Automatic embossing equipment

An equipment and embossing technology, applied in decorative arts, embossed ornaments and other directions, can solve the problems of low production efficiency, low precision of pressed shape, etc., and achieve the effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

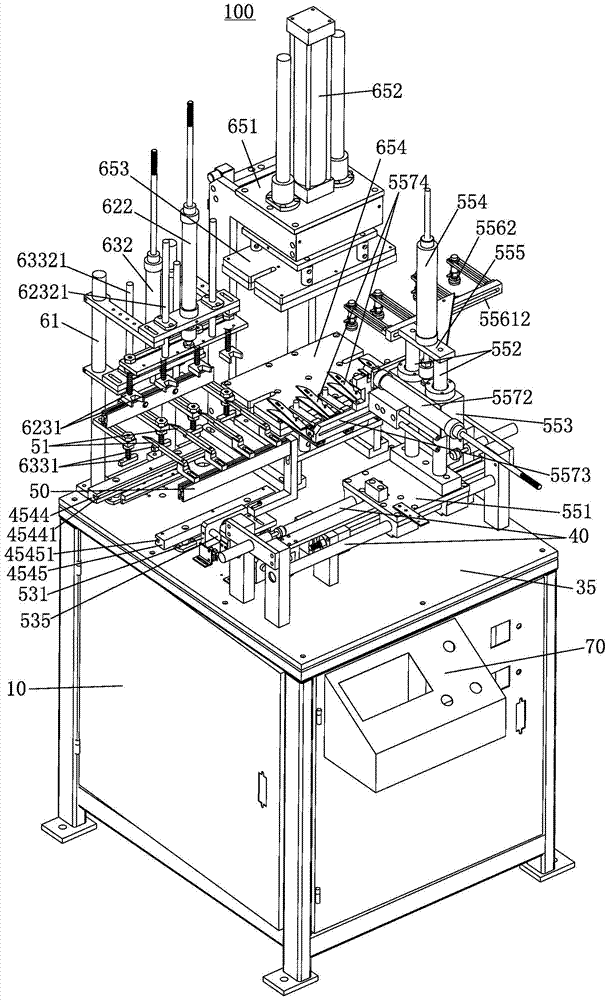

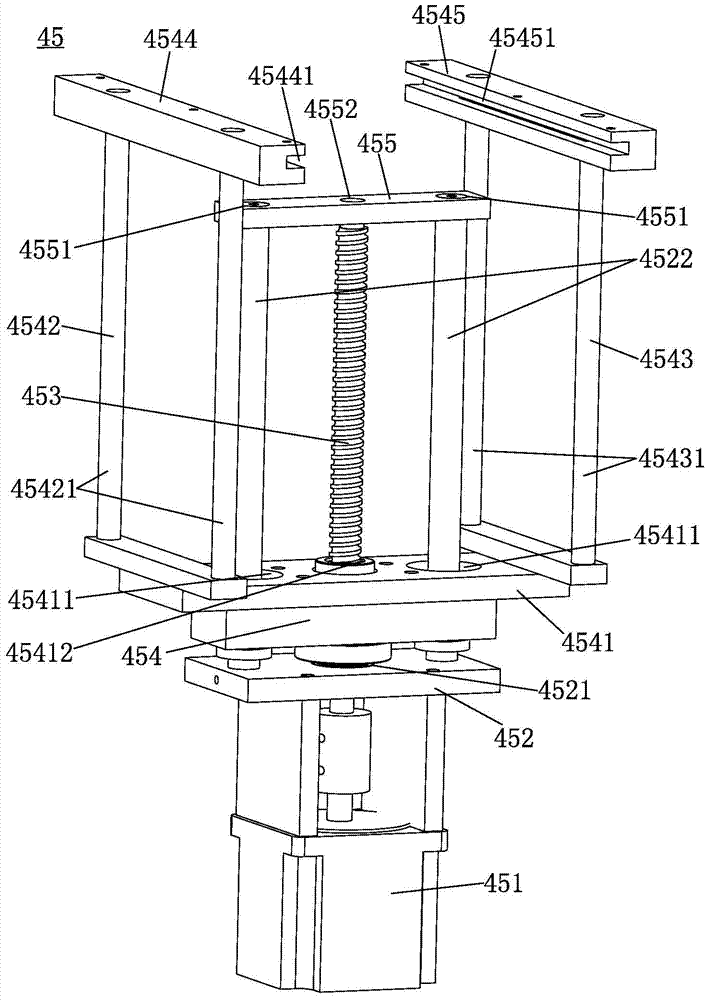

[0016] refer to Figure 1 to Figure 6 The automatic embossing equipment 100 of the present invention comprises a frame 10, a mounting plate 35 mounted on the top of the frame 10, and two transverse slide rails 40 mounted on the top of the mounting plate 35, a multifunctional embossing manipulator 55, an embossing lift Feeding mechanism 45 , flower