Rust-proof heat-resistant deformed steel and processing technology thereof

A processing technology and special-shaped steel technology, which is applied in the field of steel rolling processing, can solve the problems of being easily corroded by acidic and alkaline objects, increasing the difficulty of pass design and production, and affecting the service life of special-shaped steel pipes, etc. Controllable quality, enhanced high-temperature oxidation resistance, anti-rust and reasonable heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

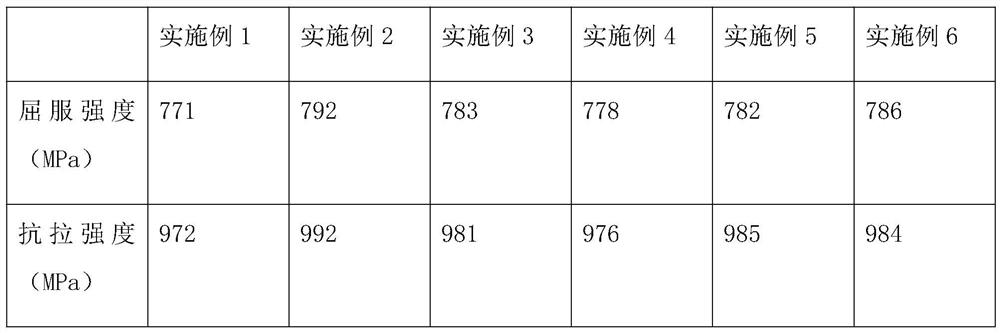

Examples

Embodiment 1

[0048] S1: Prepare the substrate

[0049] (1) Add molten iron and scrap steel to the converter for compound blowing, tap steel at 1580°C, blow argon and stir throughout the tapping process; add carbon powder, cobalt powder, molybdenum powder, high-carbon ferromanganese, high-carbon ferrochrome, high-carbon The ferro-tungsten and vanadium-iron alloy powders are then hoisted to the ladle refining furnace for argon blowing and stirring, the pH is adjusted to 5.0, and then the temperature of the molten steel is heated to 1450°C by a graphite electrode, and then an insulating agent is added. The chemical composition of the molten steel is: carbon: 0.2% , silicon: 2%, tungsten: 8.2%, molybdenum: 2%, chromium: 45%, cobalt: 0.1%, manganese: 0.5%, vanadium: 0.2%, the rest is iron, poured into billets, and put the billets into In the cleaning solution, under the action of ultrasound, wash at 60°C for 30 minutes, take it out and dry it; after drying, heat it in the furnace to 1000°C, and...

Embodiment 2

[0060] S1: Prepare the substrate

[0061] (1) Add molten iron and scrap steel to the converter for compound blowing, tap steel at 1610°C, blow argon and stir throughout the tapping process; add carbon powder, cobalt powder, molybdenum powder, high-carbon ferromanganese, high-carbon ferrochrome, high-carbon The ferro-tungsten and vanadium-iron alloy powders are then hoisted to the ladle refining furnace for argon blowing and stirring, and the pH is adjusted to 6.2. After that, the temperature of the molten steel is heated to 1480°C by graphite electrodes, and then an insulating agent is added. The chemical composition of the molten steel is: carbon: 0.5% , silicon: 2.4%, tungsten: 8.6%, molybdenum: 4%, chromium: 40%, cobalt: 0.15%, manganese: 0.8%, vanadium: 0.4%, and the rest is iron. In the cleaning solution, under the action of ultrasound, wash at 80°C for 20 minutes, take it out and dry it; after drying, heat it in the furnace to 1100°C, and after cooling out of the furnace...

Embodiment 3

[0072] S1: Prepare the substrate

[0073](1) Add molten iron and scrap steel to the converter for compound blowing, tap steel at 1620°C, blow argon and stir throughout the tapping process; add carbon powder, cobalt powder, molybdenum powder, high-carbon ferromanganese, high-carbon ferrochrome, high-carbon Iron-tungsten and iron-vanadium alloy powders are then hoisted to the ladle refining furnace for argon blowing and stirring, and the pH is adjusted to 7.0. Afterwards, the temperature of the molten steel is heated to 1500°C by a graphite electrode, and then an insulating agent is added. The chemical composition of the molten steel is: carbon: 1% , silicon: 3%, tungsten: 10%, molybdenum: 6%, chromium: 20%, cobalt: 0.2%, manganese: 1%, vanadium: 0.6%, the rest is iron, poured into billets, and put the billets into In the cleaning solution, under the action of ultrasound, wash at 100°C for 10 minutes, take it out and dry it; after drying, heat it in the furnace to 1200°C, and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com