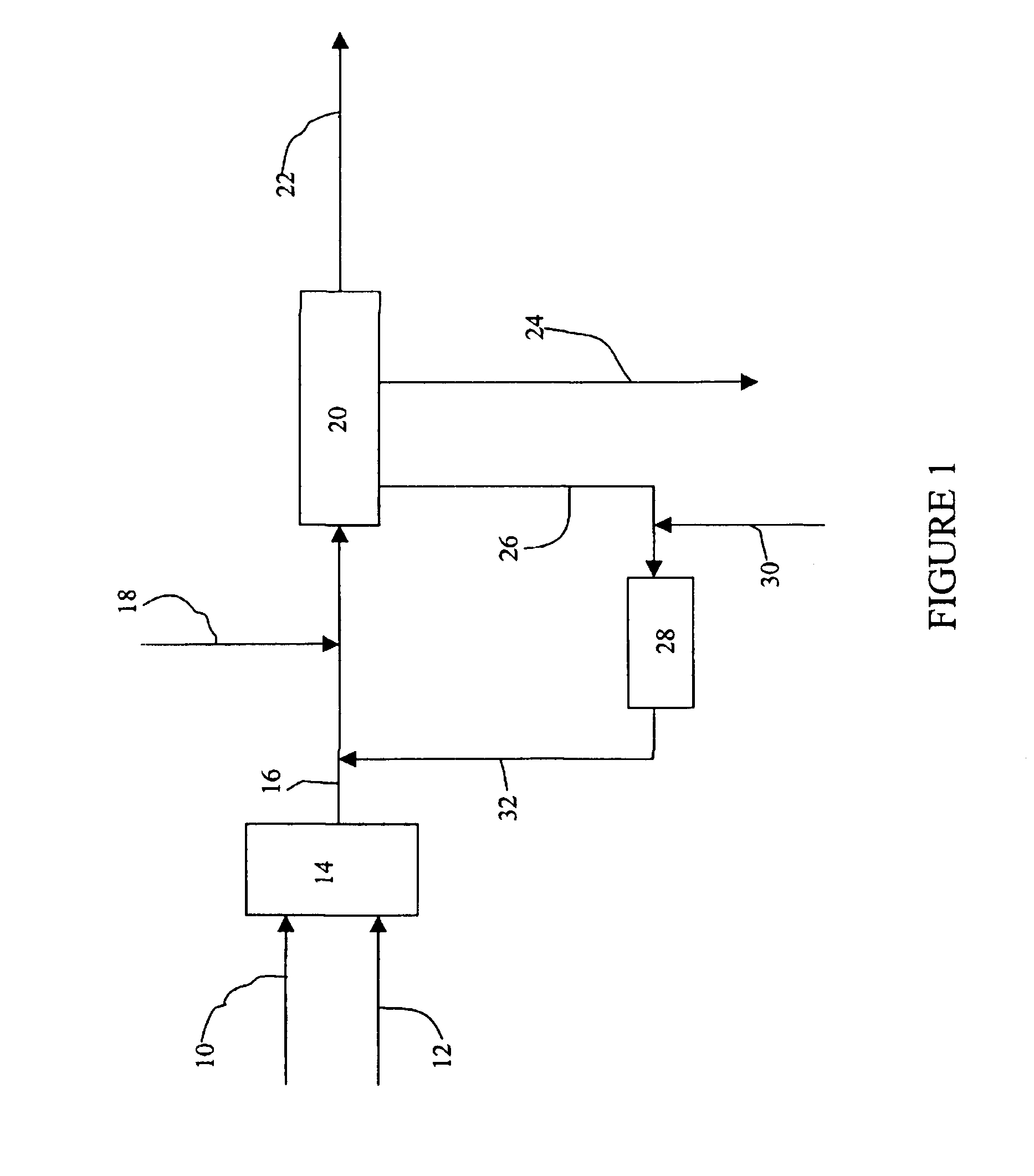

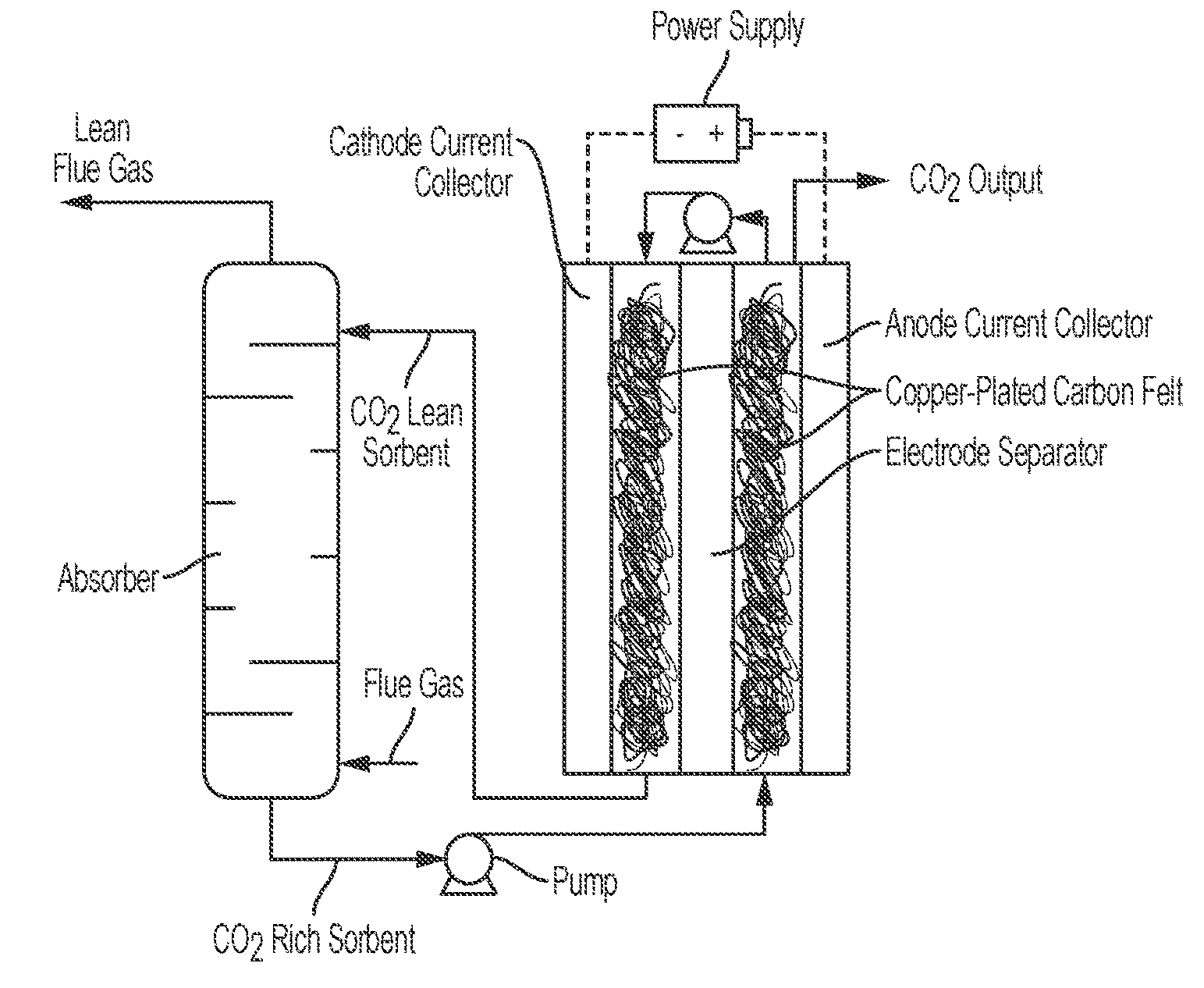

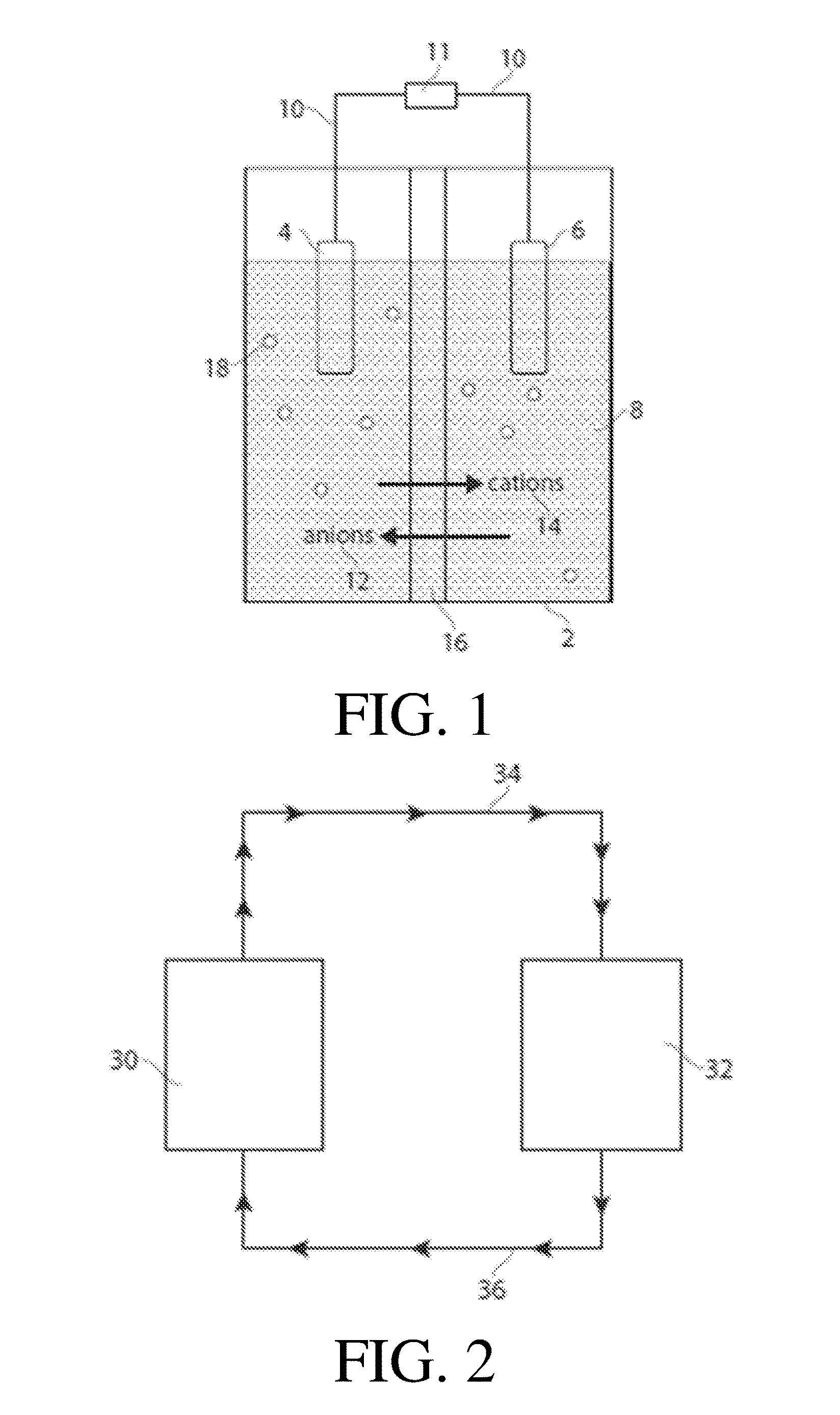

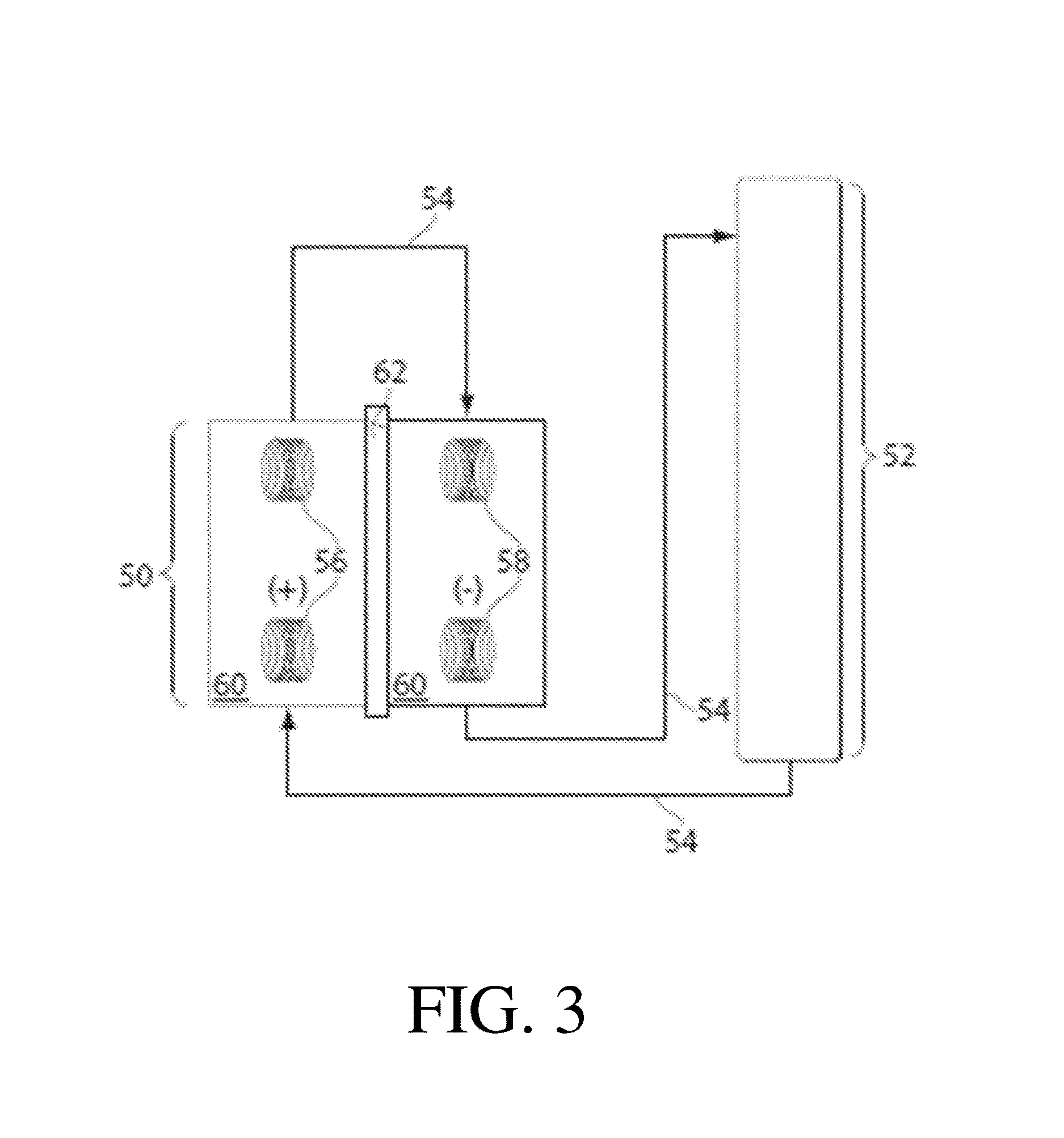

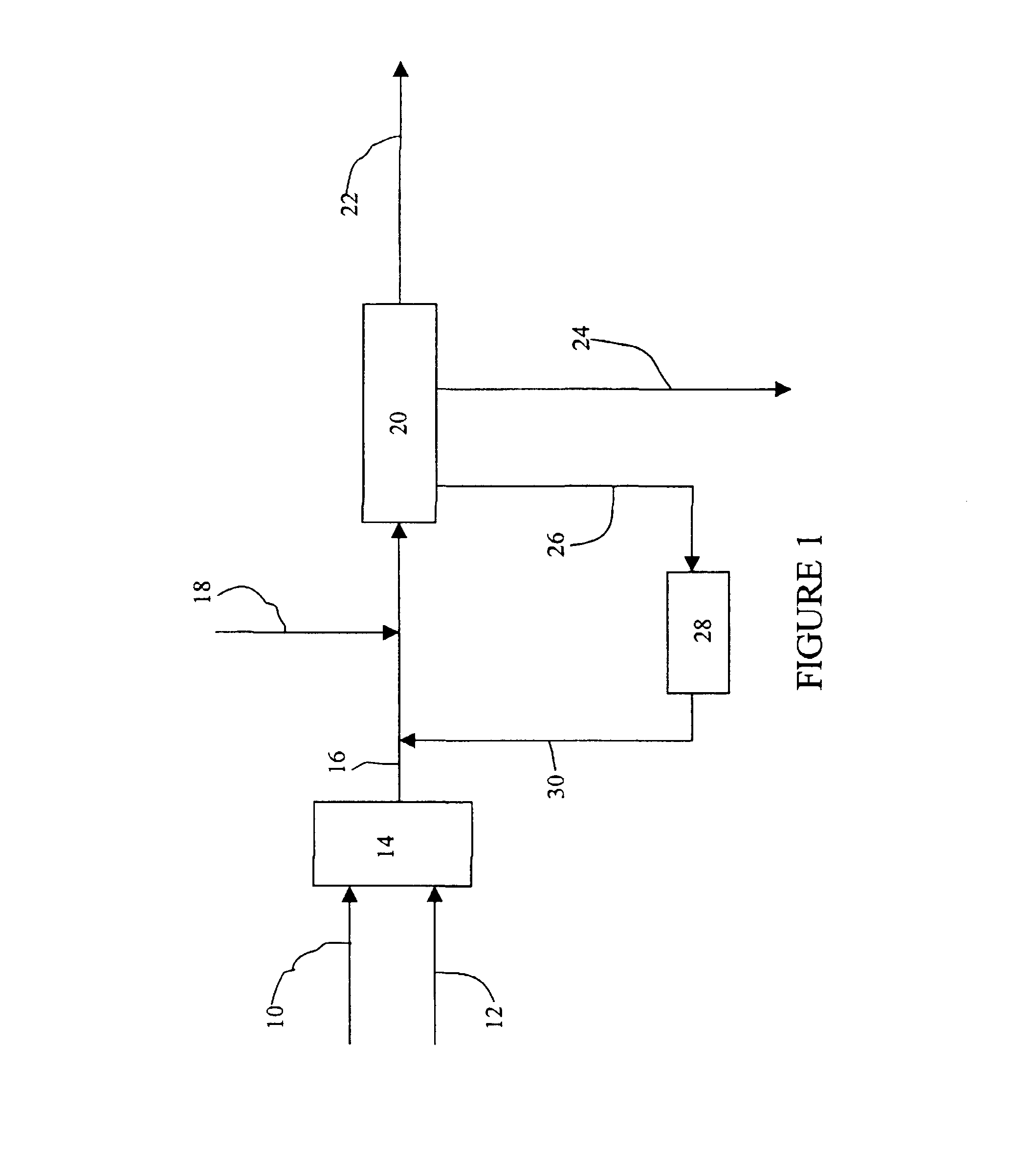

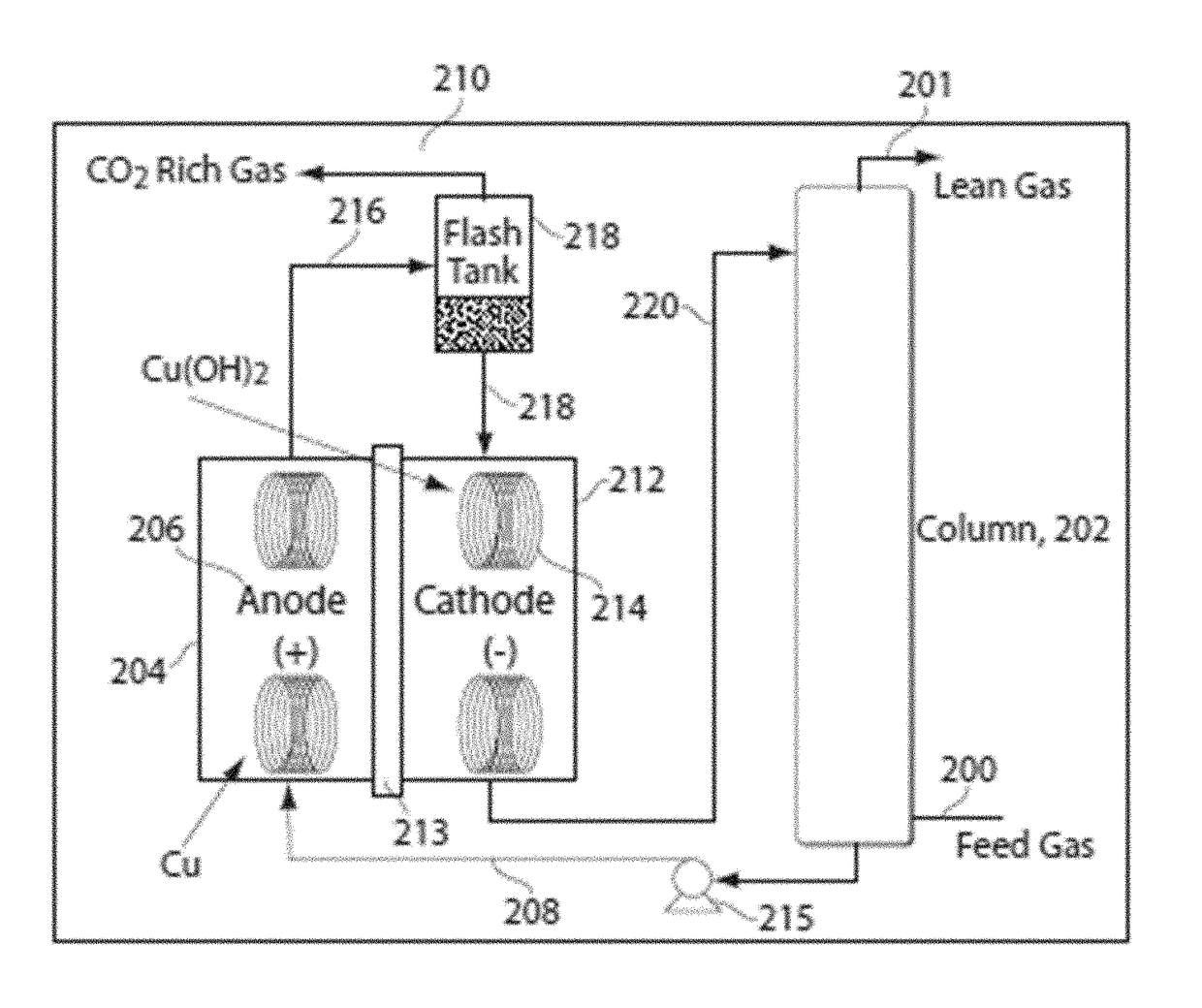

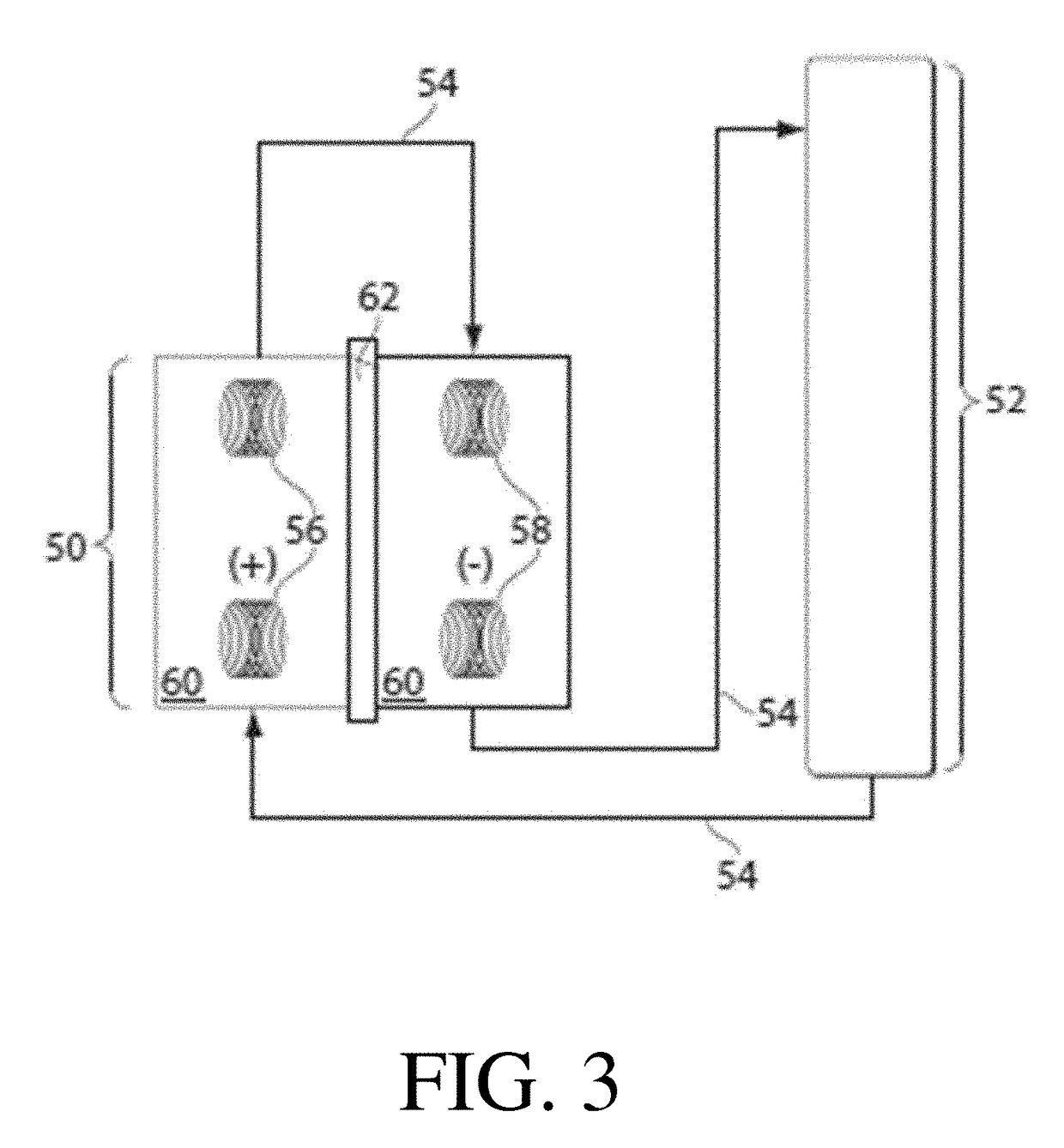

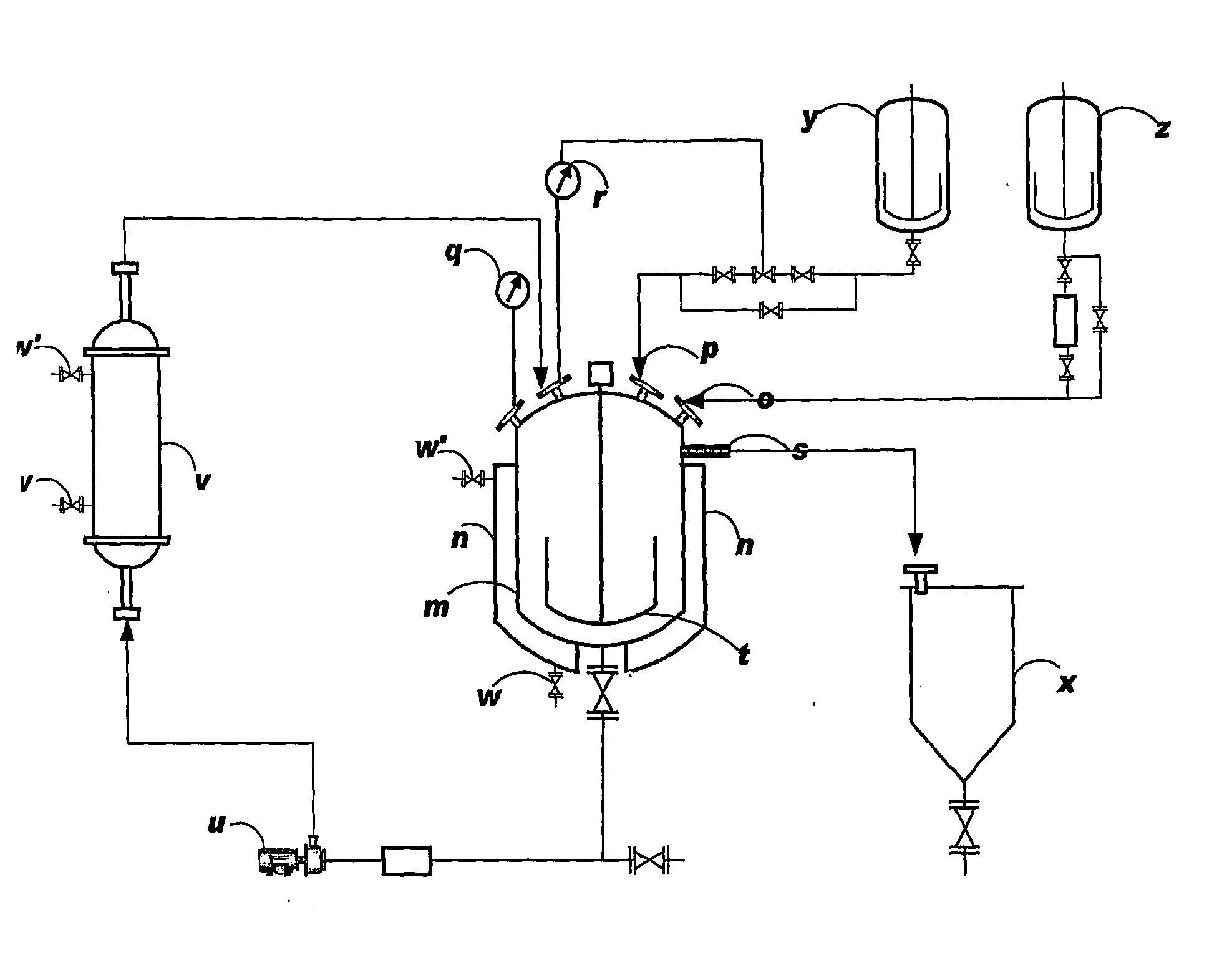

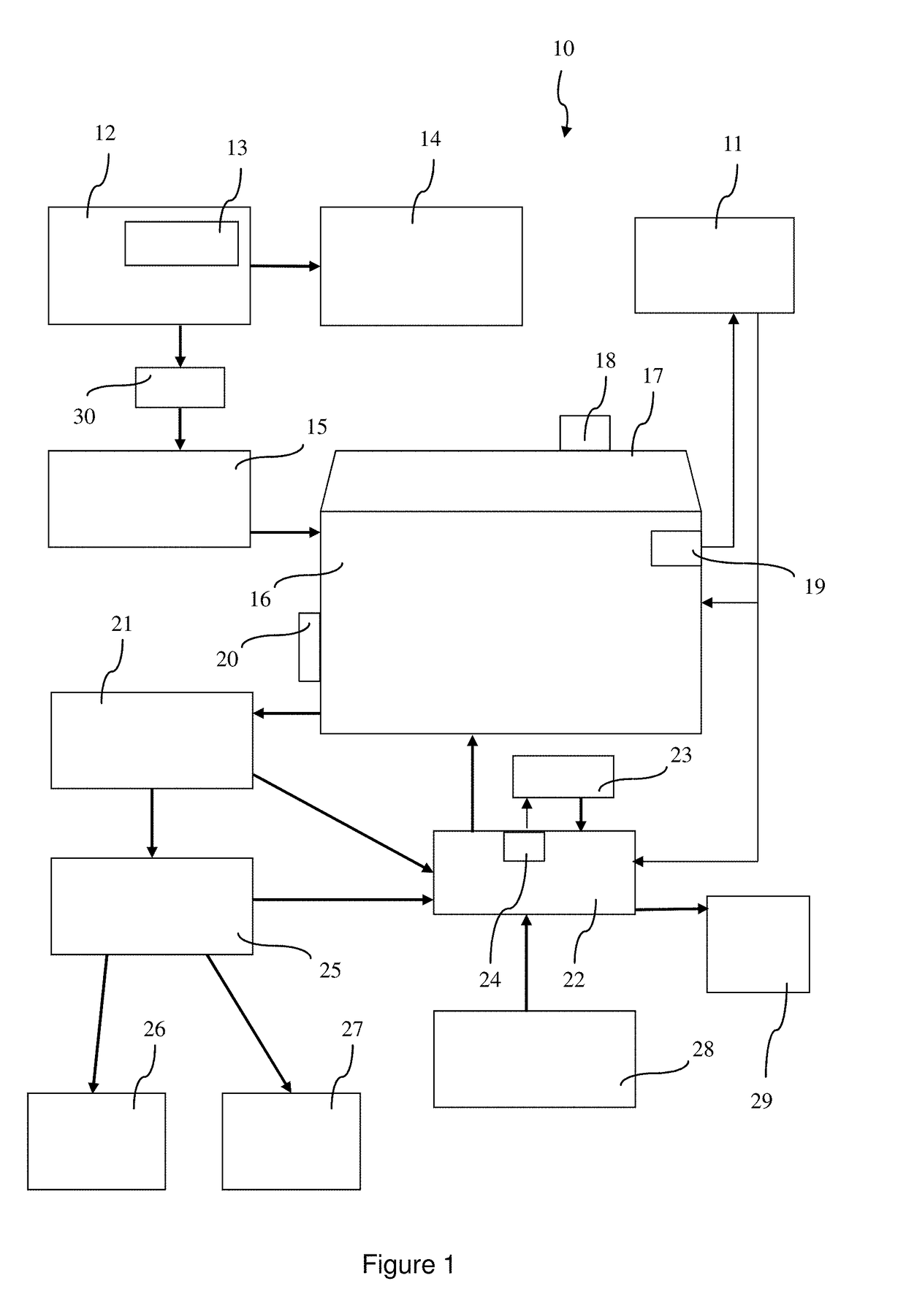

