Iron removal device for nickel-cobalt-manganese sulfuric acid solution and method for continuously removing iron ions in nickel-cobalt-manganese sulfuric acid solution at low temperature

A nickel-cobalt-manganese sulfuric acid and solution technology, applied in the field of non-ferrous metal hydrometallurgy, can solve the problems of large energy consumption, low production efficiency, high iron removal temperature, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

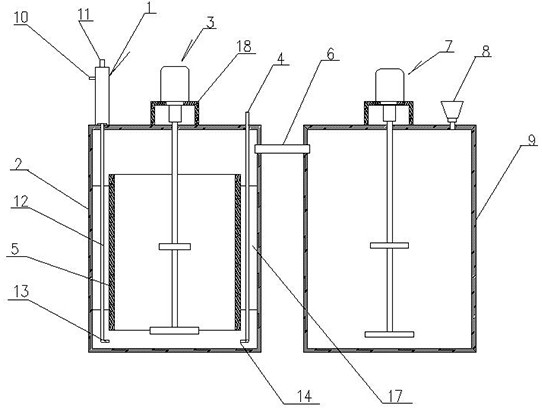

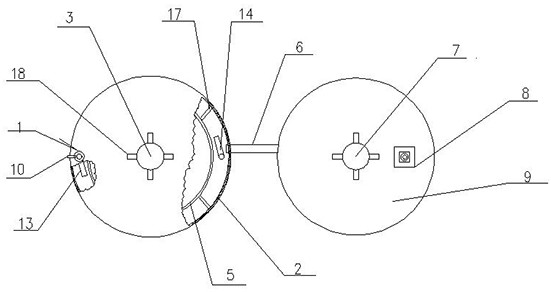

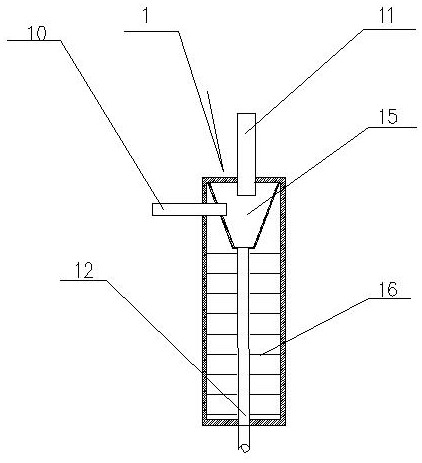

[0049] Embodiment 1: be used for the deironing device of nickel cobalt manganese sulfuric acid solution, be provided with deironing reactor 2 and aging reactor 9, be provided with the first agitator 3 in deironing reactor 2, in aging reactor 9 The second agitator 7 is arranged inside, and the iron removal reactor 2 is connected with the aging reactor 9 with an overflow port connecting pipe 5, and the iron removal reactor inner cylinder 5 is arranged in the iron removal reactor 2, and the iron removal reactor 2 and the interlayer of the inner cylinder 5 of the iron removal reactor are provided with a mixing feed pipe 12 and a carbonate solution feed pipe 4, and the top of the mixing feed pipe 12 is provided with a mixer 1 of a preheating device. The mixer 1 is provided with a compressed air inlet 11 and a feed port 10 for the liquid to be removed, and an automatic stone powder feeder 8 is provided on the aging reactor 9 . The mixer 1 is provided with a mixing chamber 15, the mi...

Embodiment 2

[0051] Embodiment 2: The iron removal device for nickel-cobalt-manganese sulfuric acid solution is provided with an iron removal reactor 2 and an aging reactor 9, and the aspect ratio of the iron removal reactor 2 is 1.0-2.5:1. The first agitator 3 is arranged in the iron removal reactor 2, and the first agitator 3 is composed of a motor and a stirring paddle. 1 / 3 of the diameter, the bottom stirring blade is 50-80cm away from the bottom of the reactor, and the upper and lower stirring blades are 50-115cm apart. A second agitator 7 is provided in the aging reactor 9 . The second agitator 7 is made up of two parts, a motor and a stirring paddle. The motor is fixed on the support 18. The stirring paddle adopts a cross-shaped double-layer stirring blade. The diameter of the stirring blade is 1 / 3 of the diameter of the aging reactor 9. The bottom layer stirs The blade is 50-80cm away from the bottom of the reactor, and the upper and lower stirring blades are 50-115cm apart. The ...

Embodiment 3

[0053] Embodiment 3: adopt the method for the low-temperature continuous removal of iron ions in the nickel-cobalt-manganese sulfuric acid solution of the iron removal device of the nickel-cobalt-manganese sulfuric acid solution, comprising the following steps:

[0054] a. Composition of sulfuric acid solution to be removed: Fe: 1.15g / L, Co: 26.03g / L, Mn: 5.41g / L, Ni: 7.35g / L;

[0055] b. Prepare 124g / L manganese carbonate slurry and heat it to 45°C;

[0056] c. Iron removal reactor 2 and aging reactor 9 both have a diameter of 3m, a height of 4m, and an effective volume of 24.72 cubic meters;

[0057] d. Turn on the mixer 1 and inject the iron removal solution, compressed air and manganese carbonate slurry at the same time, and the flow rate of the iron removal solution is 10.5m 3 / h, compressed air 21m 3 / h;

[0058] e. The temperature of the mixer is controlled at 45°C, the temperature in the reactor is controlled at 45°C, and the reaction pH value is controlled at 3.05;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com