Continuous neutralizer mixer reactor and a continuous process for quenching chlorination reaction mixture in production of chlorinated sucrose

A technology of chlorination reaction and reactor, which is applied in chemical methods for reacting liquids with liquids, esterified saccharides, chemical instruments and methods, etc., and can solve problems such as reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

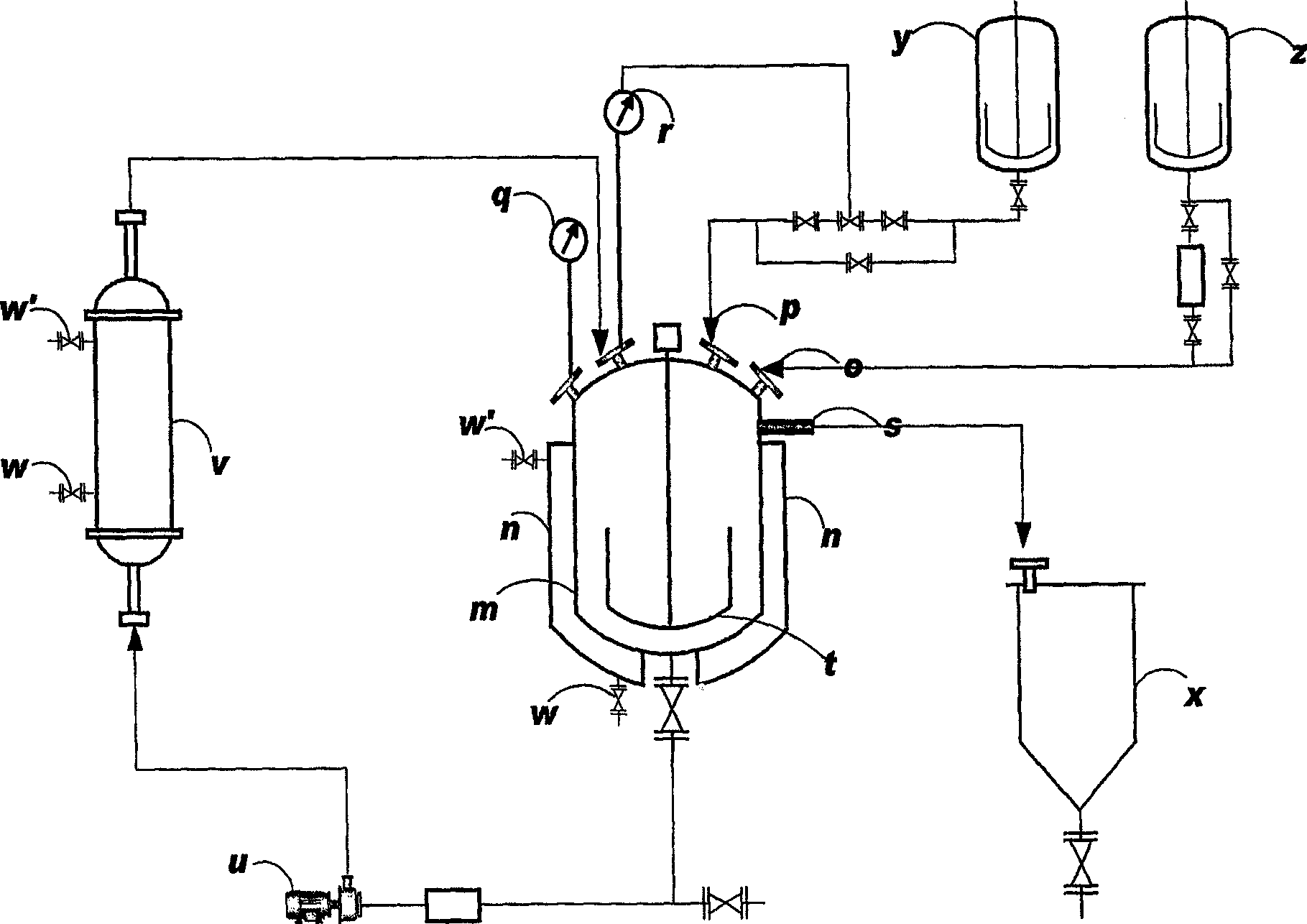

Image

Examples

Embodiment 1

[0018] Example 1: Chlorination of sucrose-6-acetate using thionyl chloride

[0019] Put 400L DMF into a glass-lined reactor, add 16kg of carbon, and mix well. Nitrogen bubbling was started and 344 L of thionyl chloride was added dropwise to the reactor. Keep the temperature below 40°C. When the thionyl chloride is added dropwise, keep the material at 35-40°C for complete reaction. Then the material was cooled to 0-5° C., and 80 kg of 92% 6-acetyl sucrose in DMF (300 L) was added dropwise to the material. The temperature was controlled below 5°C, and after the addition of 6-acetyl sucrose was complete, the material was raised to room temperature and stirred at 30°C for 3 hours. The mass was then heated to 85°C and held for 60 minutes, further heated to 100°C and held for 6 hours, and further heated to 114°C and held for 90 minutes.

[0020] The mass was then cooled to 60°C for the neutralization reaction.

Embodiment 2

[0021] Example 2: Neutralization of chlorinated materials in a continuous quenching system

[0022] 150L of DMF and 30L of 25% ammonia solution were charged into the continuous neutralization reactor. The solution was continuously circulated and cooled to 10°C via a heat exchanger loop.

[0023] Chlorinated feed (-950 L containing 28 kg 6-acetyl TGS) was started at a flow rate of 120 L / hr through a dip pipe arrangement. The reactor was also connected to a 7% ammonia solution tank through which the ammonia solution was also added to the reactor at the same time. The temperature was maintained at 20°C by continuous operation through loop circulation. The pH was monitored online and controlled between 7.0-7.5 by the flow of ammonia solution.

[0024] The quenched material is collected through the overflow point set by the reactor. The total volume of quenched material obtained from 900 L of chlorination reaction material in 8 hours was about 2500 L. The capacity of the neutr...

Embodiment 3

[0030] Example 3: Comparison with Conventional Batch Quenching Systems

[0031] 150L of DMF and 500L of 7% ammonia solution were charged to the batch neutralization reactor. The temperature of the reactor was maintained at -5 °C. The reactor was equipped with a pH sensor and charged with chlorinated feed (-950 L containing 28 kg 6-acetyl TGS). The reactor was kept under continuous agitation and the pH was maintained between 7.0 and 7.5. When the pH becomes acidic, add more 7% ammonia solution (for example, it can be a weight concentration). Even with cooling to -14°C in the jacket, the temperature in the reactor rose to 30°C. When the temperature increased above 30°C, ice cubes were added to the inside of the reactor to lower the temperature.

[0032] The total volume of quenched material obtained from 900 L of chlorination reaction material in 15 hours was about 4500 L. The capacity of the neutralization reactor is 5000L. The quenched material from this method was analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com