Phosphorosilicate glass removal processing production line for crystalline silicon solar cell processing

A technology for solar cells and dephosphorization silicon, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve problems such as inconvenience in use, easy vibration of silicon wafers, affecting product quality, etc., to improve product quality and production efficiency. , Avoid vibration and splash of hydrofluoric acid, improve the effect of conveying roller structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

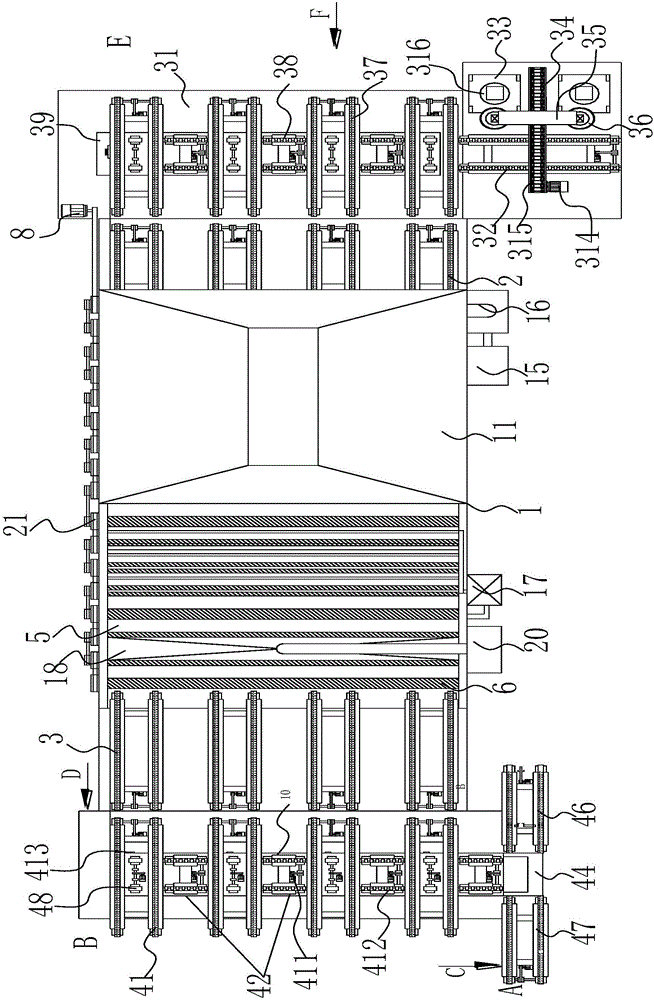

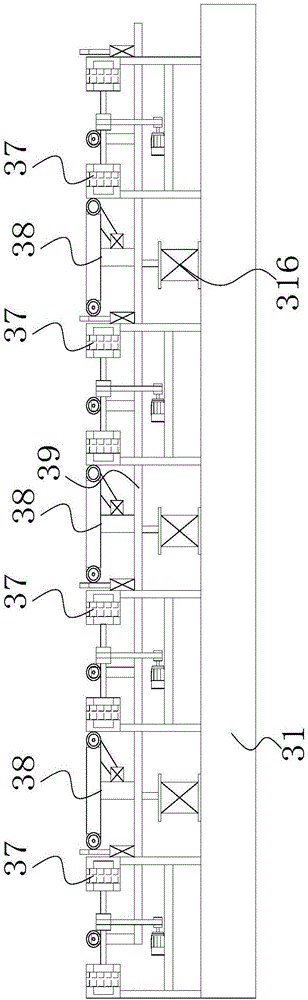

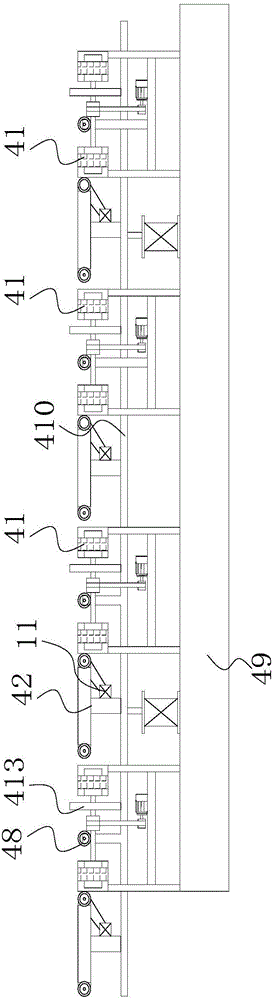

[0026] refer to Figure 1 to Figure 8, the present invention includes a tank body 1 provided with a feed belt 2 and a discharge belt 3, the feed belt 2 and the discharge belt 3 are double rows, and the feed belt 2 and the discharge belt 3 are evenly spaced Horizontally arranged at both ends of the pool body 1, one end of the feed belt is provided with a uniform sheet distribution mechanism, and one end of the discharge belt is provided with a silicon chip collection mechanism, and the pool body 1 is from the feed belt 2 to the discharge belt. 3. A corrosion pool 4 and a cleaning pool 5 with a housing chamber are arranged in the direction. The corrosion pool 4 and the cleaning pool 5 are provided with several conveying rollers 6 placed horizontally in the housing chamber. The conveying rollers 6 are driven by a timing belt 21 The transmission is connected together and connected with the driving motor 8. The conveying roller 6 is provided with a spiral 7 distributed along its sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com