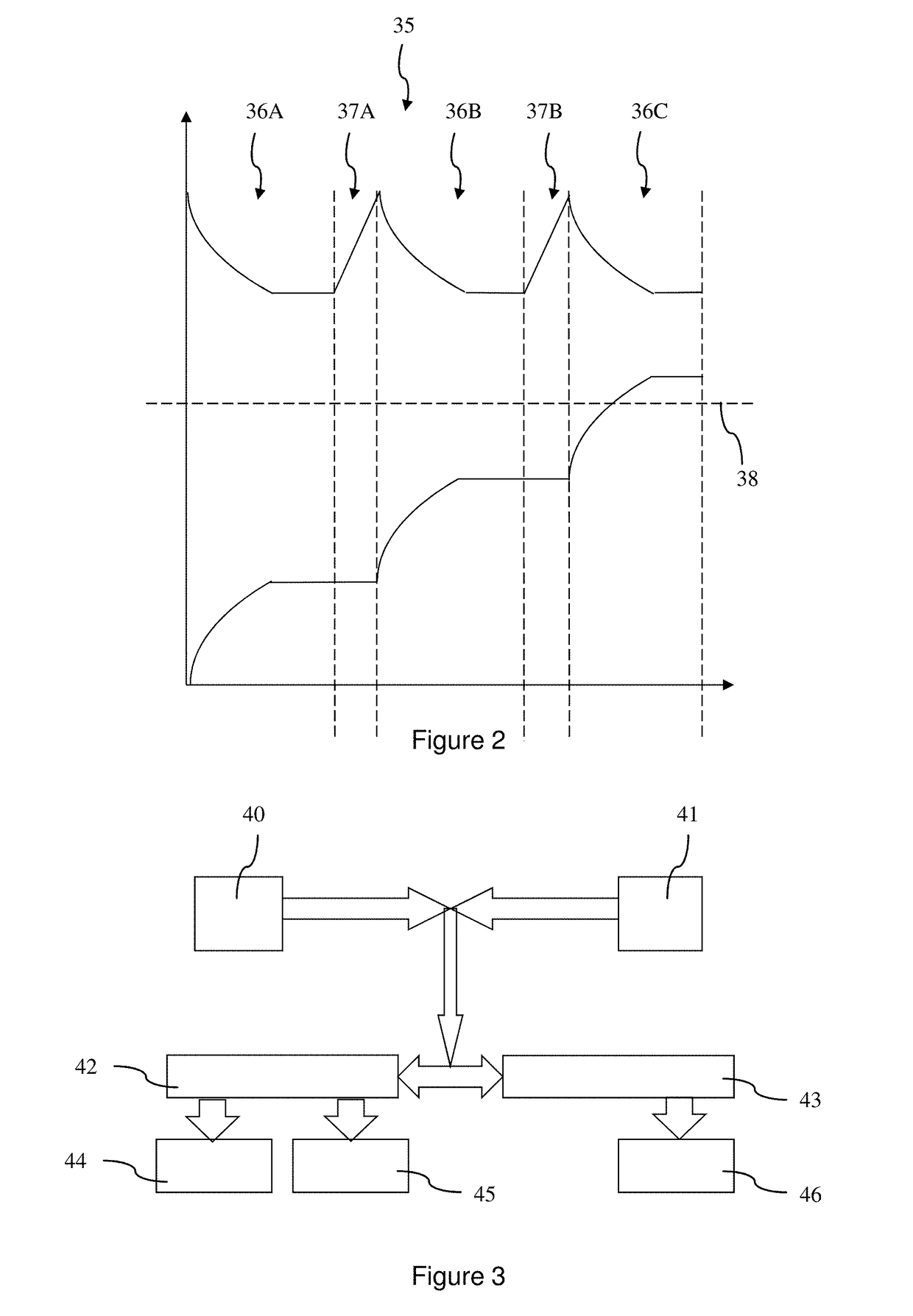

METHODS AND SYSTEMS FOR CARRYING OUT A pH-INFLUENCED CHEMICAL AND/OR BIOLOGICAL REACTION

The present invention generally relates to methods and systems for carrying out a pH-influenced chemical and / or biological reaction. In some embodiments, the pH-influenced reaction involves the conversion of CO2 to a dissolved species.

