Inner and external wall insulating paste materials, preparation method thereof and application

An external wall insulation, internal and external wall technology, applied in the field of building materials, can solve the problems of increased building load, increased wall bearing capacity, casualties, etc., and achieves the effects of reducing water absorption, enhancing life, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

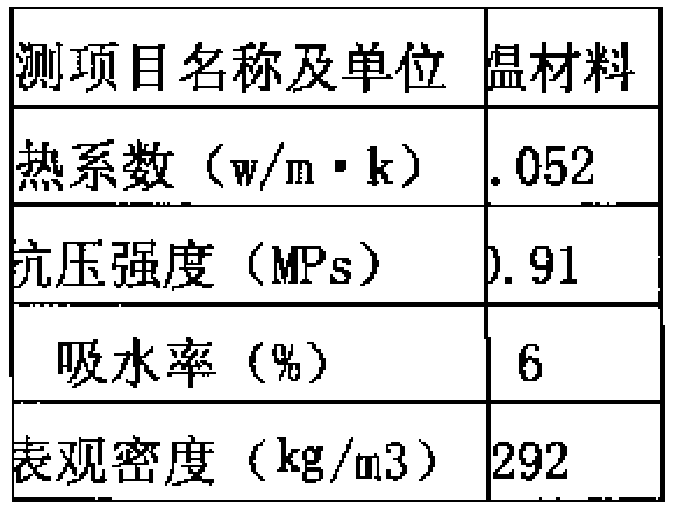

Embodiment 1

[0026] Preparation of polystyrene particle powder: crush the purchased waste polystyrene board into a fine powder with a particle size of 10-30 mesh;

[0027] Preparation of powder: mix magnesium oxide and magnesium sulfate according to the weight ratio of 7:3 to obtain;

[0028] Preparation of additives: According to the method disclosed in the Chinese patent No. ZL200310113325.2 (authorized announcement number: CN 1268574C), the superfine building material high-efficiency additive is prepared, and the prepared ultrafine building material high-efficiency additive is crushed into more than 3800 meshes; Micro-building material high-efficiency additives and commercially available polyester fibers (purchased from Shenzhen Jianbite Industrial Development Co., Ltd.) are mixed together according to a weight ratio of 5:3 to obtain additives;

[0029] Preparation of waterproof solution: mix organosilicon and water evenly according to the weight ratio of 1:9 to obtain waterproof soluti...

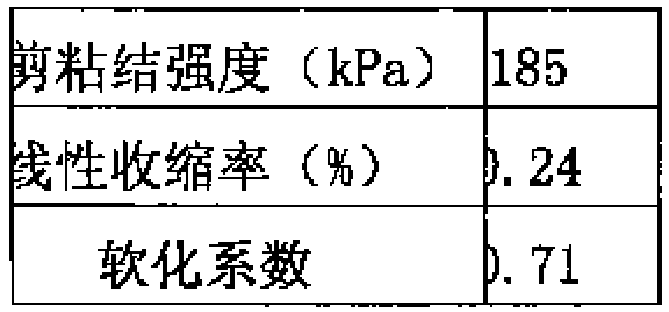

Embodiment 2

[0036] Preparation of polystyrene particle powder: crush the purchased waste polystyrene board into a fine powder with a particle size of 10-30 mesh;

[0037] Preparation of powder: mix magnesium oxide and magnesium sulfate according to the weight ratio of 7:3 to obtain;

[0038]Preparation of additives: According to the method disclosed in the Chinese patent No. ZL200310113325.2 (authorized announcement number: CN 1268574C), the superfine building material high-efficiency additive is prepared, and the prepared ultrafine building material high-efficiency additive is crushed into more than 3800 meshes; Micro-building material high-efficiency additives are mixed with commercially available glass fibers (produced by Henan Boai Glass Fiber Factory) in a weight ratio of 5:3 to obtain additives;

[0039] Preparation of waterproof solution: Mix organic silicon and water evenly in a weight ratio of 1:9 to obtain a waterproof solution;

[0040] Weigh each raw material according to the...

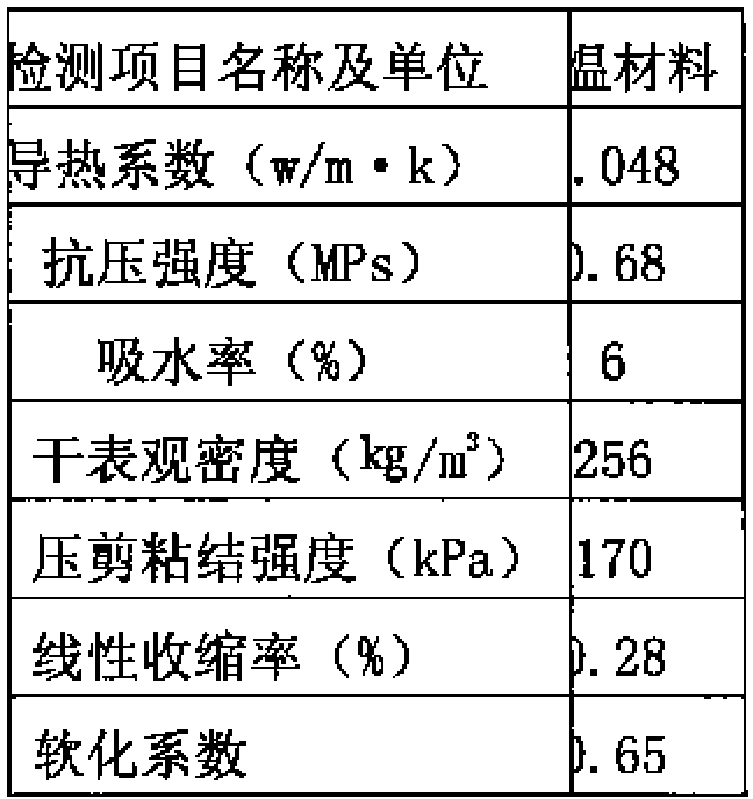

Embodiment 3

[0045] Preparation of polystyrene particle powder: crush the purchased waste polystyrene board into a fine powder with a particle size of 10-30 mesh;

[0046] Preparation of powder: mix magnesium oxide and magnesium sulfate according to the weight ratio of 7:3 to obtain;

[0047] Preparation of additives: According to the method disclosed in the Chinese patent No. ZL200310113325.2 (authorized announcement number: CN 1268574C), the superfine building material high-efficiency additive is prepared, and the prepared ultrafine building material high-efficiency additive is crushed into more than 3800 meshes; Micro-building material high-efficiency additives and commercially available polyester fibers (purchased from Shenzhen Jianbite Industrial Development Co., Ltd.) are mixed together according to a weight ratio of 5:3 to obtain additives;

[0048] Preparation of waterproof solution: Mix organic silicon and water evenly in a weight ratio of 1:9 to obtain a waterproof solution;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com