Hydrothermal treatment device and method for preparing high-peptizing large-pore-volume pseudo-boehmite powder

A technology of heat treatment device and quasi-aluminum water, which is applied in the direction of feeding device, chemical instrument and method, bulk chemical production, etc., can solve the problems that the pH value solution affects the process quality, and the rate of dripping ammonia water is difficult to control, etc., and achieves the improvement Work efficiency, accurate detection, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

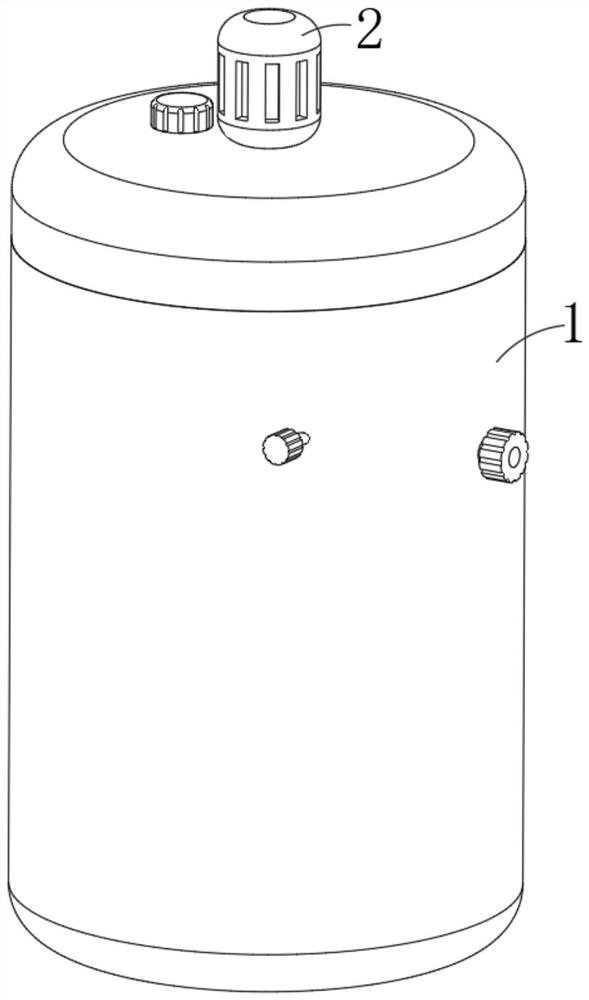

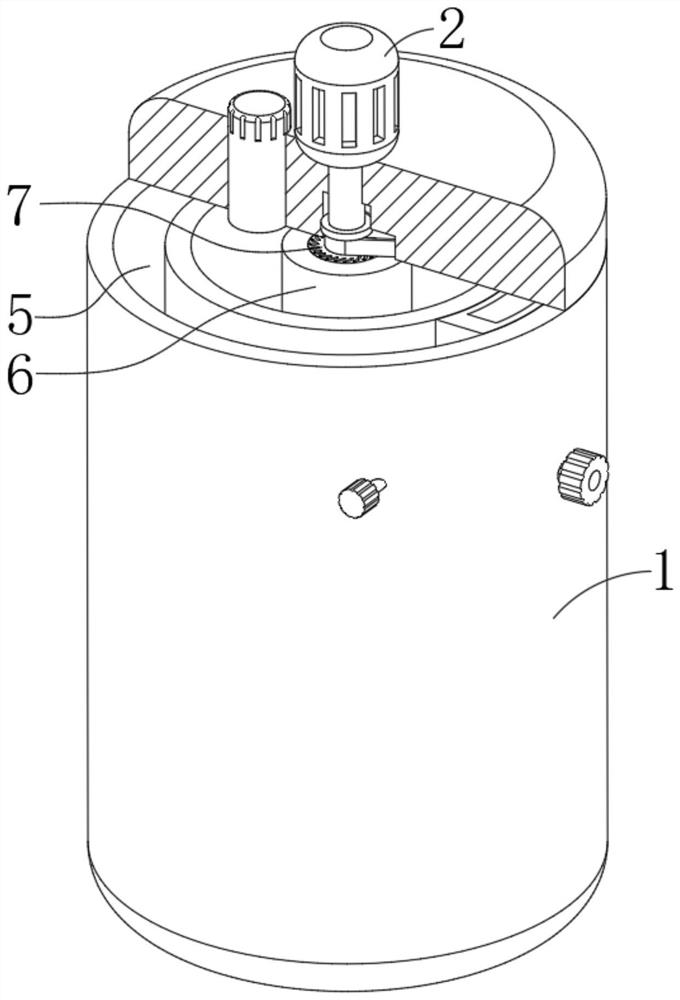

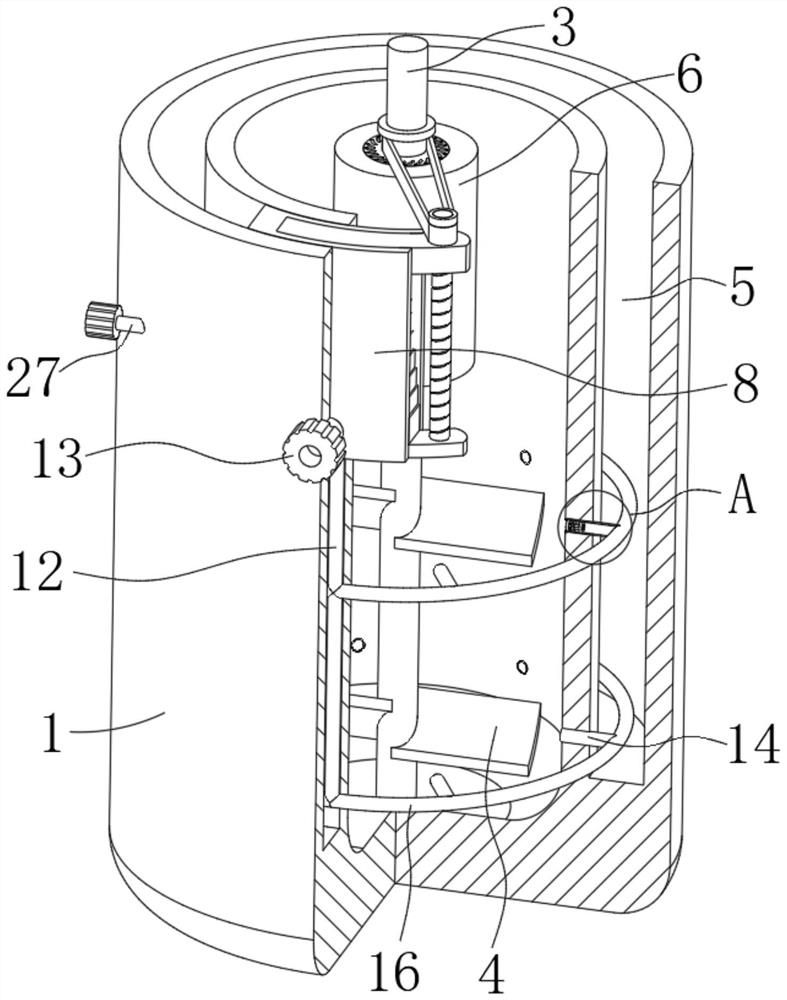

[0034] see Figure 1-Figure 4 , a hydrothermal treatment device for preparing a pseudo-thin water aluminum powder with high peptization and large pore volume in the figure includes a reaction kettle body 1, a detection device 7 and a dripping device 8, and a driving motor 2 is fixedly connected to the reaction kettle body 1. , the output end of the drive motor 2 is fixedly connected with a drive shaft 3 that runs through the top of the reaction kettle body 1 and is rotatably connected to the reaction kettle body 1, the drive shaft 3 is fixedly connected with a stirring blade 4, and the reaction kettle body 1 is provided with a device cavity 5 inside , the top of the inside of the reaction kettle body 1 is fixedly connected with a device tube 6 that is movably sleeved with the drive shaft 3, and the detection device 7 is installed in the device tube 6, for when the driving motor 2 rotates in the reverse direction. The pH value of the solution is detected, and when the driving m...

Embodiment 2