Owner:MASSACHUSETTS INST OF TECH

Method and system for purifying cumene hydroperoxide cleavage products

InactiveUS6576798B1High materialEliminate needOrganic compound preparationPH-change processesWater solubleAqueous solution

A system for purifying a cumene hydroperoxide cleavage product mixture comprises a cumene hydroperoxide cleavage product mixture feed containing impurities in fluid communication with an aqueous alkaline solution feed; the cumene hydroperoxide cleavage product mixture and aqueous alkaline solution feeds in fluid communication with a neutralization drum having a aqueous salt phase outlet; a aqueous salt phase feed containing impurities in fluid communication with a decomposer reactor having an oxidized aqueous salt phase outlet; an oxidizing agent feed in fluid communication with the aqueous salt phase feed containing the impurities prior to the decomposer reactor; and an oxidized aqueous salt phase feed containing water-soluble oxidized derivatives of the impurities in fluid communication with the cumene hydroperoxide cleavage product mixture prior to the neutralization drum.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Method of manufacturing nanoparticles

ActiveUS20070151418A1Less-expensive to practiceImprove securityMaterial nanotechnologyTransportation and packagingModal particleReaction temperature

Provided are methods and systems for generating nanoparticles from an inorganic precursor compound using a hydrothermal process within at least one CSTR or PFR maintained at an elevated temperature and an elevated pressure and a treatment vessel in which this reaction solution can be applied to one or more catalyst substrates. In operation, the reaction solution may be maintained within the CSTR at a substantially constant concentration and within a reaction temperature range for a reaction period sufficient to obtain nanoparticles having a desired average particle size of, for example, less than 10 nm formation and / or deposition. Variations of the basic method and system can provide, for example, the generation of complex particle size distribution profiles, the selective deposition of a multi-modal particle size distribution on a single substrate.

Owner:GENERAL ELECTRIC CO

High energy disinfection of waste

An apparatus subjects fluid waste to waves from an RF plasma. This allows continuous production of “activated water” characterized by cluster sizes below about 4 molecules per cluster, water having pH below 4 or above 10, or water having ORP of less than −350 mV or more than +800 mV. The basic frequency of the plasma is preferably between 0.44 MHz and 40.68 MHz, and the plasma is preferably modulated at a frequency between 10 kHz and 34 kHz. Flow rates typically range from 20 1 / hr to about 2000 1 hr.

