Nitride semiconductor epitaxial structure

A technology of nitride semiconductor and epitaxial structure, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as the mismatch between crystal lattice and thermal expansion coefficient, and achieve the goal of increasing product yield, relieving stress, and improving the quality of gallium nitride Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and embodiments.

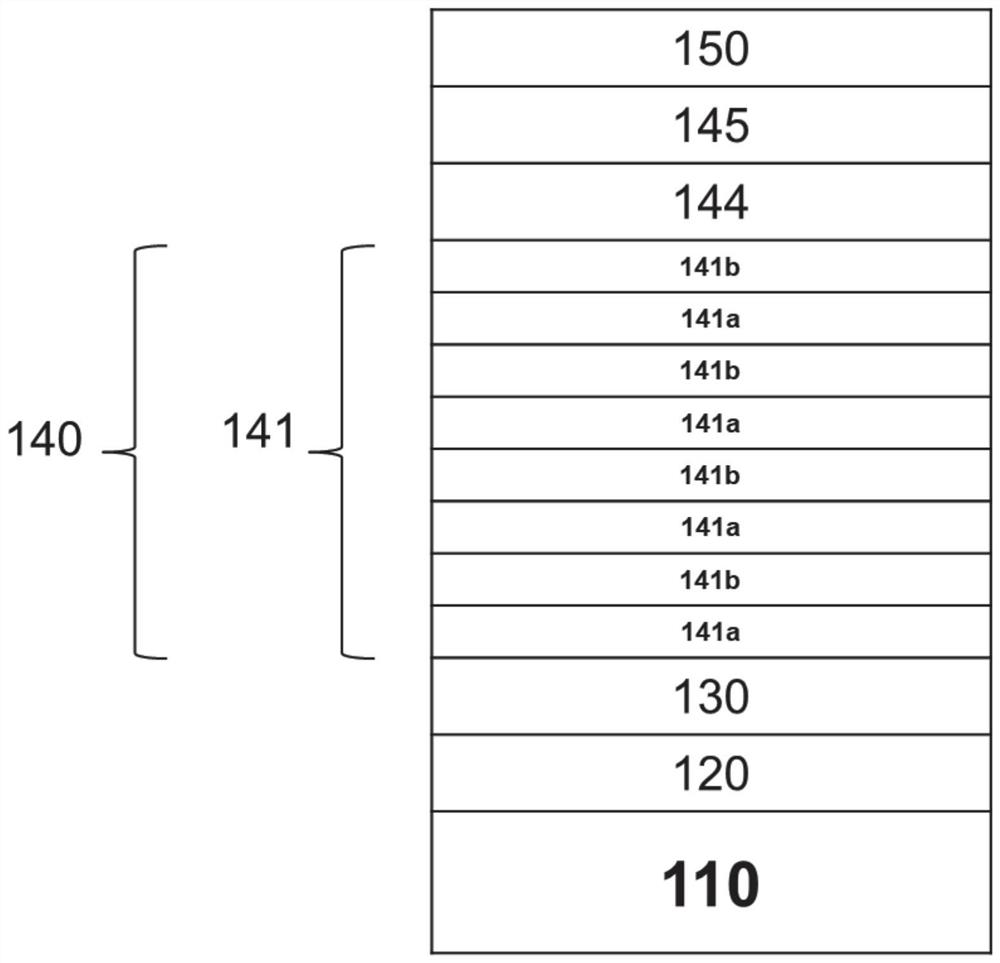

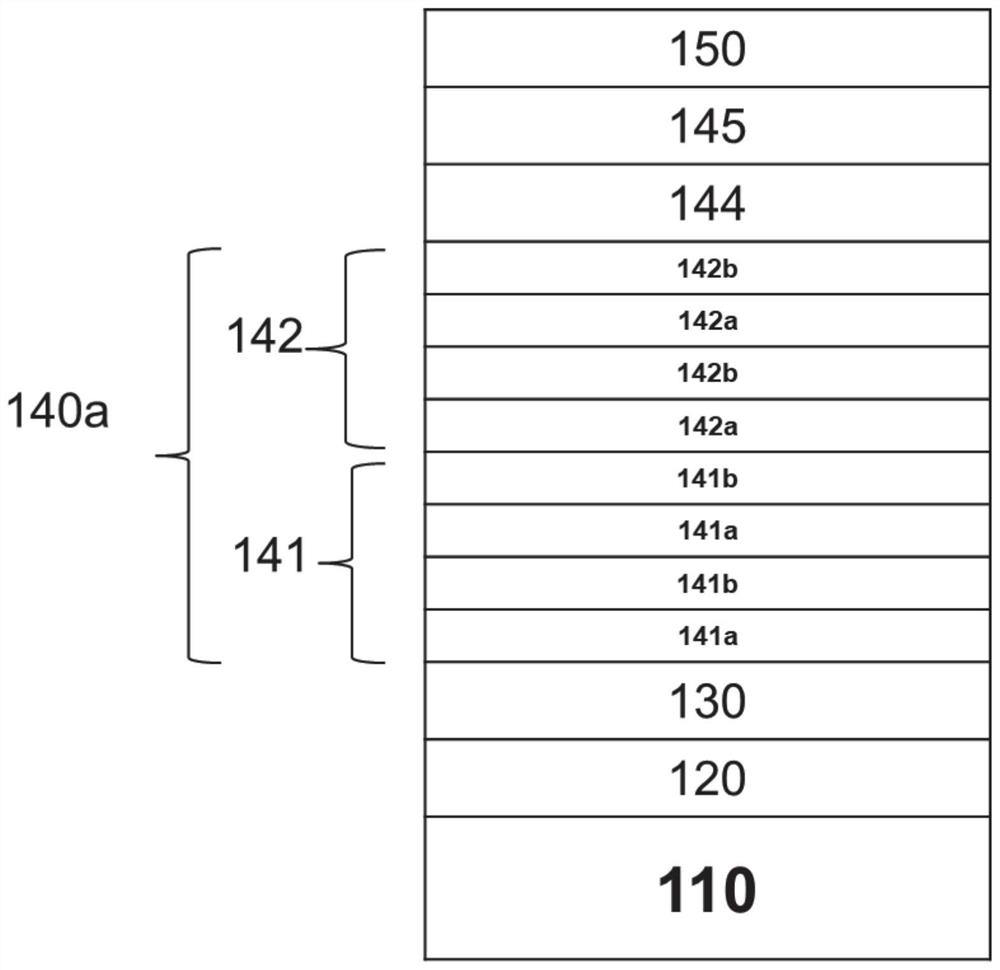

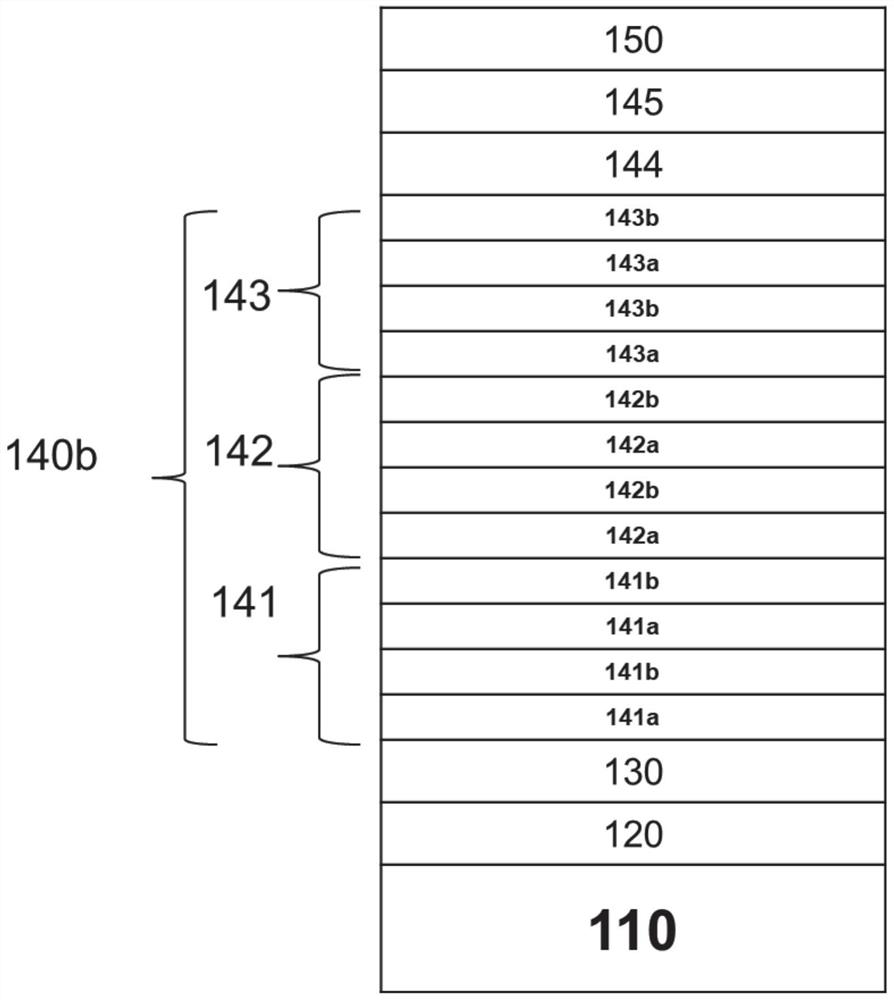

[0025] figure 1 It is a schematic cross-sectional view of a nitride semiconductor epitaxial structure according to an embodiment of the present invention, wherein the first superlattice composite buffer layer schematically shows several overlapping layers of the first Aly1GaN layer and several layers of the first GaN layer. layer, not representing its actual number of layers.

[0026] see figure 1 In this embodiment, the nitride semiconductor structure 100 includes a substrate 110, a nucleation layer 120, a transition layer 130, and a composite buffer structure 140, wherein the material of the substrate 110 may include silicon, aluminum oxide or glass. Taking a silicon substrate as an example, the substrate 110 may be a patterned silicon substrate, and the pattern may be a regular or irregular micro-pattern or nano-pattern. For example, after the subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com