Online pH adjusting device and online pH adjusting process of catalytic hydrogenation reaction

A regulating device, catalytic hydrogenation technology, applied in the direction of control/regulation process, chemical/physical/physicochemical fixed reactor, feeding device, etc., can solve the problems of high temperature and pressure, difficulty in measurement and adjustment, etc., to achieve Reduce the difficulty of operation and ensure the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

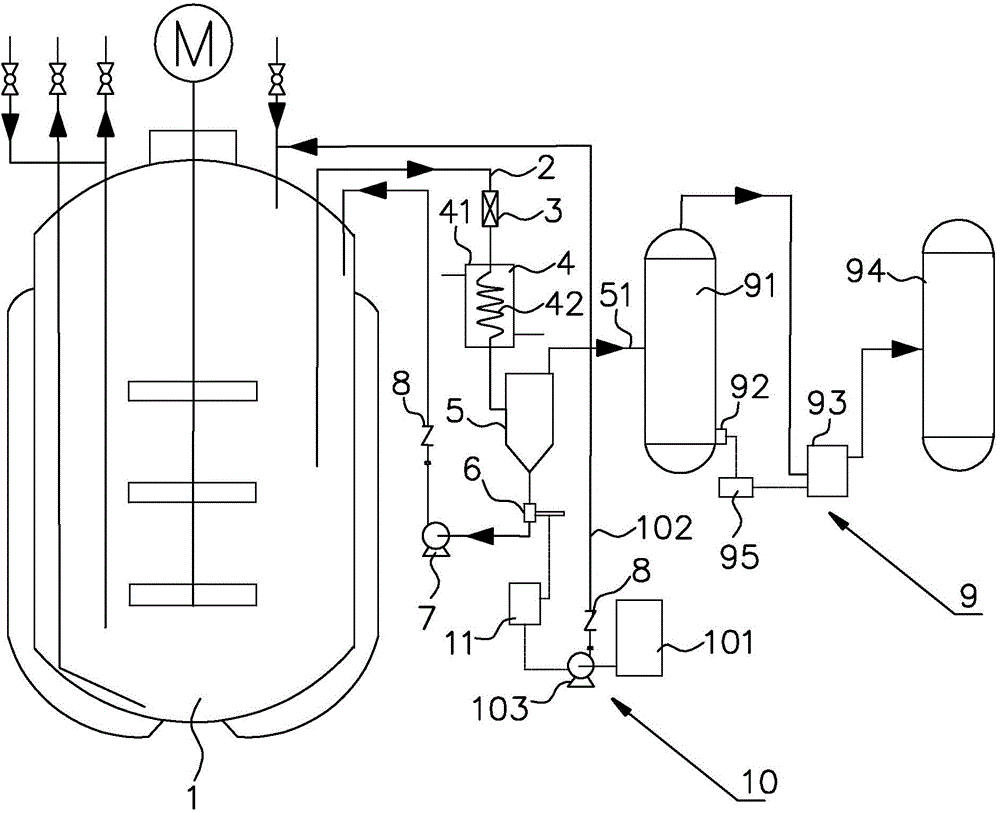

[0037] Example 1 pH online adjustment device for catalytic hydrogenation reaction

[0038] Such as figure 1 As shown, the pH on-line adjustment device of a catalytic hydrogenation reaction in this embodiment includes an external pipeline 2 connected between the material outlet of the reactor 1 and the material return port, and the external pipeline 2 is sequentially installed with a pneumatic switch valve 3, Cooler 4, gas-liquid separator 5, online pH meter 6, high-pressure plunger pump 7, check valve 8. The high-pressure plunger pump 7 is used to drive the material to circulate between the reactor 1 and the cooler 4 along the external pipe 2, and the check valve 8 ensures that the reaction material will not flow back when the high-pressure plunger pump 7 stops running.

[0039] The cooler 4 includes a housing 41, inside which is installed a snake pipe 42 with both ends connected to the external pipe 2, the housing 41 is also provided with a cooling water inlet and a cooling ...

Embodiment 2

[0048] Example 2 pH Online Adjustment Process of Catalytic Hydrogenation of Maltitol

[0049] A kind of pH on-line adjustment process of maltitol catalytic hydrogenation reaction in this embodiment comprises the following steps:

[0050] (1) Adjust the pH value of the maltose liquid (concentration is 50%) in the metering tank to 6.8, then squeeze it into the reaction kettle together with the Raney nickel catalyst by the high-pressure plunger pump, under the hydrogen pressure of 8.0-9.5Mpa, temperature 135-145 Under the condition of ℃, the catalytic hydrogenation reaction starts;

[0051] (2) Set the pH adjustment range of the online pH meter: the upper limit is 7.0, the lower limit is 6.5; set the pressure range of the hydrogen decompression tank at the same time: the upper limit is 2.0Mpa, and the lower limit is 0.5Mpa;

[0052] (3) When the catalytic hydrogenation reaction in step (1) is carried out for about 10 minutes, slowly open the pneumatic switch valve, so that the m...

Embodiment 3

[0059] Example 3 pH Online Adjustment Process of Catalytic Hydrogenation of Sorbitol

[0060] A kind of pH on-line adjustment process of sorbitol catalytic hydrogenation reaction of the present embodiment, comprises the following steps:

[0061] (1) adjust the pH value of the glucose solution (concentration is 52%) in the measuring tank to be 7.5, then squeeze it into the reaction kettle together with the Raney nickel catalyst by the high-pressure plunger pump, at a hydrogen pressure of 9.0-11.5Mpa, a temperature of 125-135 Under the condition of ℃, the catalytic hydrogenation reaction starts;

[0062] (2) Set the pH adjustment range of the online pH meter: the upper limit is 8.5, the lower limit is 7.0, and the pressure range of the hydrogen decompression tank is set at the same time: the upper limit is 2.5Mpa, and the lower limit is 0.5Mpa;

[0063] (3) When the catalytic hydrogenation reaction in step (1) was carried out for about 15 minutes, the pneumatic switch valve was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com