Owner:TRIAXIAL ENERGIES

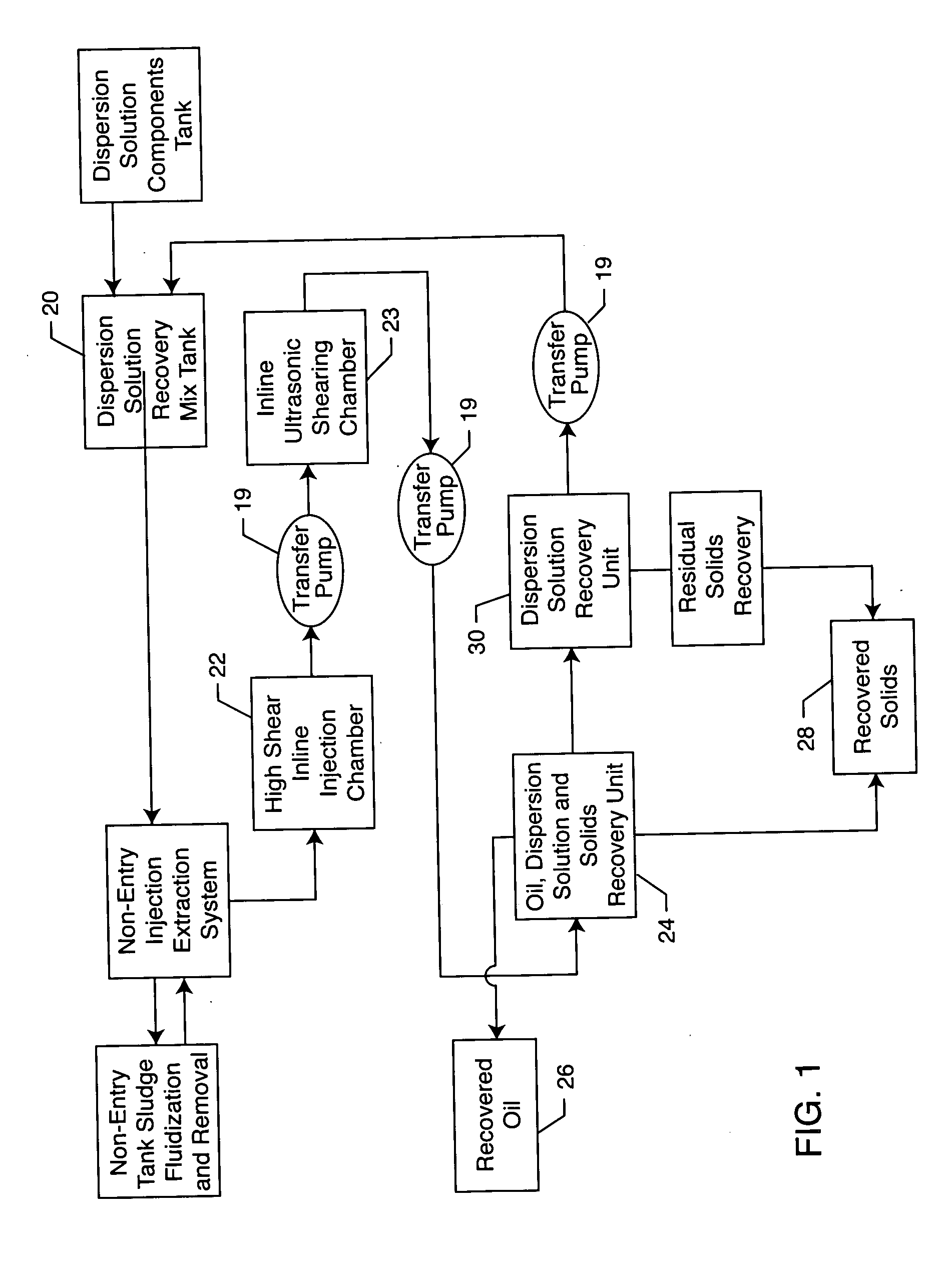

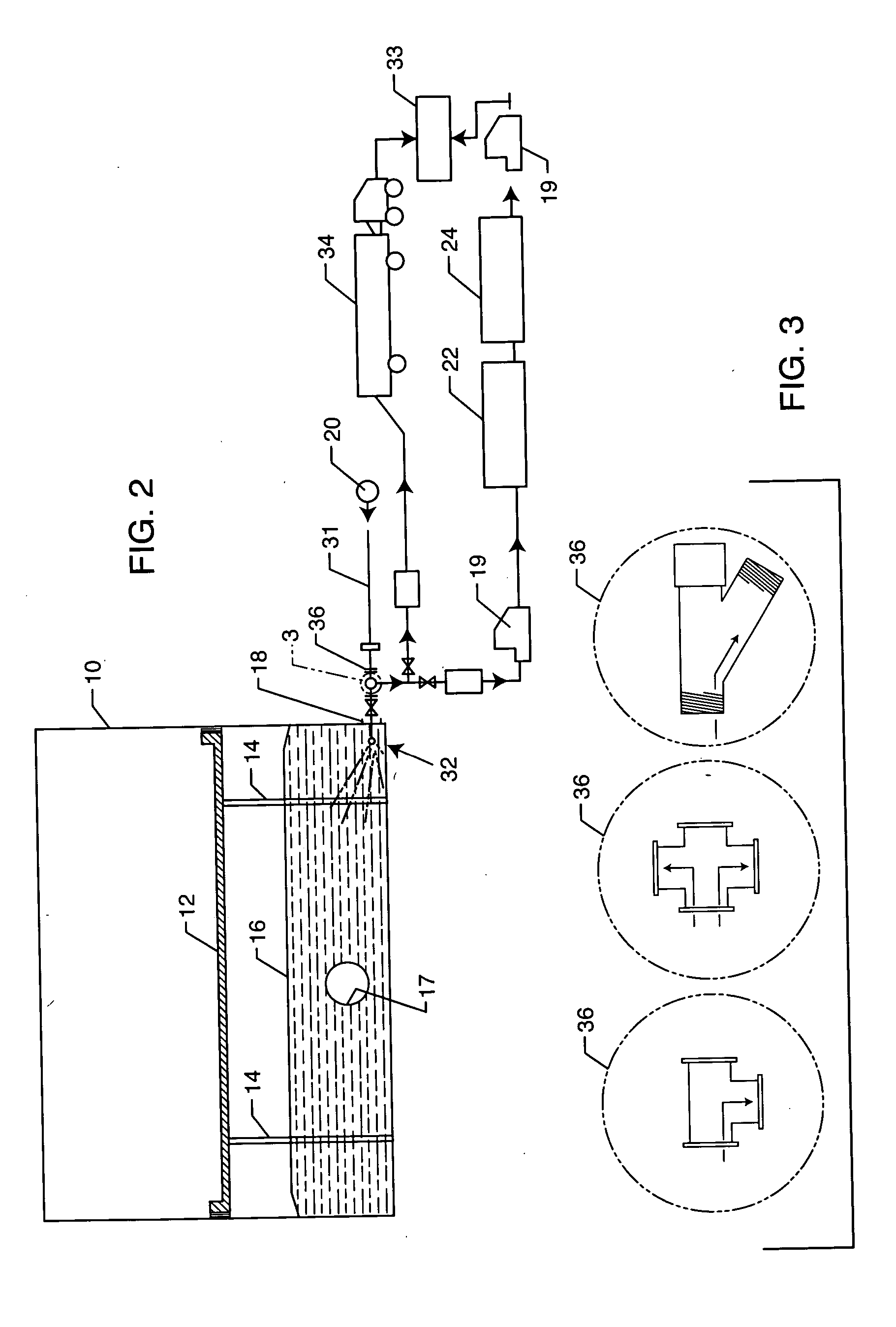

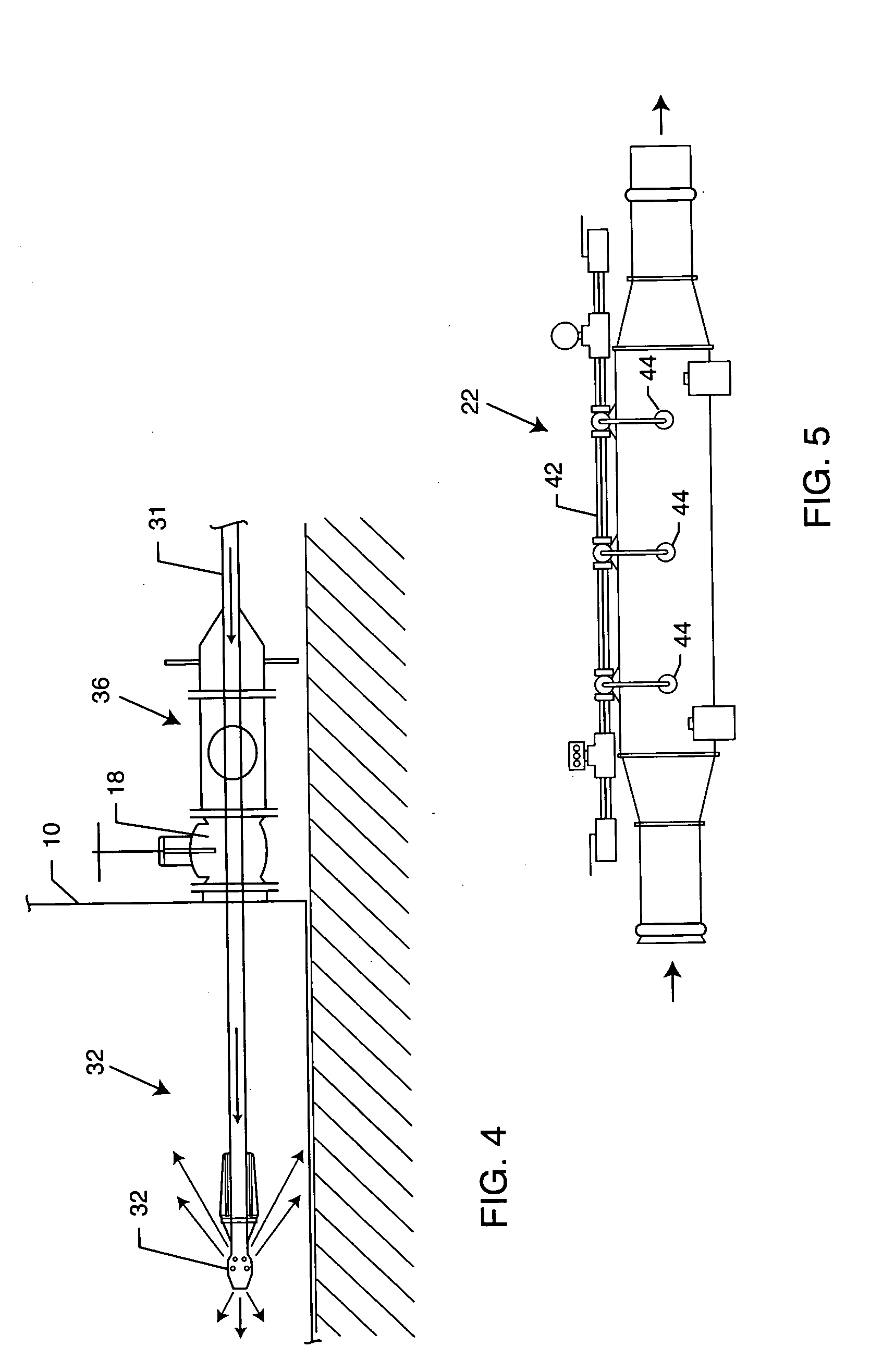

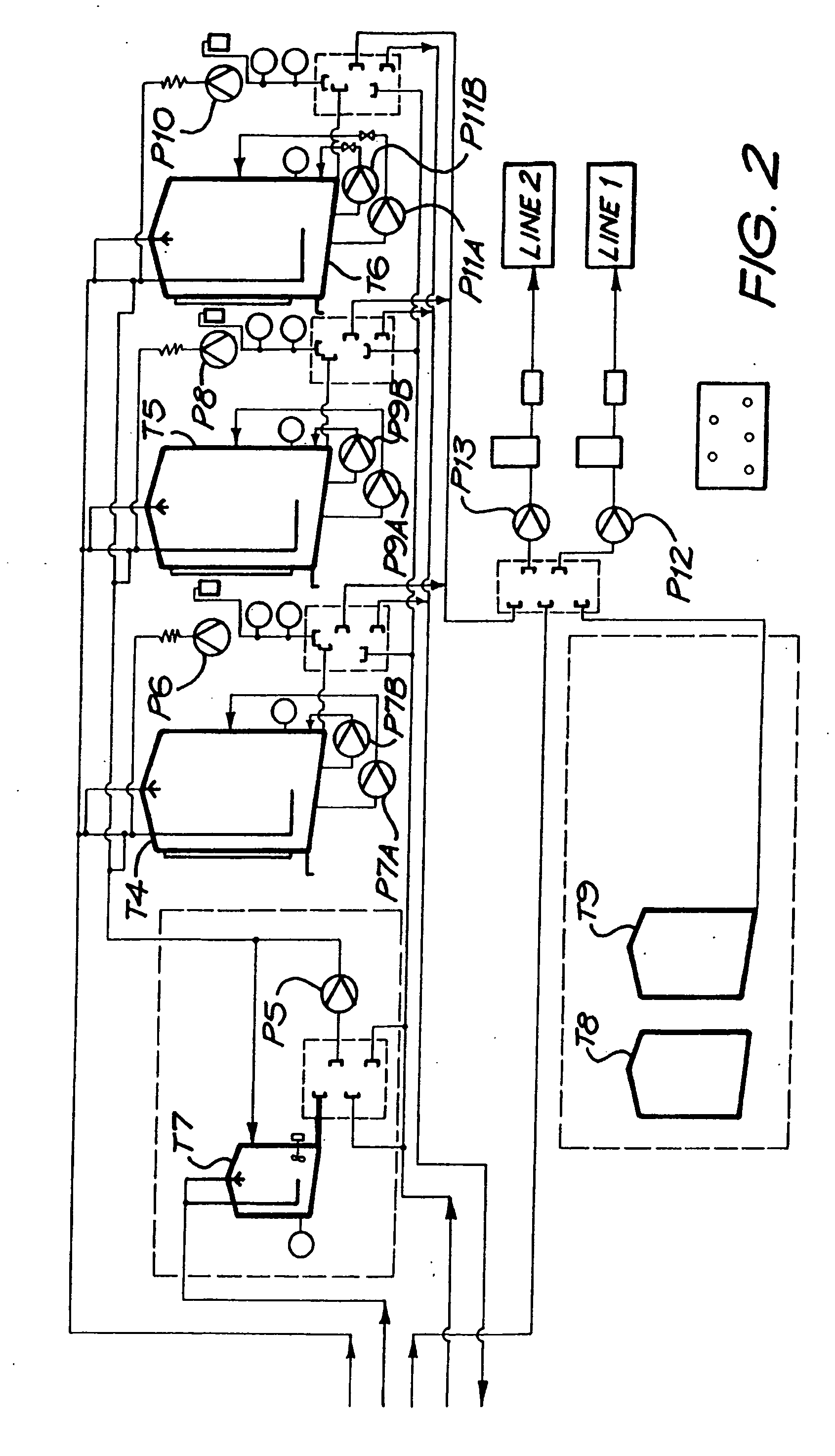

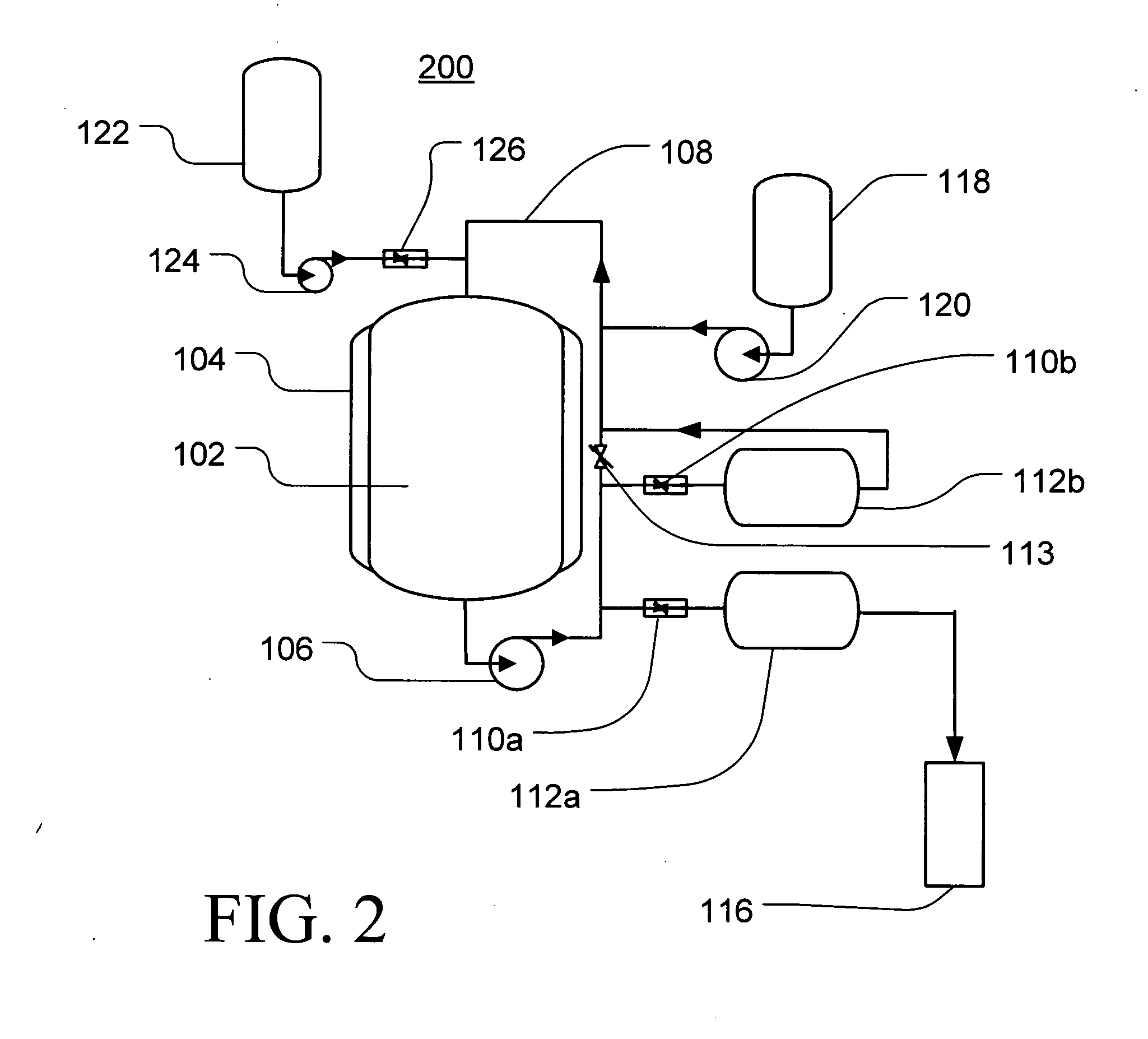

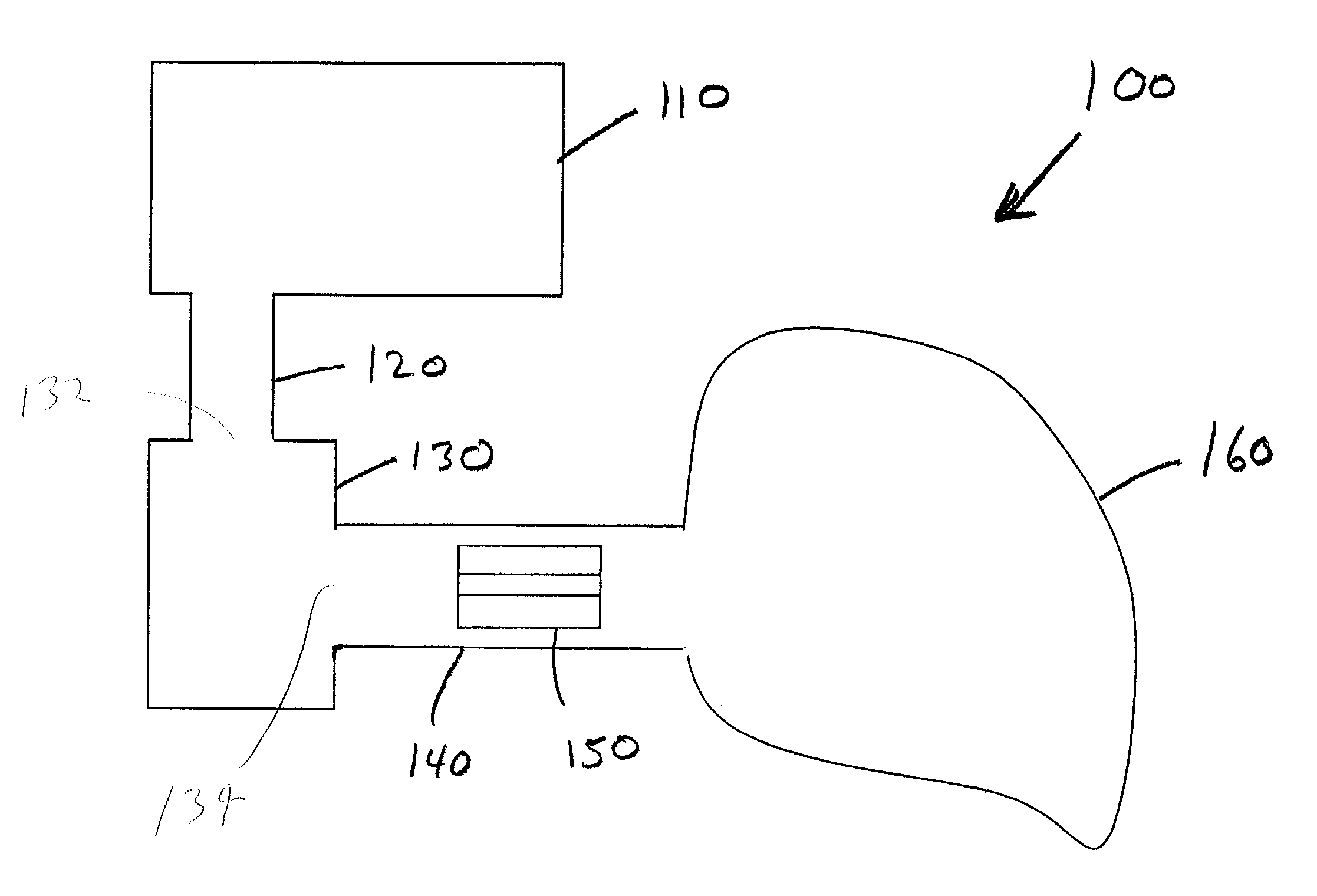

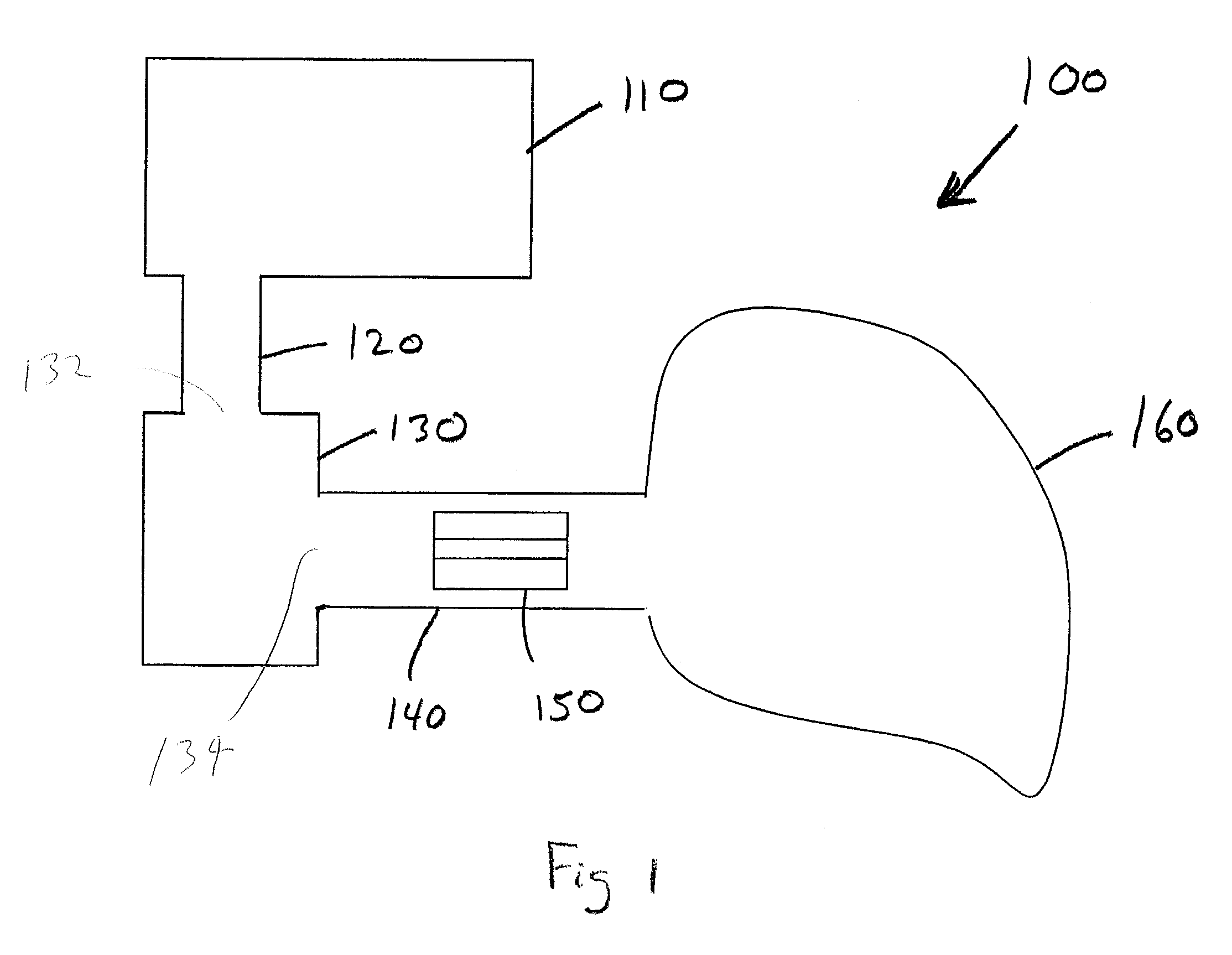

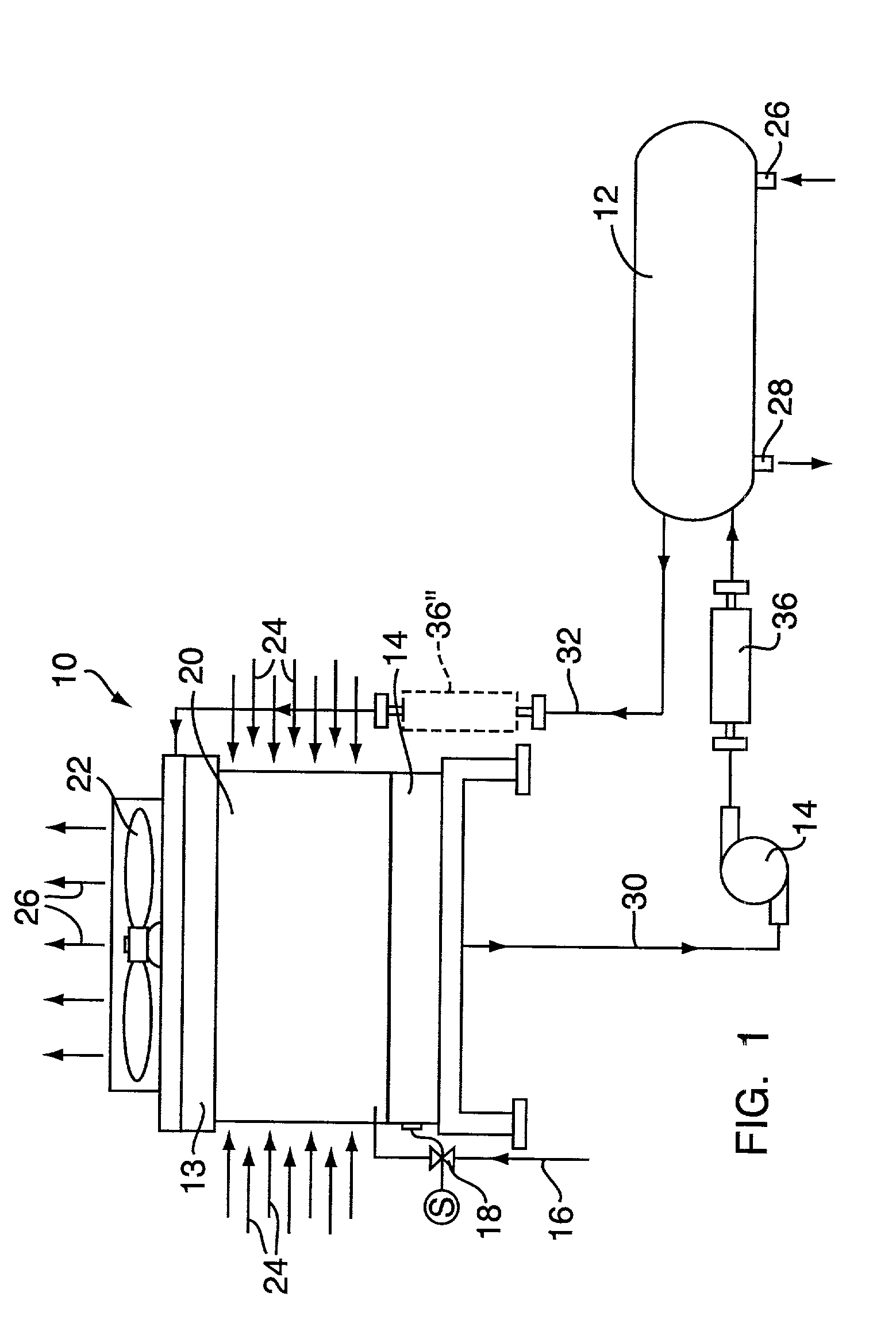

Petroleum recovery and cleaning system and process

InactiveUS7594996B2Quality improvementIncrease productionInorganic/elemental detergent compounding agentsLiquid separation auxillary apparatusProcess equipmentPetroleum product

A system and process are provided for recovering and / or cleaning residual or waste petroleum products such as sludge accumulated within a storage tank or upon process equipment surfaces, or from inorganic materials such as sand or clay, and the like. The system and process include a negatively charged aqueous-based dispersion fluid, which is contacted with the petroleum product under controlled relatively high pressure and high shear conditions for fluidizing hydrocarbon molecules and for preventing such molecules from adherence to process equipment surfaces, or contaminants such as sand or clay. Additional mechanical separation as by subjecting the mixed petroleum product and dispersion fluid slurry to sonic vibration may also be employed. The thus-fluidized slurry of petroleum products, dispersion fluid, and inorganic materials can be separated by conventional techniques, as by settling and / or flotation, for further individual processing and / or re-use.

