Production process of hydrophobic melt-blown cloth

A production process, technology of melt-blown cloth, applied in the field of production technology of hydrophobic melt-blown cloth, can solve the problems of poor embossing stability of melt-blown cloth, embossing, low processing speed of melt-blown cloth, etc., to increase stability, improve Sustained, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

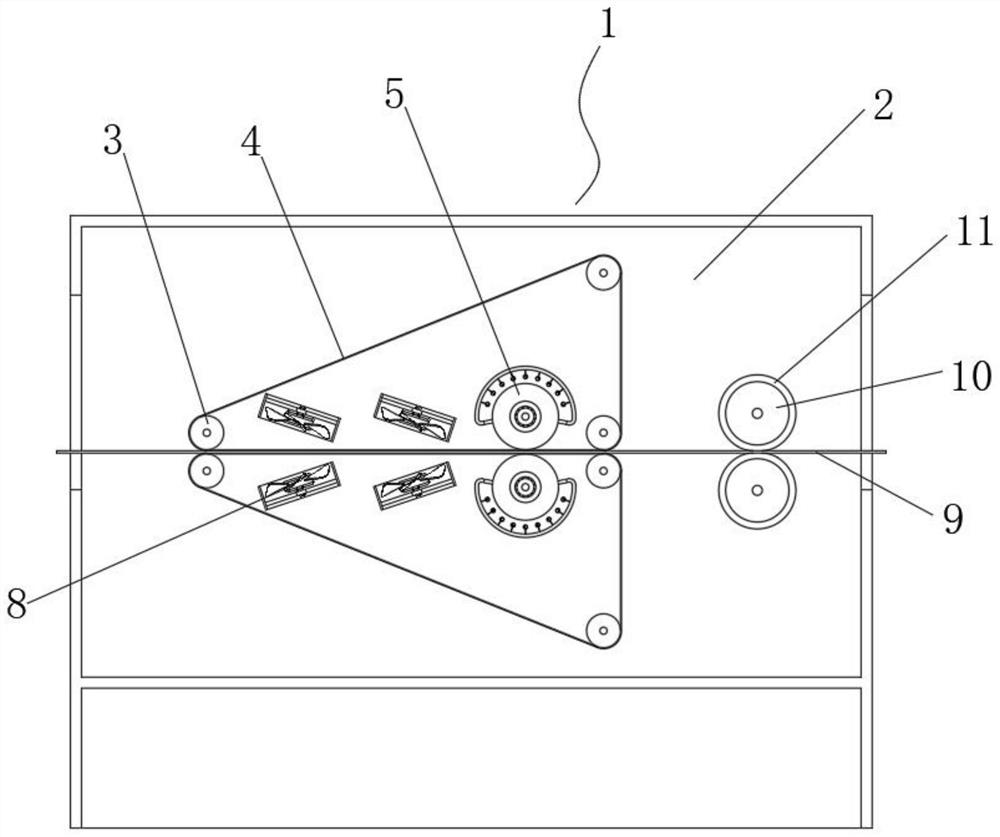

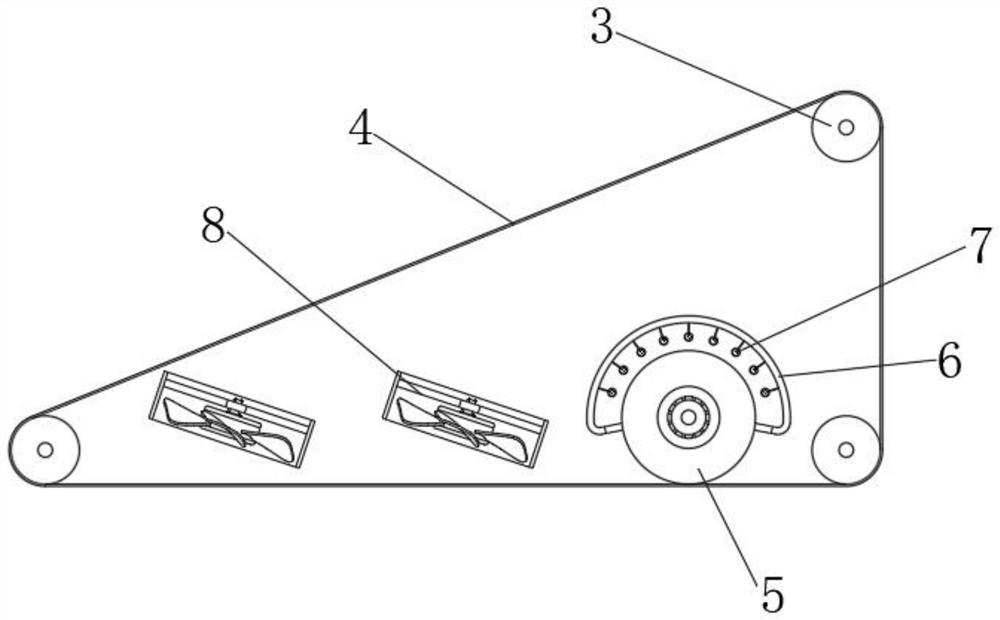

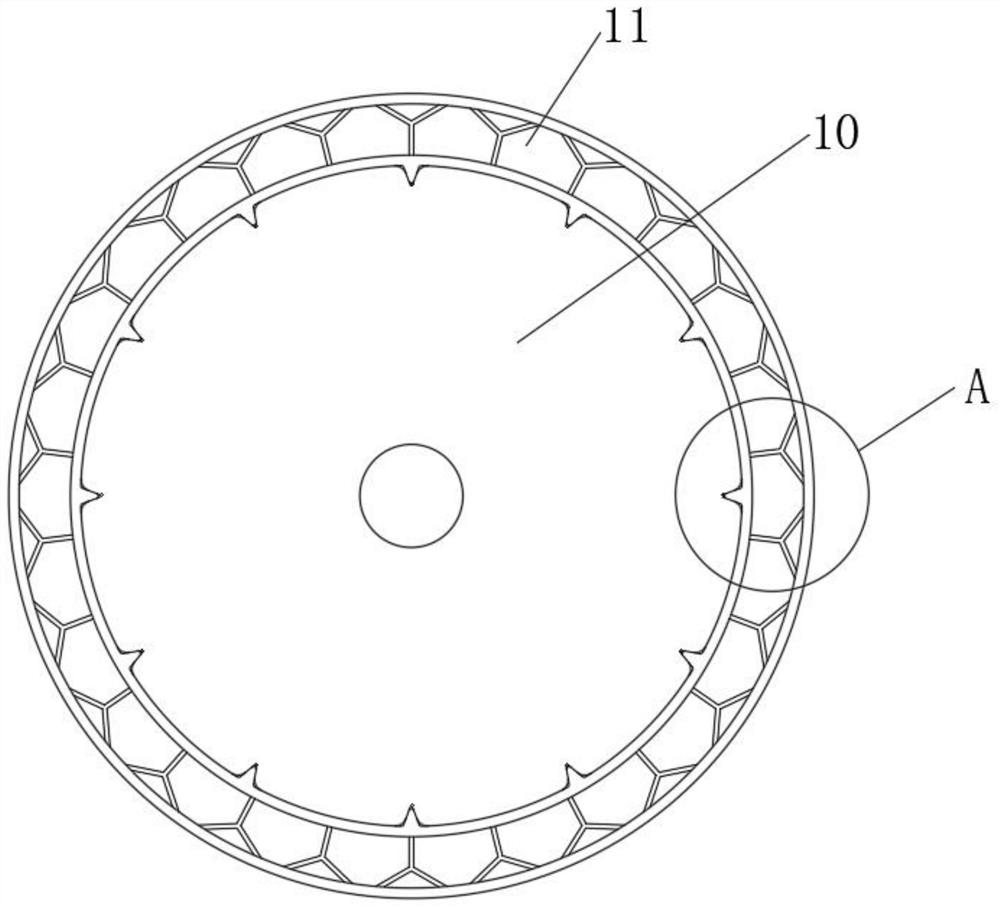

[0028] see Figure 1-4 , the present invention provides a technical solution: a production process of hydrophobic melt-blown cloth, including a melt-blown cloth double-sided embossing machine 1 and a melt-blown cloth 9 installed in the melt-blown cloth double-sided embossing machine 1, a melt-blown cloth The double-sided embossing machine 1 includes an outer casing 2 and an embossing assembly. The embossing assembly includes a driving roller 3, a steel wire embossing net 4, a heating roller 5, a heat collecting cover 6 and a heating resistance wire 7. The driving roller 3 is installed on the outer casing 2, the steel wire embossed mesh 4 is set on the outside of the driving roller 3, the two ends of the heating roller 5 are rotated and installed on the inner surface of the outer casing 2, and the heat collecting cover 6 is installed on the outer surface of the outer casing 2 close to the driving roller 3 , the heating resistance wire 7 is installed on the inner surface of the ...

Embodiment 2

[0051] see Figure 1-4 , the present invention provides a technical solution: a production process of hydrophobic melt-blown cloth, including a melt-blown cloth double-sided embossing machine 1 and a melt-blown cloth 9 installed in the melt-blown cloth double-sided embossing machine 1, a melt-blown cloth The double-sided embossing machine 1 includes an outer casing 2 and an embossing assembly. The embossing assembly includes a driving roller 3, a steel wire embossing net 4, a heating roller 5, a heat collecting cover 6 and a heating resistance wire 7. The driving roller 3 is installed on the outer casing 2, the steel wire embossed mesh 4 is set on the outside of the driving roller 3, the two ends of the heating roller 5 are rotated and installed on the inner surface of the outer casing 2, and the heat collecting cover 6 is installed on the outer surface of the outer casing 2 close to the driving roller 3 , the heating resistance wire 7 is installed on the inner surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com