Flattened bamboo high-strength composite laminate with sawtooth interlocking structure and manufacturing method thereof

A manufacturing method and technology of composite layers, which are applied in manufacturing tools, plywood presses, wood compression, etc., can solve the problems of panel buckling deformation, cracks on bamboo yellow surface, large strength differences, etc., and achieve enhanced shear resistance and improved compaction. The effect of strength and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

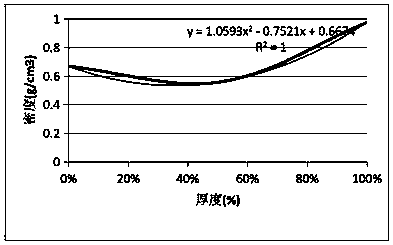

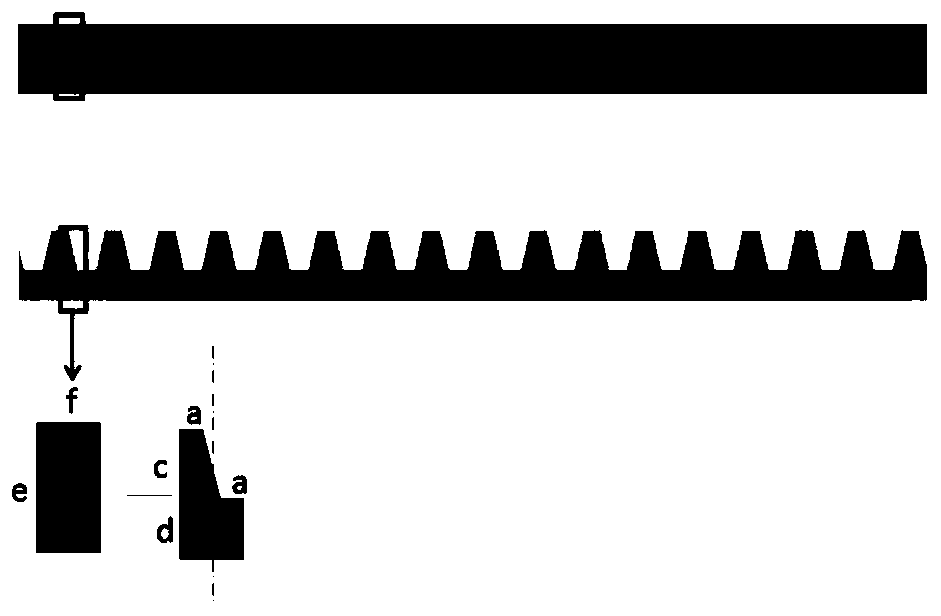

[0024] The embodiment of the present invention provides a flat bamboo high-strength composite laminate with a sawtooth interlocking structure, which is composed of several basic units of the composite laminate, such as Figure 5 As shown, the basic unit of the composite laminate board is obtained by hot-pressing and gluing two pieces of flattened bamboo 1 with saw teeth, and the glue layer 2 adopts a phenolic resin adhesive.

[0025] The embodiment of the present invention provides a method for manufacturing a flat bamboo high-strength composite laminate with a sawtooth interlocking structure, which includes the following steps:

[0026] S1. Ma...

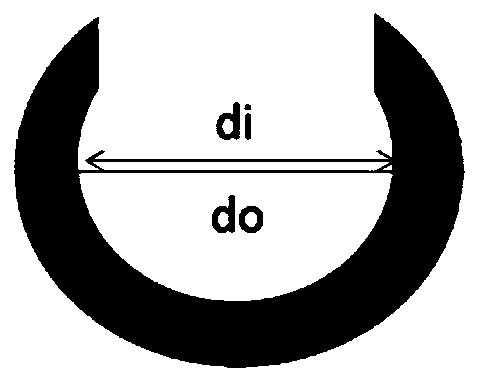

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com