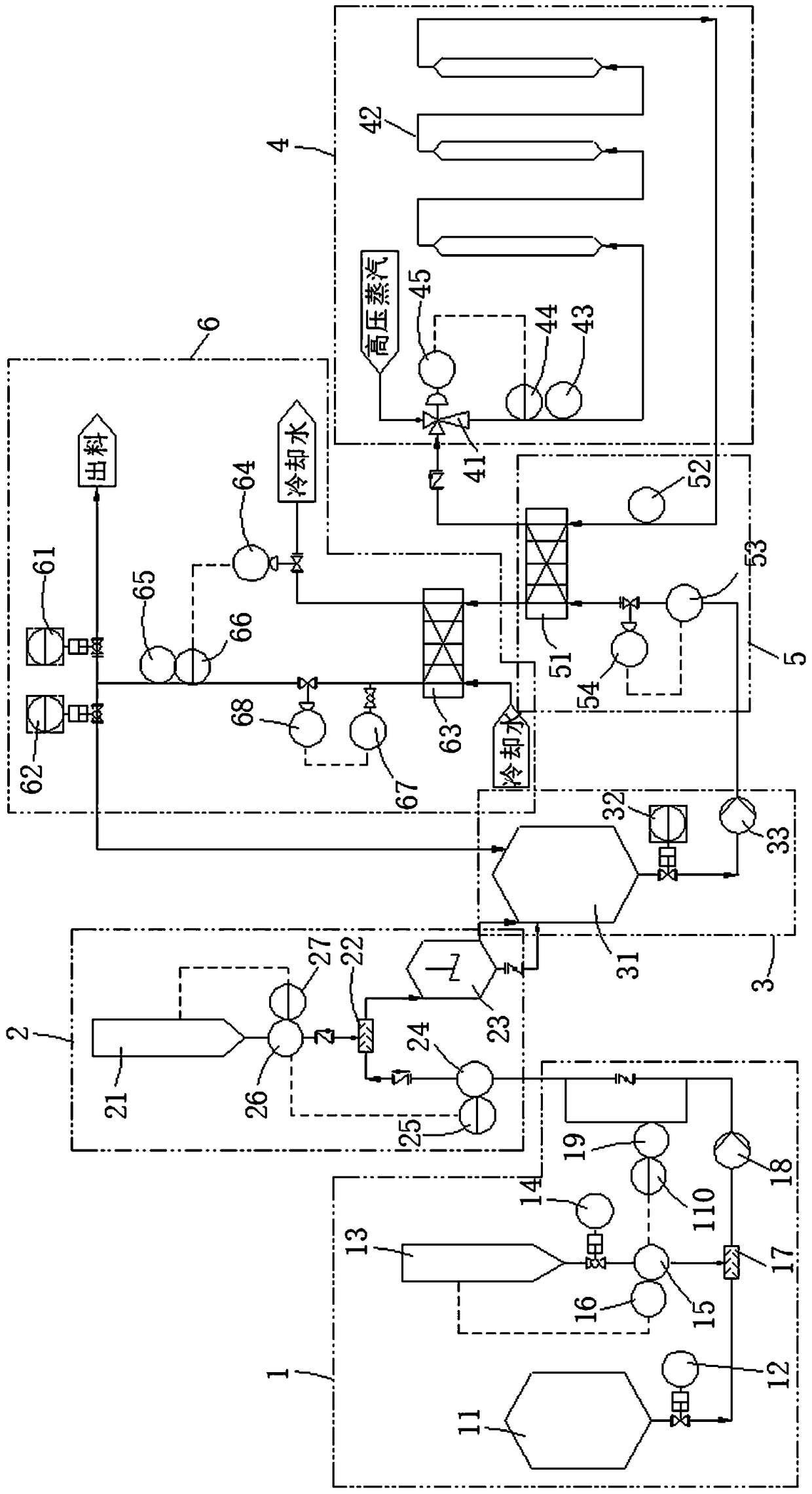

System and method for continuously hydrolyzing hemicellulose to prepare xylose liquid

A technology of hemicellulose and xylose, which is applied in the system field of continuous hydrolysis of hemicellulose to prepare xylose liquid, can solve the problems of poor utilization of heat energy, waste of resources, complicated operation of reaction feeding and discharging, and achieve equipment energy consumption The effect of high utilization rate, convenient operation and controllable continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] With hemicellulose lye (alkaline concentration 1.5%, hemicellulose concentration 8%, flow rate 6m 3 / h) for continuous hydrolysis to prepare xylose liquid as an example.

[0045] In the first step, the neutralization end point of the pH sensor 19 in the neutralization process is set to pH7, and the flow rate of the concentrated sulfuric acid is controlled by the pH controller 110 to be 58L / h, so that the frequency of the neutralized concentrated sulfuric acid pump 13 is 36HZ. . After passing through the neutralization unit, the hemicellulose lye is transported to the acid adjustment unit through the material pump 18.

[0046] In the second step, the flow rate of the material flowmeter 24 of the hemicellulose liquid raw material in the acid adjustment operation is 6m 3 / h, chain control the flow 66L / h of the acid-adjusting sulfuric acid flow meter 26, thus controlling the frequency of the acid-adjusting concentrated sulfuric acid pump 21 to be 30HZ.

[0047] In the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com