Owner:AQUA TECH LLC

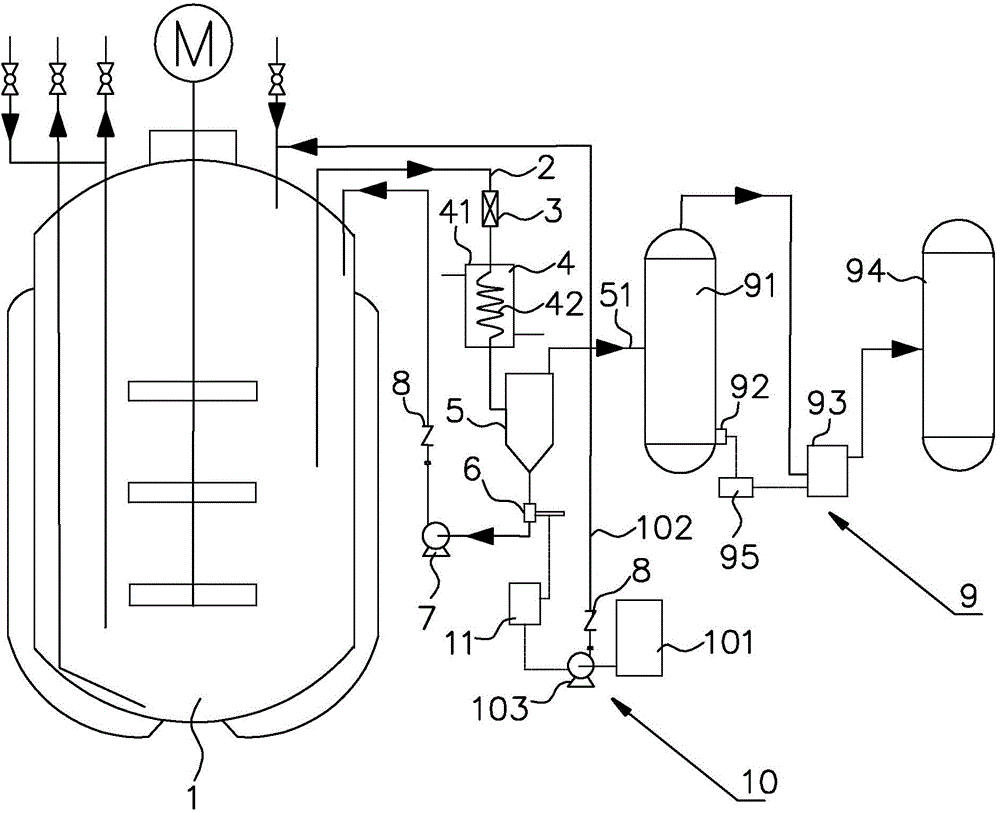

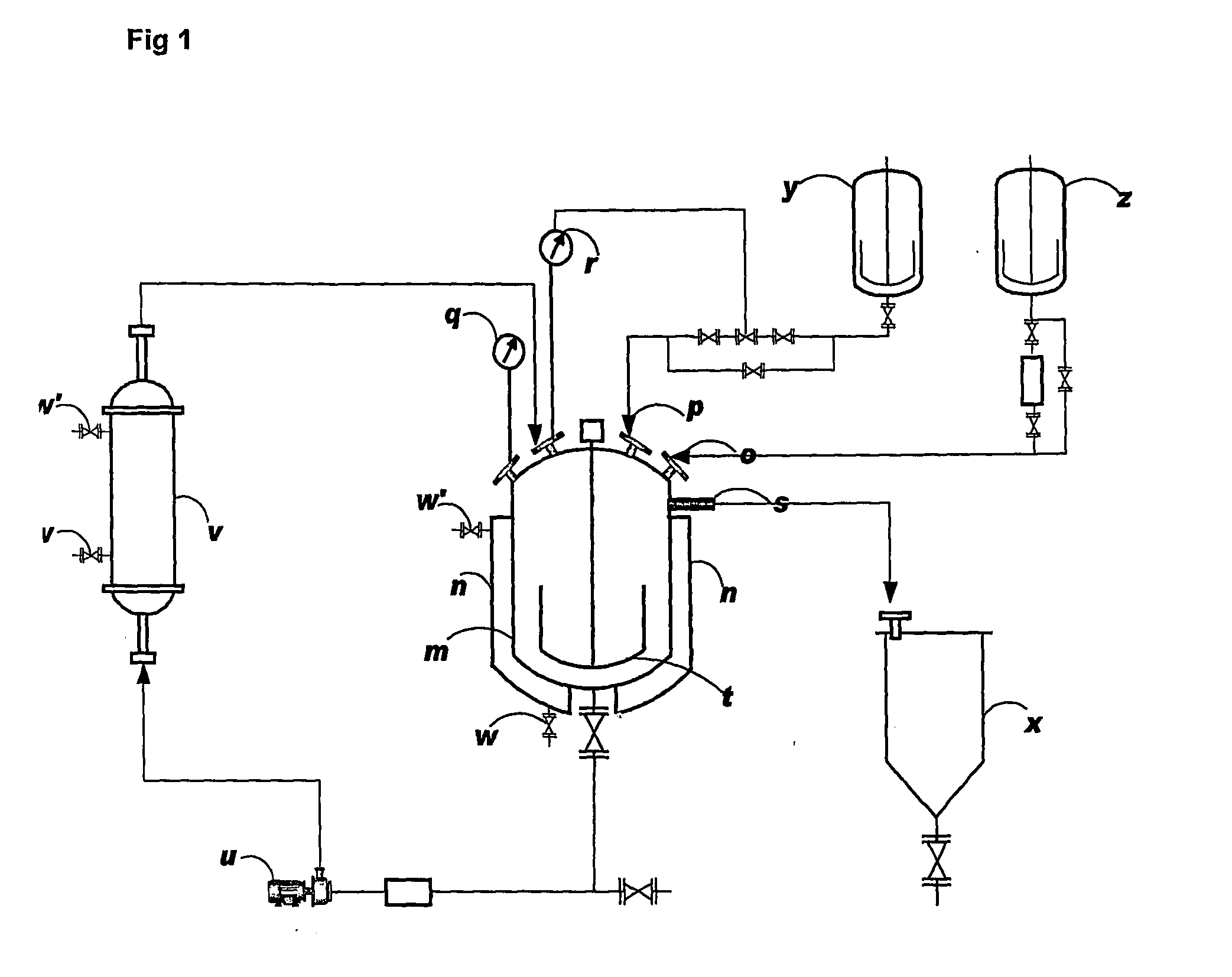

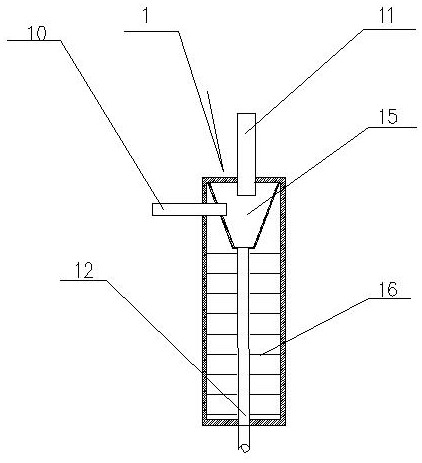

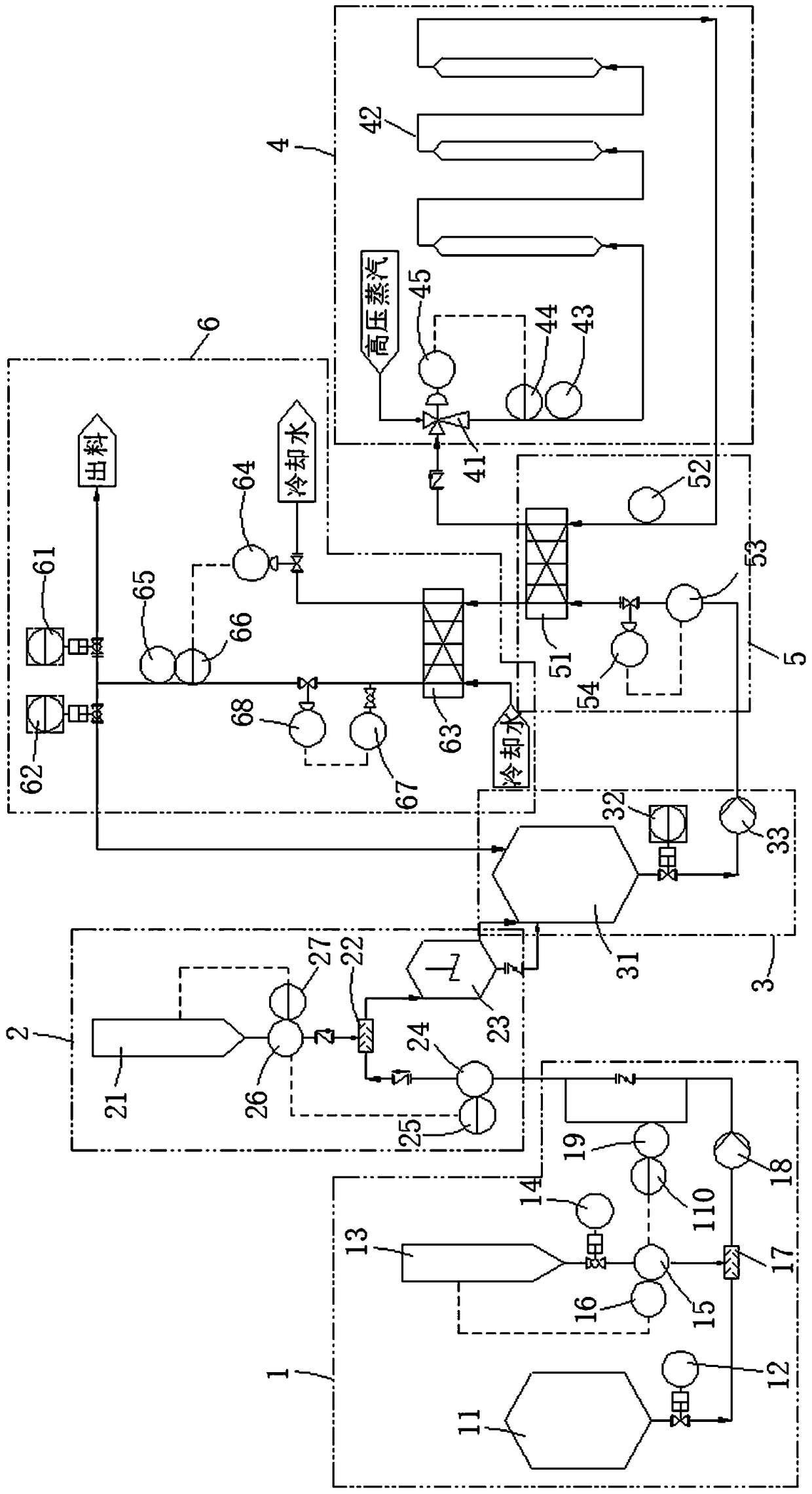

Online pH adjusting device and online pH adjusting process of catalytic hydrogenation reaction

ActiveCN104525074AImprove efficiencyReduce the difficulty of operationProcess control/regulationPH-change processesAutomatic controlControl unit

The invention discloses an online pH adjusting device and an online pH adjusting process of catalytic hydrogenation reaction. The online pH adjusting device comprises a material cooling system, an online pH detection unit, an alkaline liquid supplementing unit and a control unit, wherein the material cooling system is communicated with a reaction kettle, and a material circulating loop is formed between the material cooling system and the reaction kettle; the online pH detection unit is used for detecting a pH value of a material cooled by the material cooling system; the alkaline liquid supplementing unit is used for conveying alkaline liquid into the reaction kettle; the control unit is used for receiving a signal of the online pH detection unit and controlling the alkaline liquid supplementing unit to be started and stopped according to the signal. The material cooling system and the reaction kettle form the material circulating loop, the pH value of the cooled material on the material circulating loop and adjusted according to the measurement result, and the variation of the pH value in the reaction process can be monitored in real time, so that the pH value in the entire catalytic hydrogenation reaction process is stable, the high efficiency of the catalytic hydrogenation reaction can be guaranteed, automatic control for the entire process is adopted, and the operation difficulty of workers can be alleviated.

Owner:ZHEJIANG HUAKANG PHARMA

Methods and systems for carrying out a pH-influenced chemical and/or biological reaction

The present invention generally relates to methods and systems for carrying out a pH-influenced chemical and / or biological reaction. In some embodiments, the pH-influenced reaction involves the conversion of CO2 to a dissolved species.

Owner:MASSACHUSETTS INST OF TECH

System and method for purifying cumene hydroperoxide cleavage products

InactiveUS6573408B1Eliminate needPressurized chemical processOrganic compound preparationWater solubleAqueous solution

A system for purifying a cumene hydroperoxide cleavage product mixture comprises a cumene hydroperoxide cleavage product mixture feed containing impurities in fluid communication with an aqueous alkaline solution feed; the cumene hydroperoxide cleavage product mixture and aqueous alkaline solution feeds are in fluid communication with a neutralization drum having an aqueous salt phase outlet; an aqueous salt phase feed containing impurities in fluid communication with a heat treatment vessel having a heat-treated aqueous salt phase outlet; and a heat-treated aqueous salt phase feed containing water-soluble derivatives of the impurities in fluid communication with the cumene hydroperoxide cleavage product mixture prior to the neutralization drum.

Owner:SABIC GLOBAL TECH BV

Methods and systems for carrying out a ph-influenced chemical and/or biological reaction

The present invention generally relates to methods and systems for carrying out a pH-influenced chemical and / or biological reaction. In some embodiments, the pH-influenced reaction involves the conversion of CO2 to a dissolved species.

Owner:MASSACHUSETTS INST OF TECH

Process of forming an oxidizing agent in liquid by use of ringing magnetic flux

InactiveUS20030111420A1Reduce the populationQuick killLiquid separation auxillary apparatusLiquid separation by electricityMagnetic fluxOxygen rich

A method of making an oxygen-rich and stabilized oxidizing agent in a liquid, preferably water, involves exposure of aerated liquid to repeated bursts of ringing magnetic flux having a primary frequency of 10 kHz to 80 kHz, with the bursts repeated at a frequency of 1 Hz to 100 Hz, and with the water being kept basic at a pH level between pH 7 to pH 10. The oxidizing agent is believed to be a relatively stable complex of hydrogen peroxide, and has a significant anti-microbial effect on microorganisms, including biofilms, in the water achieved by oxidation of the oxidizing agent with chemical components of the microorganisms.

