Low warpage ABS material for 3D printing, and preparation method thereof

An ABS material and 3D printing technology, applied in the field of 3D printing materials, can solve the problems of easy warping of printing, unprintable 3D printing materials, and inability to print large-size parts, etc., to achieve the effect of controlling warping and improving printing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

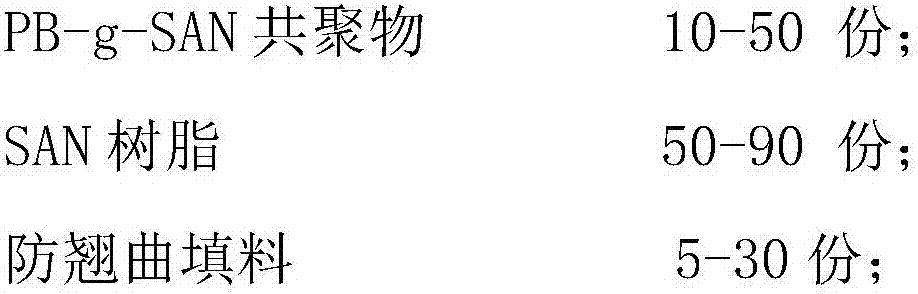

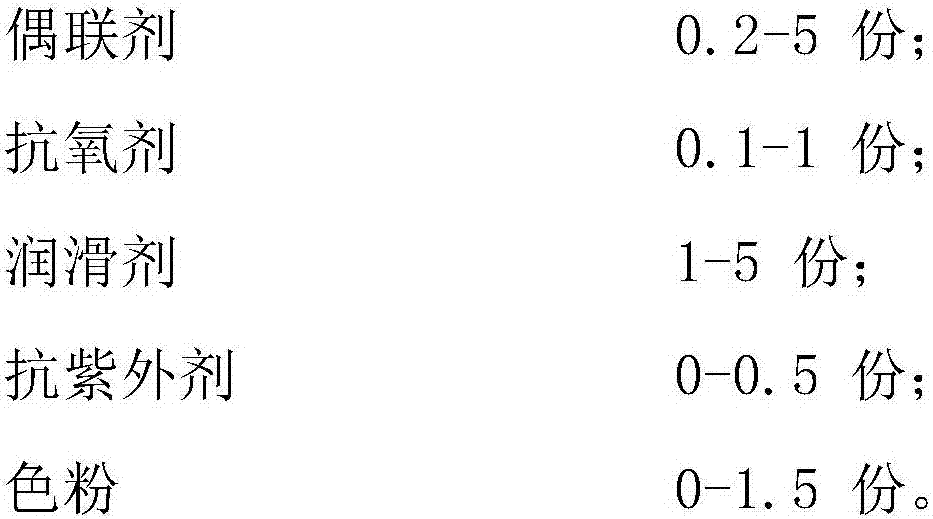

Method used

Image

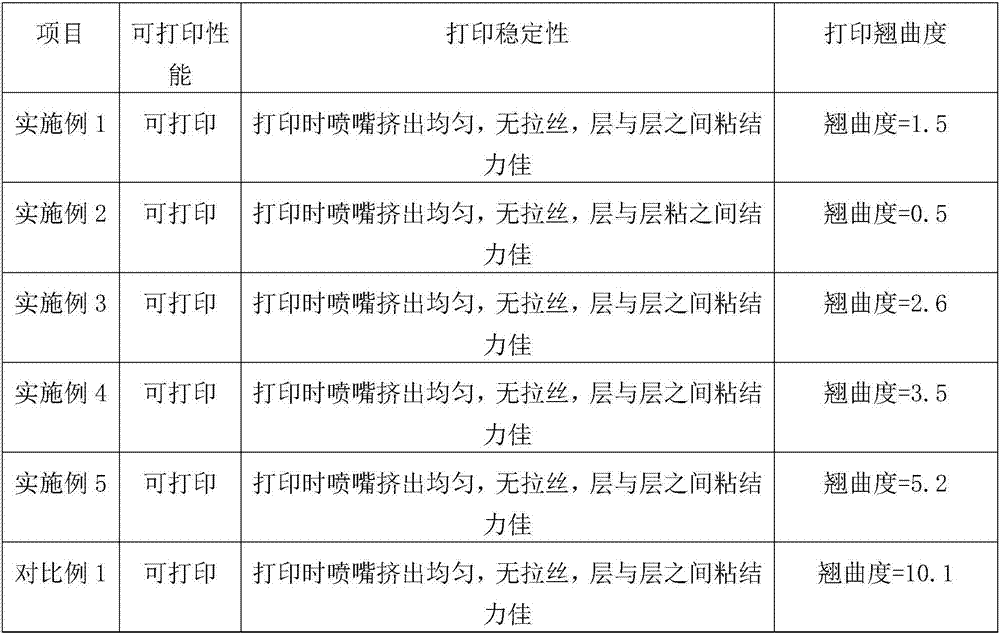

Examples

Embodiment 1

[0031] Step 1: Weigh the raw materials of each component, 5 parts of PB-g-SAN copolymer, 45 parts of SAN resin, 5 parts of glass beads, 0.5 part of silane coupling agent, 0.3 part of antioxidant 168, magnesium stearate 1 part and 3 parts of talcum powder are mechanically mixed evenly;

[0032] Step 2: Extrude the mixed material through a twin-screw extruder at a processing temperature of 220°C, cool at room temperature, air-dry, and pelletize to make modified ABS pellets;

[0033] Step 3: Extrude the modified ABS pellets through a 3D printing material extruder at a processing temperature of 210°C, cool at a high temperature at a high temperature at 50°C, cool at a medium temperature at a constant temperature at 20°C, cool at a normal temperature, air-dry, draw strips, and coil. Low warpage ABS material for 3D printing and its preparation method.

Embodiment 2

[0035] Step 1: Weigh the raw materials of each component, mix 10 parts of PB-g-SAN copolymer, 40 parts of SAN resin, 5 parts of glass beads, 0.5 part of silane coupling agent, 0.3 part of antioxidant 1010, calcium stearate 1 part, 3 parts of talcum powder, 0.5 part of anti-ultraviolet agent 944, 1 part of titanium dioxide, mechanically mix evenly;

