High-purity high-basicity nanoscale PACS flocculating agent and preparation method thereof

A nano-scale flocculant technology, which is applied in the field of high-purity and high-salinity nano-scale PACS flocculant and its preparation, and PACS flocculant for water purification, which can solve the problem of molecular weight drop, influence on colloidal chemical electrical neutralization, and alkalization It can achieve the effect of good polymerization degree, high basicity degree and improved application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the contents of the examples are not intended to limit the protection scope of the present invention.

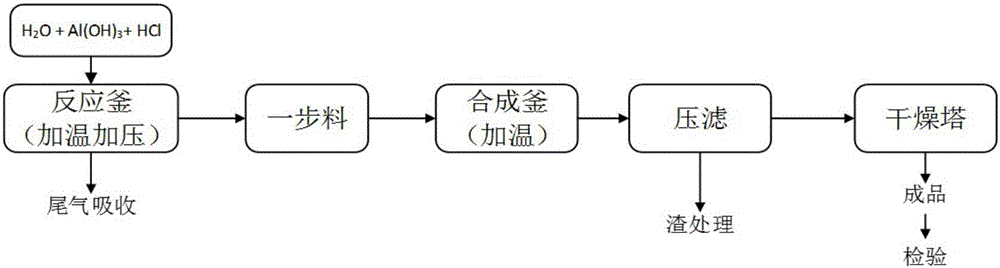

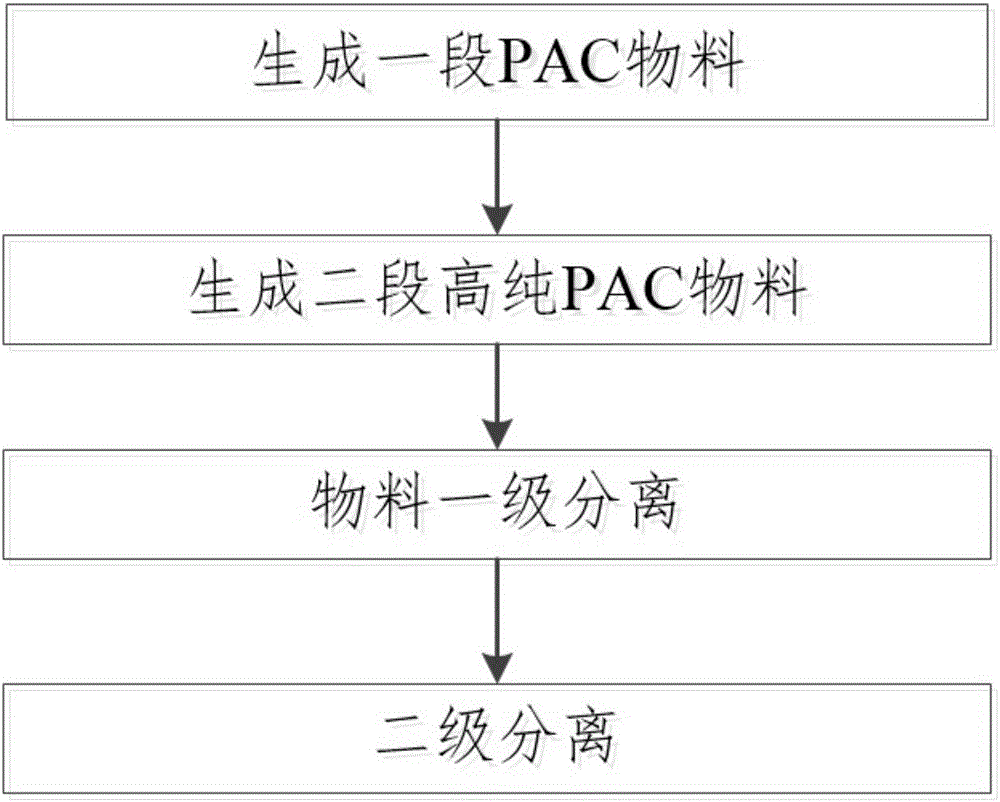

[0044] figure 2 A flowchart showing the preparation method of the high-purity and high-basicity nano-scale PACS flocculant of the present invention. Such as figure 1 Shown, the preparation method of high-purity high salinity degree nano-scale PACS flocculant of the present invention comprises the following steps:

[0045] First, generate a piece of PAC material.

[0046] In the present invention, aluminum hydroxide, water and hydrochloric acid with an acidity of 31% are added into the reaction kettle for reaction. Wherein, the consumption of aluminum hydroxide is to control Al in the total reactant 2 o 3 The mass percentage is 13.5%-14.5%. At the same time, the amount of hydrochloric acid with a concentration of 31% was such that the acidity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com