Owner:EVAPCO PROD INC

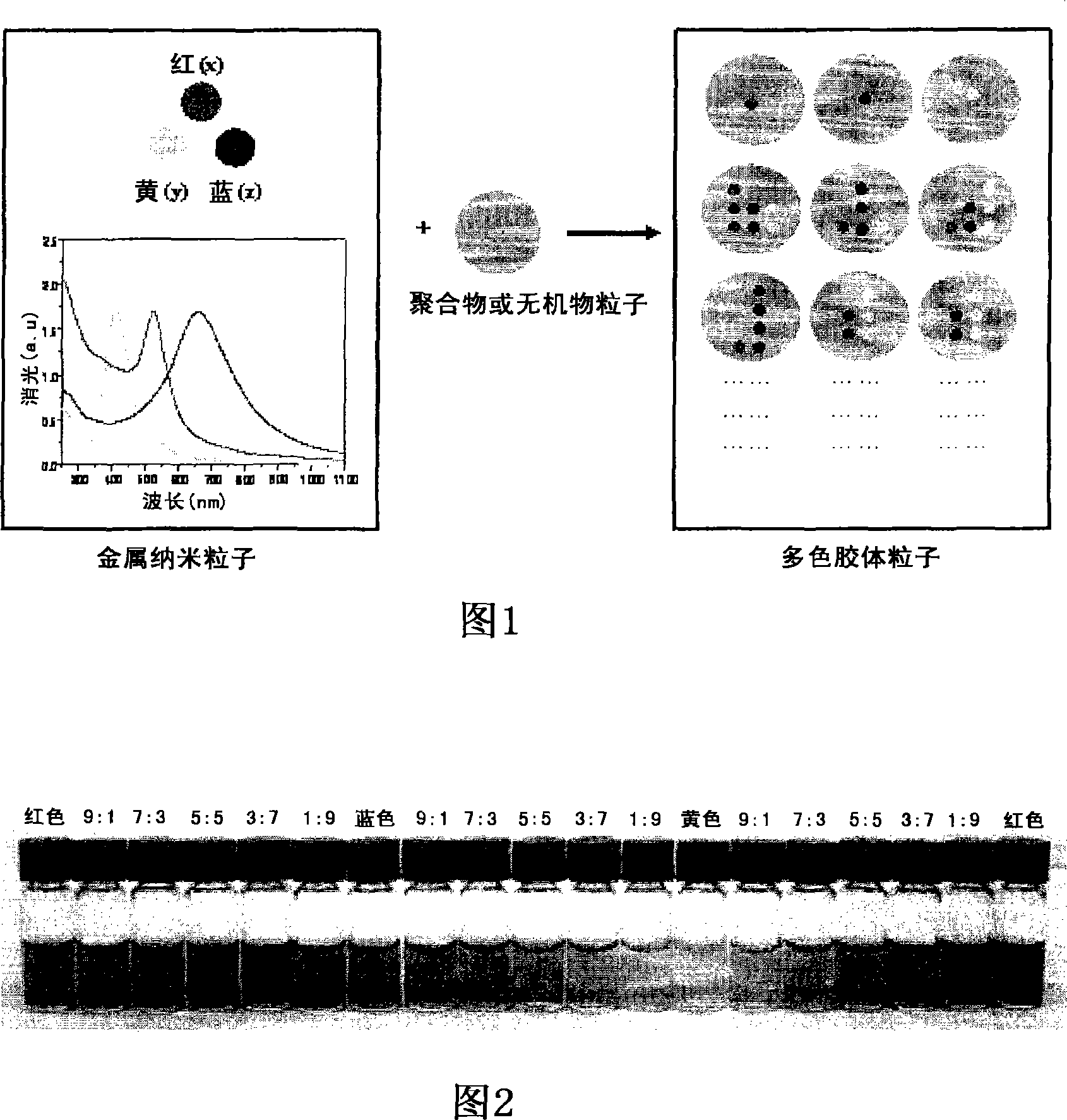

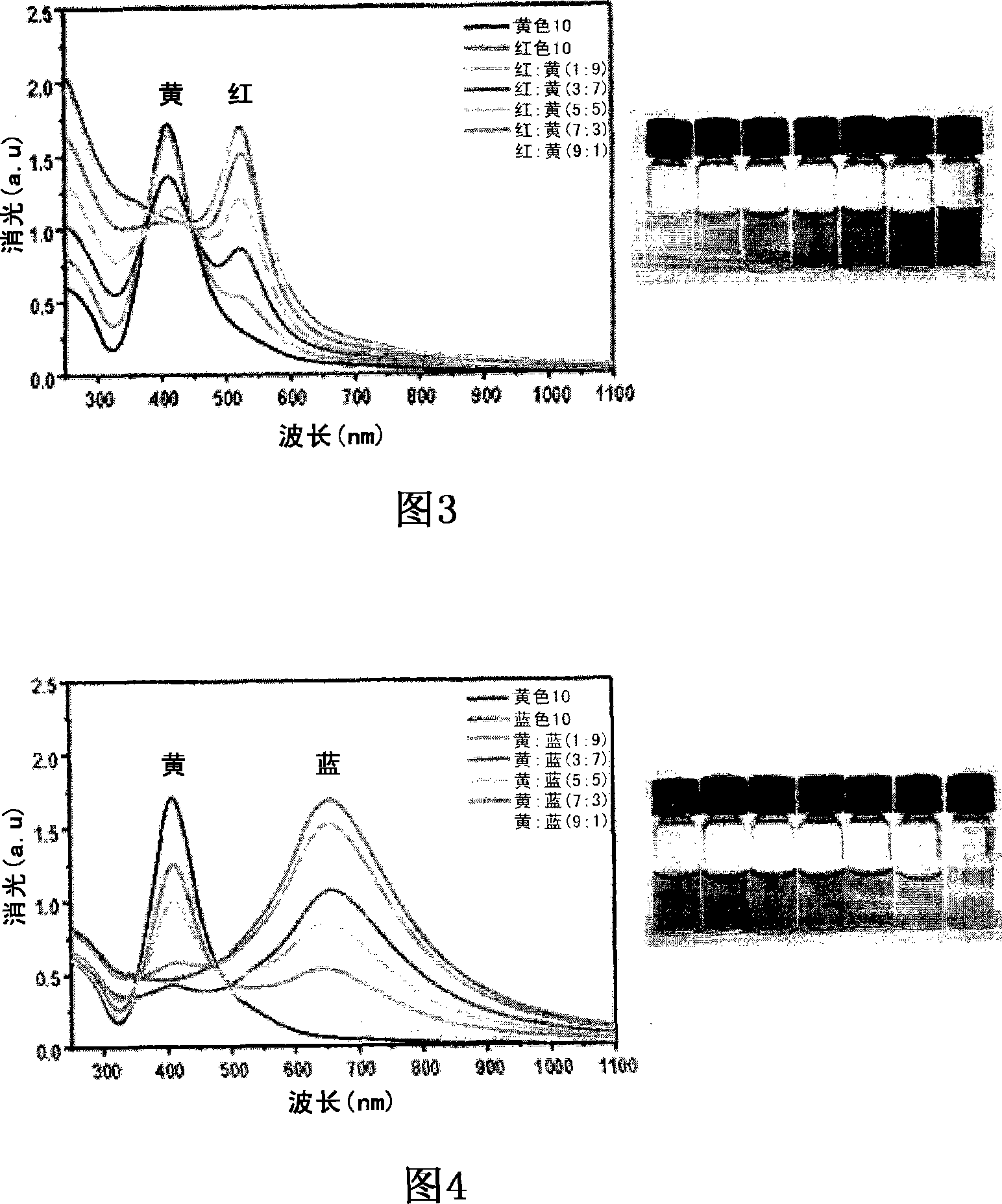

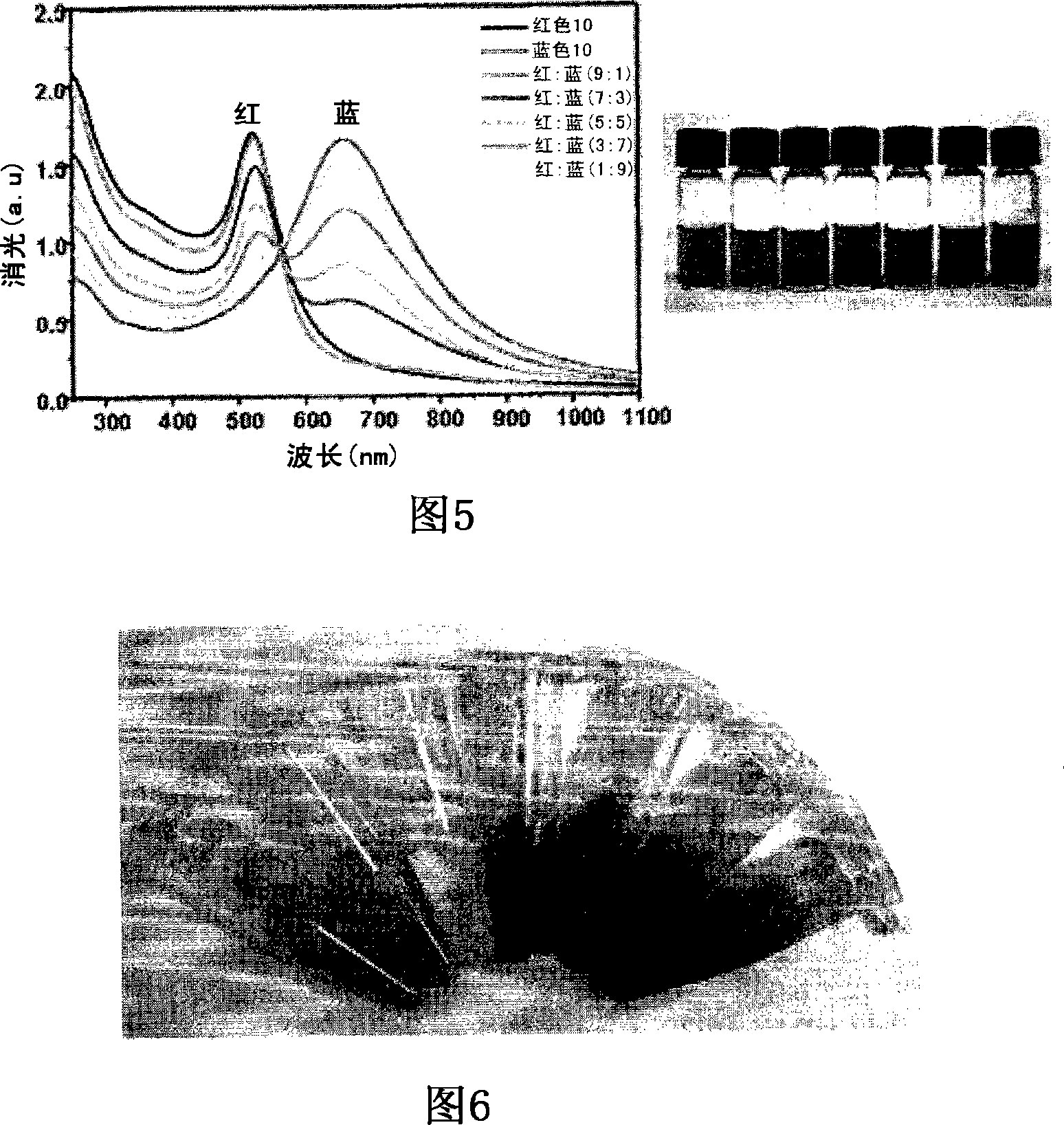

Multicolor-encoded colloidal particles coated with metal nanoparticles mixture having colors in the visible region and method for preparing the same

InactiveCN101203298AMaterial nanotechnologyTransportation and packagingNanoparti clesColloidal particle

The present invention relates to multicolor colloidal particles coated with a metal nanoparticle mixture having colors in the visible region and a method for preparing the same. In particular, relates to a metal nanoparticle mixture in which two or more nanoparticles selected from the group consisting of metal nanoparticles exhibiting red color; metal nanoparticles exhibiting yellow color; and metal nanoparticles exhibiting blue color, are mixed in various compositional ratio, multicolor colloidal particles in which polymer or mineral colloidal particles are coated with the metal nanoparticle mixture, and a method for preparing the same. According to the present invention, all colors that are in the visible region can be developed by suitably mixing metal nanoparticles exhibiting three colors, and multicolor colloidal particles can be prepared by coating polymer or mineral colloidal particles with a metal nanoparticle mixture exhibiting various colors.

Owner:KOREA RES INST OF BIOSCI & BIOTECH

Continuous Neutralizer Mixer Reactor and a Continuous Process for Quenching Chlorination Reaction Mixture in Production of Chlorinated Sucrose

An improved process of production of a chlorinated sugar is described comprising chlorination of a partially protected sugar, wherein quenching as well as neutralization of chlorinated reaction mass is carried out concurrently and continuously in a reactor which is a continuous mixer as well as quencher providing continuous mixing of chlorination reaction mixture and pH adjusting solution and also provides for continuous quenching and continuous removal of quenched chlorinated reaction mixture.

Owner:V B MEDICARE PVT LTD

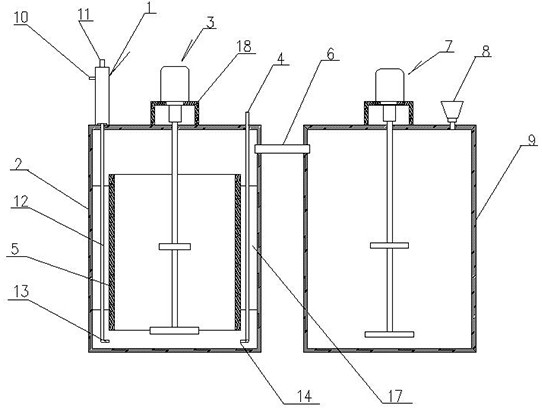

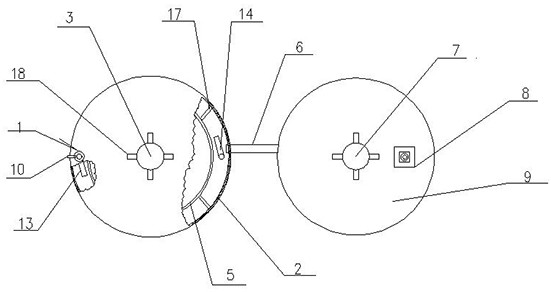

Iron removal device for nickel-cobalt-manganese sulfuric acid solution and method for continuously removing iron ions in nickel-cobalt-manganese sulfuric acid solution at low temperature

PendingCN113046555ARealize continuous productionImprove production efficiencyProcess efficiency improvementPH-change processesIron removalPhysical chemistry

The invention discloses an iron removal device for a nickel-cobalt-manganese sulfuric acid solution and a method for continuously removing iron ions in the nickel-cobalt-manganese sulfuric acid solution at low temperature, and relates to a method for removing iron in a nickel-cobalt-manganese sulfuric acid solution. The device is provided with an iron removal reactor and an aging reactor, a stirrer is arranged in the iron removal reactor, an aging reactor stirrer is arranged in the aging reactor, an iron removal reactor inner barrel is arranged in the iron removal reactor, a mixed feeding pipe and a carbonate solution feeding pipe are arranged between interlayers of the iron removal reactor and the iron removal reactor inner barrel, a mixer of a preheating device is arranged at the top of the mixed feeding pipe, a compressed air inlet and a to-be-deironed liquid feeding hole are formed in the mixer, and an automatic mountain flour feeder is arranged on the aging reactor. The invention further discloses the iron removal method. The device has the advantages that the requirement for equipment is not high, energy is saved, continuous production can be achieved, the productivity efficiency is greatly improved, ferrous iron ions can be oxidized into trivalent iron ions under the condition that an oxidizing agent is not added, and the iron removal rate is 99.5% or above.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