arrangement separation mechanism 50 , embossing mechanism 60 , stamping mechanism 65 and control panel 70 . The control panel 70 is installed on the side wall of the frame 10 and is used to control the actions of the multifunctional embossing manipulator 55 , the embossing lifting and feeding mechanism 45 , the flower arrangement separation mechanism 50 , the embossing mechanism 60 and the stamping mechanism 65 . The transverse slide rail 40 is transversely installed on the front part of the upper surface of the mounting plate 35,

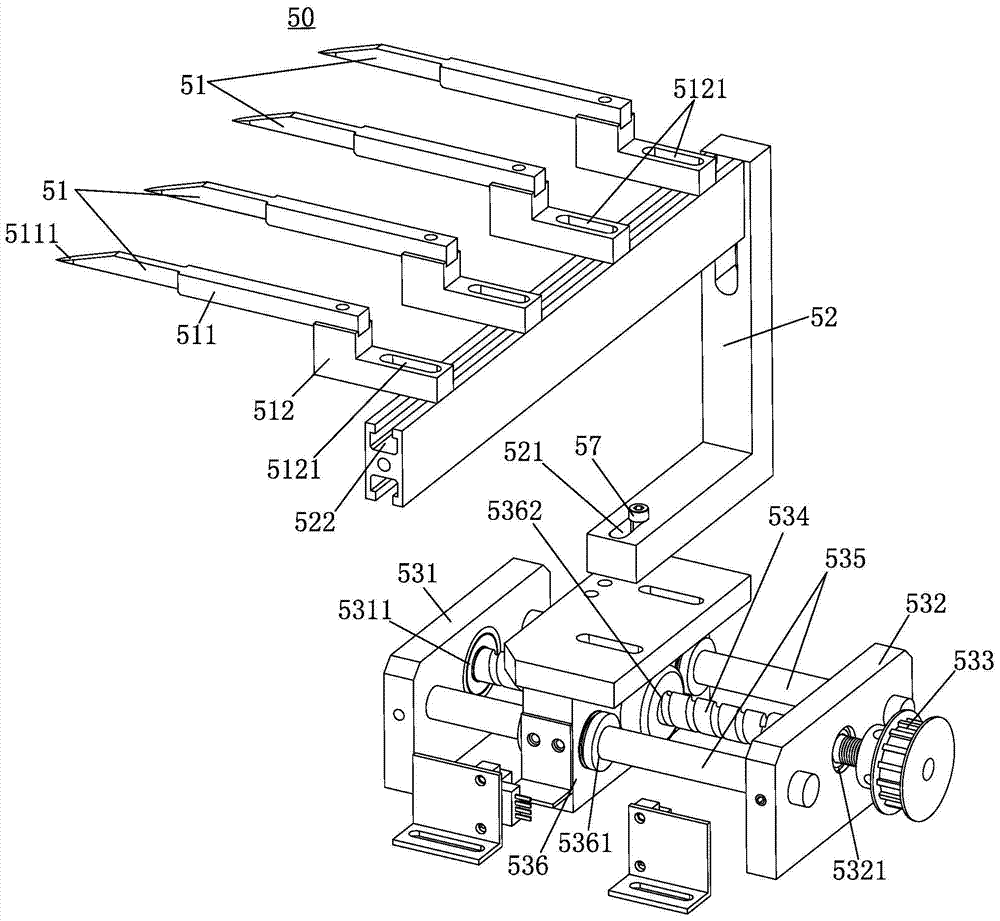

[0017] The flower separation mechanism 50 is located at the middle left of the installation plate 35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com