Automatic control reactor for solid-liquid reaction separation

A solid-liquid reaction and reactor technology, which is applied in chemical/physical/physical-chemical fixed reactors, pH reaction, chemical instruments and methods, etc., can solve the problem of not being able to feel the temperature change of the reaction vessel, and increase the stirring range. , the effect of increasing the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

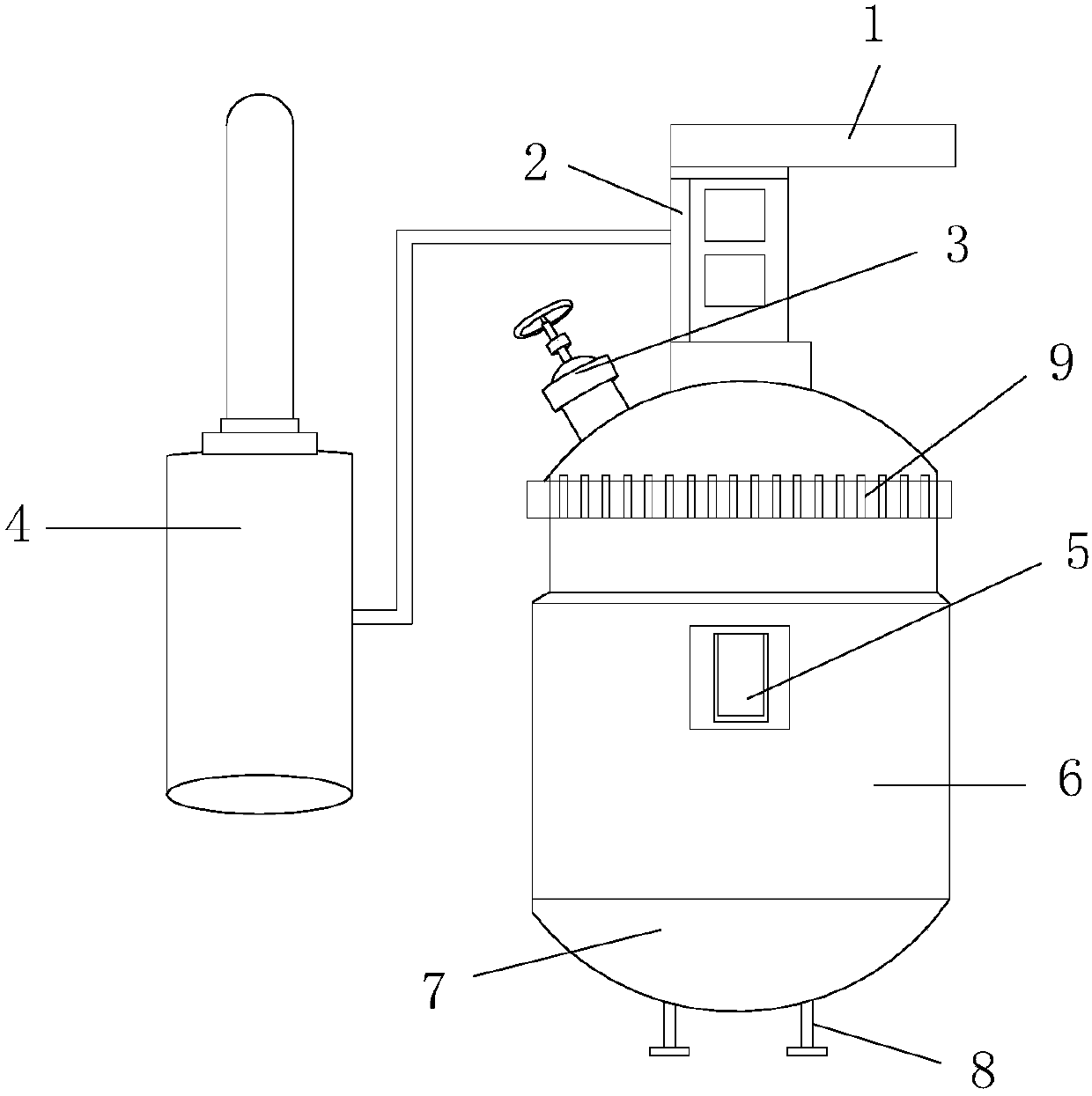

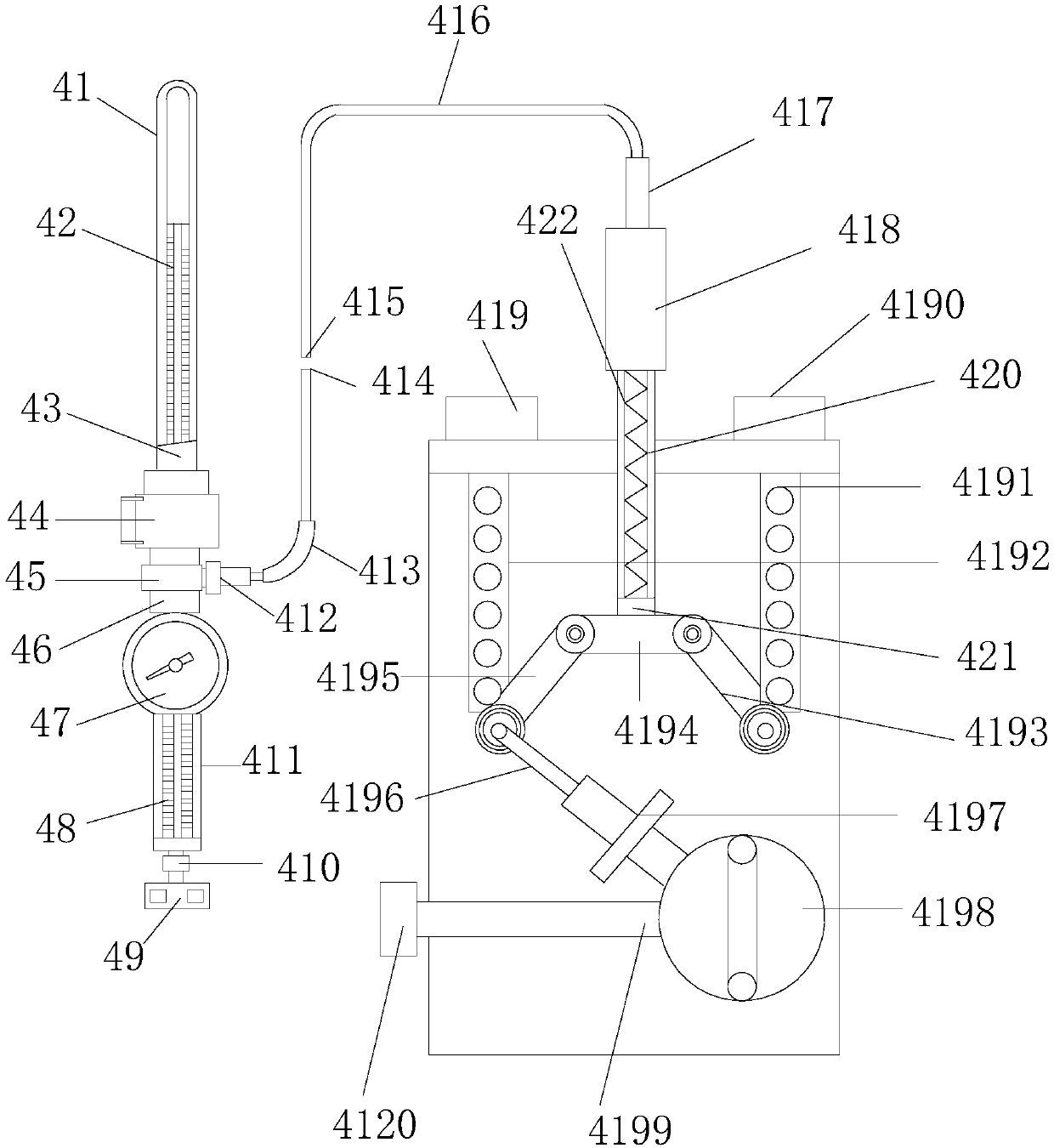

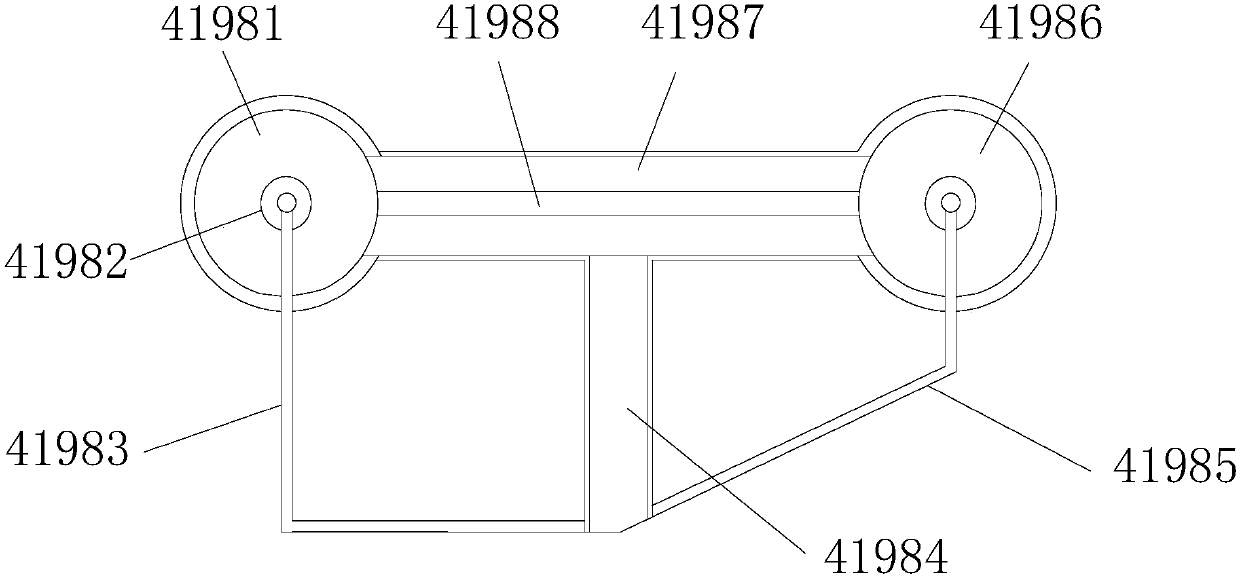

[0023] see Figure 1 to Figure 4, the present invention provides a self-controlled reactor for solid-liquid reaction separation, its structure includes a motor 1, a transmission seat 2, a material inlet 3, a temperature automatic controller 4, a visible window 5, a reactor body 6, and a bottom 7. Fixed legs 8, sealing plate 9, the bottom of the reactor body 6 and the bottom of the kettle 7 are an integrated structure, and the fixed legs 8 are provided with two fixed feet at the bottom of the kettle bottom 7 and welded with the bottom of the kettle 7. The sealing plate 9 is arranged on the upper outer layer of the reactor body 6, and the sealing plate 9 is movably connected with the reactor body 6 and is vertical, and the upper left side of the reactor body 6 is movably provided with a material inlet 3, and the reactor body 6 The center of the top is fixedly connected with the transmission seat 2 and is perpendicular to each other. The transmission seat 2 is connected to the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com