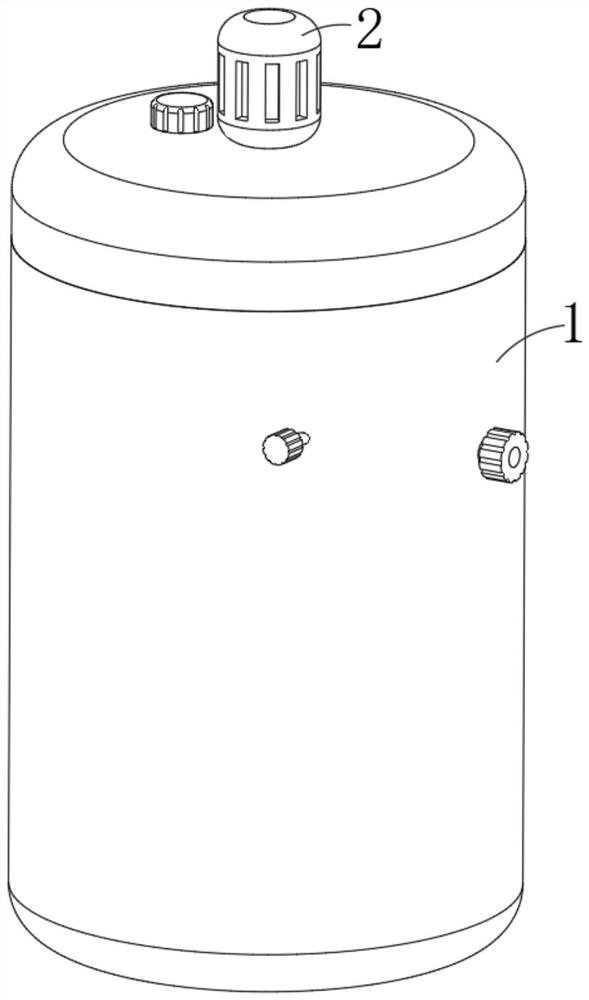

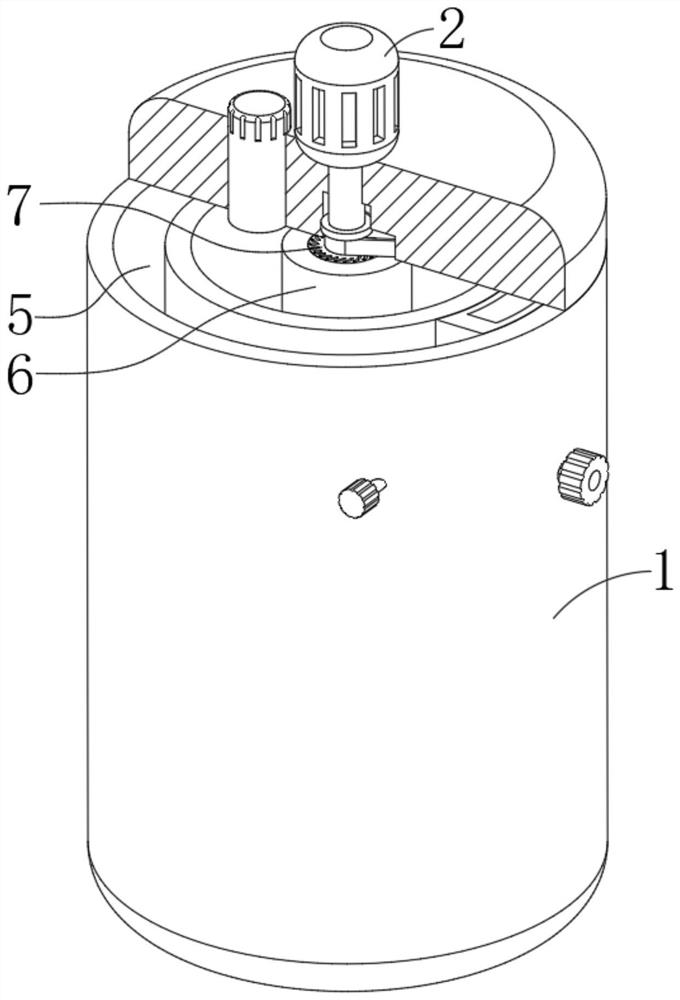

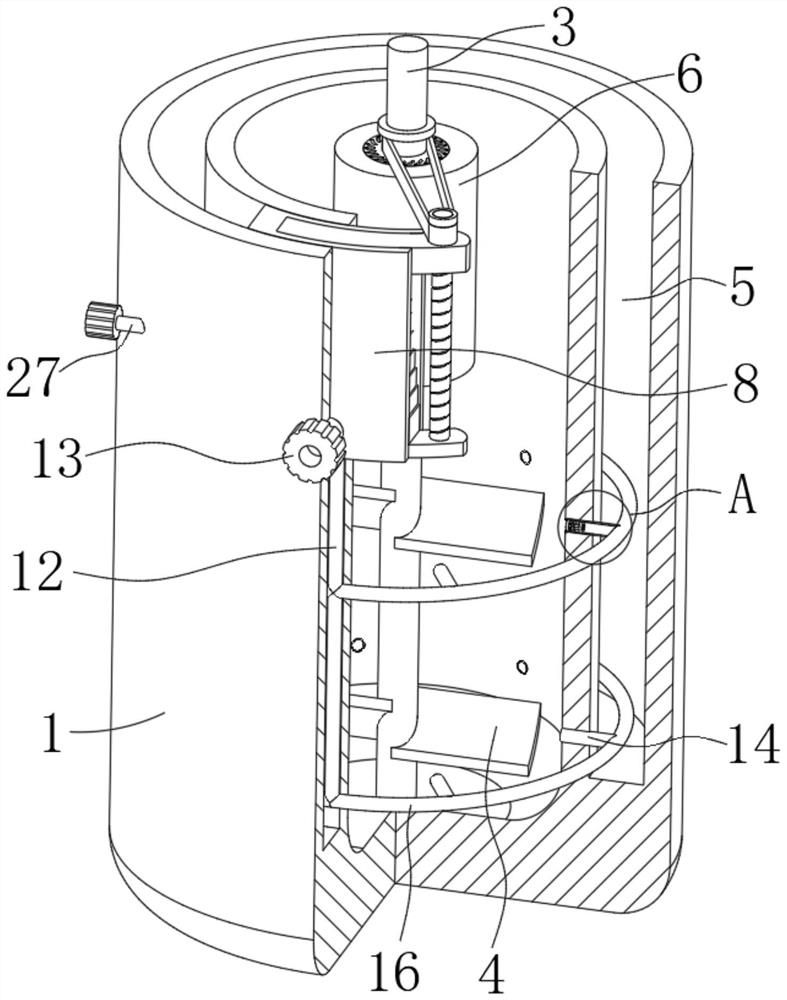

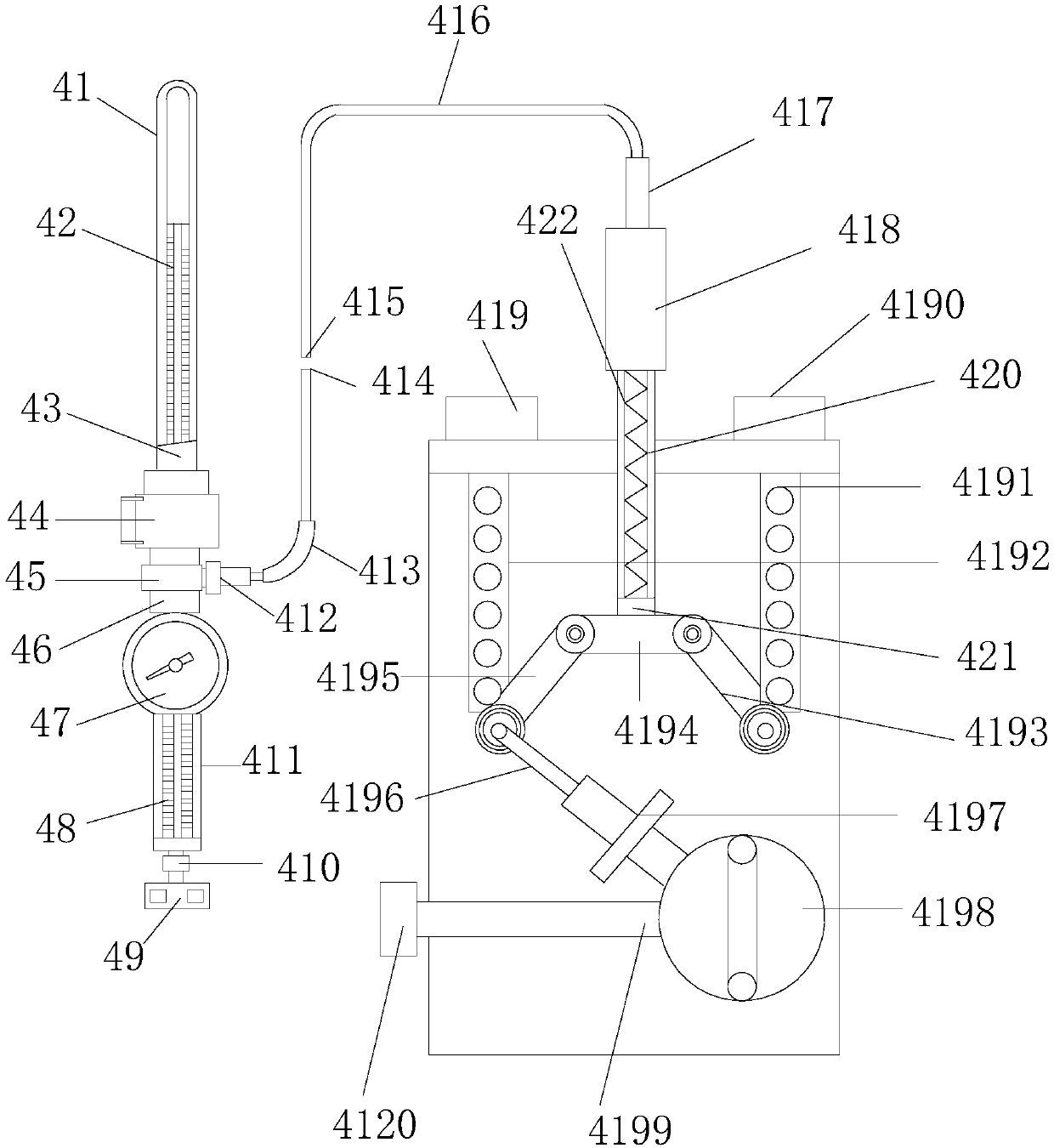

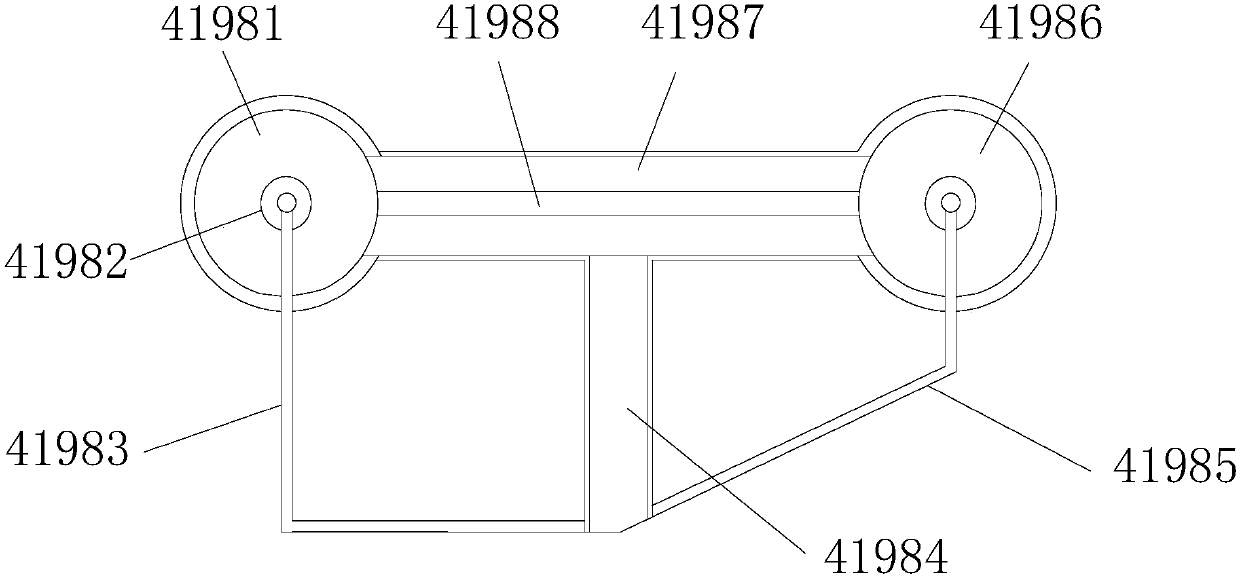

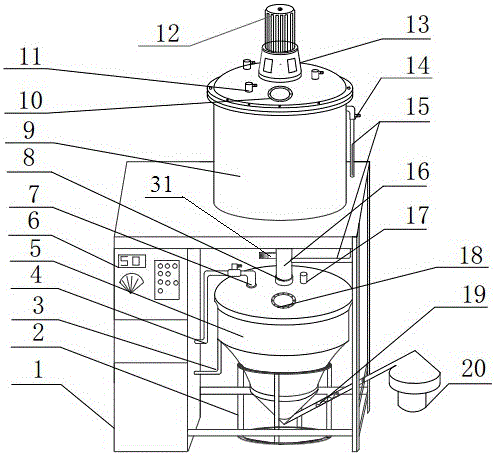

Hydrothermal treatment device and method for preparing high-peptizing large-pore-volume pseudo-boehmite powder

PendingCN114534656ASolve the problem of cumbersome operation and easy deviationEasy to sprayProcess control/regulationPH-change processesPhysical chemistrySlurry

The invention discloses a hydro-thermal treatment device and method for preparing high-peptization large-pore-volume pseudo-boehmite powder, relates to the field of preparation of pseudo-boehmite powder, and solves the problems that an existing hydro-thermal treatment device for preparing the high-peptization large-pore-volume pseudo-boehmite powder is tedious in operation and prone to deviation during pH value adjustment. Comprising a reaction kettle body, a detection device and a dropwise adding device, a driving motor is fixedly connected to the reaction kettle body, according to the hydro-thermal treatment device for preparing the high-peptizing large-pore-volume pseudo-boehmite powder, by arranging the detection device and the dropwise adding device, ammonia water can be intermittently and uniformly sprayed into slurry when the pH value is adjusted, and the stirring speed is increased; the pH value at the moment is obtained through the detection of the stirring, mixing and detecting device, the ammonia water is in a non-adding state at the moment, when the pH value does not reach a specified value, the dropwise adding device continues to intermittently add the ammonia water, and when the pH value reaches the specified value, dropwise adding and detecting are stopped immediately, so that the detection is more accurate, and the working efficiency is improved.

Owner:山西炬华铝业股份有限公司

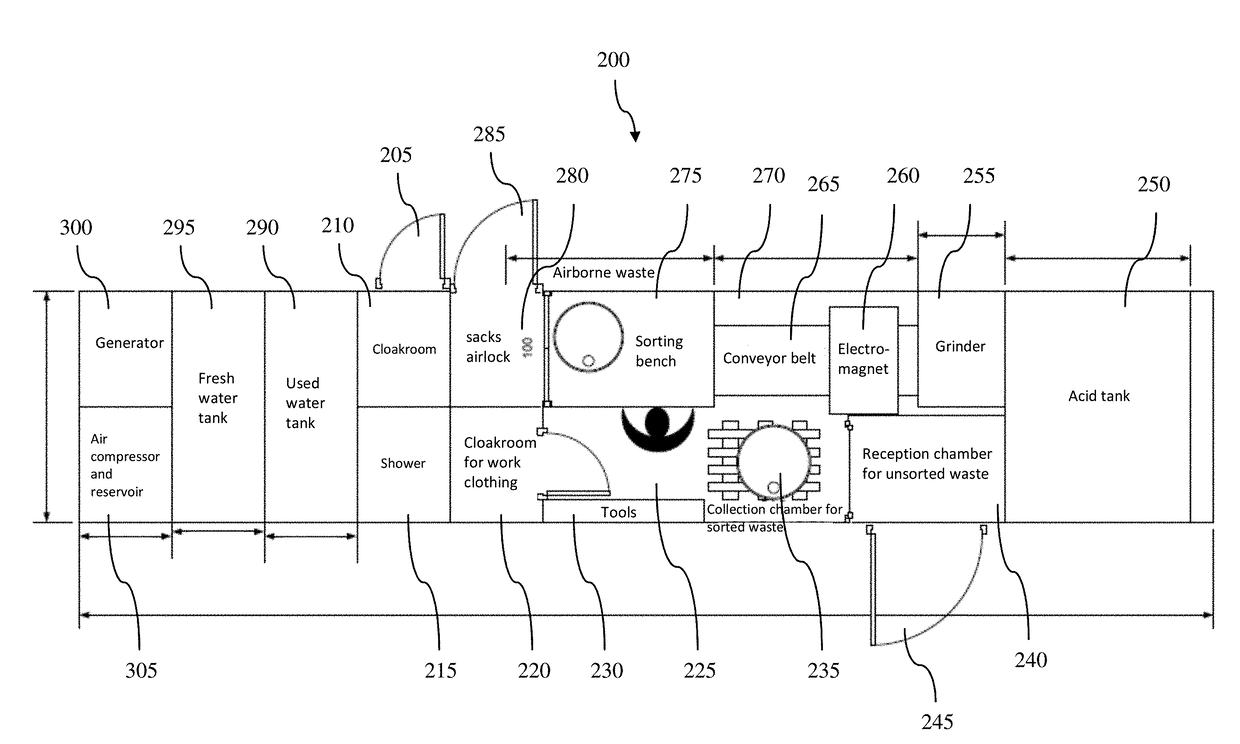

Method and stationary or movable device for neutralizing and recycling asbestos waste

ActiveUS20180256930A1Small sizeSpeed up neutralizationSolid waste disposalCalcium/strontium/barium sulfatesHydrogenFiltration

The asbestos waste neutralization device (10) comprises:an acid tank (23),a vat (16) containing a diluted acid solution, in which waste containing asbestos is dipped, with this solution neutralizing the asbestos waste,a filtration unit (21) to separate, at the end of the neutralization reaction, the solid inert waste from the liquid phase of the acid solution,a regeneration unit (22) for the attacking acid solution, which adjusts the hydrogen potential of the extracted liquid phase by adding concentrated acid contained in the acid reservoir, andmeans for transferring the regenerated solution into the vat.

Owner:BLACK ASBESTOS

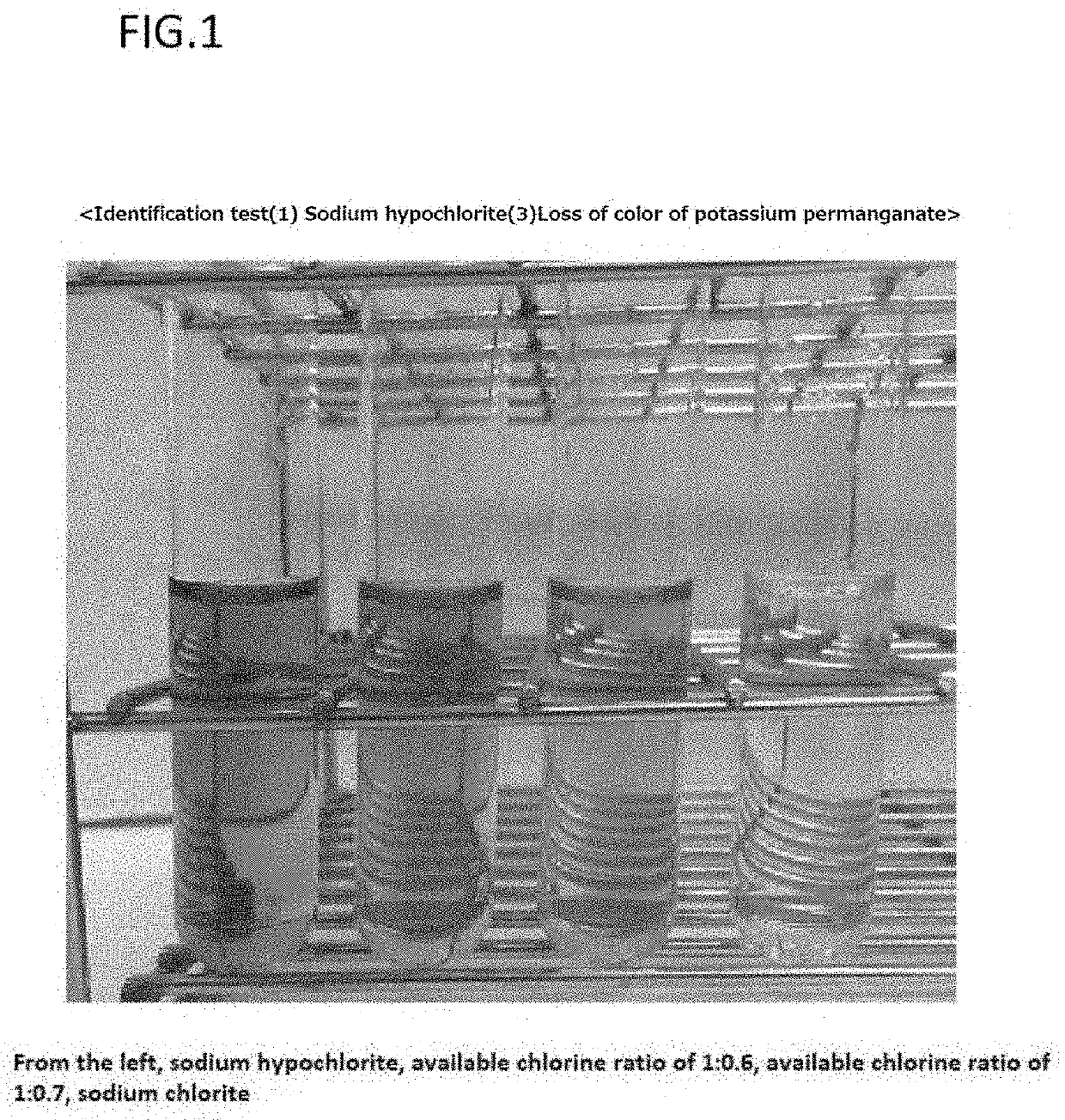

Manufacturing method for obtaining novel chlorine oxide composition from degraded hypochlorite

