Method for producing substrates for superconducting layers

A superconducting and substrate technology, used in the manufacture of stretchable conductors/cables, for forming corrugations on conductors/cables, superconducting devices, etc. Loss and other issues, to minimize material costs and achieve the effect of large-scale manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

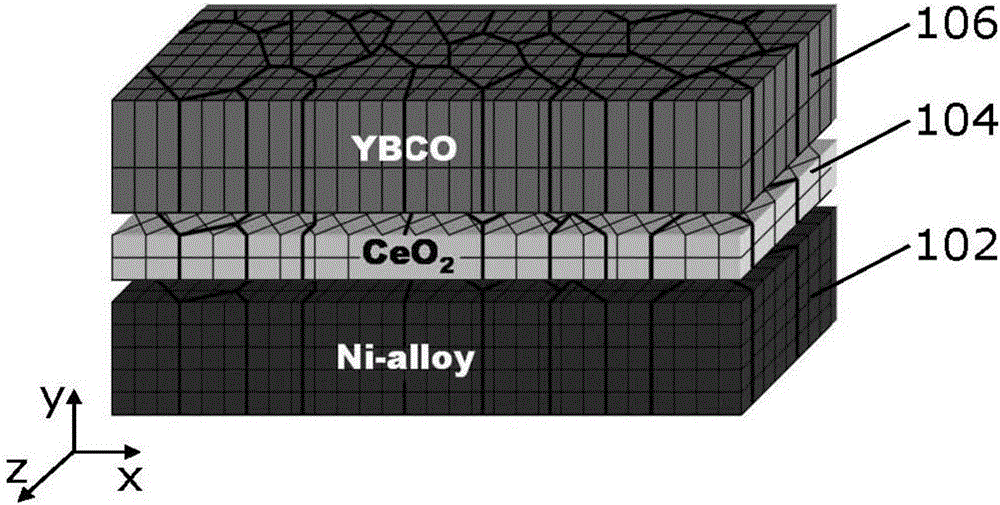

[0136] figure 1 A typical superconductor structure is shown, which is a sandwich structure comprising a substrate 102 , a buffer layer 104 and a superconducting material 106 . In this figure, it is assumed that the current flows through the superconducting material 106 in the z-direction.

[0137] When the superconducting material is a relatively wide (where width is measured in the x-direction) layer of material, such as when formed as a layer on a broad planar substrate, the superconducting layer exhibits relatively large AC losses, which can The reduction is achieved by converting a single wide superconducting layer into a plurality of relatively narrower lines (ie, lines having a cross section in the yx plane with a smaller width measured in the x direction compared to the original wide layer).

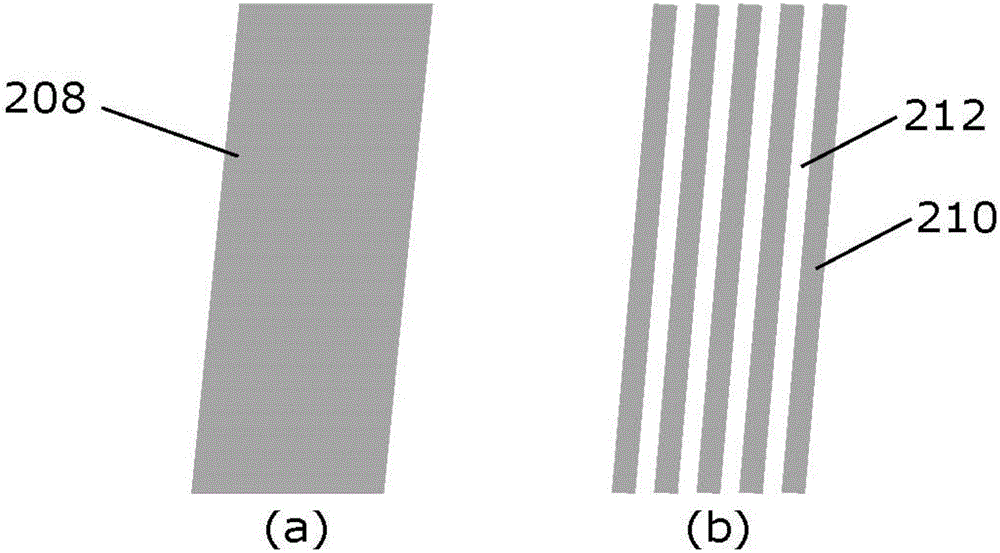

[0138] figure 2 is a top view of a superconducting material, where the left side (a) illustrates a non-striped superconductor 208 formed on a planar layer, and the right side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com