Pressure-sensitive adhesive layer attached polarizing film set, liquid crystal panel and liquid crystal display device

A technology of adhesive layer and liquid crystal panel, which is applied in optics, instruments, nonlinear optics, etc., can solve problems such as uneven display and warpage, and achieve the effects of stable humidity expansion coefficient, warpage suppression, and small change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Hereinafter, examples of the present invention will be described, but embodiments of the present invention are not limited to these examples.

[0098]

[0099] A polyvinyl alcohol film with an average degree of polymerization of 2400, a degree of saponification of 99.9 mol%, and a thickness of 30 μm is immersed in warm water at 30°C, and uniaxially stretched while swelling it until the length of the PVA-based resin film reaches 2.0 times the original length . Next, it was dipped in a 0.3% by weight (weight ratio: iodine / potassium iodide = 0.5 / 8) iodine solution at 30° C., and dyed while uniaxially stretching the PVA-based resin film until its length reached 3.0 times the original length. After that, it was stretched in an aqueous solution of 4% by weight of 6 boric acid and 5% by weight of potassium iodide until the length of the PVA-based resin film became 6 times the original length. Further, after performing iodide ion impregnation treatment with a 3% by weight po...

Embodiment 3

[0120]

[0121] While applying a polyvinyl alcohol-based adhesive to the surface of the polarizing film (thickness 5 μm) of the above-mentioned optical film laminate so that the thickness of the adhesive layer becomes 0.1 μm, the first transparent protective film (b11) was attached. , followed by drying at 50° C. for 5 minutes.

[0122] Next, after peeling off the amorphous PET substrate, an active energy ray-curable adhesive is applied on the peeled surface so that the thickness of the adhesive layer becomes 1 μm, and a second transparent protective film (film 12: The side of the above-mentioned film E on which the surface treatment layer is not provided) was cured with ultraviolet rays to produce a first polarizing film using a thin polarizing film.

[0123]

[0124] After applying an active energy ray-curable adhesive to the surface of the polarizing film (5 μm in thickness) of the optical film laminate so that the thickness of the adhesive layer becomes 1 μm, and attac...

Embodiment 1~6、 comparative example 1~5

[0140]

[0141] Take out the liquid crystal panel (70 mm in length, 130 mm in width) from the liquid crystal display device [liquid crystal panel of smartphone (screen size: 5.8 inches:)] including the liquid crystal cell in IPS mode, remove all the optical films placed on the upper and lower sides of the liquid crystal cell, The glass surfaces (front and back) of the above-mentioned liquid crystal cell were cleaned. In this way, a liquid crystal cell (70 mm in length and 130 mm in width) was prepared.

[0142]