[0036] Step 2: Extrude the mixed material through a twin-screw extruder at a processing temperature of 220°C, cool at room temperature, air-dry, and pelletize to make modified ABS pellets;

[0037] Step 3: Extrude the modified ABS pellets through a 3D printing material extruder at a processing temperature of 210°C, cool at a high temperature at 70°C, cool at a medium temperature at a constant temperature at 50°C, cool at room temperature, air-dry, draw strips, and coil. Low warpage ABS material for 3D printing and its preparation method.

Embodiment 3

[0039] Step 1: Weigh the raw materials of each component, 15 parts of PB-g-SAN copolymer, 35 parts of SAN resin, 5 parts of glass microspheres, 0.5 parts of silane coupling agent, 0.1 part of antioxidant 1010, antioxidant 0.2 part of 168, 0.1 part of EBS, 0.1 part of calcium stearate, 3 parts of talcum powder, 0.1 part of anti-ultraviolet agent V703 and mechanically mix evenly;

[0040] Step 2: Extrude the mixed material through a twin-screw extruder at a processing temperature of 210°C, cool at normal temperature, air-dry, and pelletize to make modified ABS pellets;

[0041] Step 3: Extrude the modified ABS pellets through a 3D printing material extruder at a processing temperature of 210°C, cool at a high temperature at a high temperature at 50°C, cool at a medium temperature at a constant temperature at 20°C, cool at a normal temperature, air-dry, draw strips, and coil. Low warpage ABS material for 3D printing and its preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com