Special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and preparation method thereof

A technology of polyolefin resin and functional masterbatch, applied in the field of plastic modification processing, can solve the problems of flame retardant efficiency and physical and mechanical decline, large loss of flame retardant performance, weak interface adhesion, etc., and achieve excellent pre-dispersion effect, Advantages Flame retardant properties, high surface charge density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

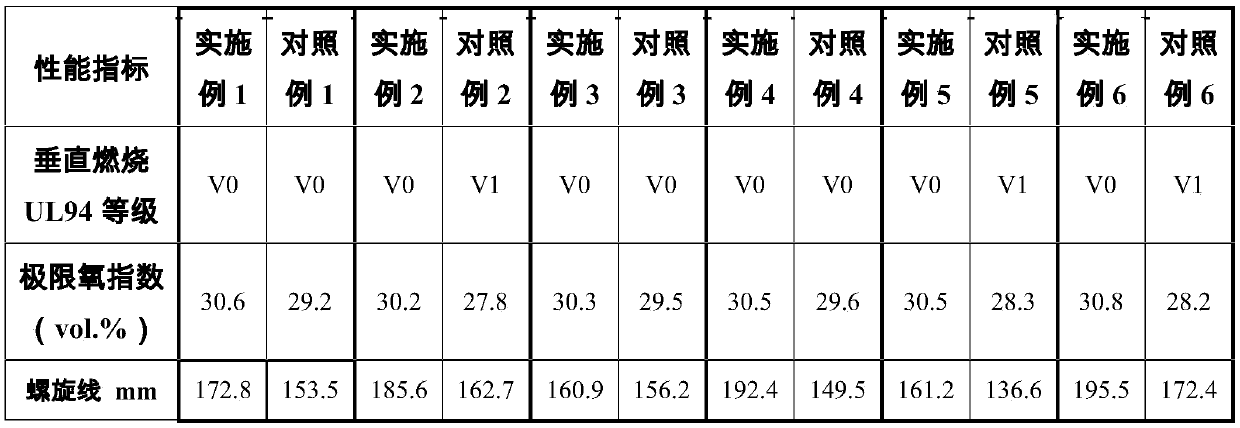

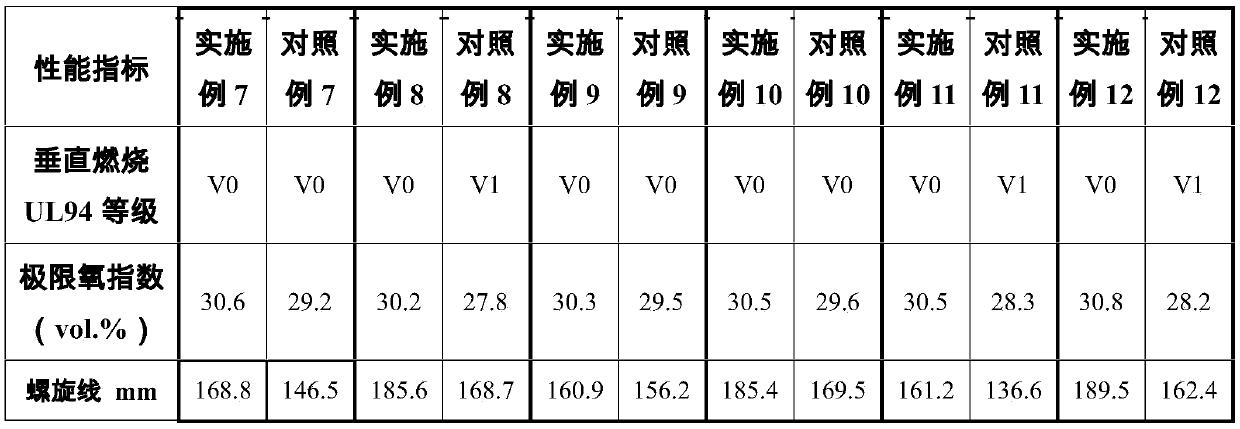

Examples

Embodiment 1

[0034] Multiple compound coated ammonium polyphosphate 65.0kg Melamine cyanurate 25.0 kg High Flow Polypropylene 5.0 kg Atactic polypropylene 3.0 kg Styrene-acrylonitrile copolymer coated PTFE 1.0 kg stearic acid 500.0 g Ethylene bis stearamide 500.0 g

[0035] The preparation method of the multi-composite-coated ammonium polyphosphate used in the above-mentioned polyolefin resin modified special-purpose halogen-free flame-retardant synergistic functional masterbatch is as follows:

[0036] Add 230 L of absolute ethanol, 120 kg of ammonium polyphosphate, 7 kg of aluminum sol, and 1 kg of zinc oxide sol into the enamel reaction kettle with a stirring and temperature control device, stir evenly and add to 40°C, then add mass Ammonia water with a percentage content of 10.0 wt.%, and the pH value of the reaction solution is controlled at 7.5 to 8.5 to promote the sol-gel reaction between the aluminum sol and the zinc oxide sol....

Embodiment 2

[0040] Multiple compound coated ammonium polyphosphate 55.0 kg Melamine cyanurate 35.0 kg High Flow Polypropylene 5.0 kg Atactic polypropylene 3.2kg Styrene-acrylonitrile copolymer coated PTFE 500.0 g Oleamide 1.0 kg polyethylene wax 300.0 g

[0041] The preparation method of the multi-composite-coated ammonium polyphosphate used in the above-mentioned polyolefin resin modified special-purpose halogen-free flame-retardant synergistic functional masterbatch is as follows:

[0042] Add 230L of absolute ethanol, 120kg of ammonium polyphosphate, 8 kg of aluminum sol, and 1.5 kg of zinc oxide sol into the enamel reaction kettle with a stirring and temperature control device, stir evenly and add to 35°C, then add the mass percentage content dropwise at an even speed 11.5 wt.% ammonia water, and the pH value of the reaction solution was controlled at 7.5 to 8.5 to promote the sol-gel reaction between the aluminum sol and the zinc ...

Embodiment 3

[0045] Multiple compound coated ammonium polyphosphate 60.0kg Melamine cyanurate 29.0kg High Flow Polypropylene 7.0kg Atactic polypropylene 2.0 kg Styrene-acrylonitrile copolymer coated PTFE 700.0 g Zinc stearate 1.0 kg Polydimethylsiloxane 300.0 g

[0046] The preparation method of the multi-composite-coated ammonium polyphosphate used in the above-mentioned polyolefin resin modified special-purpose halogen-free flame-retardant synergistic functional masterbatch is as follows:

[0047] Add 230 L of absolute ethanol, 120 kg of ammonium polyphosphate, 7.5 kg of aluminum sol, and 2 kg of zinc oxide sol into the enamel reaction kettle with a stirring and temperature control device, stir evenly and add to 37°C, and then dropwise add mass Ammonia water with a percentage content of 12.5 wt.%, and the pH value of the reaction solution was controlled at 7.5 to 8.5 to promote the sol-gel reaction between the aluminum sol and the zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com