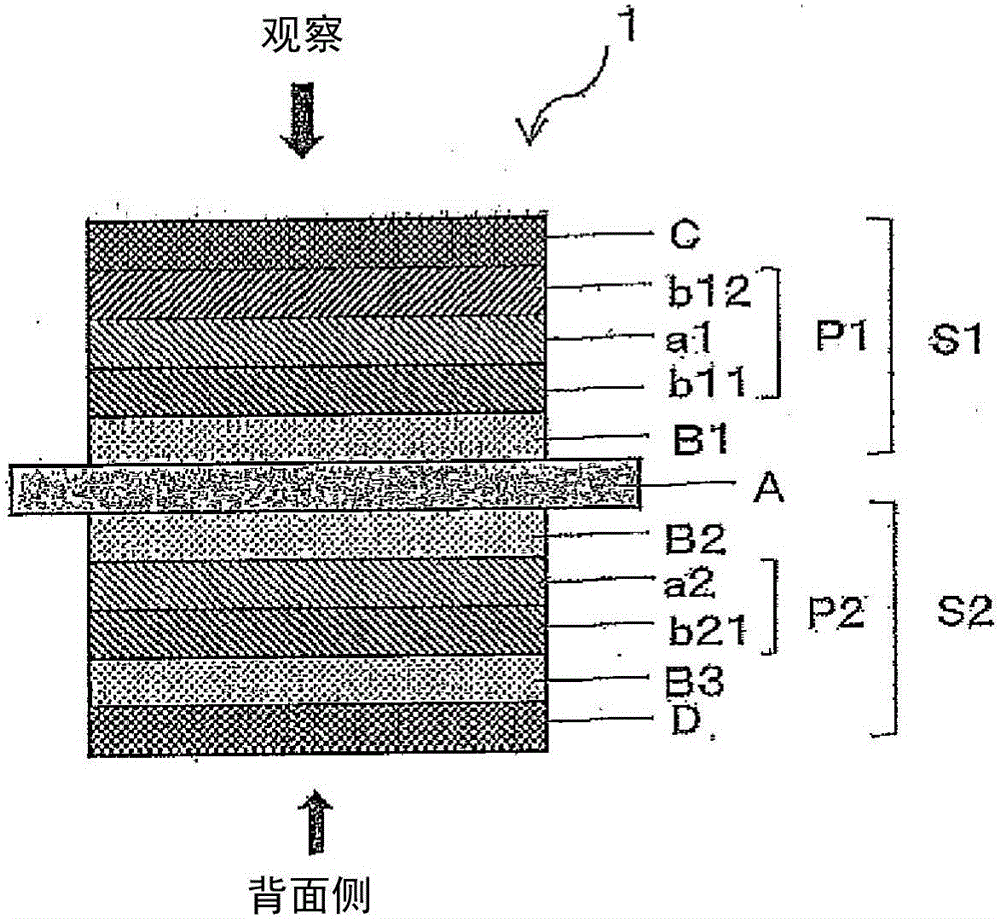

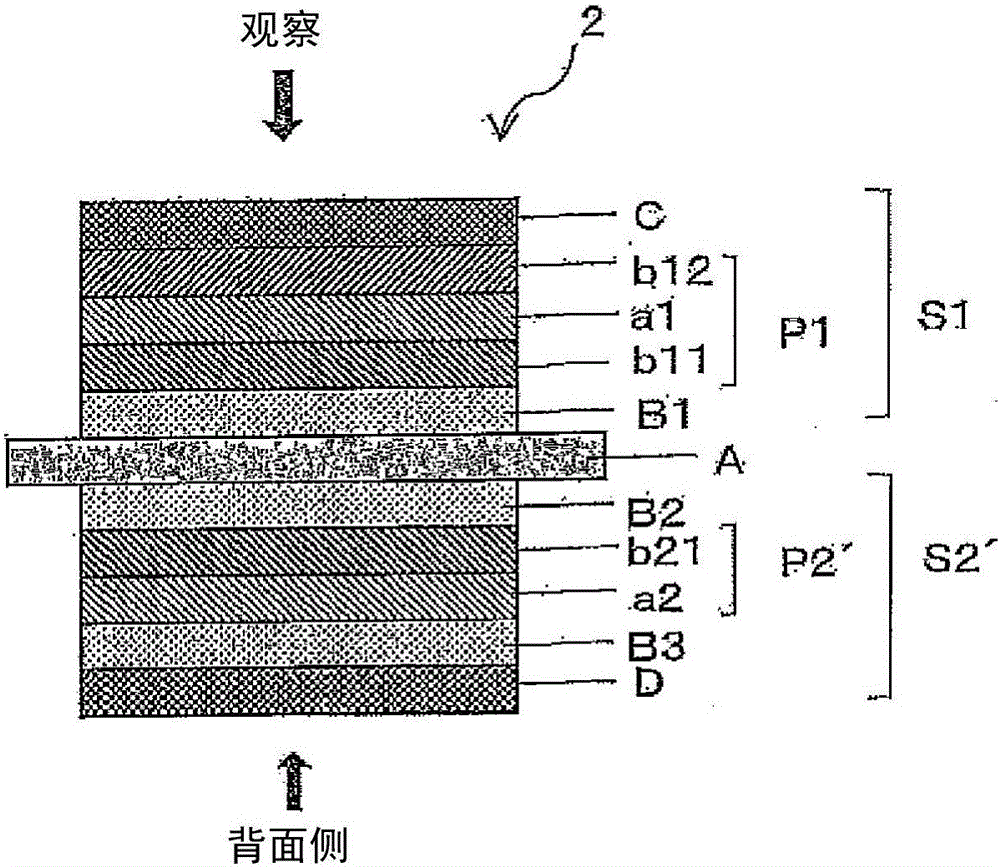

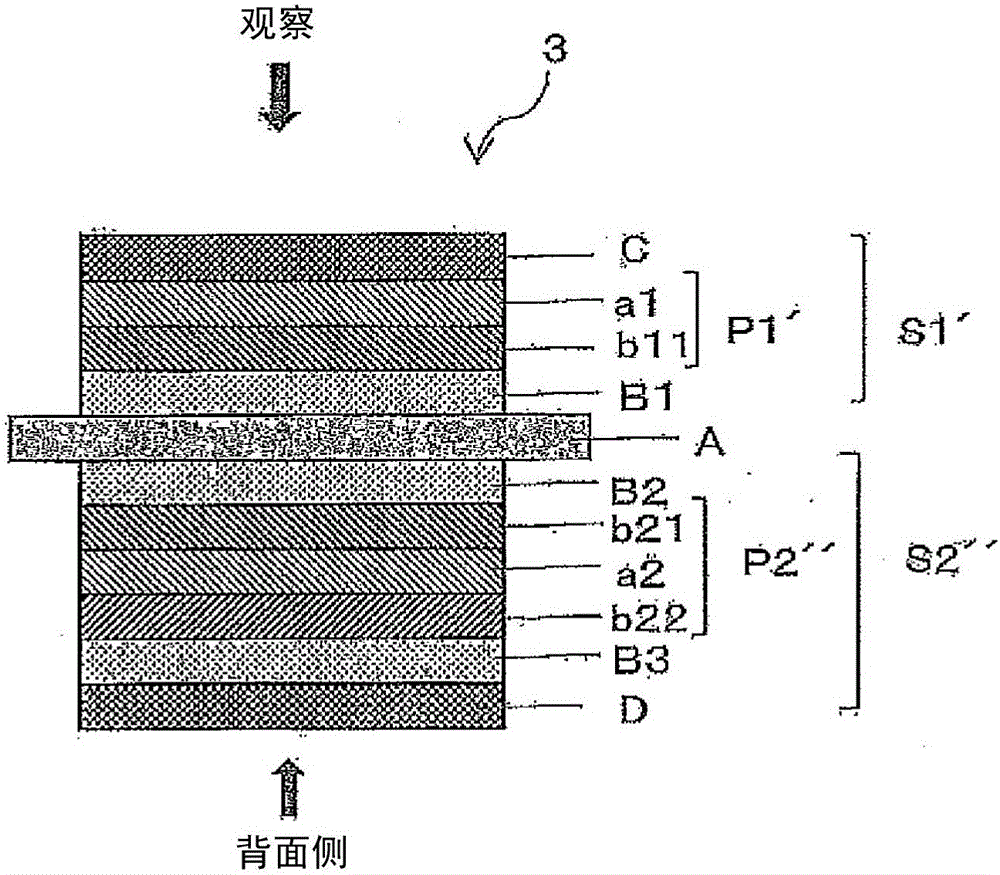

[0143] The first adhesive layer was transferred on the first transparent protective film (b11) side of the first polarizing film to prepare a polarizing film with the first adhesive layer. In addition, the second adhesive layer was transferred to the second polarizer side of the second polarizing film, and on the other hand, the brightness improving film was bonded on the first transparent protective film (b21) side via the third adhesive layer (but , Except for Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com