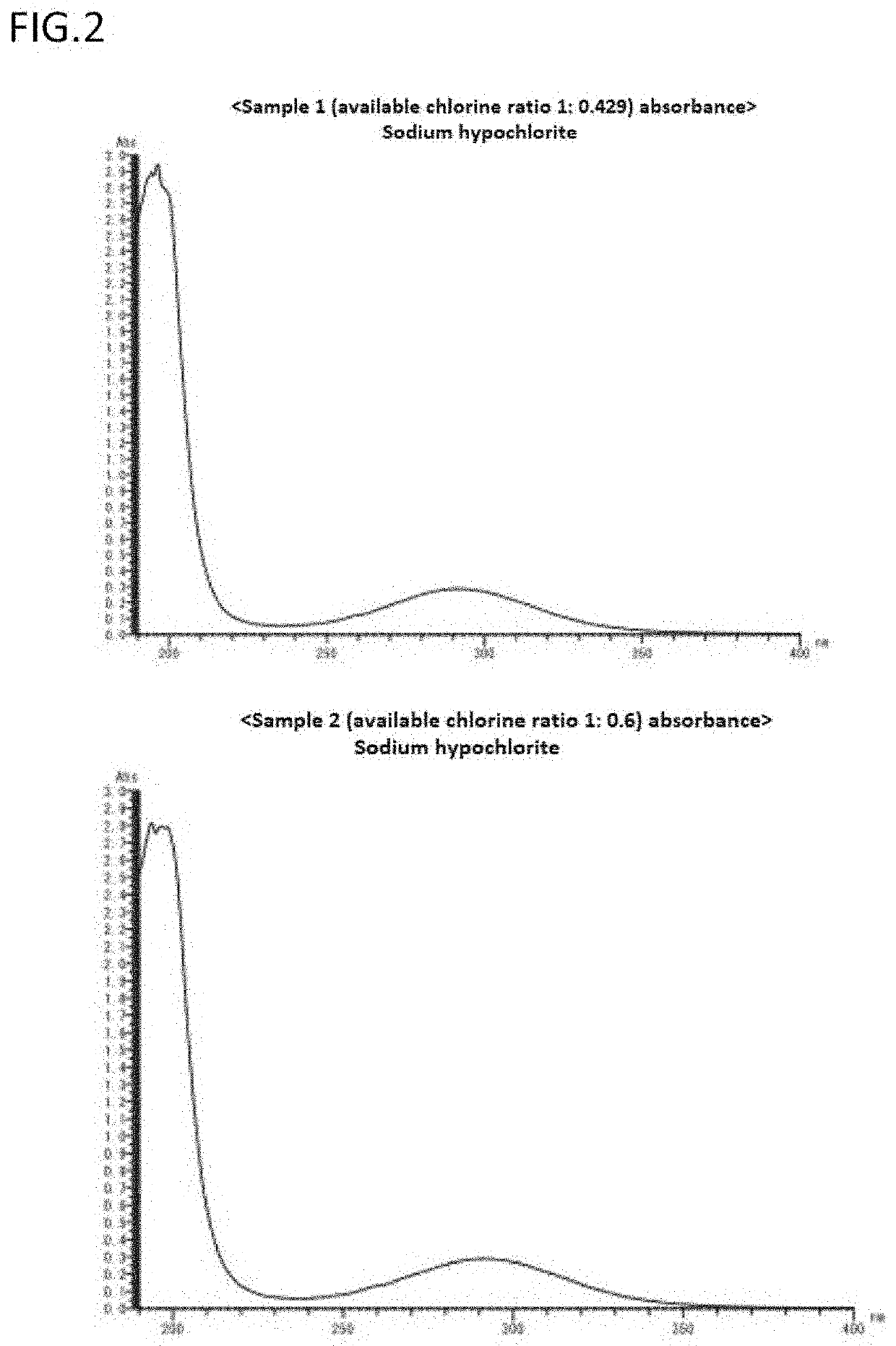

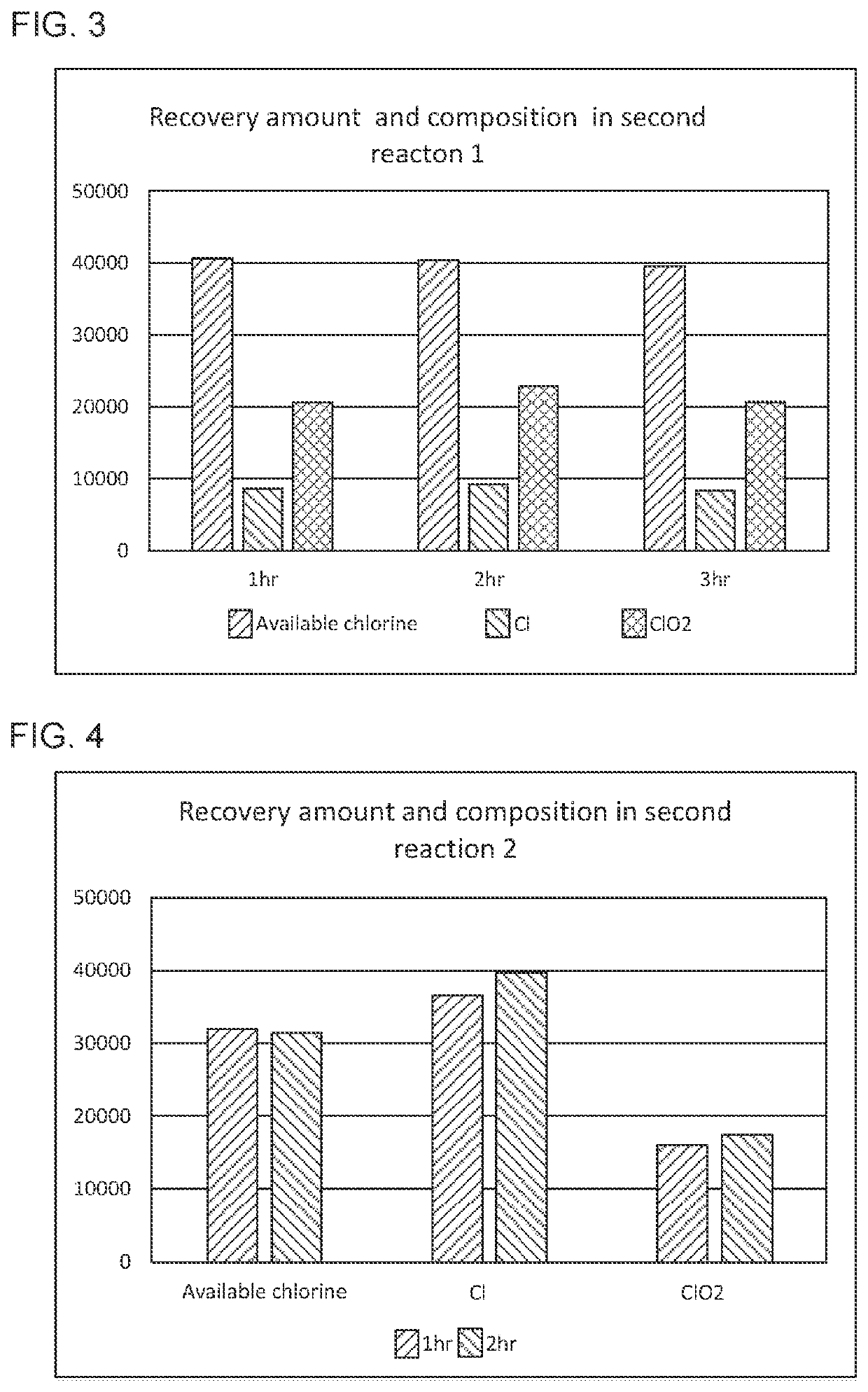

PendingUS20210206636A1Poor storabilityChlorine odorBiocideSedimentation separationHypochloriteChlorine dioxide

The purpose of the present invention is to provide a method for manufacturing a new disinfectant from sodium hypochlorite that has degraded in quality during storage. A method for manufacturing a novel disinfectant from a solution containing hypochlorite ions, chlorate ions, and chloride ions, wherein the method includes: a first reaction step for adding sulfuric acid to the solution and generating chlorine gas; a step in which, in a recovery liquid A, the generated chlorine gas is caused to react with sodium hydroxide or calcium hydroxide and recovered as hypochlorite ions; a second reaction step for adding, to a reaction mother liquid after the first reaction step, sulfuric acid having a higher concentration than that in the first reaction step, and generating chlorine dioxide gas; a step in which, in a recovery liquid B, the generated chlorine dioxide gas is caused to react with sodium hydroxide and hydrogen peroxide and recovered as chlorite ions; and a step for mixing the recovery liquid A and the recovery liquid B and obtaining a novel disinfectant.

Owner:HONBU SANKEI

System and method for continuously hydrolyzing hemicellulose to prepare xylose liquid

ActiveCN109355443AContinuous hydrolysisHydrolytically stablePH-change processesXylose productionReflux valveHemicellulose

The invention relates to a system for continuously hydrolyzing hemicellulose to prepare a xylose liquid. The system comprises a neutralization unit, an acid regulating unit, a feeding unit, a liquidation jet unit, a feeding and discharging heat exchange unit and a discharging control unit, wherein the neutralization unit comprises a raw material tank, a neutralizing concentrated sulfuric acid pumpand a neutralizing pipeline mixer, the acid regulating unit comprises an acid-regulating concentrated sulfuric acid pump, an acid-regulating pipeline mixer and an acid regulating tank, the feeding unit comprises a feeding tank, the liquidation jet unit comprises a liquidation injector and a liquidation maintainer, the feeding and discharging heat exchange unit comprises a feeding and dischargingplate type heat exchanger and a first discharging temperature sensor, and the discharging control unit comprises a discharging valve and a reflux valve. The prepared xylose liquid exchanges heat witha hemicellulose liquid in the feeding and discharging plate type heat exchanger, so that the temperature of the xylose liquid is reduced, and the temperature of the hemicellulose liquid is increased.The invention also discloses a method for using the system. The system for continuously hydrolyzing the hemicellulose to prepare the xylose liquid has the advantages that heat exchanging is performedon feeding and discharging simultaneously, thereby greatly reducing the energy consumption; feeding and discharging are performed continuously, thereby improving the production efficiency, and simplifying the workers' operation.

Owner:ZHEJIANG HUAKANG PHARMA +1

Stannous oxide and method for producing same

PendingCN110997570AImprove solubilityProcess control/regulationPH-change processesSTANNOUS OXIDEAmmonium carbonate

Owner:JX NIPPON MINING & METALS CORP

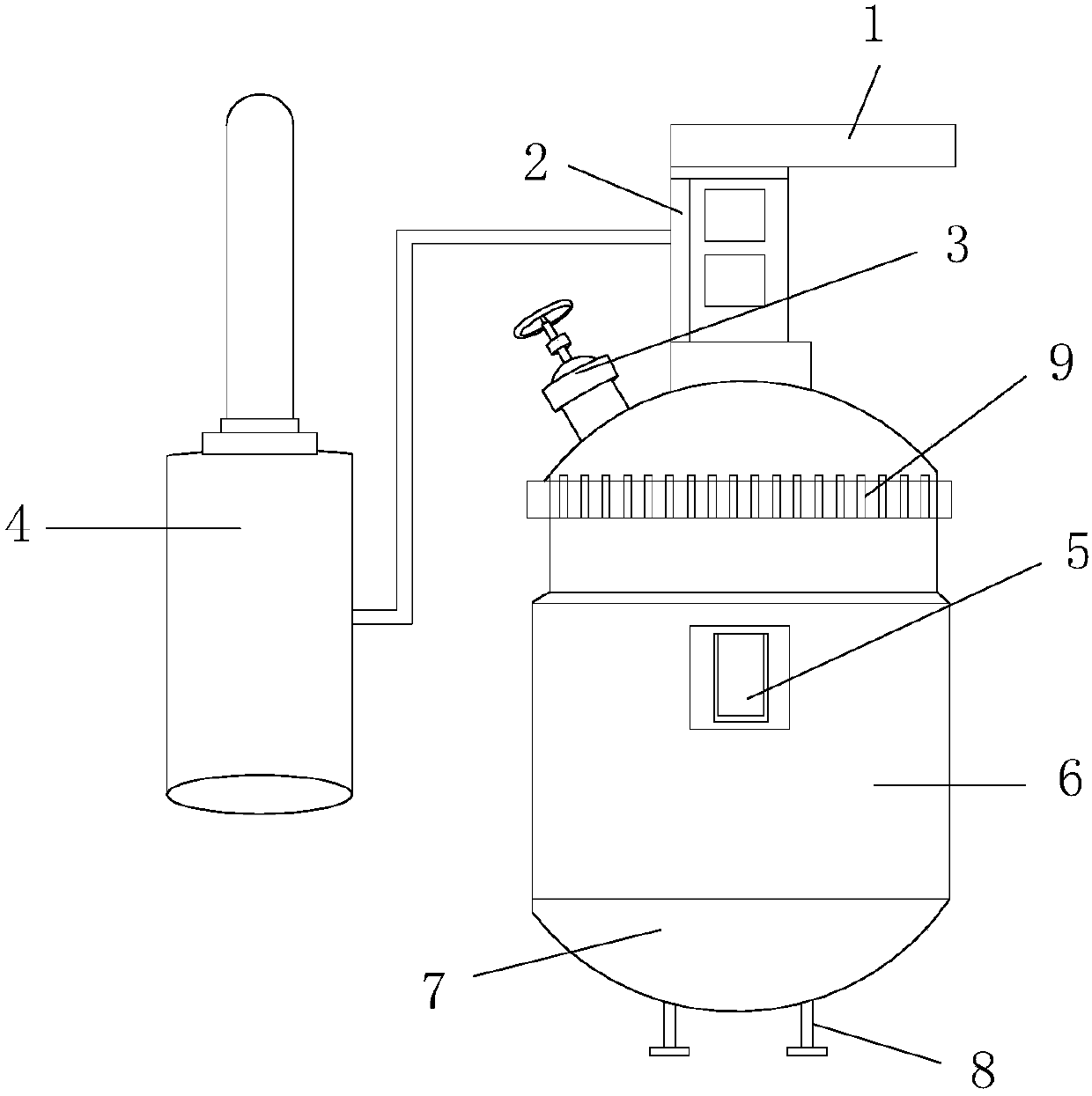

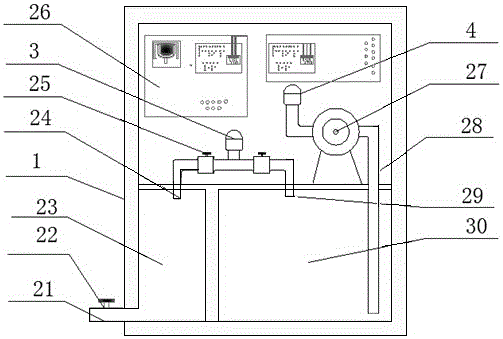

Automatic control reactor for solid-liquid reaction separation

ActiveCN107837768APrevent leakageImprove sealingPH-change processesChemical/physical/physico-chemical stationary reactorsAutomatic controlProcess engineering

The invention discloses an automatic control reactor for solid-liquid reaction separation. The automatic control reactor structurally comprises a motor, a retainer, a feeding inlet, an automatic temperature controller, a visual window, a reactor body, a kettle bottom, fixed supporting legs and sealing plates. The automatic control reactor is characterized in that a power source plate is connectedwith a temperature bulb pipe; the temperature bulb pipe is inserted into the reactor by a detection capillary; when the temperature in a temperature bulb is changed, the liquid volume is also changed,so that temperature change inside the reactor can be sensed according to volume change of expanded liquid in the temperature bulb pipe; the detection capillary transmits information to a temperatureadjusting valve according to the change phenomenon of the liquid; a valve rod is connected with a spring; the opening degree of the valve is controlled according to spring expansion, and further automatic control of the temperature inside the reactor is realized; meanwhile, a prompting port and a metering coiled tube can measure the liquid in the temperature bulb pipe and gives out prompt, so thatan operator conveniently learns the temperature in the reactor; by connection of a drawing rod and a control lever, reactants can be quickly separated out of a tank.

Owner:东营顺利生物科技有限公司

Chemical precipitation reaction integrated equipment

InactiveCN105727866ASmall footprintLess investmentPH-change processesChemical/physical/physico-chemical stationary reactorsCompound (substance)Sewage

An integrated equipment for chemical precipitation reaction, including a stirring tank and a centrifuge. The stirring tank is provided with a feeding port, the centrifuge is provided with a feeding port and a first water inlet, and the stirring tank is provided with a continuous operation discharge pipe and / or The intermittent operation discharge pipe and the continuous operation discharge pipe are respectively connected with the stirring tank and the centrifuge; the intermittent operation discharge pipe is respectively connected with the stirring tank and the centrifuge; there are also a first liquid storage room, a second liquid storage room and a water pump , the first liquid storage chamber is provided with a second water inlet and a liquid discharge port, and the second liquid storage chamber is provided with a third water inlet; the centrifuge is provided with a drainage pipe, which is connected to the second water inlet and the third water inlet respectively. The water port is connected; the centrifuge is provided with a circulating water pipe, one end of which is connected with the first water inlet, and the other end is connected with the water pump; machine, the screw feeder is connected with the centrifuge. The invention can carry out diversion treatment on the sewage, which is energy-saving and environment-friendly.

Owner:CENT SOUTH UNIV

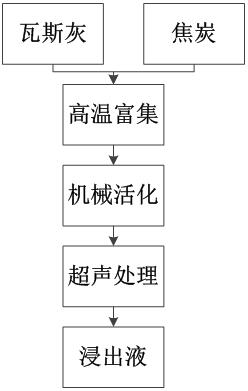

Method of Mechanochemical Coupling Ultrasonic Chemical Enhancement of Metal Leaching in Secondary Zinc Oxide Powder

ActiveCN110042230BUse low concentrationLow costPH-change processesEnergy based chemical/physical/physico-chemical processesPregnant leach solutionMetal leaching

The invention discloses a method for mechanochemical coupling ultrasonic chemical strengthening of metal leaching in secondary zinc oxide powder, comprising: mechanical activation: mechanically activating raw materials containing secondary zinc oxide powder to obtain an activation material; ultrasonic treatment: combining the activation material with the The acidic leaching solution is mixed to obtain a mixture, and the mixture is subjected to ultrasonic treatment, and the obtained liquid phase is the leachate. The combination of mechanochemical activation and sonochemistry enhanced the leaching rate and leaching rate of multi-metals through structural destruction and cavitation of secondary zinc oxide powder. This process can indirectly reduce the use concentration of acidic leaching solution and shorten the leaching time. In actual production, the specific application of this process can reduce the anti-corrosion cost and operating production cost of reaction equipment, and indirectly produce good production benefits.

Owner:GREENNOVO ENVIRONMENTAL TECH CO LTD

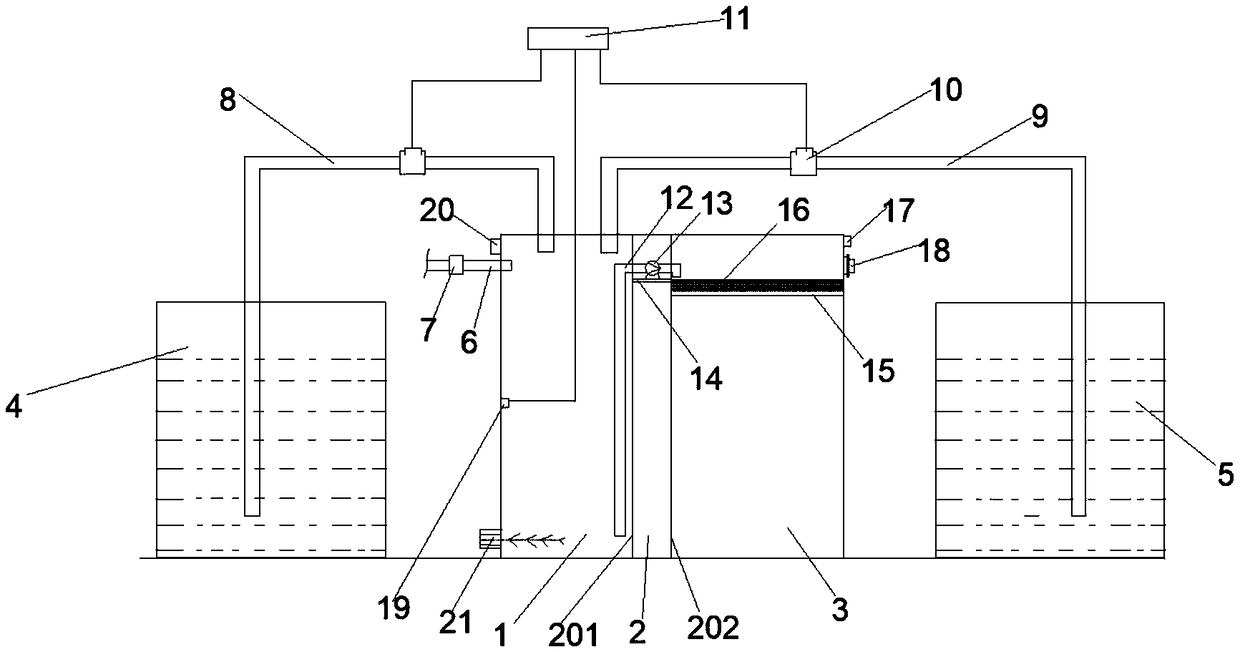

pH (potential of hydrogen) adjusting device

InactiveCN109453727ASmall footprintEasy to operate and managePH-change processesHydrogenAgricultural engineering

The invention relates to a pH (potential of hydrogen) adjusting device. The pH adjusting device comprises an adjusting machine body, wherein the adjusting machine body comprises an adjusting container, a separating layer and a neutralizing tank; the left upper end of the adjusting machine body is provided with a liquid inlet; the liquid inlet is connected with a liquid intake pipeline; the separating layer comprises a first blocking plate and a second blocking plate; the first blocking plate and the second blocking plate are fixedly connected with the bottom part of the adjusting machine bodyalong the vertical direction; a water passing pipe is arranged at the upper end of the separating plate; the left end and right end of the water passing pipe respectively penetrate through the surfaces of the first blocking plate and the second blocking plate; the left end of the water passing pipe extends to the bottom end of the adjusting container; a third blocking plate is arranged at the upper end of the neutralizing tank, a filtering net is arranged on the third blocking plate, and the right end of the water intake pipe extends to the upper end of the filtering net; an alkaline solutionstorage tank and an acid solution storage tank are arranged at the left end and right end of the adjusting machine body; a first pipeline and a second pipeline are arranged at the upper end of the adjusting container; one end of the first pipeline is communicated to the bottom end of the acid solution storage tank, and one end of the second pipeline is communicated to the bottom end of the alkaline solution storage tank; a pipeline is connected with an electromagnetic dosage pump; digital control equipment is arranged at the outer side of the machine body. The pH adjusting device has the advantages that the structure is simple, and the suitability is strong.

Owner:唐林

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com