Multi-station garment embossing machine for garment equipment

A multi-station, garment pressing technology, applied in the field of garment processing, can solve the problems of labor and low embossing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

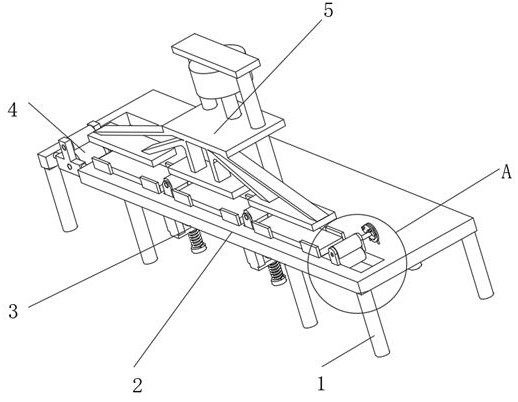

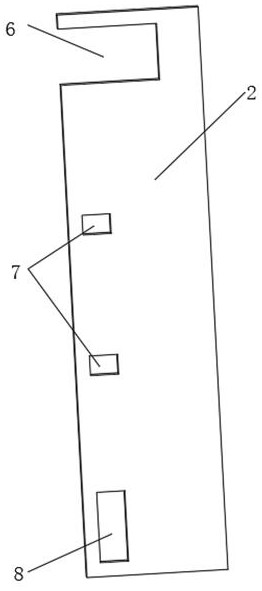

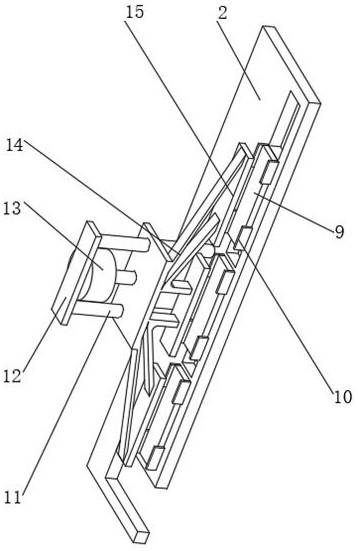

[0039] A multi-station garment embossing machine for garment equipment, such as figure 1 , 5 As shown, in order to solve the problem of reliable tensioning and demoulding; this embodiment makes the following improvements on the basis of embodiment 1: it also includes a tensioning mechanism 3, which includes a tensioning roller 28 and a tensioning spring 32. The outer wall of the bottom of the workbench 2 close to the tensioning groove 7 is fixedly equipped with a tensioning bracket 26, the inner wall of the tensioning bracket 26 is slidably connected with a tensioning slide bar 30, and one side of the outer wall of the tensioning slide bar 30 is welded with The roller bracket 29, the tension roller 28 is connected to the inner wall of the roller bracket 29 through the rotation of the tension shaft 27, and the other side outer wall of the tension slide bar 30 is fixed with a second tension limit block 33 by bolts, and the tension roller 28 is tightened. The outer walls on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com