Electric brush keeping device for a motor

A technology for holding devices and motors, applied in the direction of electromechanical devices, electric components, electrical components, etc., to achieve miniaturization, mechanical strength, and height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

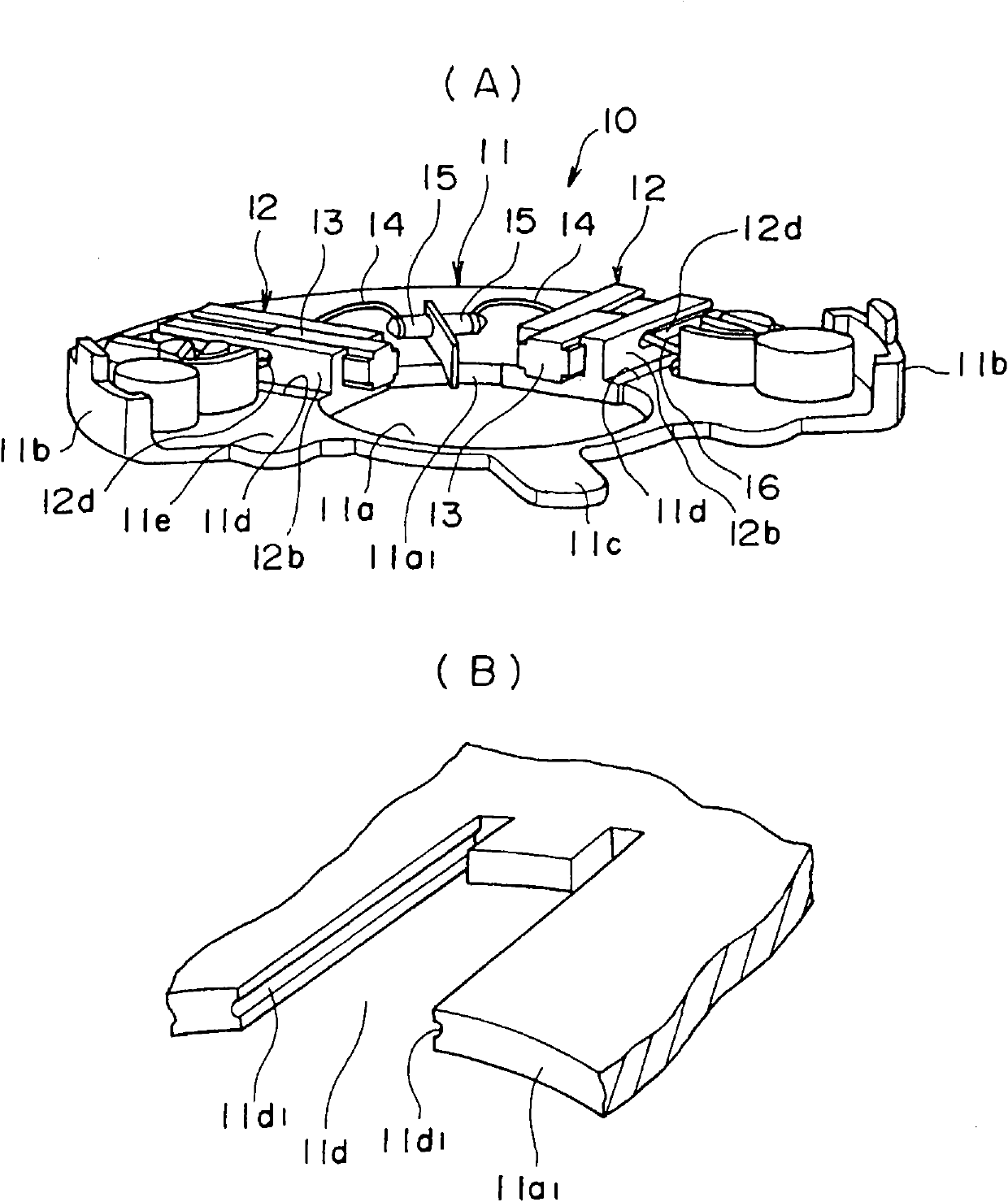

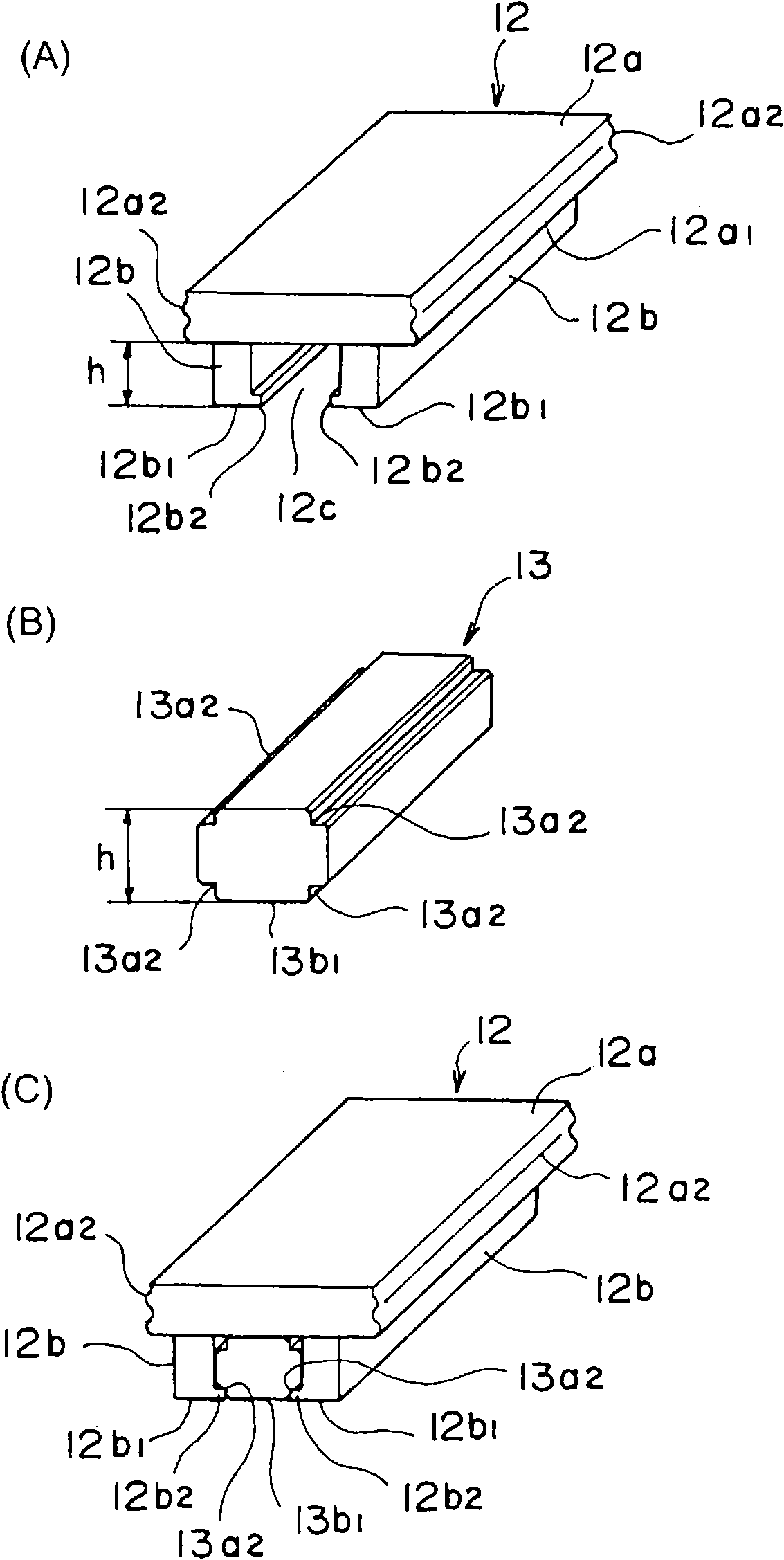

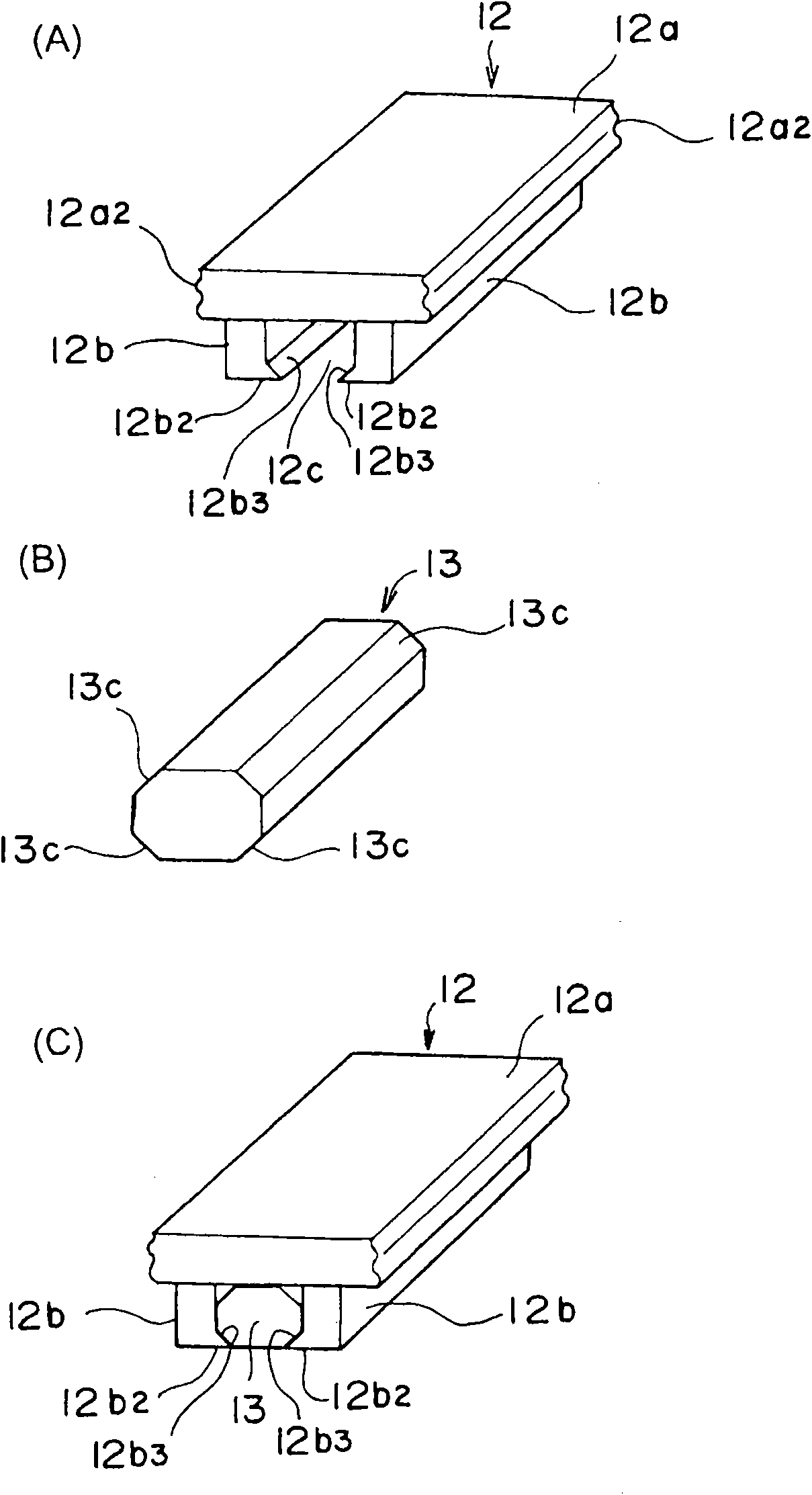

[0031] figure 1 A is a perspective view showing an embodiment of the present invention. The illustrated brush holding device 10 includes a brush holding plate 11 , a pair of brush holders 12 , 12 fixed to the brush holding plate 11 , and brushes 13 , 13 respectively held by the pair of brush holders 12 , 12 .

[0032] The brush holding plate 11 is produced by molding an insulating resin. The brush holding plate 11 has a commutator ( figure 1 A. figure 1 B (not shown) through the opening 11a. A pair of upright wall portions 11b, 11b are formed at symmetrical positions separated by 180° on the outer peripheral portion of the brush holding plate 11, and a tongue-shaped protruding portion 11c is formed between the upright wall portions 11b, 11b.

[0033] In the brush holding plate 11 , the central axis of the opening 11 a is arranged so as to coincide with the central axis of the not-shown commutator. A pair of substantially U-shaped notches 11 d extending in the radial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com