[0041] see Figure 3-Figure 7 Embodiment 2 is described. This embodiment further describes Embodiment 1. The dripping device 8 in the figure includes a storage box 9 that is fixedly installed in the device cavity 5 for storing the solution to be added. The internal sliding connection of the storage box 9 There is a compression plate 10, the side of the compression plate 10 is fixedly connected with a telescopic baffle 11 that is fixedly connected to the storage box 9, the bottom of the storage box 9 is fixedly connected with a first water pipe 12 that communicates with the storage box 9, and the storage box 9 is threaded A one-way air intake valve 13 is connected, the first water pipe 12 is provided with a spray device 14 for evenly spraying the ammonia water to be dripped into the reactor body 1, and the storage box 9 is provided with a spray device 14 for making the compression plate 10 intermittently lower. moving drive 15.

[0042] see Figure 3-Figure 4 , the spraying d...

Embodiment 3

[0047] see Figure 8-Figure 9 The third embodiment will be described. The present embodiment will further illustrate the first embodiment. The detection device 7 in the figure includes a detection rod 32 for detecting pH value. The device tube 6 is provided with a device slot 33. The detection rod 32 is connected to the device slot. 33 is slidingly connected, the bottom opening of the device slot 33 is fixedly connected with a cleaning brush 34, the detection rod 32 is signally connected to the driving motor 2, and the device slot 33 is provided with a lifting member 35 for controlling the detection rod 32 to rise and fall.

[0048] see Figure 8-Figure 11 , the lifting member 35 in the figure includes a rotating plate 36 fixedly connected with the drive shaft 3, a rotating ring 37 is rotatably connected in the device groove 33, and a plurality of first sliding grooves 38 are opened on the rotating ring 37. A fourth spring 39 is fixedly connected in the groove 38, and the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com