Embossing machine

An embossing machine and pressure adjustment technology, which is applied in the fields of leather surface mechanical treatment, small raw hide/big raw hide/leather/fur mechanical treatment, raw hide/leather/fur manufacturing equipment, etc. It can solve the embossing process that does not have full automation , high embossing efficiency, high safety factor in the embossing process, etc., to achieve the effect of simple structure, high embossing efficiency and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Leather embossing machine, also known as high-frequency embossing machine, high-frequency embossing machine, high-frequency branding machine, mainly adopts high-voltage rectification self-excited high-frequency electron tube oscillation to generate electromagnetic wave current electric field instantly, and uses processed PVC, TPU, EVA, PET and other plastics, The internal molecules of the leather material in the electromagnetic wave electric field produce polarized friction and heat generation, and a certain pressure makes the leather and plastic products that need to be heat-sealed and welded to achieve branding and welding sealing. The prior art does not have a fully automated embossing process, high temperature resistant dust collector device, anti-interference equipment, high embossing efficiency, simple structure, and high safety factor in the embossing process.

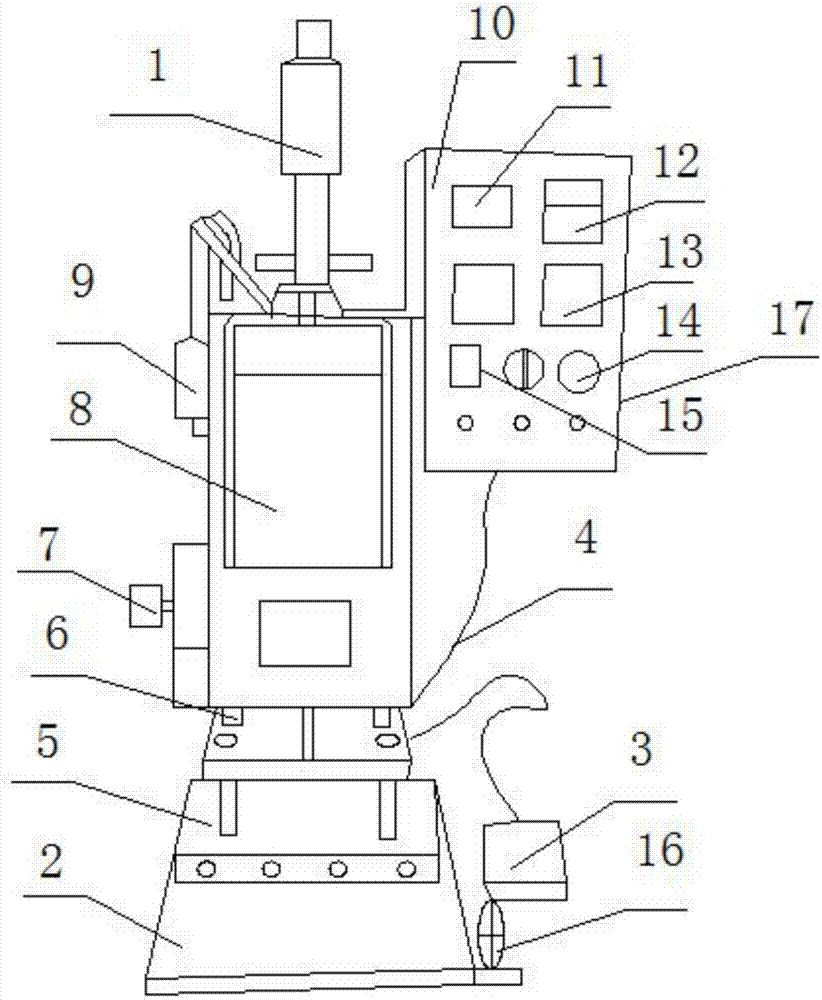

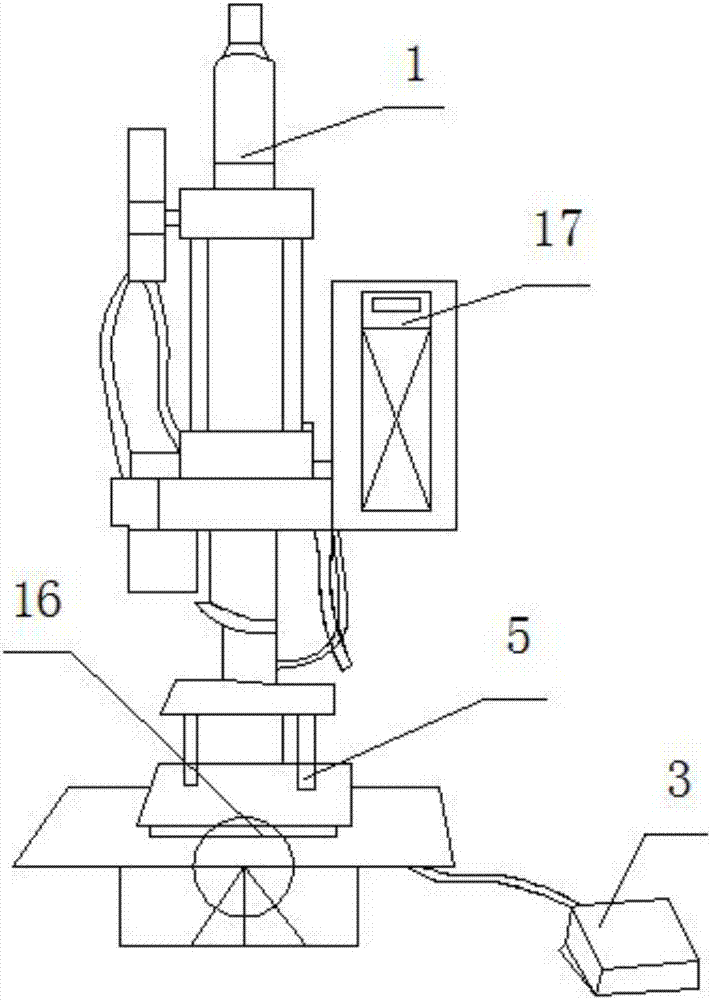

[0016] refer to figure 1 , figure 2 , including depth adjustment screw 1, fixed base 2, foot switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com