Steel wire rope climbing device

A technology of wire rope and climbing rope, which is applied in hoisting devices, clockwork mechanisms, etc., can solve problems such as inconvenient climbing, achieve good synchronization, reduce labor intensity and safety risks, and ensure efficient development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

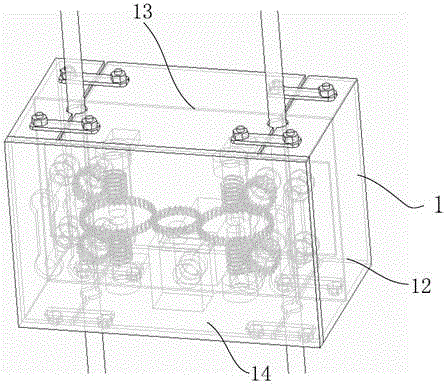

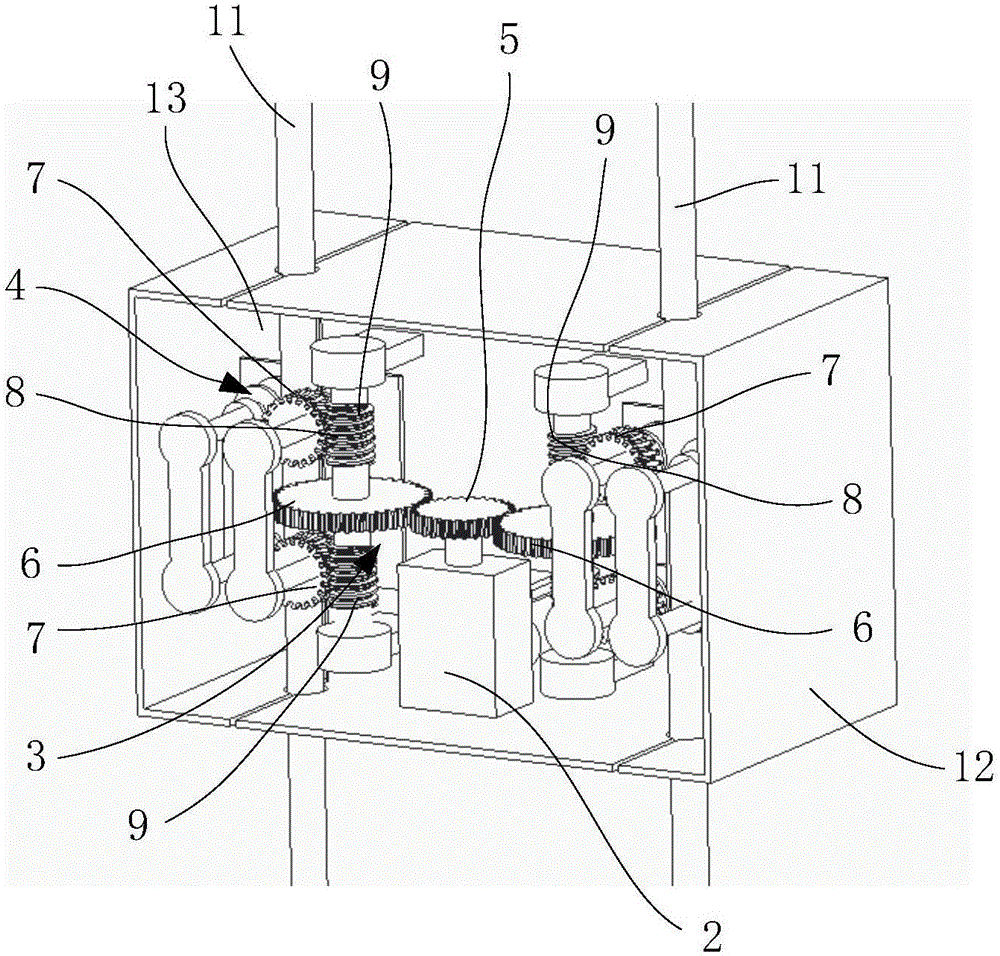

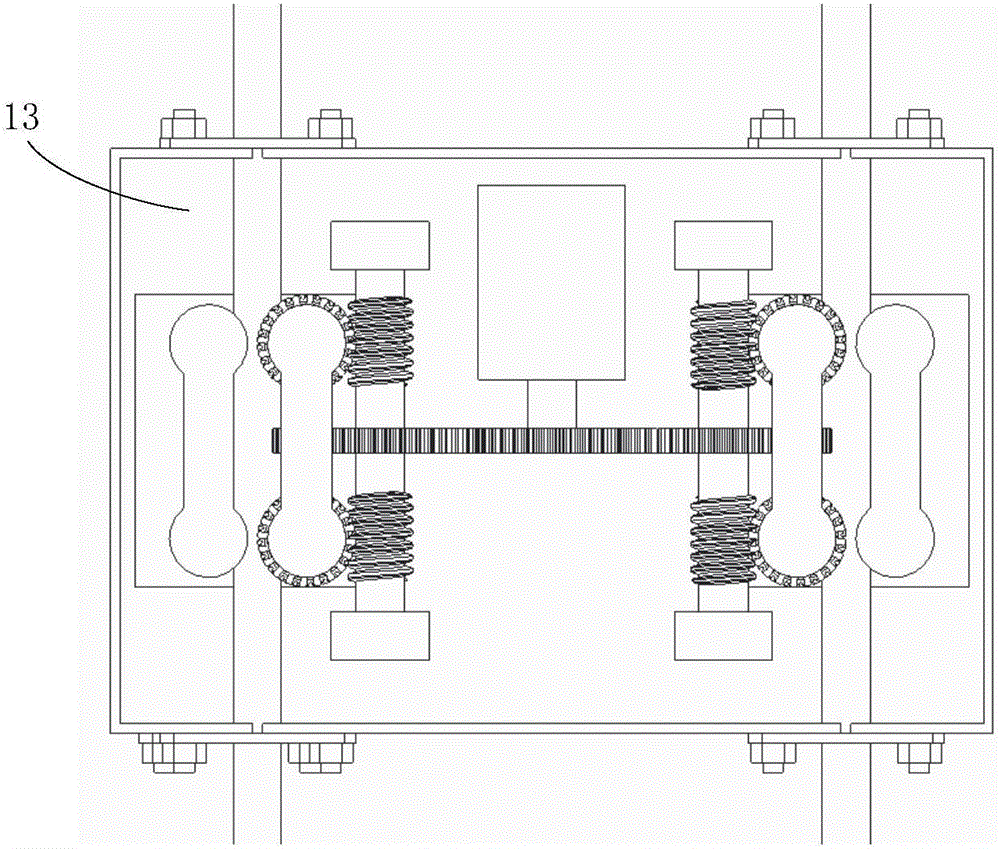

[0031] Such as Figure 1 to Figure 5 Shown, a kind of wire rope rope climbing device, it comprises carrying device 1, power device 2, transmission device 3 and guide wheel device 4; Described power device 2, transmission device 3 and guide wheel device 4 are arranged on described carrying device 1 Inside; the transmission device 3 includes an output gear 5, a transmission gear 6, a turbine 7 and a worm 8, the output gear 5 is connected to the power device 2, and there are two transmission gears 6, two transmission gears 6 Mesh with the output gear 5 respectively, the worm 8 is two, and the two transmission gears 6 are respectively arranged on a worm 8, and the transmission gear 6 on each worm 8 is the boundary on both sides. A section of worm gear 9 is set, and the number of said worm gears 7 is four, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com