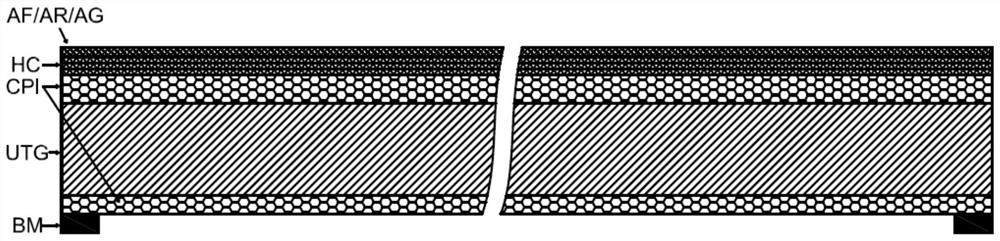

Flexible composite cover plate and manufacturing method thereof

A production method and flexible technology, applied in the field of flexible display terminal accessories, can solve the problems of high material cost, high composition cost, and thick material thickness of CPI film, so as to reduce energy consumption, high process applicability, and eliminate scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] 1) The 50um thick ultra-thin glass (UTG) attached to the glass slide is cleaned with cleaning agent and pure water ultrasonically in sequence, and then the surface is treated with air plasma until the water drop angle is less than 5°. Use 5% KH550 in isopropanol (IPA) solution to evenly treat the surface of the UTG, and bake it on a hot plate at 110°C for 5 minutes.

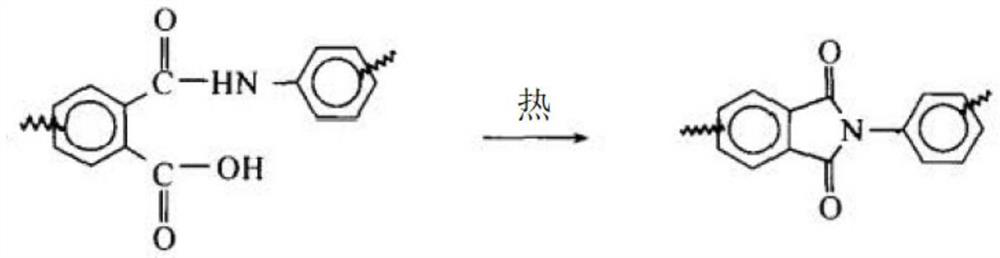

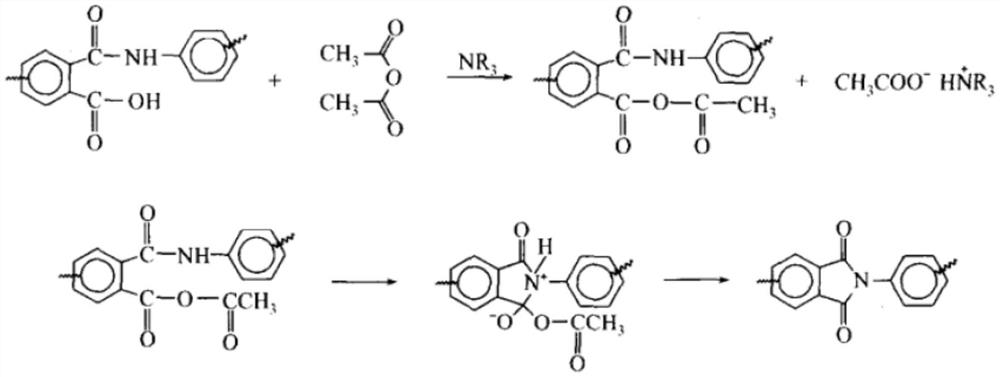

[0070] 2) Spray evenly a polyamic acid solution (CPAA) with a solid content of 6wt% on the surface of the pretreated UGT, bake it on a hot plate at 130°C for 5 minutes, and then dip it into a chemical imidization solution at 65°C for 60 minutes , blow dry at 65°C with an air knife, and move to 180°CN 2 Bake in the oven for 15 minutes to complete the removal of the solvent and the imidization of CPAA to obtain a CPI film with a thickness of 5um. alkane solution to obtain ultra-thin glass with a transparent polyimide layer (CPI)

[0071] 3) Utilize air plasma to treat the surface of the transparent polyimi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com